Alternative looping recharger

A charging device and circuit technology, which is applied in the direction of circuit devices, battery circuit devices, current collectors, etc., can solve the problems of inability to effectively reduce the size of the package, expensive, complex control circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

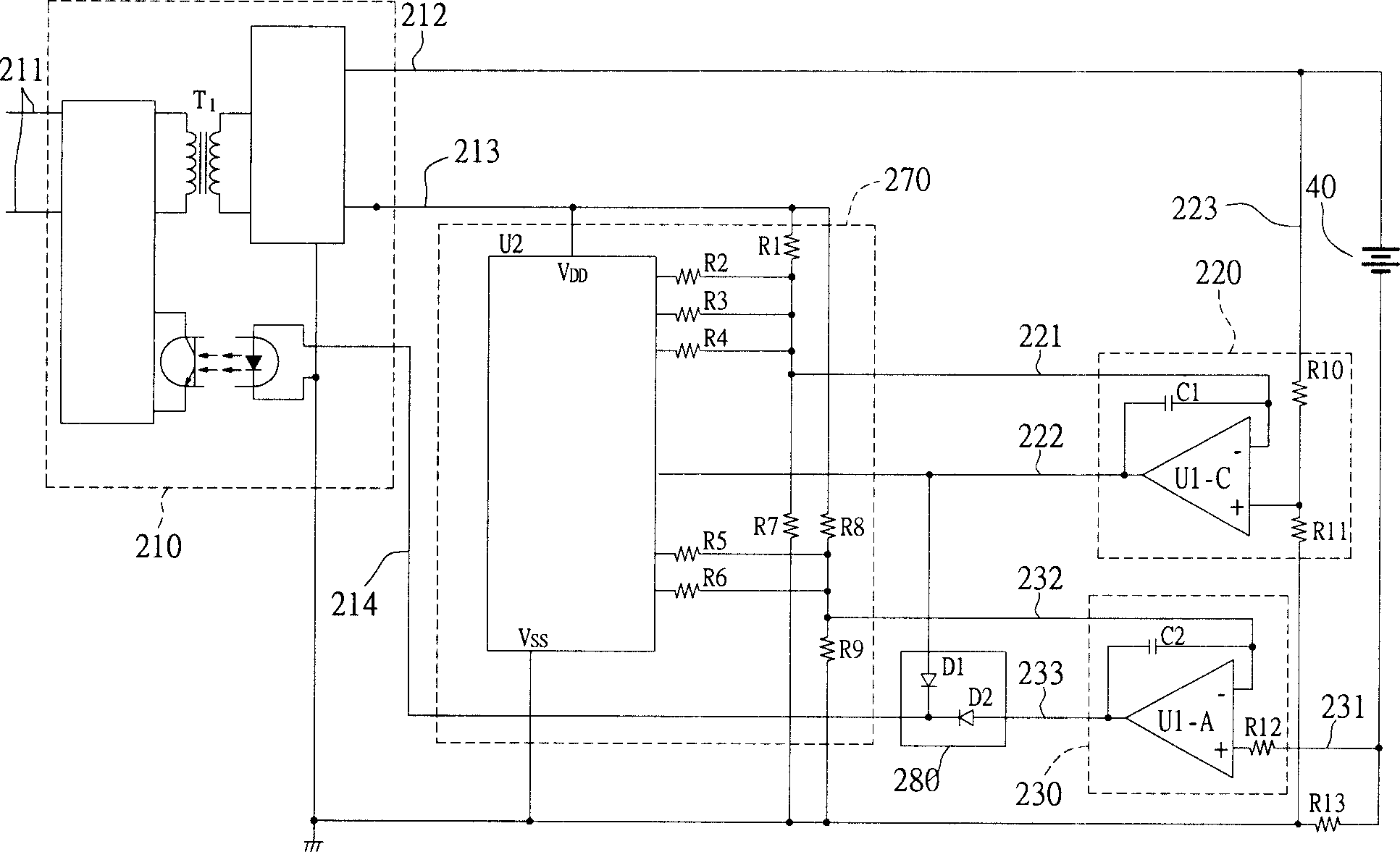

[0039] Please refer to image 3 , is a schematic circuit diagram of the present invention. The alternating circuit charging device of the present invention includes: a controller 270 capable of providing a first reference voltage 221 and a second reference voltage 232; a voltage error amplifier 220, connected to the battery 40 and the controller 270, is to detect Measure a battery voltage signal 223 and the first reference voltage 221, and compare the battery voltage signal 223 with the first reference voltage 221 to output a voltage error signal 222; a current error amplifier 230 is connected to the The battery 40 and the controller 270 obtain a battery current signal 231 and the second reference voltage 232, and compare the battery current signal 231 with the second reference voltage 232 to output a current error signal 233; A signal selector 280, connected to the voltage error amplifier 220 and the current error amplifier 230, receives the voltage error signal 222 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com