Shaftless propeller

A thruster and shaftless technology, which is applied to rotary propellers, propulsion components, ship propulsion, etc., can solve the problems of low power, low bearing load, etc., and achieve the effects of simple structure, no need for bearing seals, and good starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

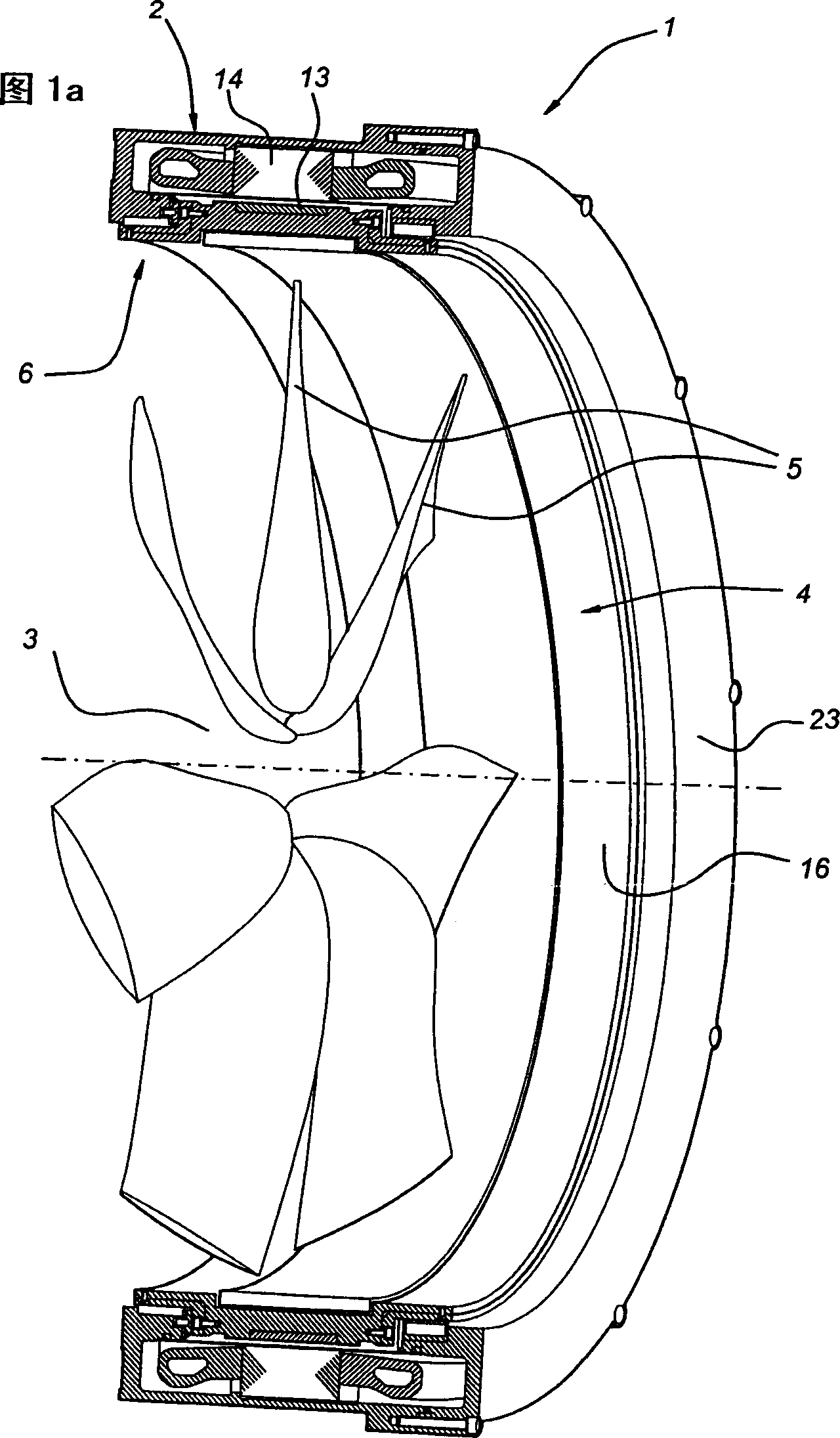

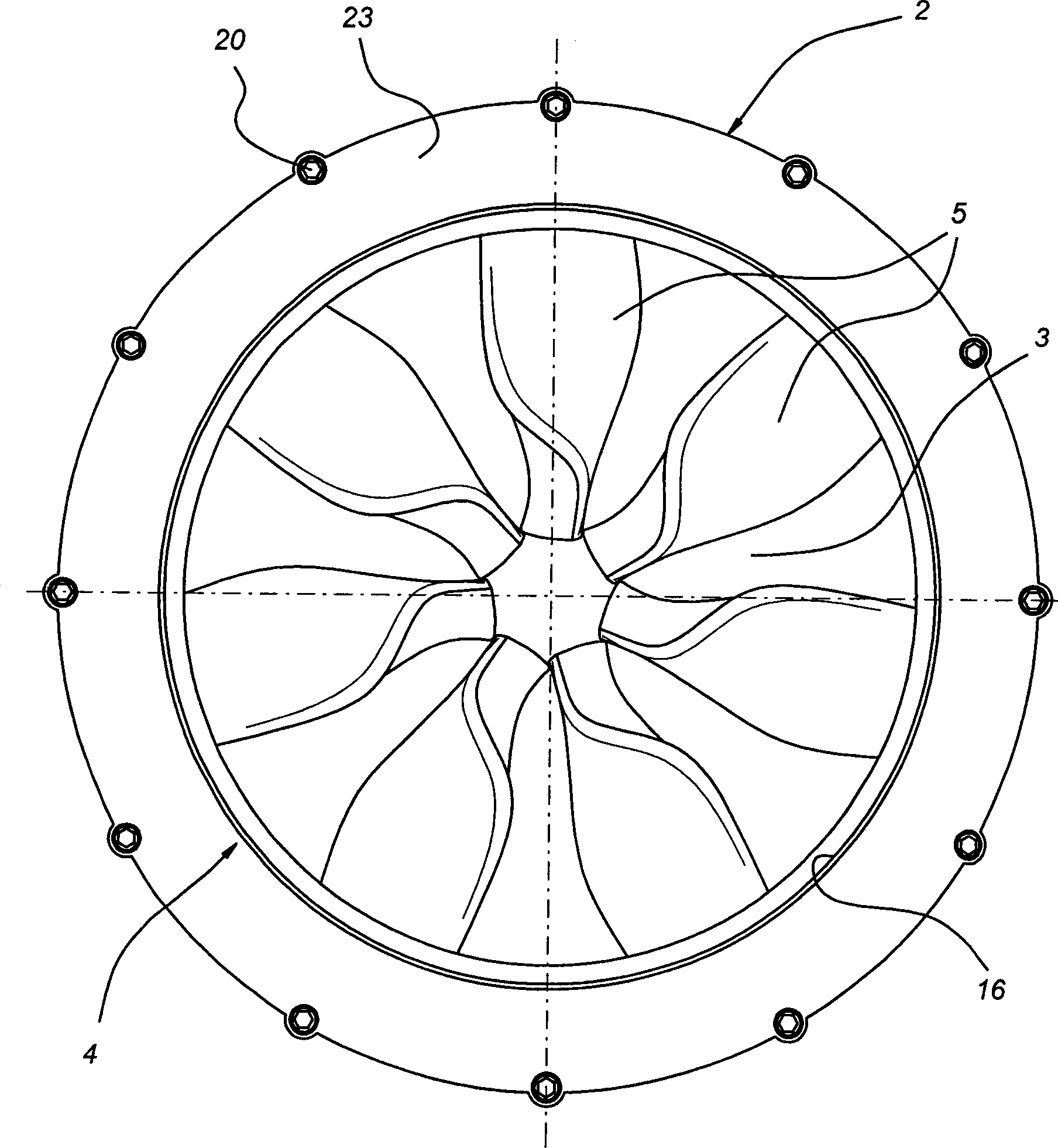

[0029] Figures 1a and 1b show a propeller propeller 1 according to the invention. The propeller 1 comprises a stator 2 with a circular opening 3 . In this opening is mounted a rotor 4 comprising an annular rotor body 16 and propeller blades 5 protruding inwardly from said rotor body. Preferably, the propeller blades 5 are detachably connected to the rotor body 16, so that their replacement will be relatively easy. The annular rotor body has permanent magnets 13 configured along its periphery, which cooperate with stator windings 14 around the opening of the stator 2 to drive the rotor 4 .

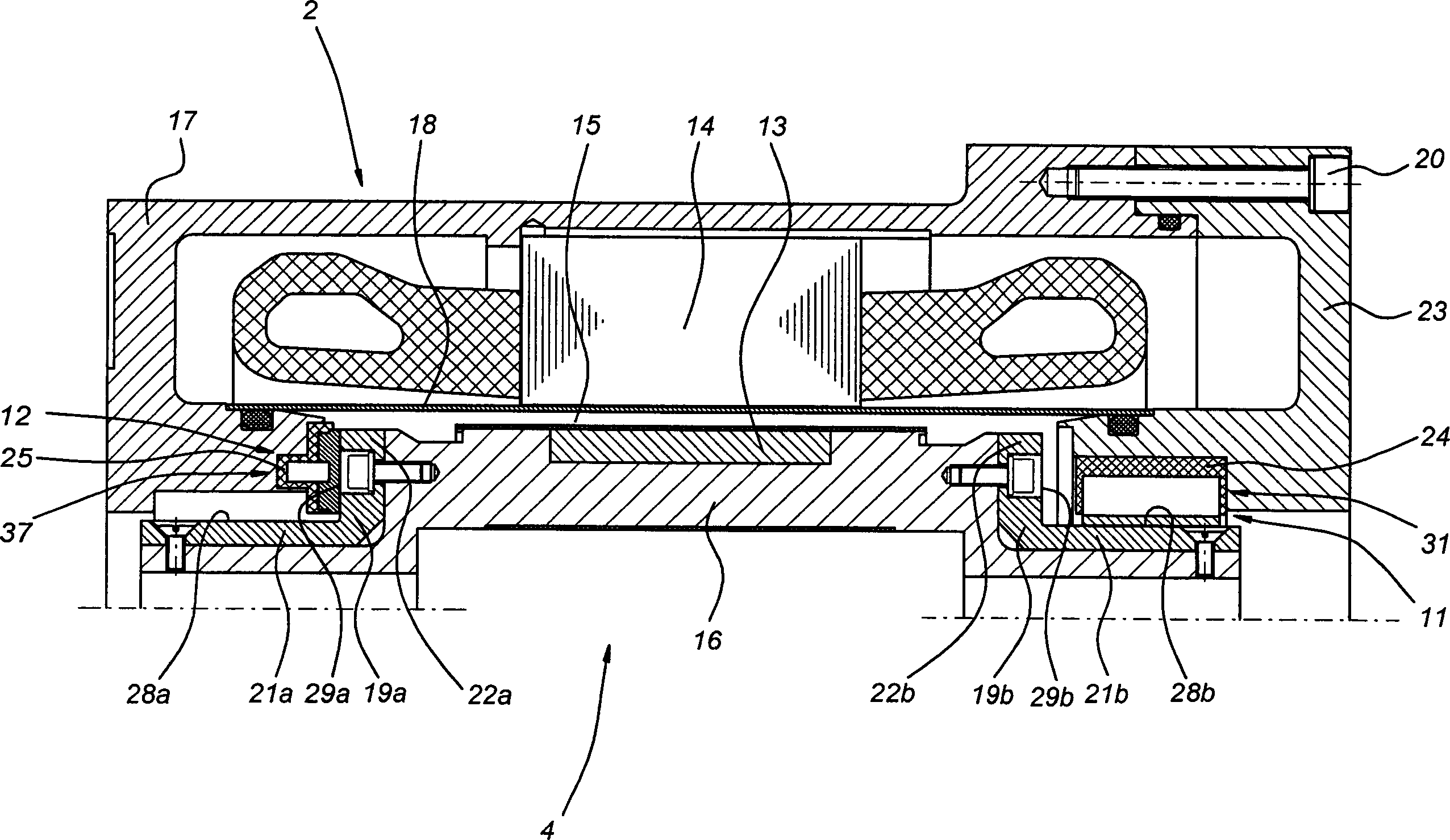

[0030] figure 2 It is the cross section of the rotor 4 and the stator 2, the bearings are clearly visible. Ring-shaped groups of stator windings 14 are connected in a stator housing 17 . On the side of the stator winding 14 facing the rotor 4 , the stator housing 17 is closed by an annular wall 18 , wherein the wall 18 consists of a material which does not have a negative effect on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com