Method for reducing online detection error affection of wire production line

A technology for detecting errors and making silk threads, which is applied in the field of reducing the influence of on-line detection errors of silk threads, can solve problems such as large errors in on-line detection of silk threads, and achieve the effects of improving product quality, eliminating the influence of measurement deviation and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

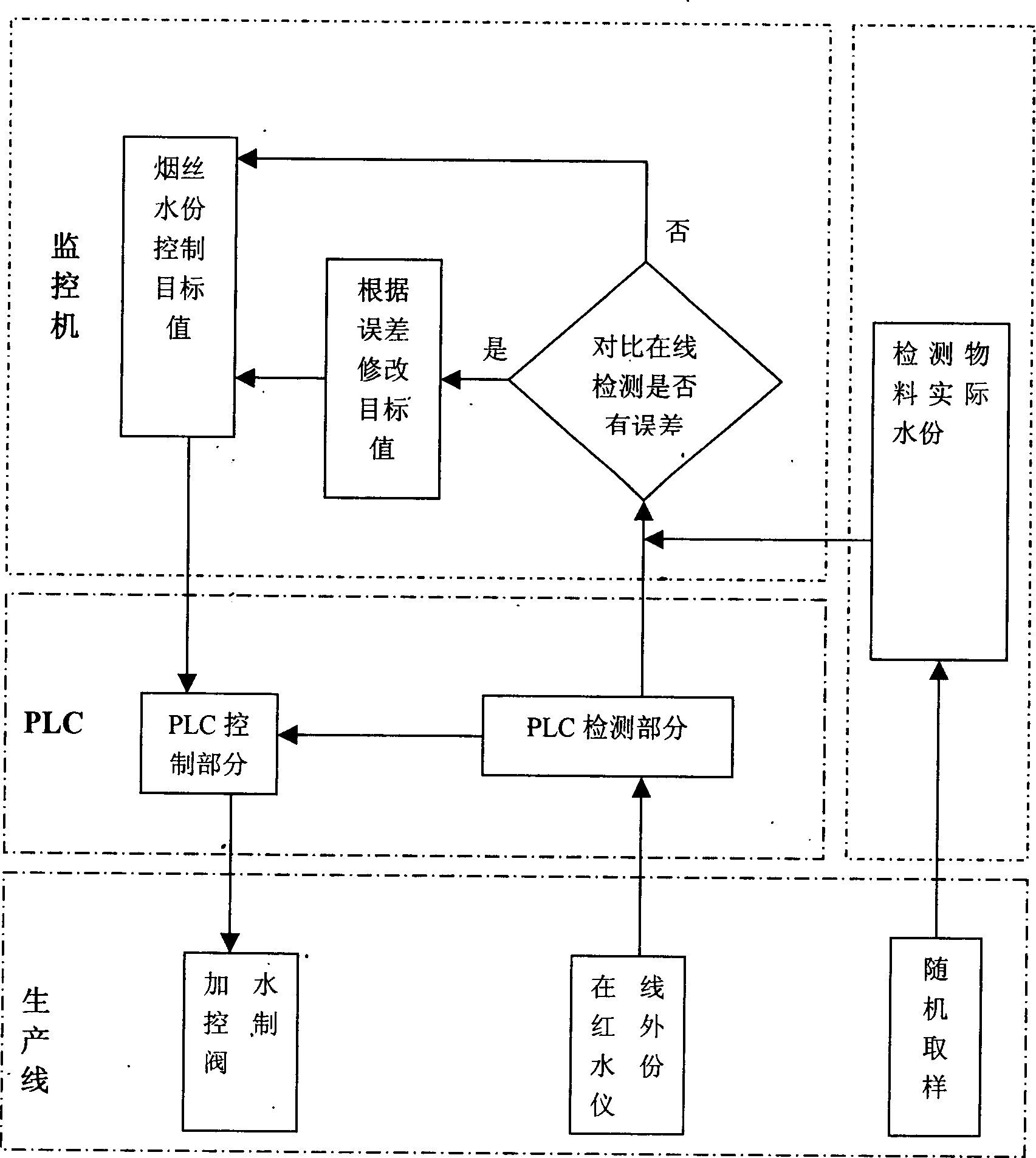

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] figure 1 Among them, 1) Set the moisture control target value, that is, the value to be displayed after controlling the online infrared moisture meter to detect the moisture content of the material. It is not the real value of the material, but the sum of the real value and the measurement error. (For example: brand A requires 12.5% moisture, and the moisture meter error is -0.5%, then set 12.0%.);

[0016] 2) PLC takes the set target value as the control target, and adjusts the control components according to the comparison between the online detection value and the set target value, so that the produced materials meet the process requirements. (For example, if the detection value is 12.3%, it indicates that the moisture content of the material is 0.3% higher. Properly increase the opening of the water control valve to reduce the moisture con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com