Device and method for measuring thickness distribution of gas condensation film in moderator component

A technology of gas condensation and film thickness, which is applied in the direction of measuring devices, optical devices, and phase-influenced characteristic measurements. It can solve the problems of short working distance of the microscope, low measurement efficiency, and long-term measurement, so as to save space in the vacuum chamber, Effects of improving measurement efficiency and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

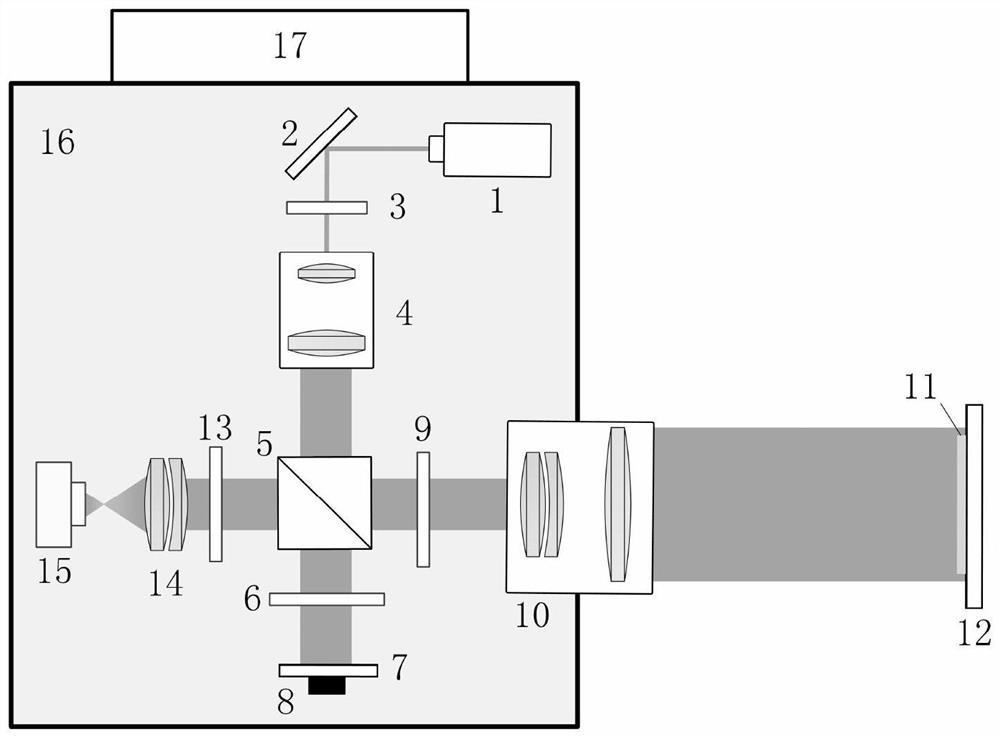

[0043] Such as figure 1 As shown, a device for measuring the thickness distribution of the gas condensation film in the moderator component includes an interferometric module and a five-dimensional freedom control module.

[0044] In the interferometric module, the light beam emitted by the frequency-stabilized linearly polarized laser 1 is reflected by the mirror 2, and the polarization state is adjusted by the half-wave plate 3. The forward propagation is divided into two paths by the polarizing beam splitter prism 5: one path of transmitted parallel polarized light continues to propagate forward, passes through the quarter-wave plate 6, is reflected by the reference plane mirror 7, and return...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com