A volumetric wear evaluation method for polyethylene liner of artificial knee joint

An artificial knee joint and polyethylene technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of increasing its own mass, affecting the accuracy of results, and not giving out, so as to reduce the impact of measurement errors, improve measurement accuracy, and accurate volume wear volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0064] Example: Using Qingdao Hexagon Global classic SR 575 three-coordinate measuring machine, to figure 1 The samples shown were measured. According to the aforementioned method, select point density n=0.5mm, tolerance coefficient c=1.3, and measure the liner before wear. The wear was then simulated by manually removing material to obtain the worn prosthesis, and the worn data was measured again. Thus two sets of data before and after wear are obtained.

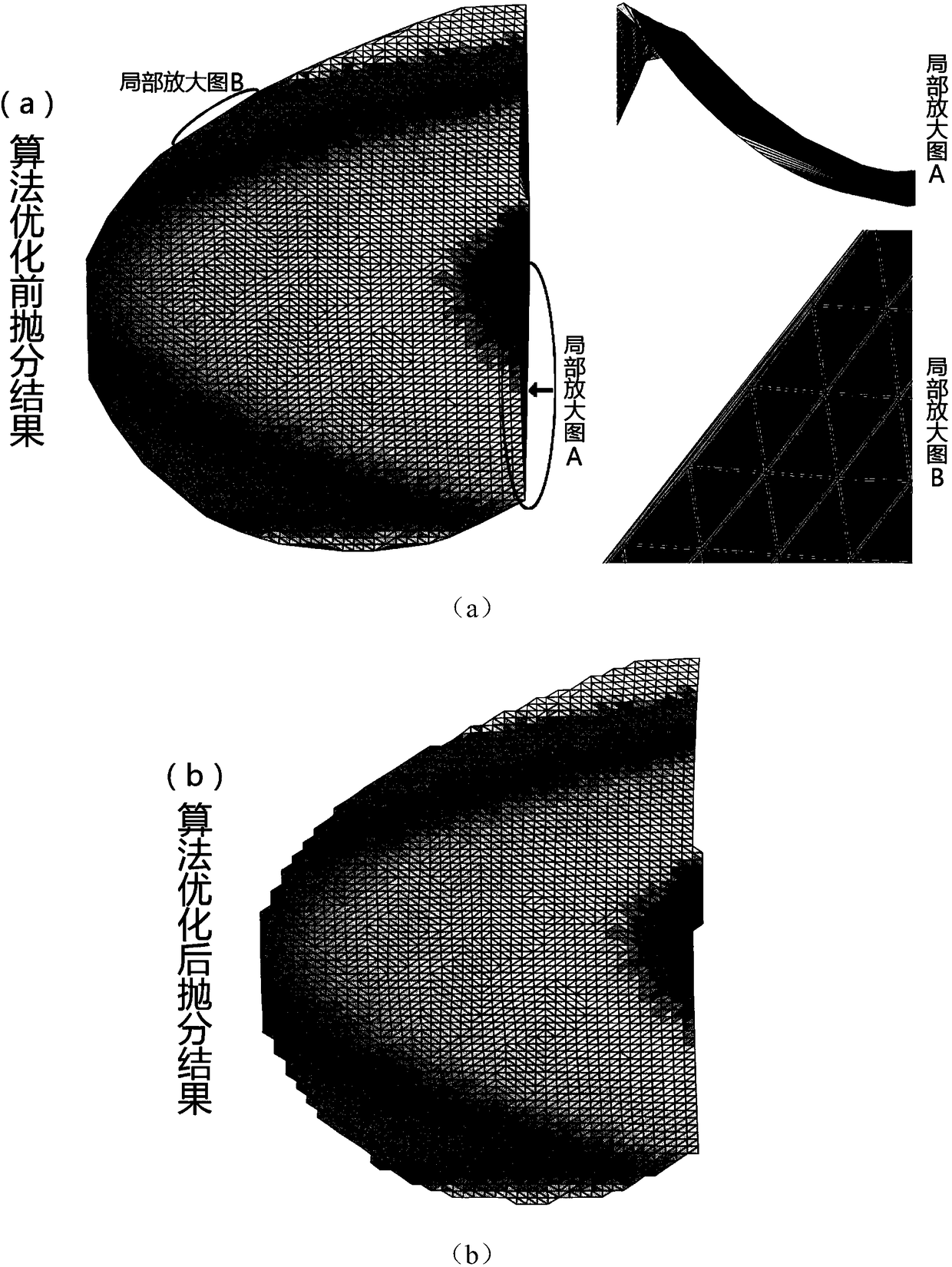

[0065] Firstly, according to the above-mentioned calculation procedure, based on the measurement data before wear, data optimization is performed on the measurement data after wear, and the single-point cumulative measurement error of the three-coordinate measuring machine used is w=0.005mm. Obtain optimized post-wear measurement data.

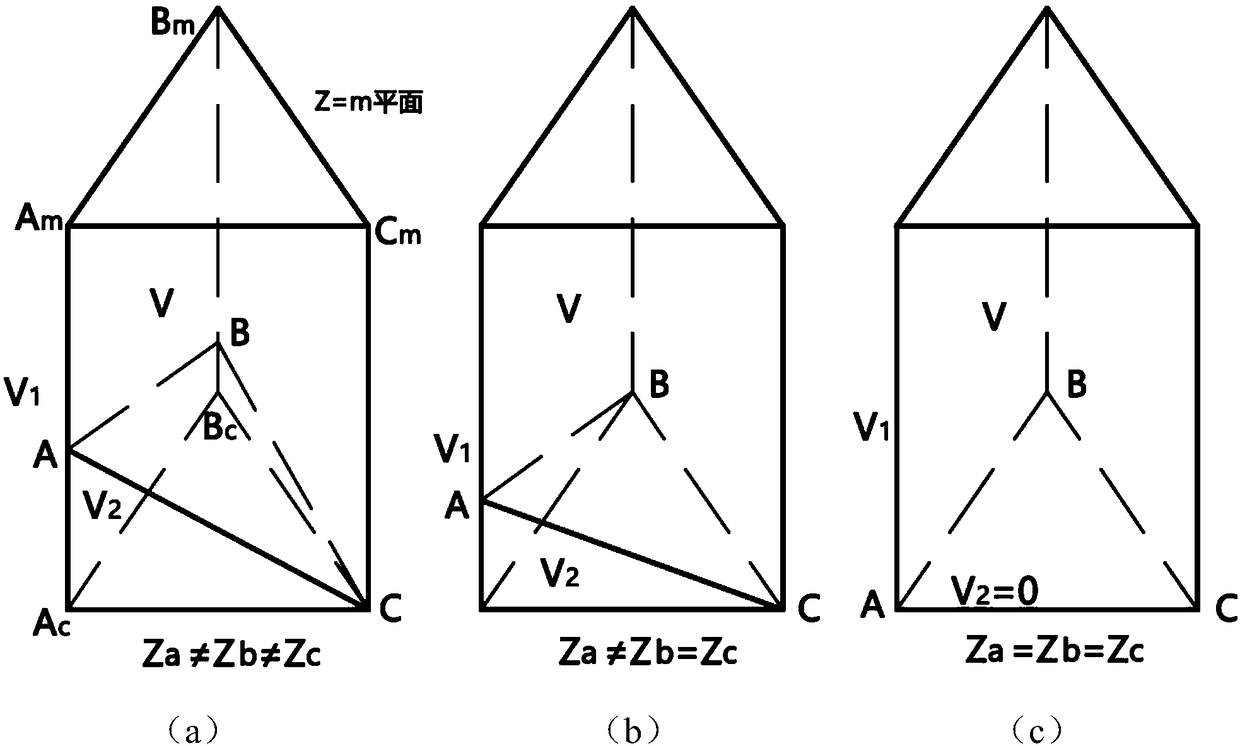

[0066] Then use the aforementioned calculation program to calculate the volume values of the data before wear and the optimized data after wear, and obtain the calculation result V 前 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com