Expanding type spongy bone hollow screw

A hollow screw and cancellous bone technology, applied in the field of medical devices, can solve the problems of loosening and prolapse of internal fixation screws, failure of fixation, insufficient lifting and fixing strength, etc., so as to improve the anti-pullout strength and anti-rotation strength, and increase the stability. and reliability, and the effect of reducing the incidence of surgical failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

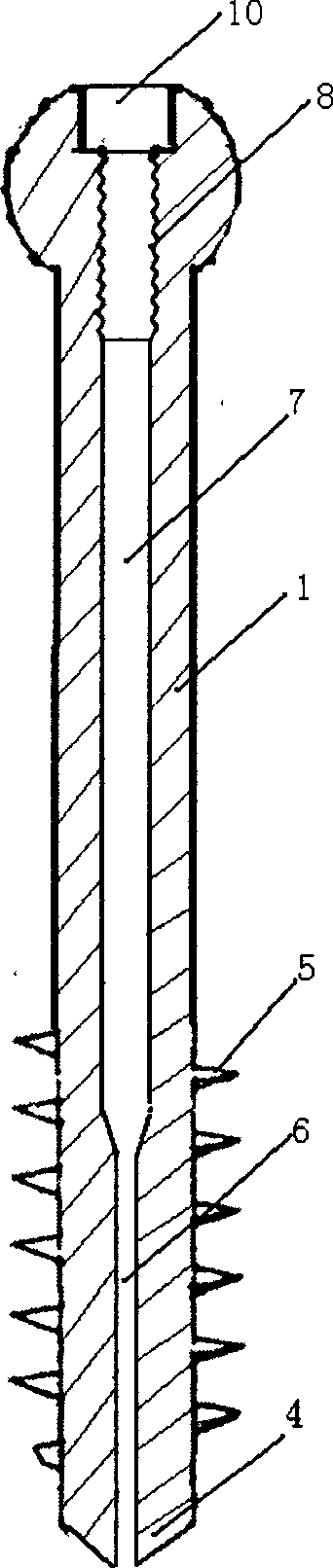

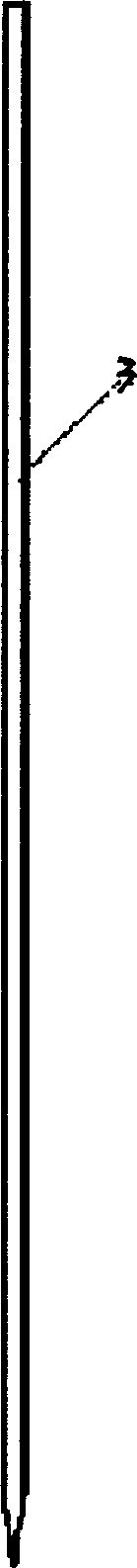

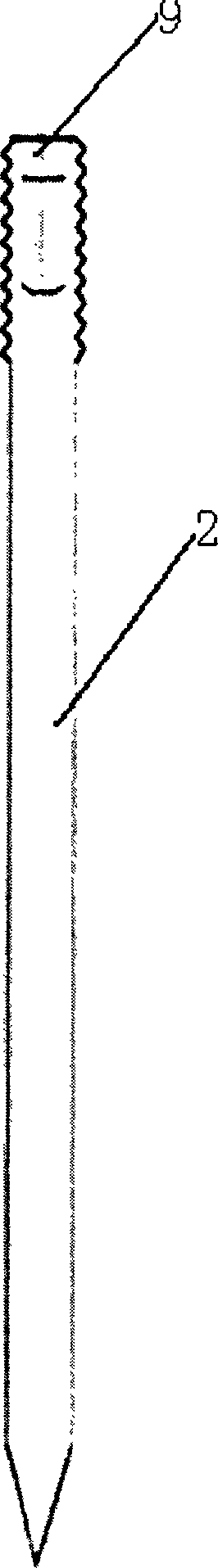

[0012] refer to figure 1 , 2 , 3, the present invention is composed of two parts, an outer screw 1 and an inner bolt 2, one end of the outer screw 1 is a tip 4, the other end of the outer screw 1 is spherical, and there is an outer thread 5 behind the tip 4, and the outer thread 5 is a self- Tapped cancellous bone threads. There are two front and rear end channels 6,7 with different diameters in the center of the outer screw 1. The diameter of the front end channel 6 is smaller than the diameter of the screw rear end channel 7, and the junction of the front and rear end channels 6 and 7 is tapered. Internal threads matching the internal bolts 2 are provided on the inner wall of the rear end channel 7 . At the tip portion 4 of the outer screw 1, two or four lobes of expansion gaps are uniformly cut from the tip along the axial direction, and the expansion gaps extend to behind the junction of the tapered channel. The other end of the outer screw 1 is spherical, with a hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com