Anti-impact wear resistance test device for high speed silt-carrying water flow water conservancy engineering material

A technology for water conservancy engineering and wear test, applied in fluid dynamics test, measuring device, analyzing materials, etc., can solve the problems of jet nozzle abrasion, limit sand-laden water flow speed, etc. The effect of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments are given below in conjunction with the accompanying drawings and the present invention is described in detail. It is necessary to point out that the following examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention, some non-essential improvements and improvements made by those skilled in the art based on the content of the present invention above. Adjustment still belongs to the protection scope of the present invention.

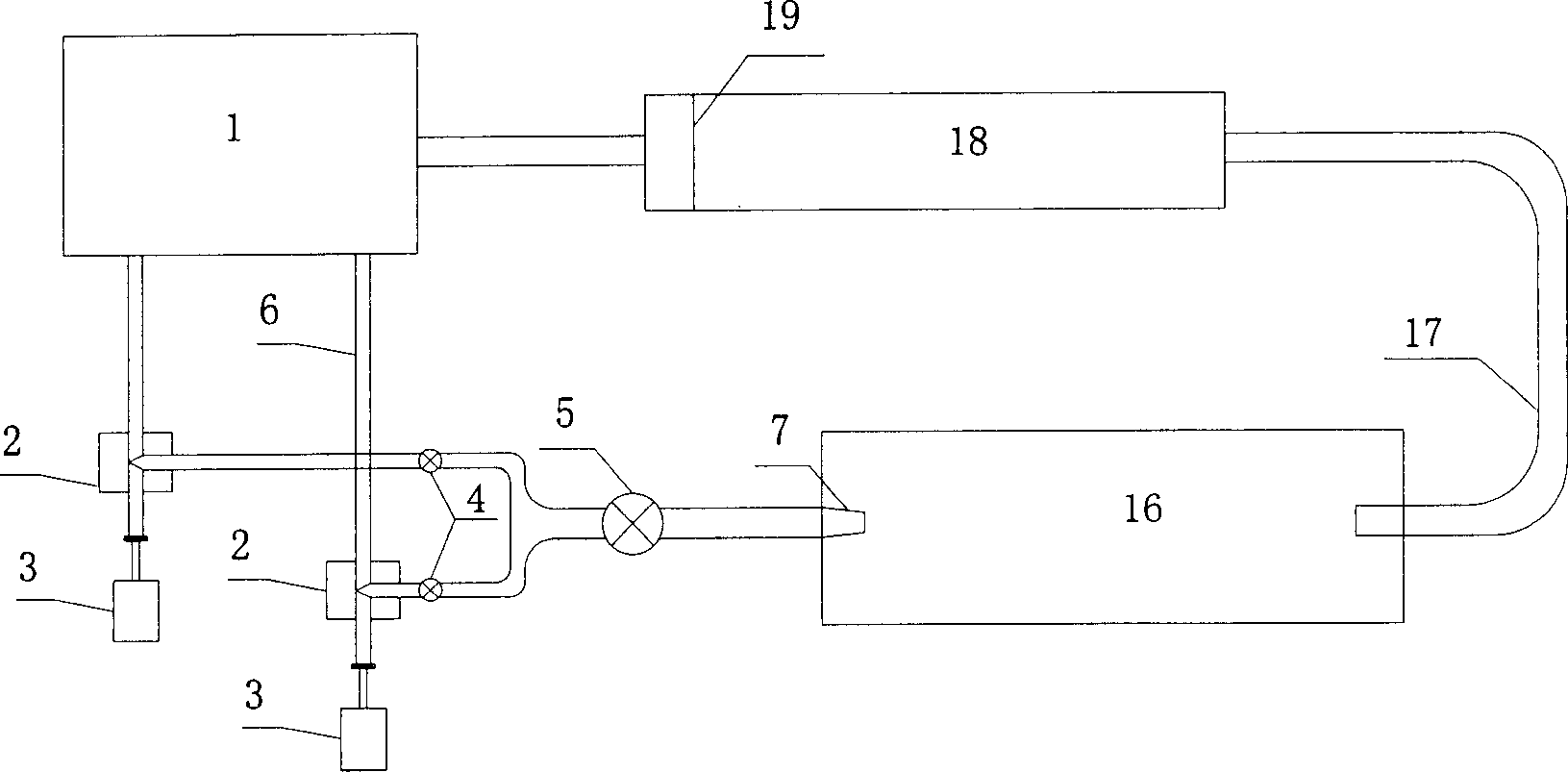

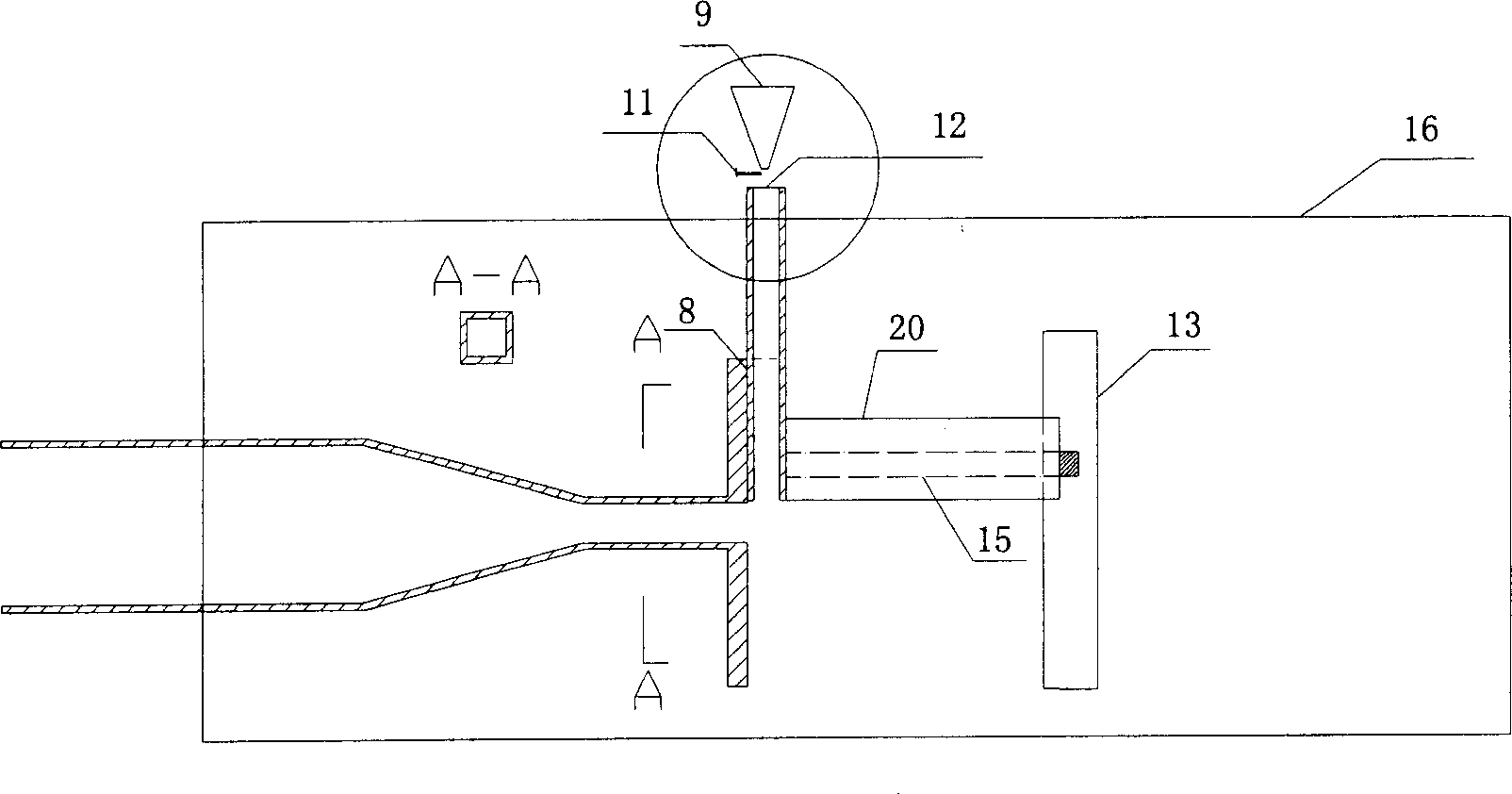

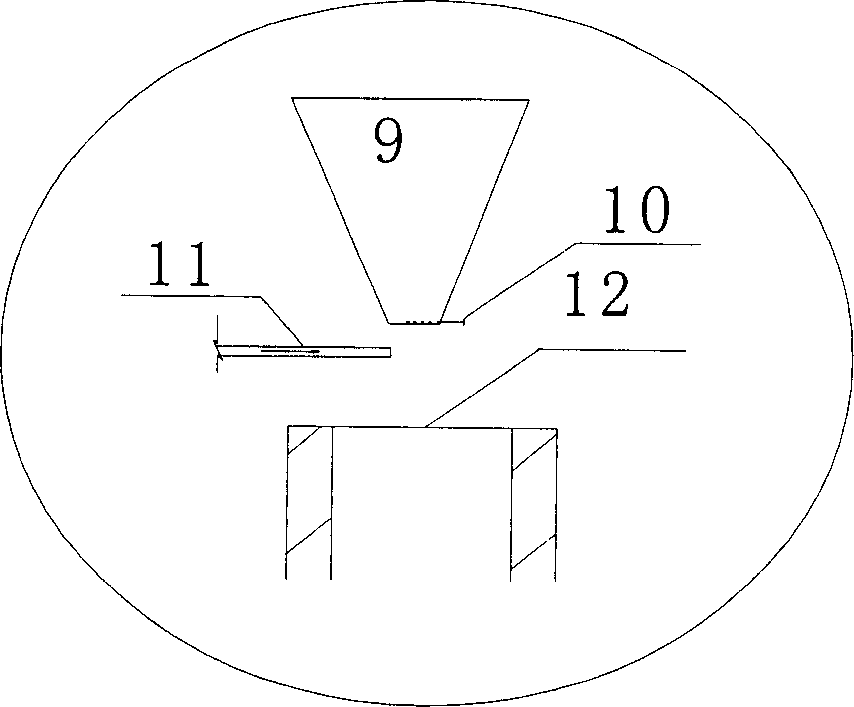

[0021] Such as figure 1 As shown, the high-speed sandy water flow hydraulic engineering material anti-shock and wear resistance test device provided in this embodiment is composed of a reservoir 1, a water pump 2, a motor 3, a control valve 5, a water flow nozzle 7, a sand filling mechanism, and a test piece support 13 , grit chamber 16 and flow meter 18 components. The reservoir 1, the water pump 2, the control valve 5, the water flow nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com