Semiconductor laser device and method for fabricating the same

A technology of laser device and semiconductor, applied in the direction of semiconductor laser device, semiconductor laser, laser device, etc., can solve the problem of laser emission stop and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

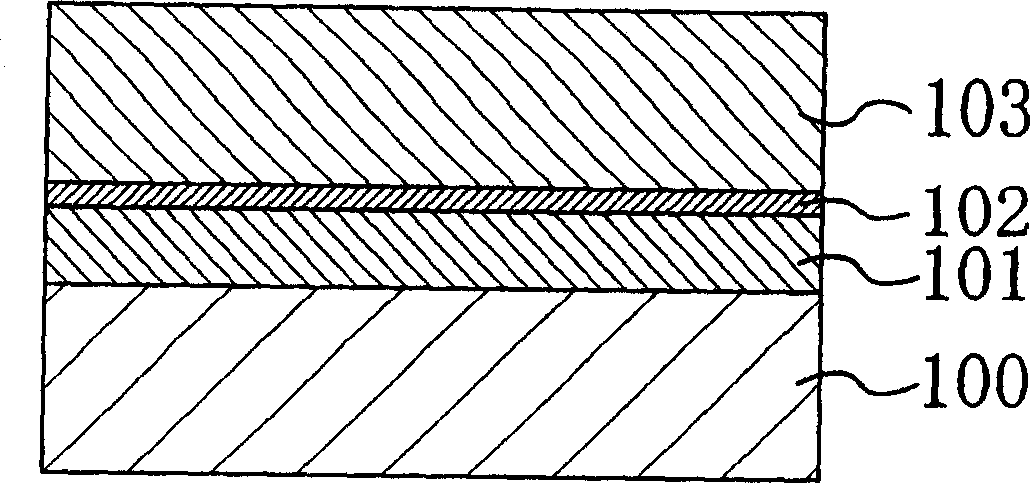

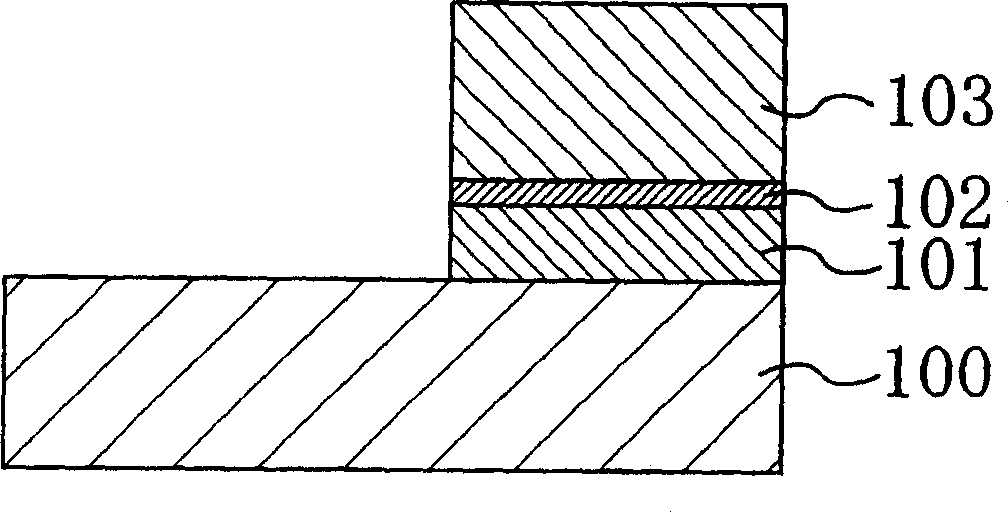

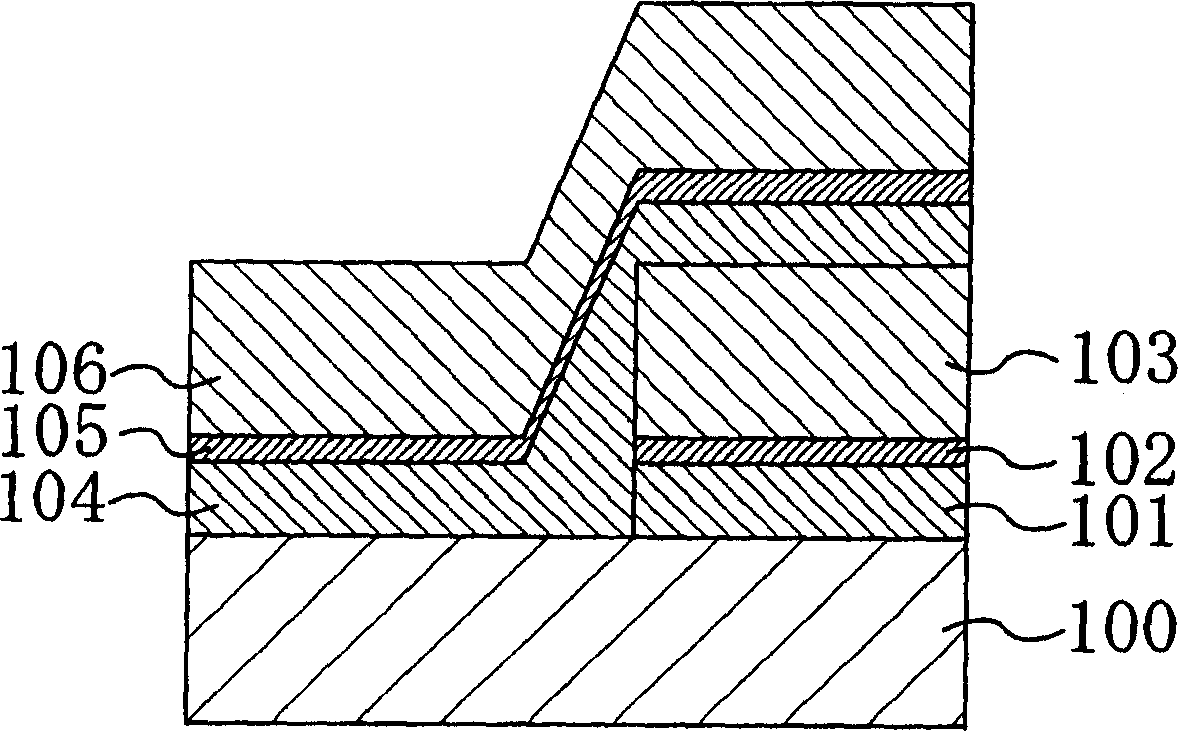

[0103] Below, refer to Figure 1(a) ~ Figure 1(d) , Figure 2(a) and Figure 2(b), and Figure 3(a) ~ Figure 3(d) , the method of manufacturing the semiconductor laser device according to the first embodiment of the present invention will be described.

[0104] Figure 1(a) ~ Figure 1(d) , Figure 2(a) and Figure 2(b), and Figure 3(a) ~ Figure 3(d) , is a sectional view showing a pivot portion step of the method of manufacturing the semiconductor laser device according to the first embodiment of the present invention.

[0105] here, Figure 1(a) ~ Figure 1(d) with Figure 3(a) ~ Figure 3(d) It is a cross-sectional view showing the pivotal part process of the manufacturing method of the semiconductor laser device, specifically, in Figure 4 The cross-sectional view of the pivotal part process of the line IIId-IIId shown, Fig. 2 (a) is the top view of the pivotal part process showing the manufacturing method of the semiconductor laser device, and Fig. 2 (b) is the manufacturing ...

no. 2 Embodiment

[0203] In the future, in response to higher-speed and multi-layer data writing such as DVD-RAM, the optical output required for semiconductor laser devices is 300 [mA] to 400 [mA], and higher output operations can be performed. Semiconductor laser devices will be required.

[0204] Therefore, the semiconductor laser device of the second embodiment of the present invention is not only the same as the aforementioned semiconductor laser device of the first embodiment of the present invention, but also has a good window area in the vicinity of the emission edge by a single Zn diffusion process. The purpose is to provide an infrared laser active layer and a red laser active layer in the region, and furthermore, to provide a semiconductor laser device capable of higher output operation.

[0205] Here, in order to realize a semiconductor laser device capable of higher output operation, it is necessary to inject more current into the active layer.

[0206] However, as the current inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com