Thread transversing device for a winding device of a cross-wound bobbin producing textile machine

A technology of cross-winding bobbins and traversing devices, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve the problems of high cleaning costs, easy to be affected by textile dust or fiber fluff, etc., and achieve reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

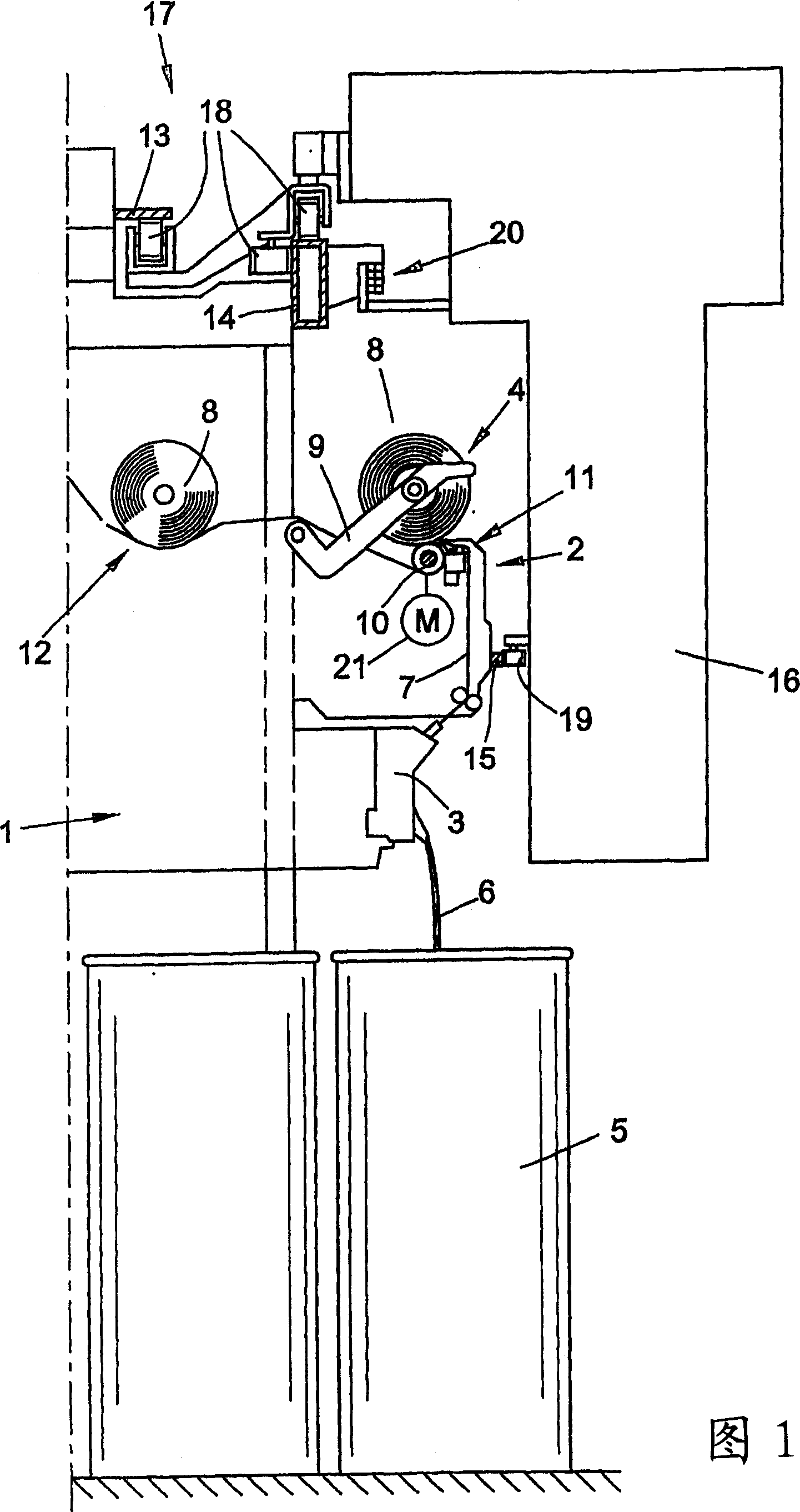

[0027] In FIG. 1, a half of a spinning machine (in this embodiment, a free-end rotor spinning machine) that produces cross-wound bobbins is shown, and is indicated by reference numeral 1. This open-end rotor spinning machine known per se has a plurality of workstations 2 which are all equipped with a spinning box 3 and a spinning device 4. In the spinning box 3, the fiber ribbon 6 present in the spinning tank 5 is spun into a yarn 7, and the yarn 7 is then wound onto the spinning device 4, thereby forming a cross-wound bobbin 8.

[0028] As shown in the figure, the winding device 4 therefore has: a creel 9 for rotatably holding the cross-winding bobbin 8; a winding drum 10 for driving the cross-winding bobbin; and a yarn traverse device 11. In the illustrated embodiment, the winding drum 10 may be driven by a single motor drive 21.

[0029] This open-end rotor spinning machine 1 usually also has a cross-wound bobbin conveying device 12 for processing the finished cross-wound bobbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com