Method of making spring core for glasses earpiece and product thereof

A production method and technology for glasses legs, applied in the field of glasses, can solve the problems of easily breaking the spring core body, unfavorable mass production, increased production cost, etc., and achieve the effects of low production cost, high production efficiency, and reduced wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

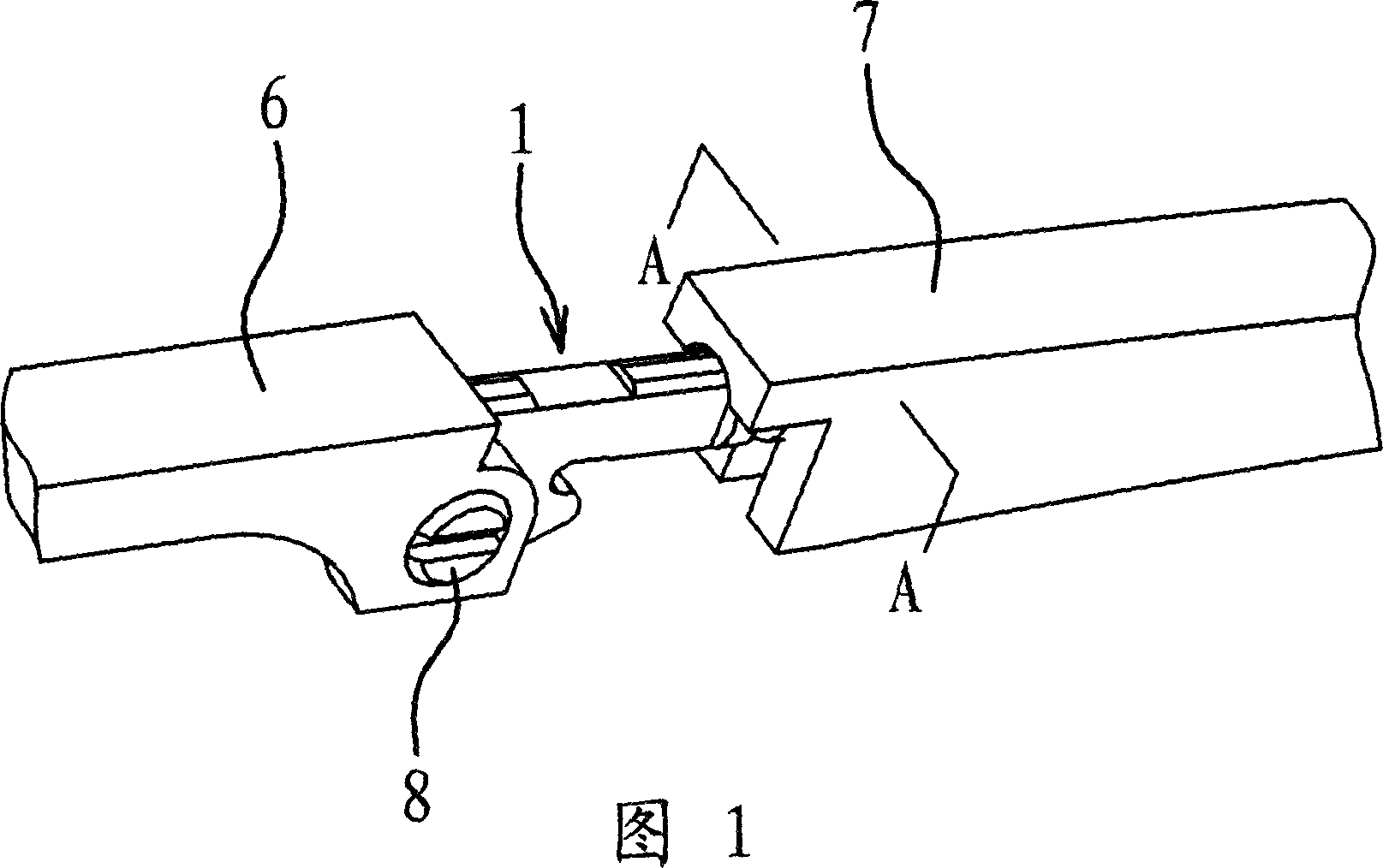

[0037] As shown in Fig. 1, the spring core body 1 is connected together with other parts of the spring core for the spectacle pins and then installed in the spectacle pins.

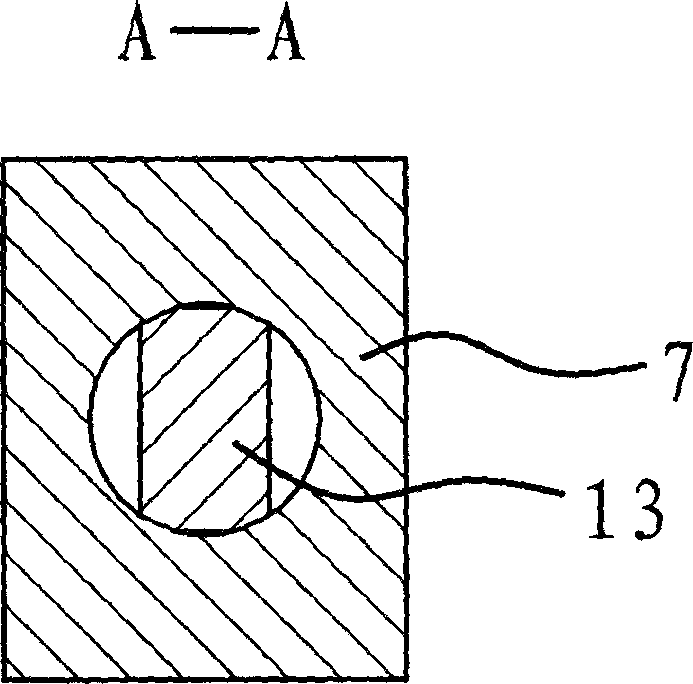

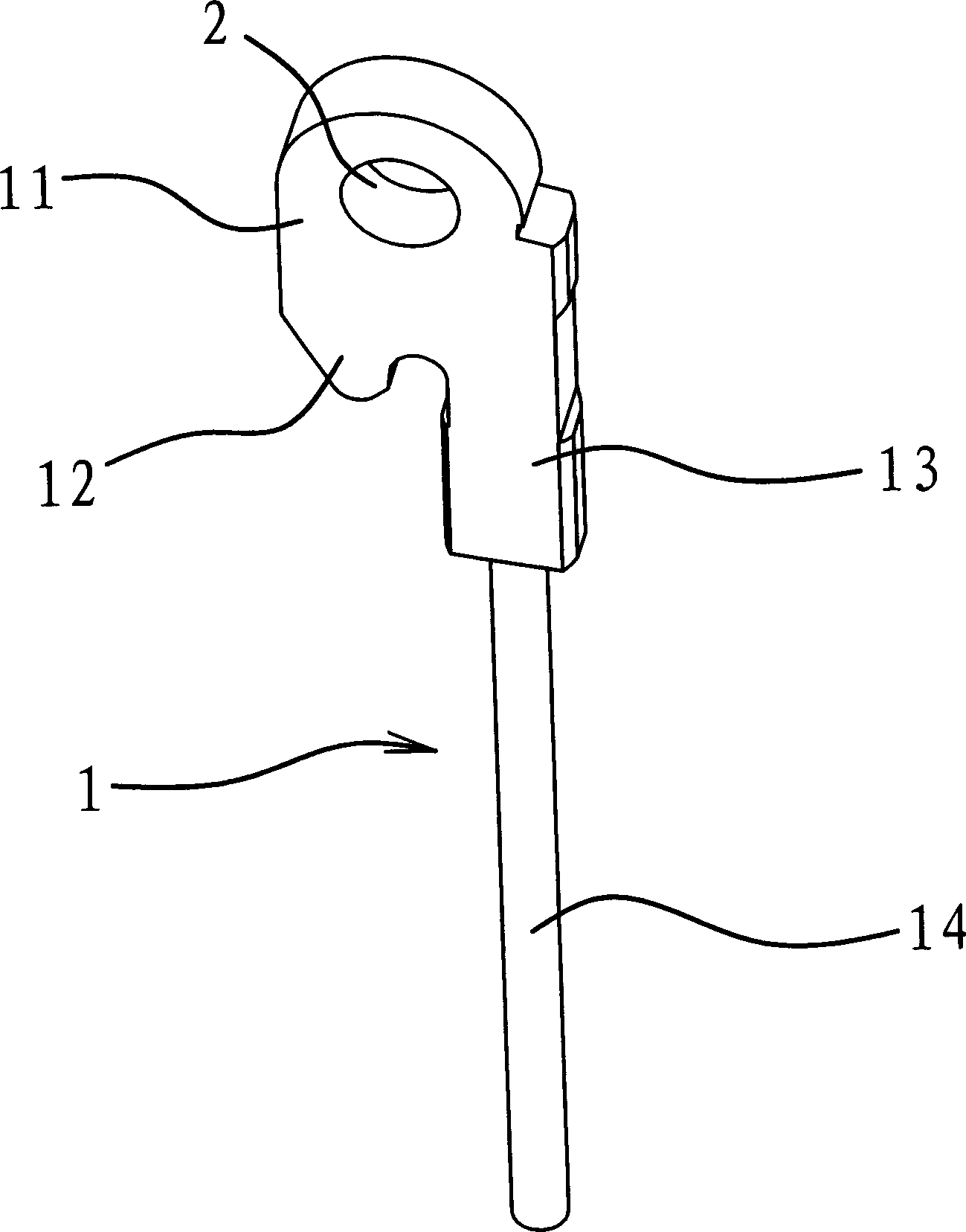

[0038] Such as image 3 As shown, one end of the body 1 of the spring core is a head 11 with a protruding hook 12 and a hinge hole 2, the other end is a cylindrical tail 14, and between the head 11 and the tail 14 is a polygonal prism-shaped middle 13. , In this embodiment, the middle part 13 is in the shape of a flat octagonal prism.

[0039] Such as Figure 4 As shown, in addition to the spring core body 1 , the spring core also includes a grooved small tube 3 , a spring 4 and a small end-sealing tube 5 , and the above-mentioned components are seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com