Double-pvariable accurate irrigation spray cap with synchronous control of shoot range and flow quantity

A double-variable, flow-rate technology, applied in the field of mechanical parts manufacturing, can solve the problems of poor work reliability, low synchronous controllability of spray area and spray volume, poor sealing of periodic energy consumption devices, etc., to increase work reliability, Increased sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

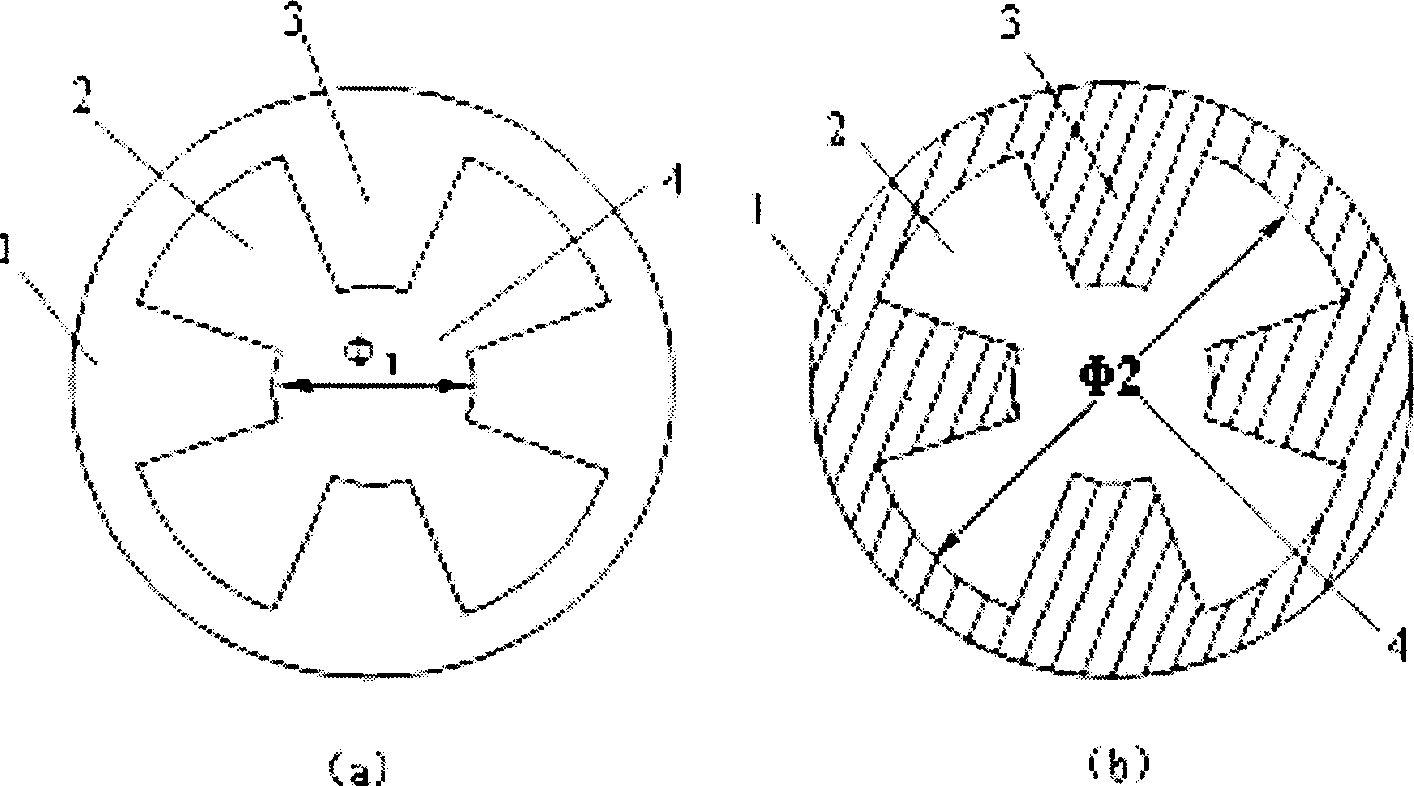

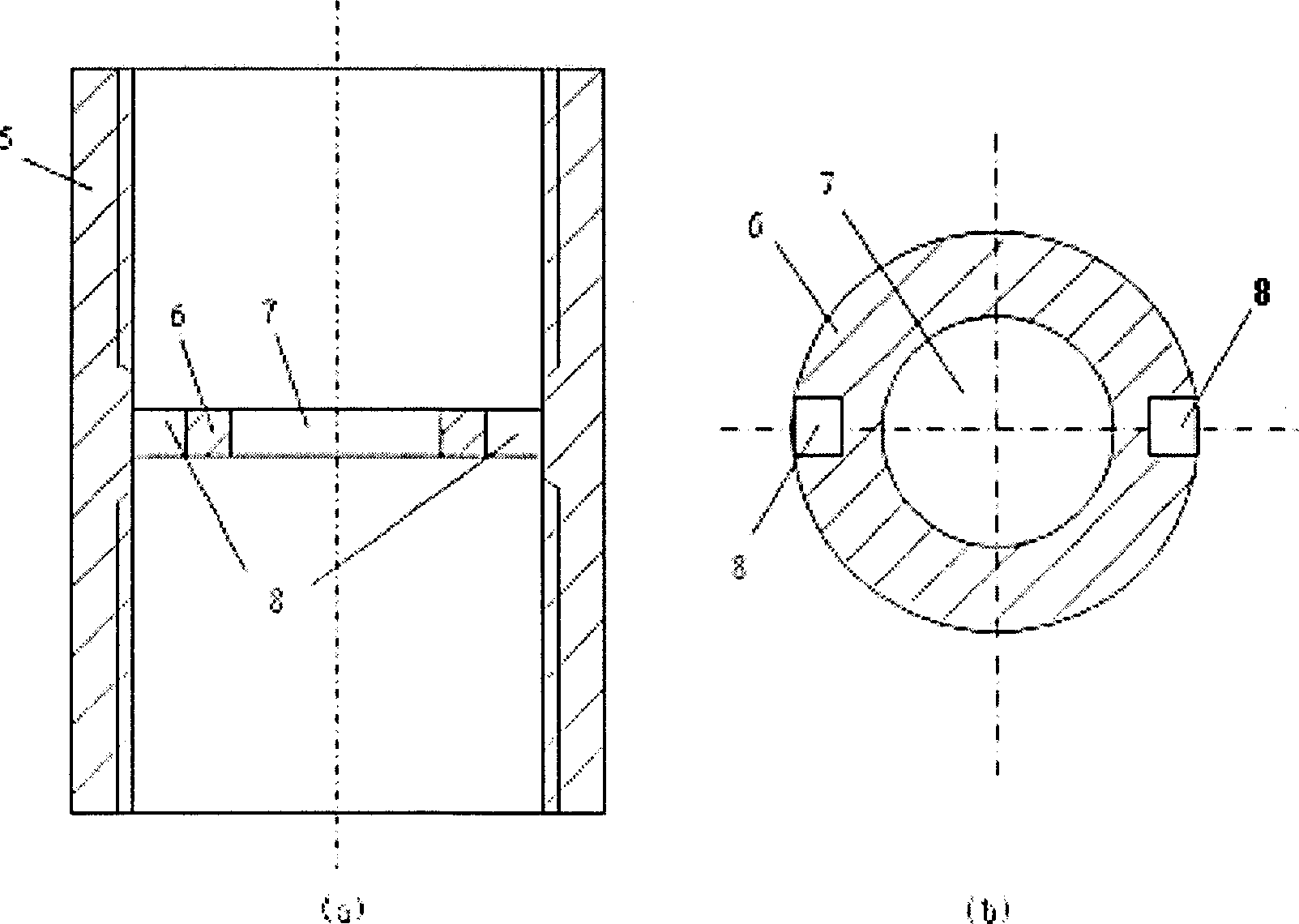

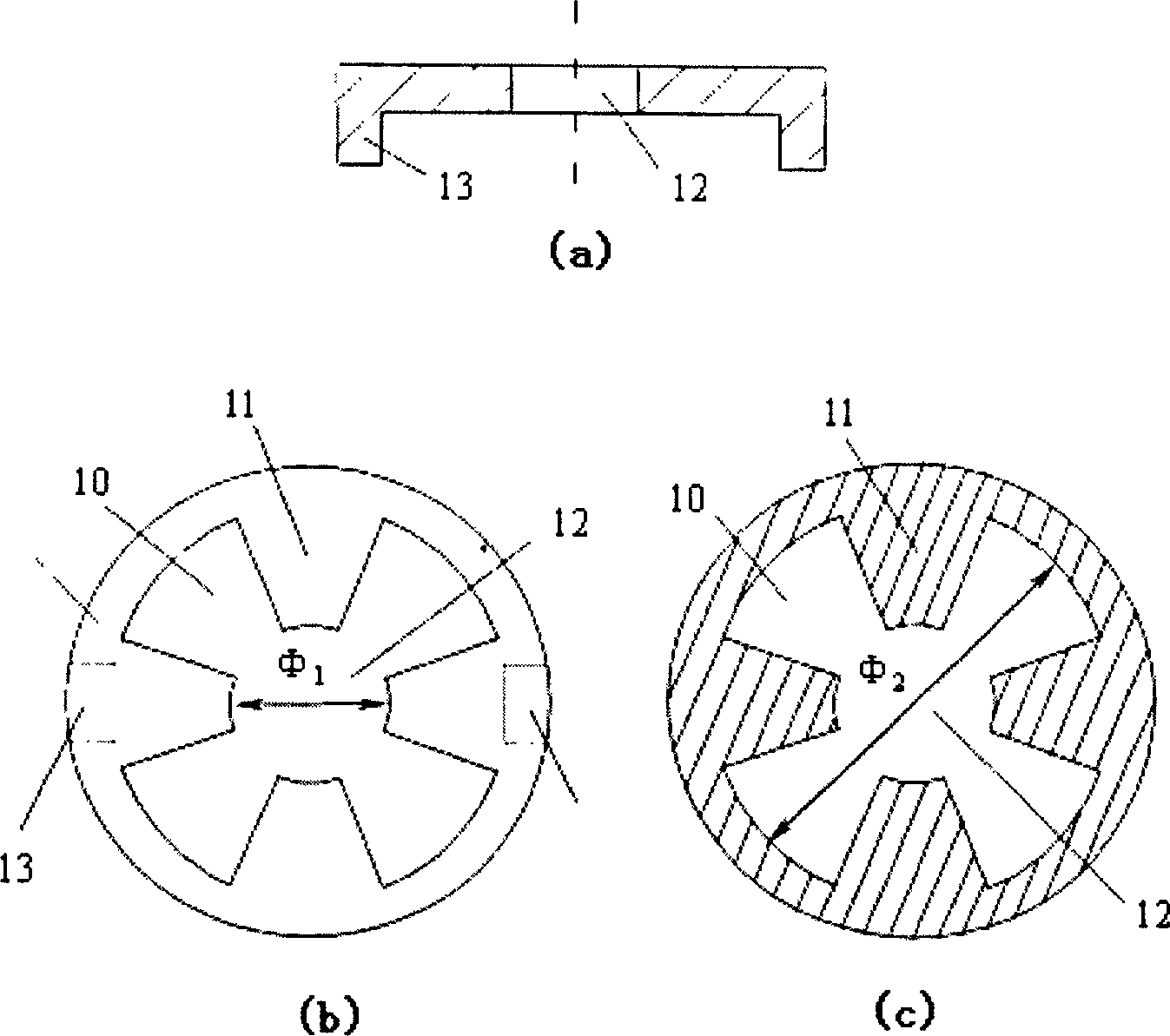

[0018] See attached Figure 4 , according to the technical scheme of the present invention, the double-variable accurate irrigation nozzle with synchronous controllable range and flow comprises a rocker-arm type nozzle 20, and the water-passing hole 1 (diameter is Φ) at the water inlet end of the rocker-arm type nozzle 20 hollow shaft 2 ) is changed from a circular cross-section to a non-circular water cross-section ( figure 1 ), the water passing hole 1 is integrated with the hollow shaft of the rocker-arm type sprinkler head. And between the hollow shaft of the original rocker-type shower head 20 and the water supply standpipe, a double-ended threaded pipe joint 5 ( figure 2 ); an annular support section 6 is provided between the two threads of the double-ended threaded pipe joint 5, and a through hole 7 is opened in the center of the annular support section 6, the diameter of which is the same as the outer diameter of the hollow shaft water passage hole 1 , there are two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com