Method and apparatus of processing aqueous solution by hydrate method

An aqueous solution and hydrate technology, which is applied in seawater treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of mother liquor entrainment, and achieve the effects of improving efficiency, low energy consumption, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

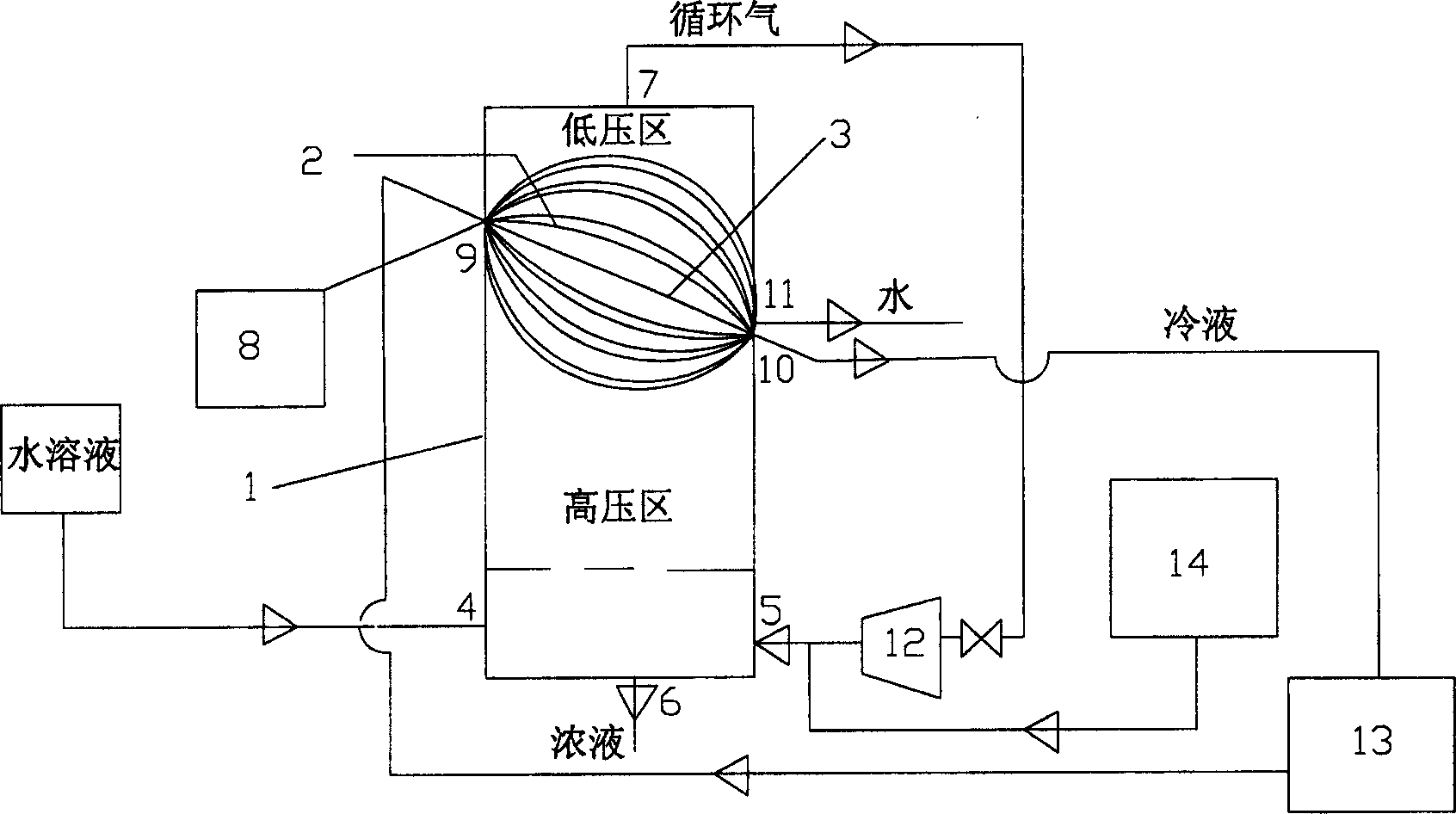

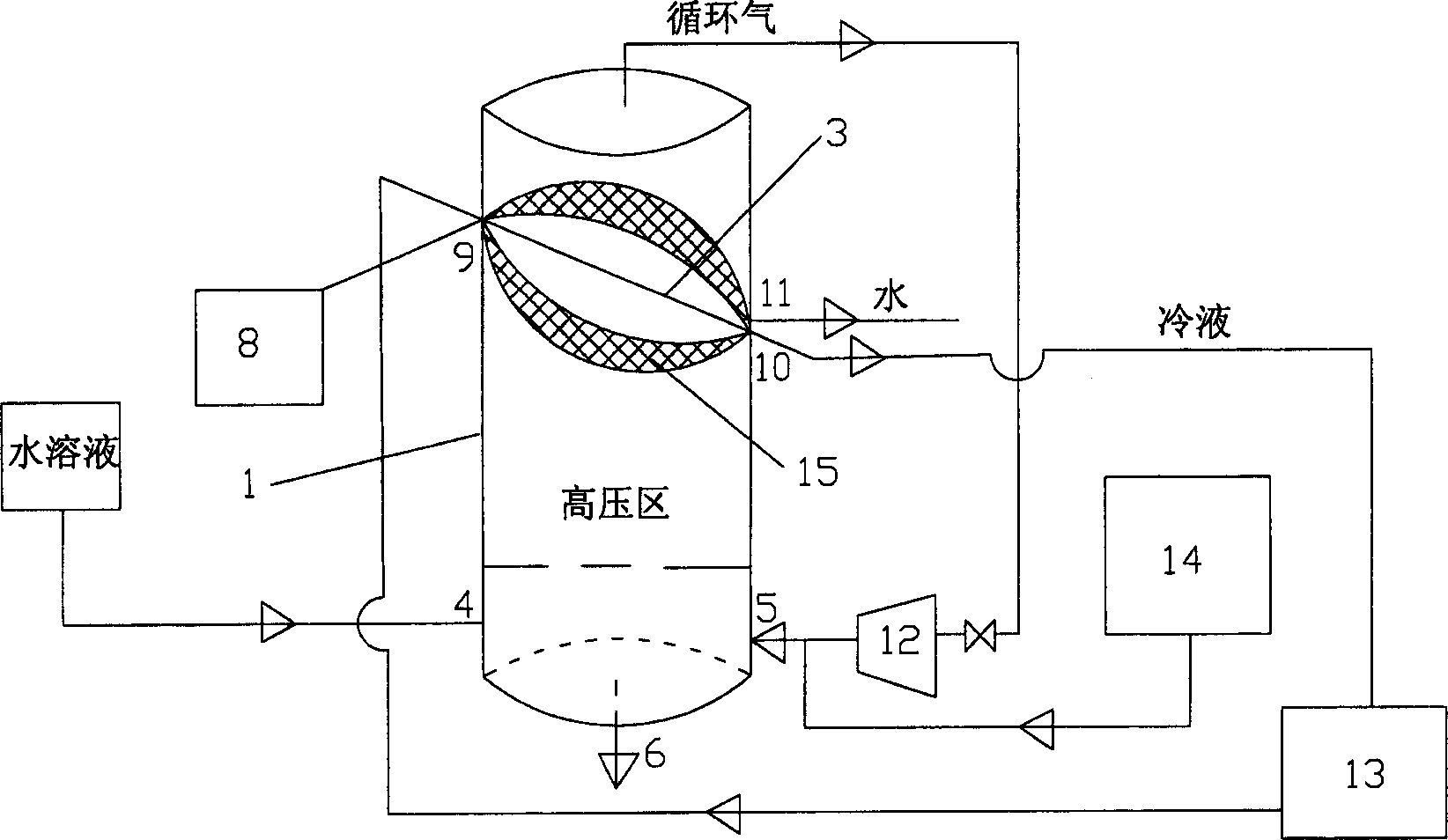

[0052] According to the above experimental procedure, the device of the present invention with a reactor volume of 500mL is used, and the carbon dioxide gas that is easy to generate hydrate is used for the experiment. The treatment object is brine of simulated seawater. The operation process is as described above. 97.0°C, the outlet pressure is 3MPa, the temperature of the aqueous solution (brine) is 4°C, the temperature of the cold liquid flowing in the shaft 3 of the runner is 3°C, and the pressure in the low-pressure zone of the reactor 1 is controlled at about 0.9MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com