Microlens production method

一种制造方法、微透镜的技术,应用在透镜、辐射控制装置、照相制版工艺曝光装置等方向,能够解决开口率降低、成品率降低、不能消除相邻透镜间隙等问题,达到聚光效率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

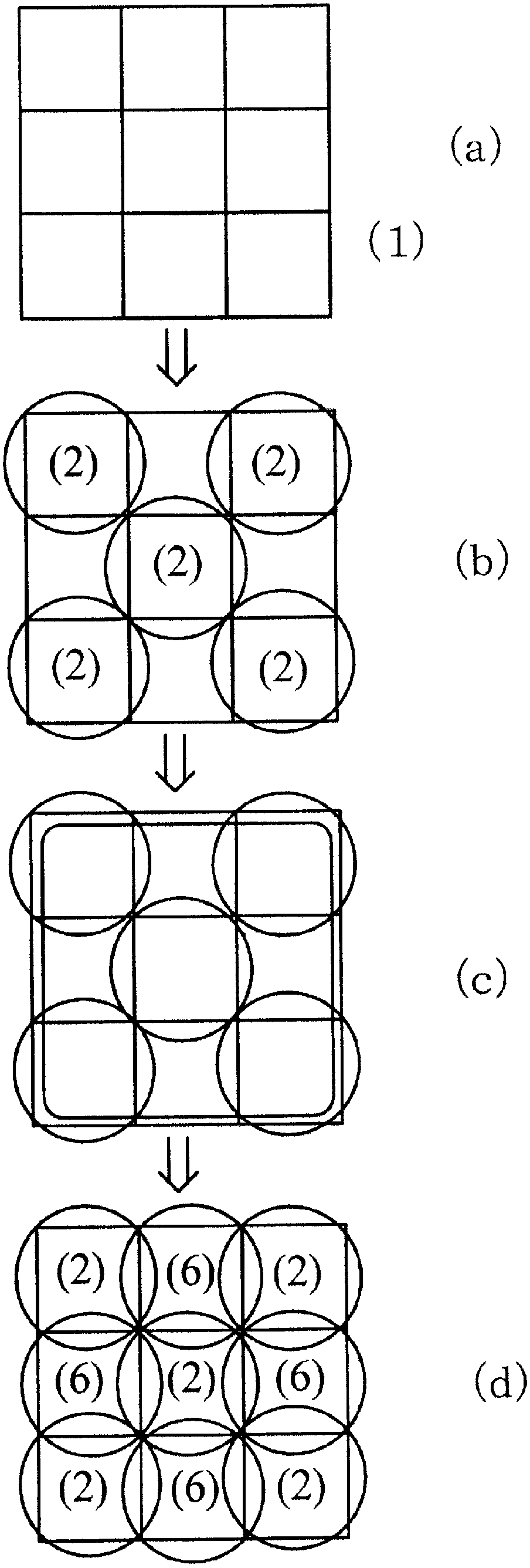

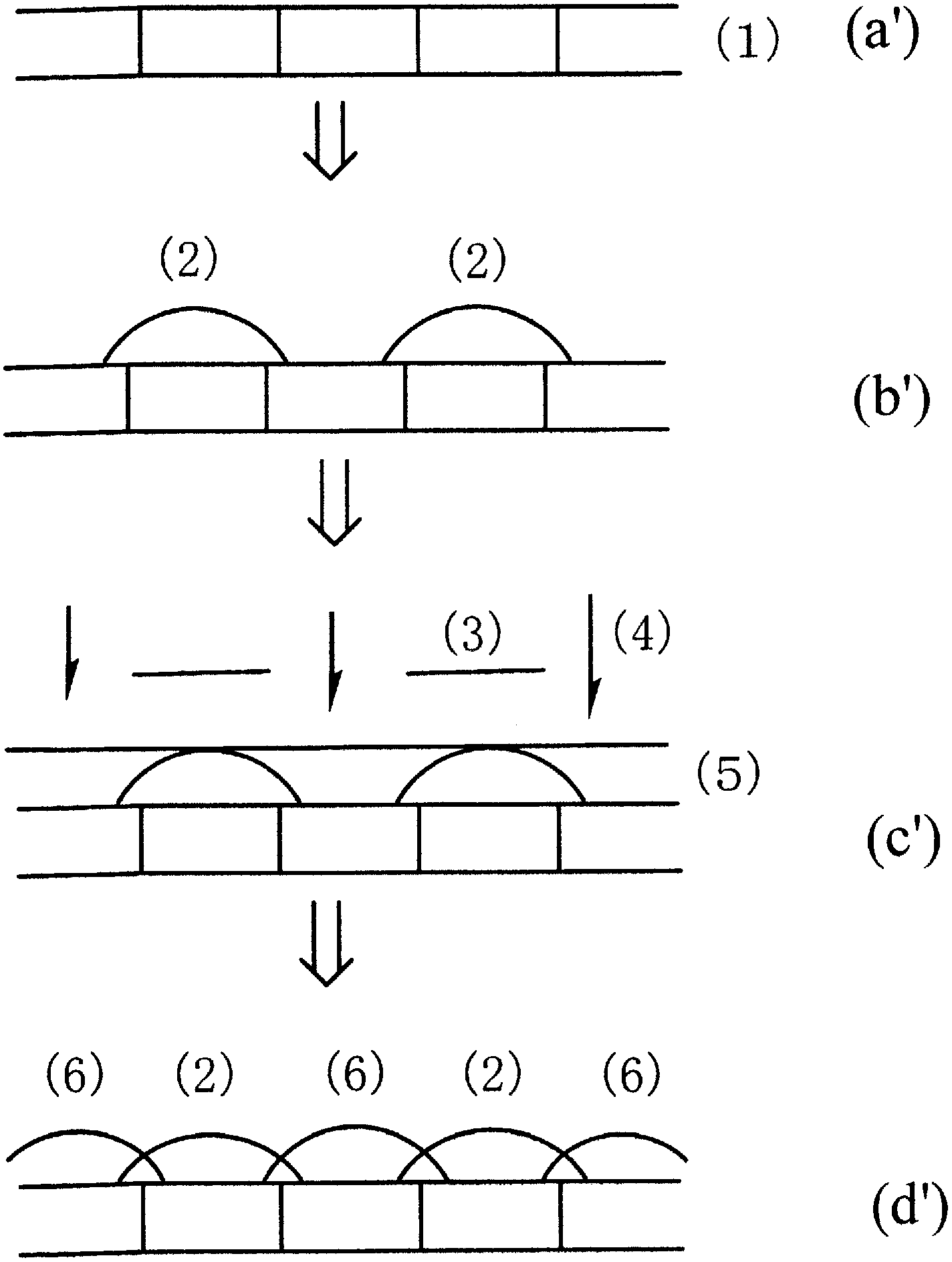

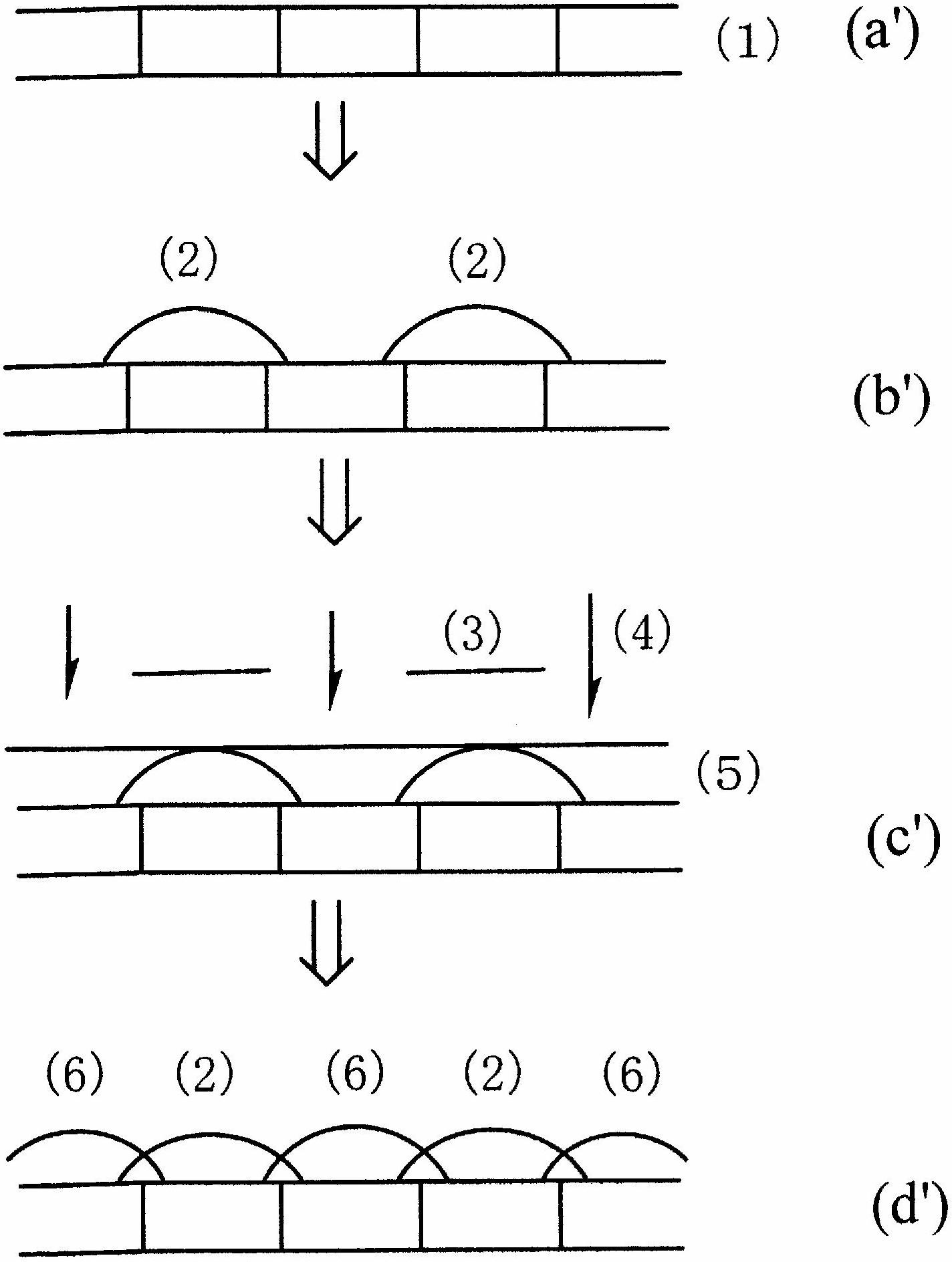

[0065] As the first step, apply a composition for forming a thermosetting microlens on a substrate, expose the formed coating film (the softening point temperature of the coating film is 170°C.) through a grayscale mask, and develop As the pattern of the first microlens ( figure 1 of (b), figure 2 (b')). At this time, the pattern film forms a two-color alternate pattern on the color filter. Next, the lens-shaped pattern film formed by the exposure and development was cured by firing at 140°C, further at 180°C. The diameter of the lens pattern is 2.5 μm. Then, as the second step, the same thermosetting microlens-forming composition as in the first step is used to form the second step through a grayscale mask on the color filter of the portion where the pattern film is not formed in the first step. 2. The lenticular pattern film is then fired at 140° C. for 5 minutes to complete curing accompanied by a crosslinking reaction, and then fired at 180° C. for 5 minutes to form a...

Embodiment 2

[0067] On the same substrate as in Example 1, a thermoplastic microlens-forming composition was used as the first step (the softening point temperature of the coating film formed from the composition is 120°C), and a dot pattern was formed through a binary mask. film (1st microlens) ( figure 1 of (b), figure 2 (b')). At this time, the dot pattern film forms a two-color alternate pattern on the color filter. Next, by performing heat treatment at 160° C., the dot pattern film formed above was heat-flowed to form a lens pattern film. Thereafter, curing is performed by firing at 200°C. The diameter of the lenticular pattern film was 2.5 μm. Then, as the second step, on the color filter of the part where the pattern film is not formed in the first step, a different thermosetting microlens-forming composition (by combining The softening point temperature of the coating film formed by the material is 170°C.) The second lenticular pattern film is formed, followed by firing at 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com