Water-saving wave wheel type or stirring type water-saving full-automatic washing machine

A fully automatic washing machine and pulsator technology, which is applied to other washing machines, washing machine appliances, washing machines with containers, etc., can solve the problems of water waste, high cost and high process requirements, and achieve the effect of water saving work and expanding use occasions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

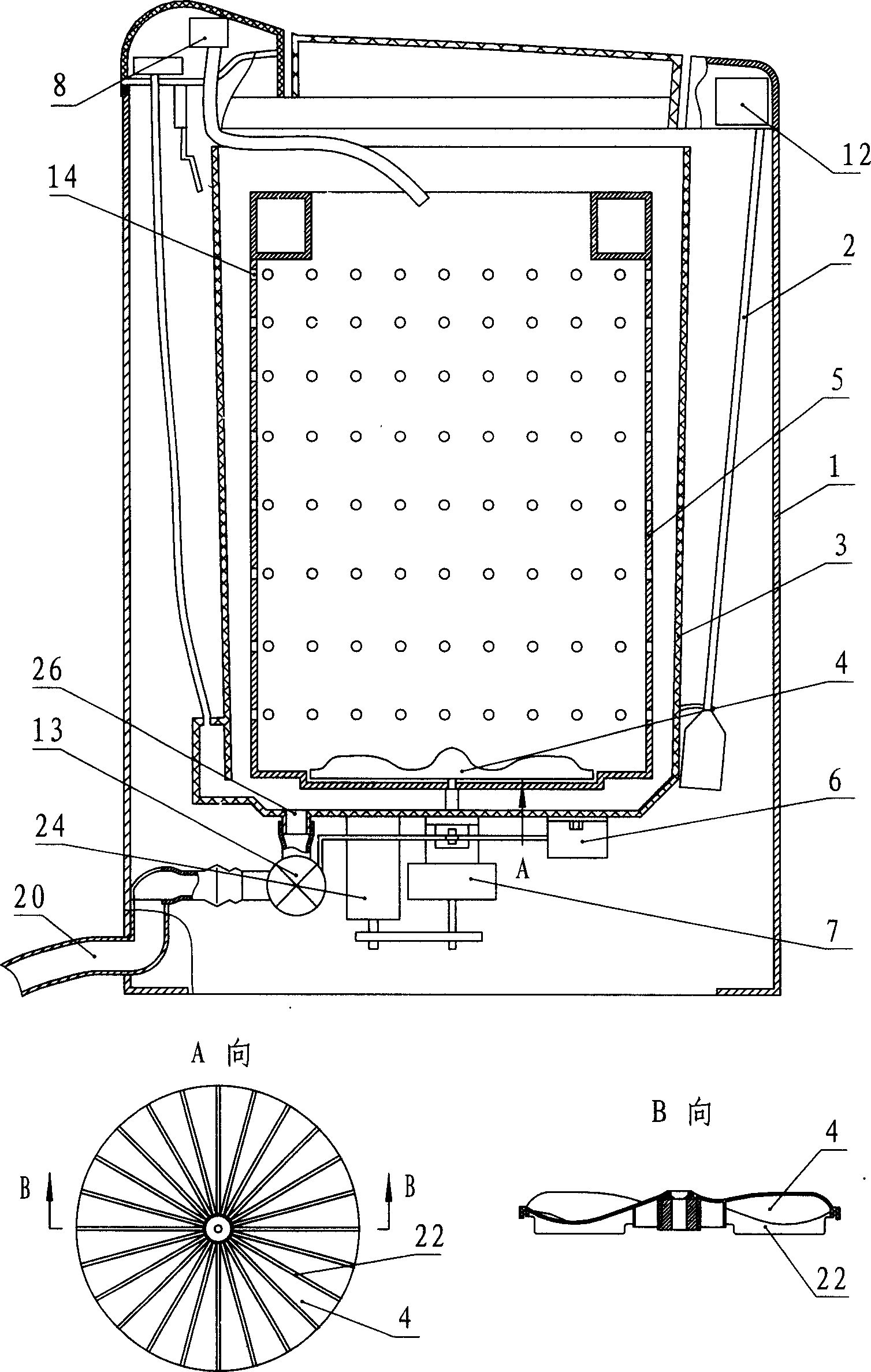

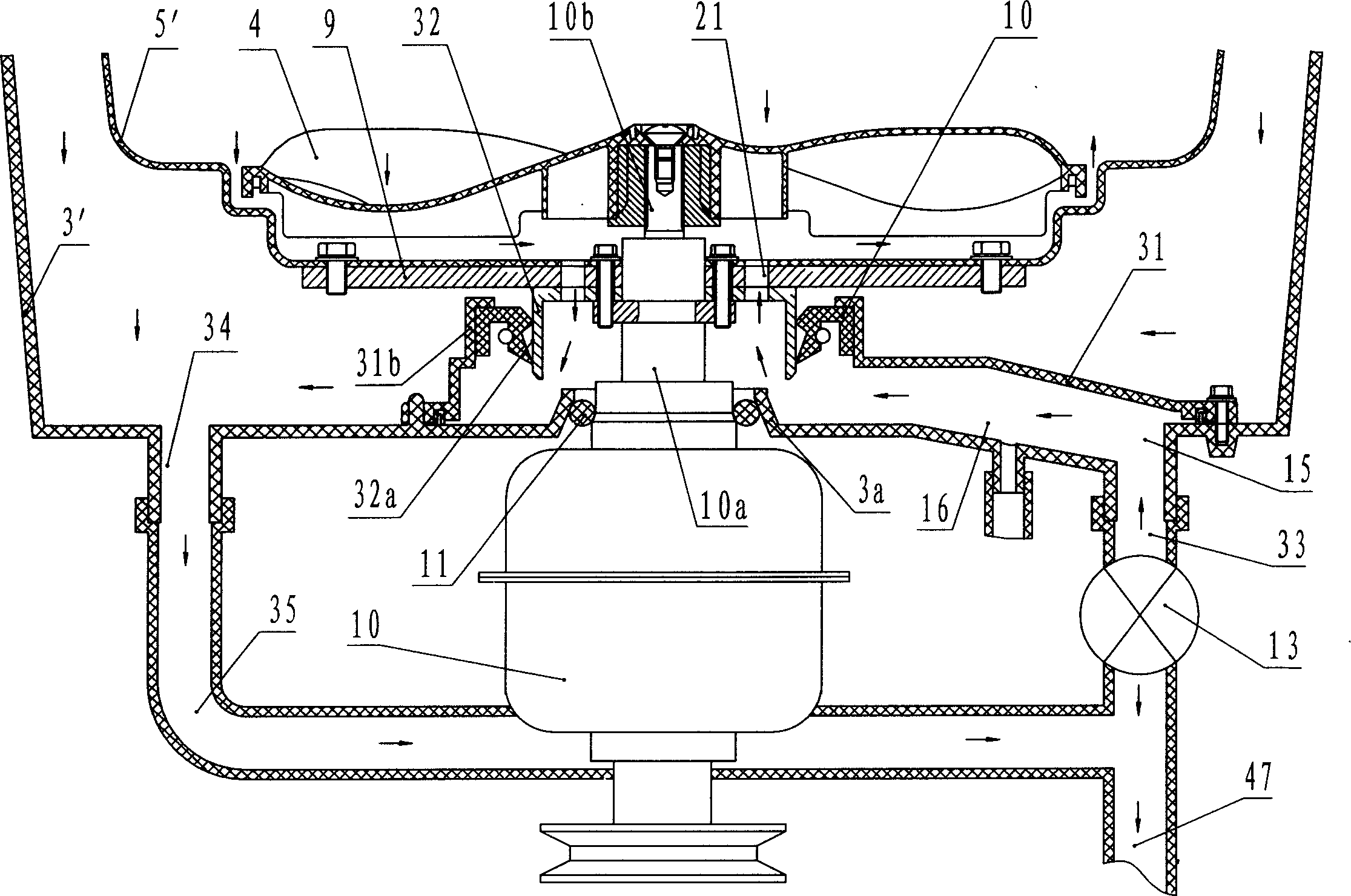

[0026] The washing machine of the first embodiment of the present invention is as image 3 As shown, it is improved on the basis of a traditional fully automatic washing machine. The structure of the traditional washing machine is as follows: figure 1As shown: the outer barrel 3 is rotatably provided with an inner barrel 5 with an agitator 4 rotatably arranged at the inner bottom thereof, the bottom surface of the inner barrel 5 is sealed, and its side wall is covered with dehydration holes 14; the outer barrel 3 is suspended Part 2 is hung in the outer casing 1 of the washing machine; the automatic controller 12 controls the motor 24 located at the bottom of the outer tub 3 to drive the deceleration clutch 7 through the transmission system, and transmits the power to the agitator 4 and the inner tub 5; the bottom of the agitator 4 Such as figure 1 To the view of A, the agitator 4 is provided with reinforcing ribs 22 (see figure 1 B to view); the automatic controller 12 con...

no. 2 Embodiment

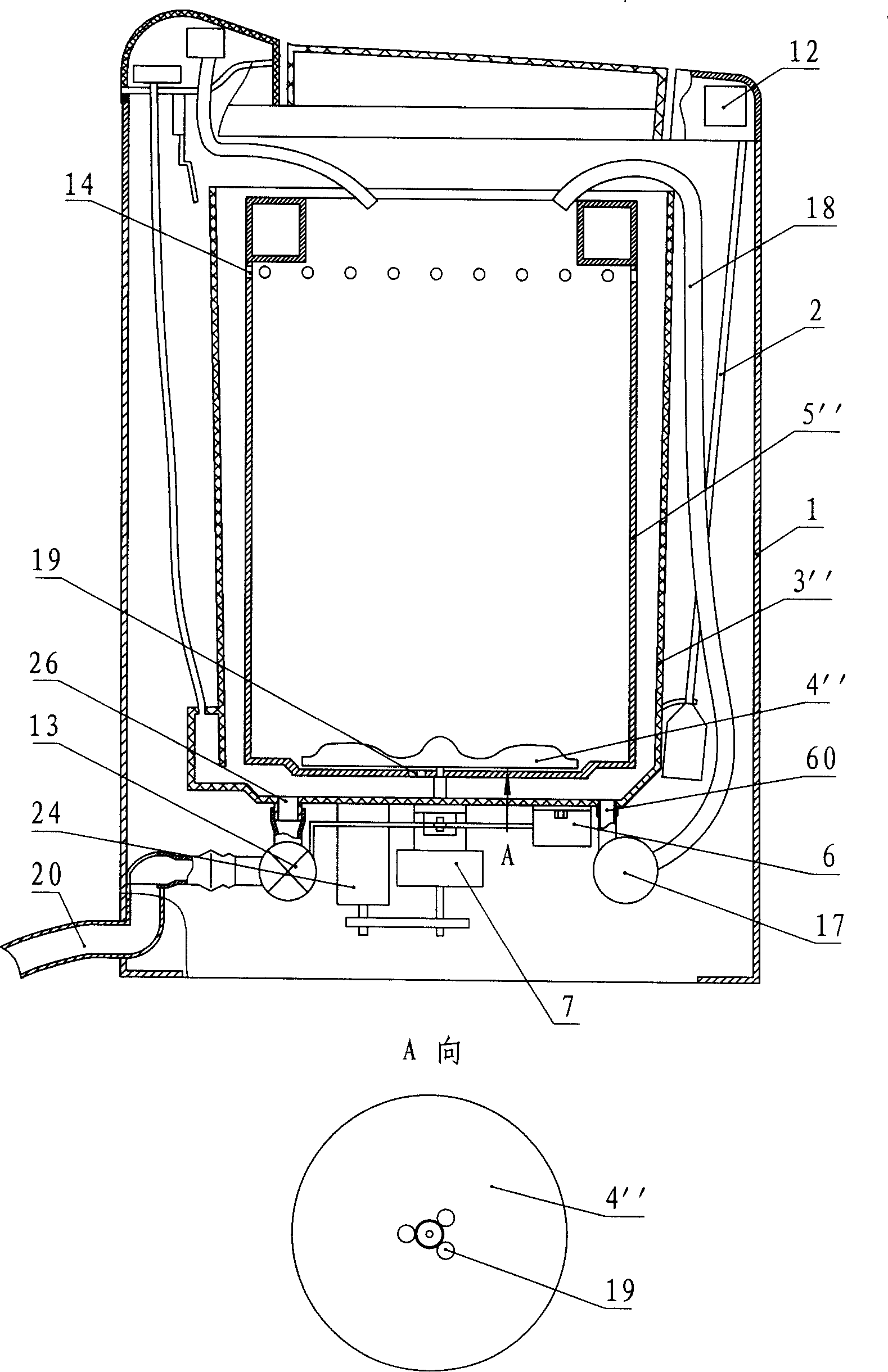

[0034] The washing machine of the second embodiment of the present invention is as Figure 4 As shown (the meaning and function of the symbols in the figure not explained in the text are the same as image 3 the same). The structure is the same as image 3 The difference of the first embodiment shown is that the drain valve of the original washing machine is canceled, the water inlet of the water pump 17 is connected to the water inlet of the drain valve of the original washing machine, and the water outlet of the water pump 17 is connected with a tee controlled by the tractor 6 The inlet of valve 13 , an outlet of this three-way valve is connected to drainpipe, and the other outlet is connected to the soft plastic pipe 18 of inner barrel 5 . When the washing machine is in the washing state, the three-way valve 13 connects the passage between the water pump 17 and the soft plastic pipe 18, so that the washing water between the inner and outer tubs passes through th...

no. 3 Embodiment

[0039] The structure of the drain valve in the washing machine in the third embodiment of the invention is as follows: Figure 8 As shown (the meaning and function of the symbols in the figure not explained in the text are the same as Figure 4 the same). The structure of this embodiment is to change the lower drainpipe 20 of the washing machine described in embodiment 2 into the upper drainpipe 20 ', then both can become a water-saving washing machine, and can become an upper drainage washing machine again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com