Integrated adaptive capacity control for a steam turbine powered chiller unit

一种汽轮机、冷却器的技术,应用在发动机控制、使用涡轮的压缩机器、主动/预测/预期控制等方向,能够解决效率损失、限制防涌浪、冷却器系统操作效率低下等问题,达到防止不安全运行的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

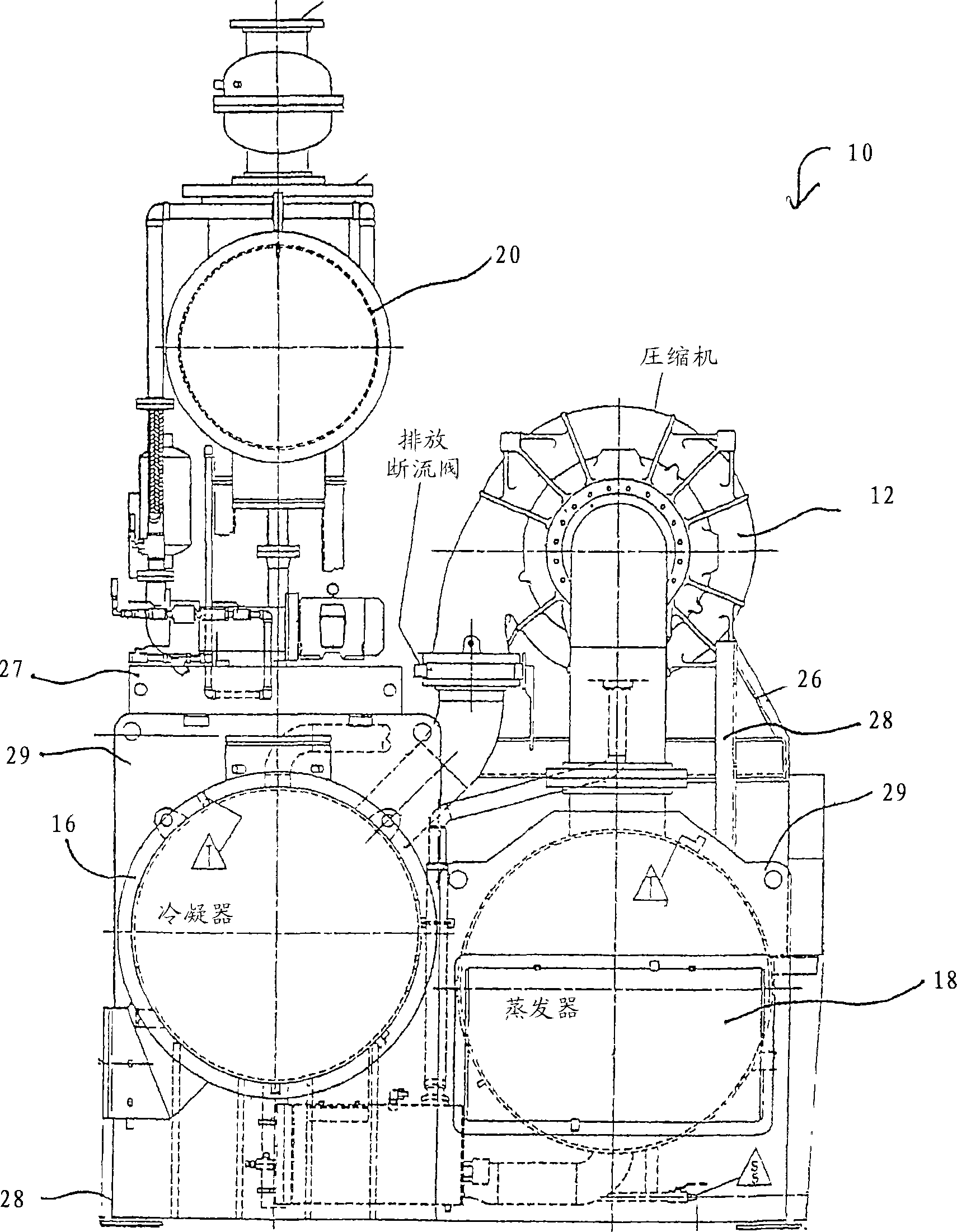

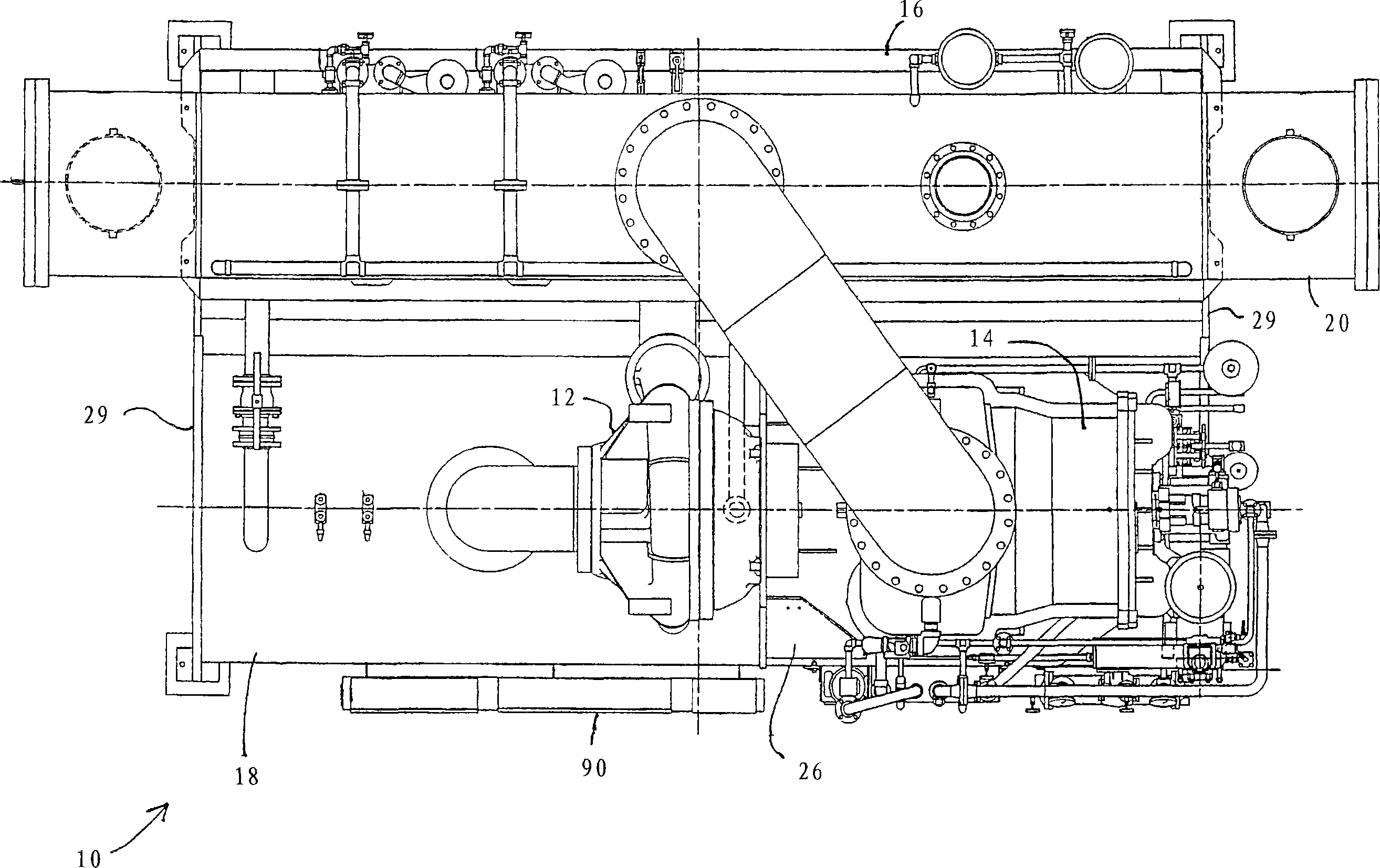

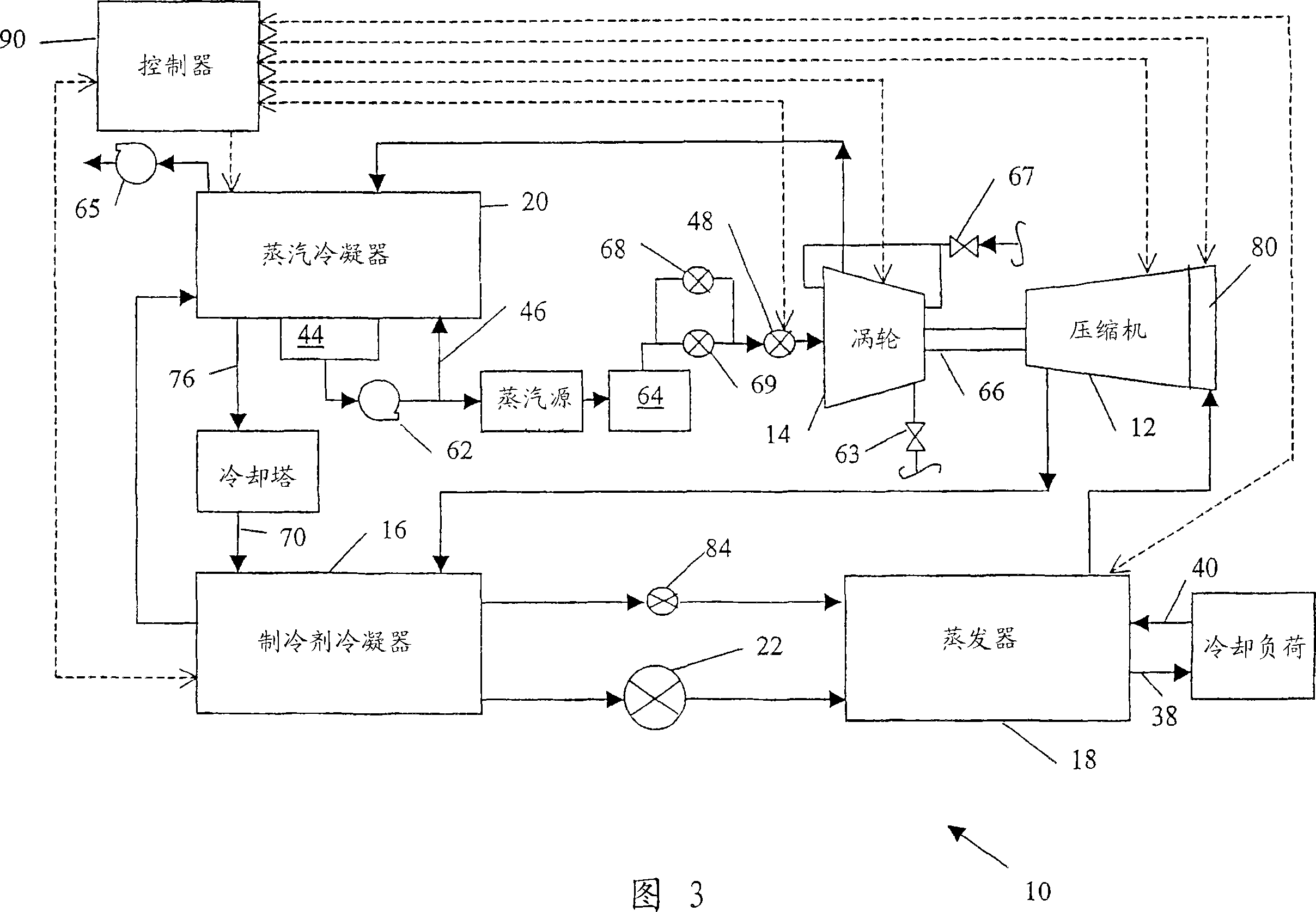

[0024] exist figure 1 In -3, a general system to which the present invention is applicable is shown by way of example. As shown, an HVAC, refrigeration, or chiller system 10 includes a compressor 12, a steam turbine 14, a refrigerant condenser 16, a water cooler or evaporator 18, a steam condenser 20, an expansion device 22, and a control panel or controller 90. The operation of the control panel 90 will be discussed in more detail below. Chiller system 10 further includes a compressor lubrication system (not shown) and a turbine lubrication system (not shown). A conventional liquid cooler system 10 consists of many in figure 1 - other features not shown in 3. These features have been specifically omitted for simplicity and ease of illustration.

[0025] In a preferred embodiment, the "structural frame" stacks or vertically arranges the major components of the chiller system 10 to provide a prepackaged unit that occupies less space in a smaller footprint than a field-fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com