Branch pipe coupling and air conditioner provided with the same

A technology of pipe joints and branches, which is applied in the field of air-conditioning devices, can solve the problems of shortening the size of the branch and easy to generate bias flow, etc., and achieve the effect of reducing the size and ensuring the working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

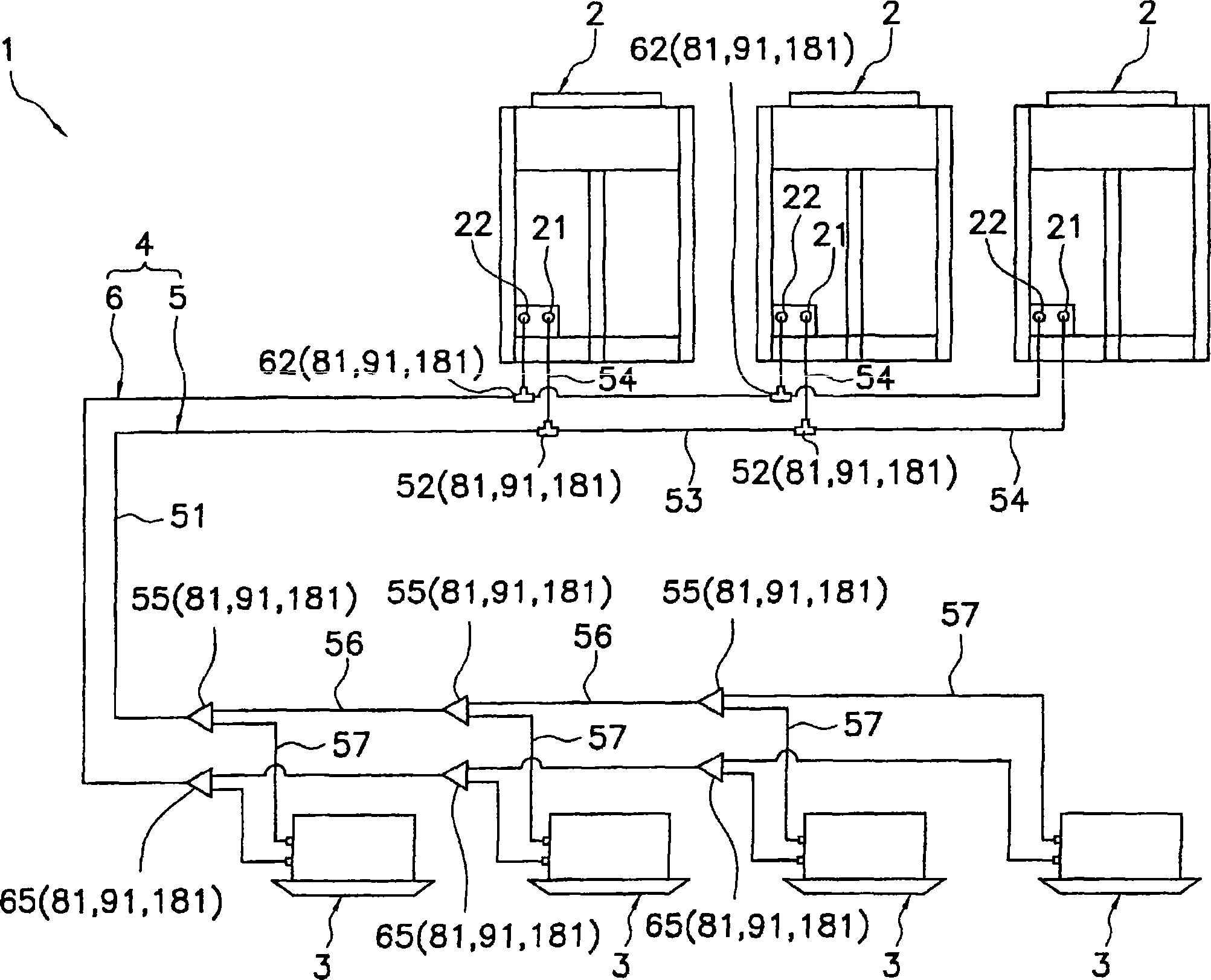

[0052] Hereinafter, a pipe joint for branching and an air conditioner having the pipe joint for branching according to an embodiment of the present invention will be described with reference to the drawings.

[0053] (1) Structure of pipe joint for branch

[0054] Figure 4 It is a figure explaining the structure of the branch pipe joint 181 in one Example of this invention.

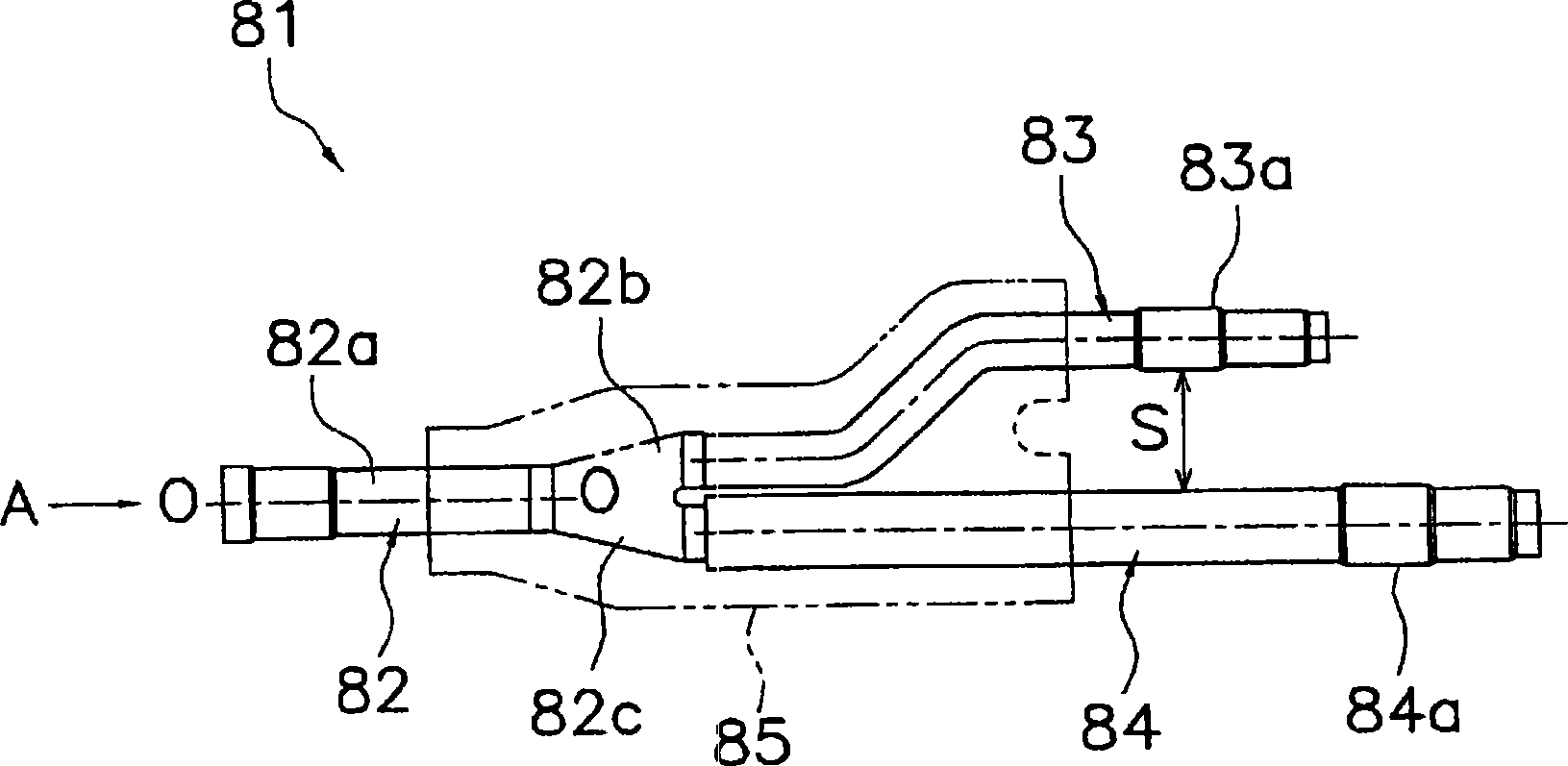

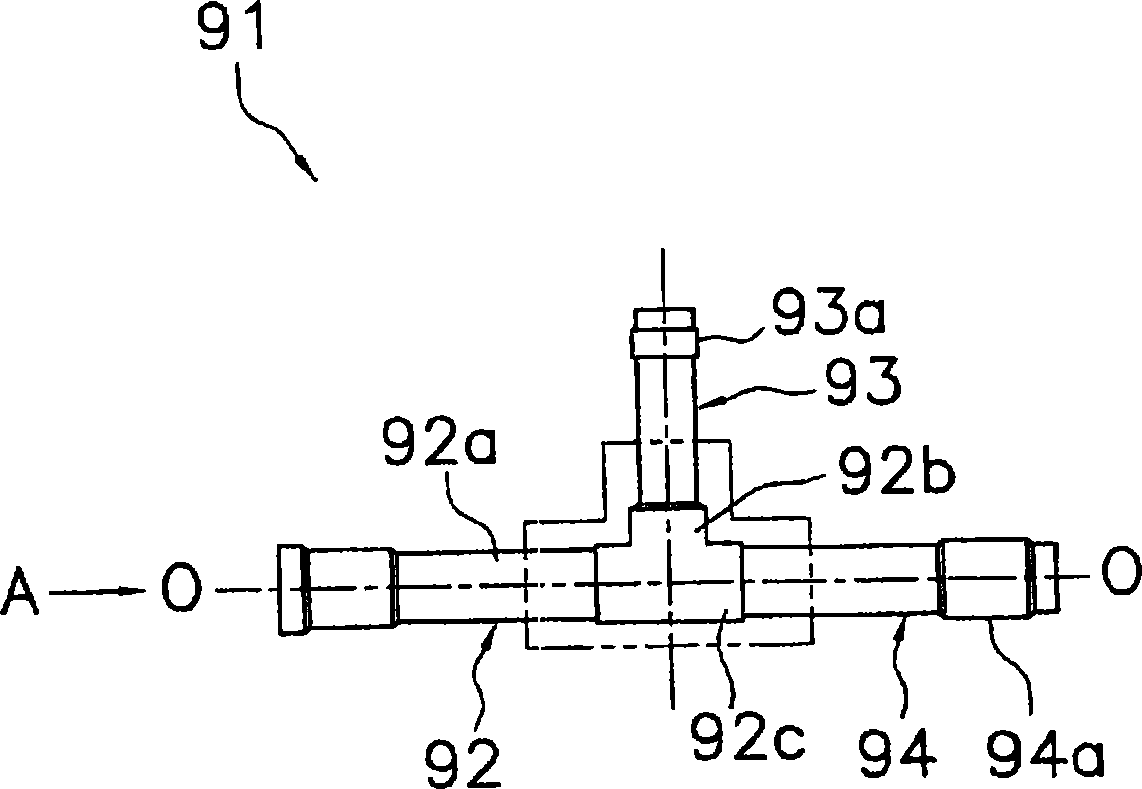

[0055] The branching pipe joint 181 has a substantially Y-shaped branching portion 182 , a first branching nozzle portion 183 , a second branching nozzle portion 184 , and a first divided pipe 186 .

[0056] The branch portion 182 has the branch portion 82 with the existing Y-shaped branch pipe 81 (refer to figure 2 ) the same shape, with: inlet pipe portion 182a, the first outlet pipe portion 182b and the second outlet pipe portion 182c, the inlet pipe portion 182a from the main pipe (for example figure 1 The shown merging connection pipe 51 and the branch connection pipe 53) flow in the refrigerant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com