Continuous press

A technology of pressing machine and extruding plate, applied in the direction of pressing machine, conveyor, manufacturing tool, etc., it can solve the problems such as the rise of the roller and the interference that is not completely eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

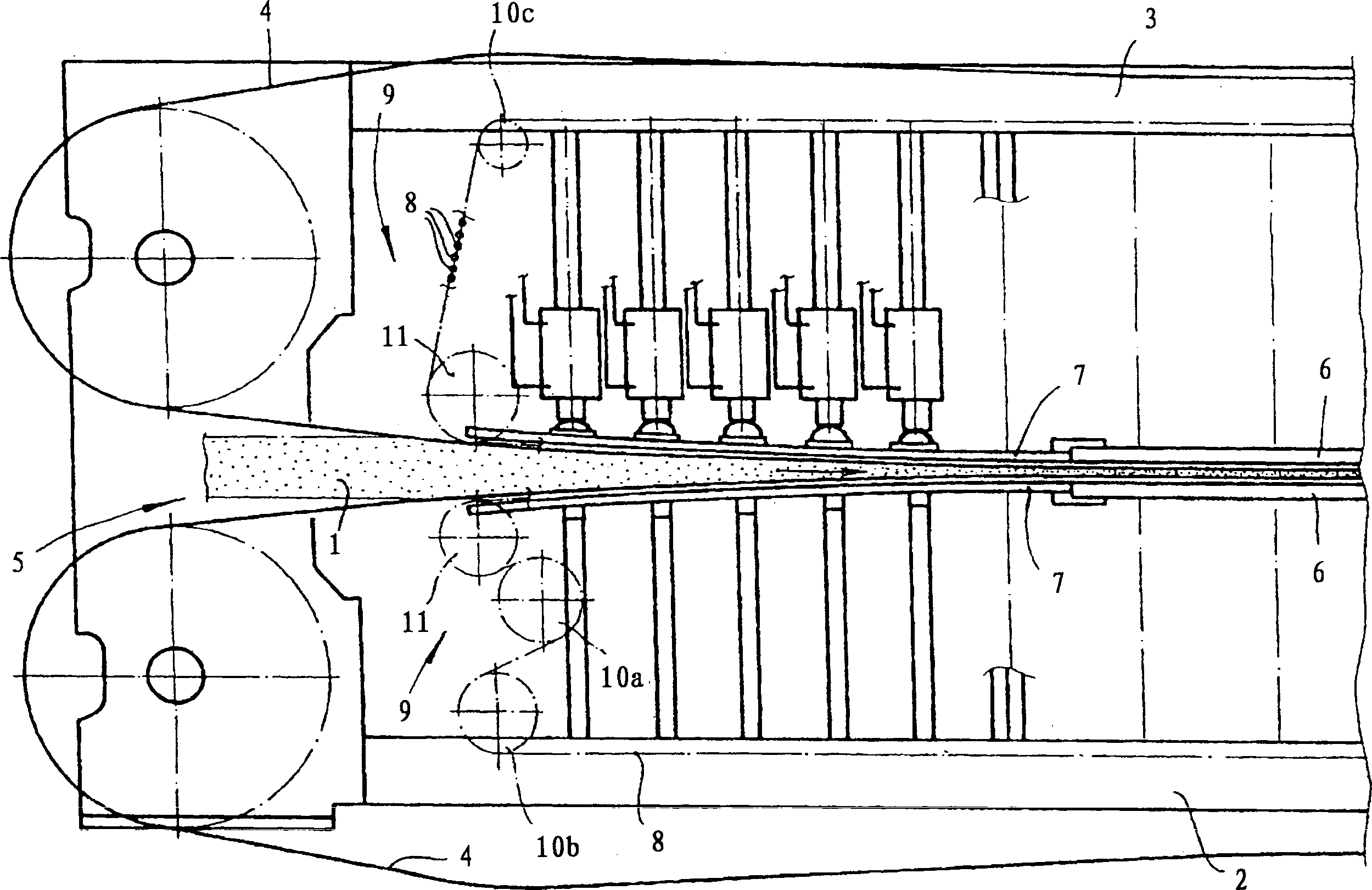

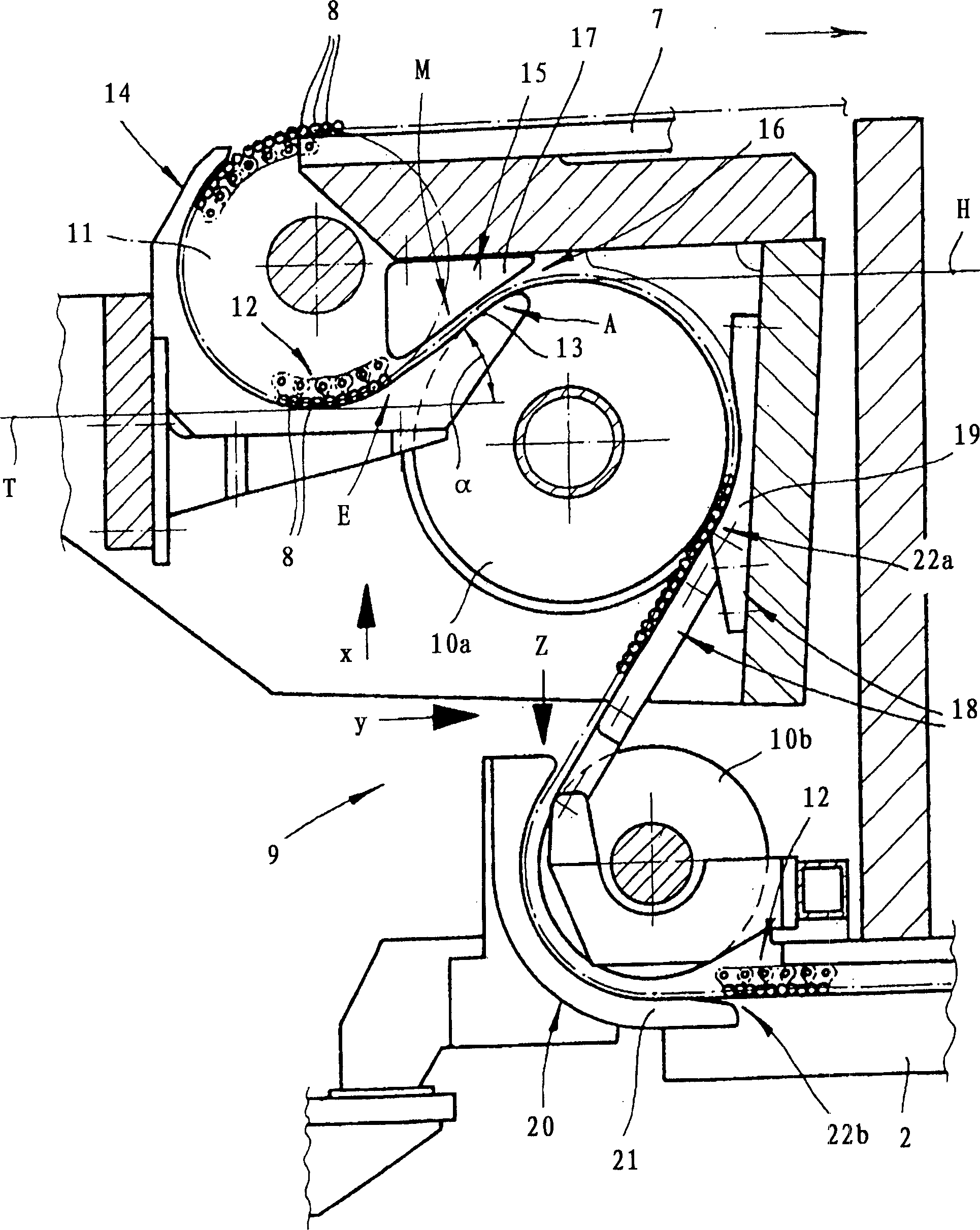

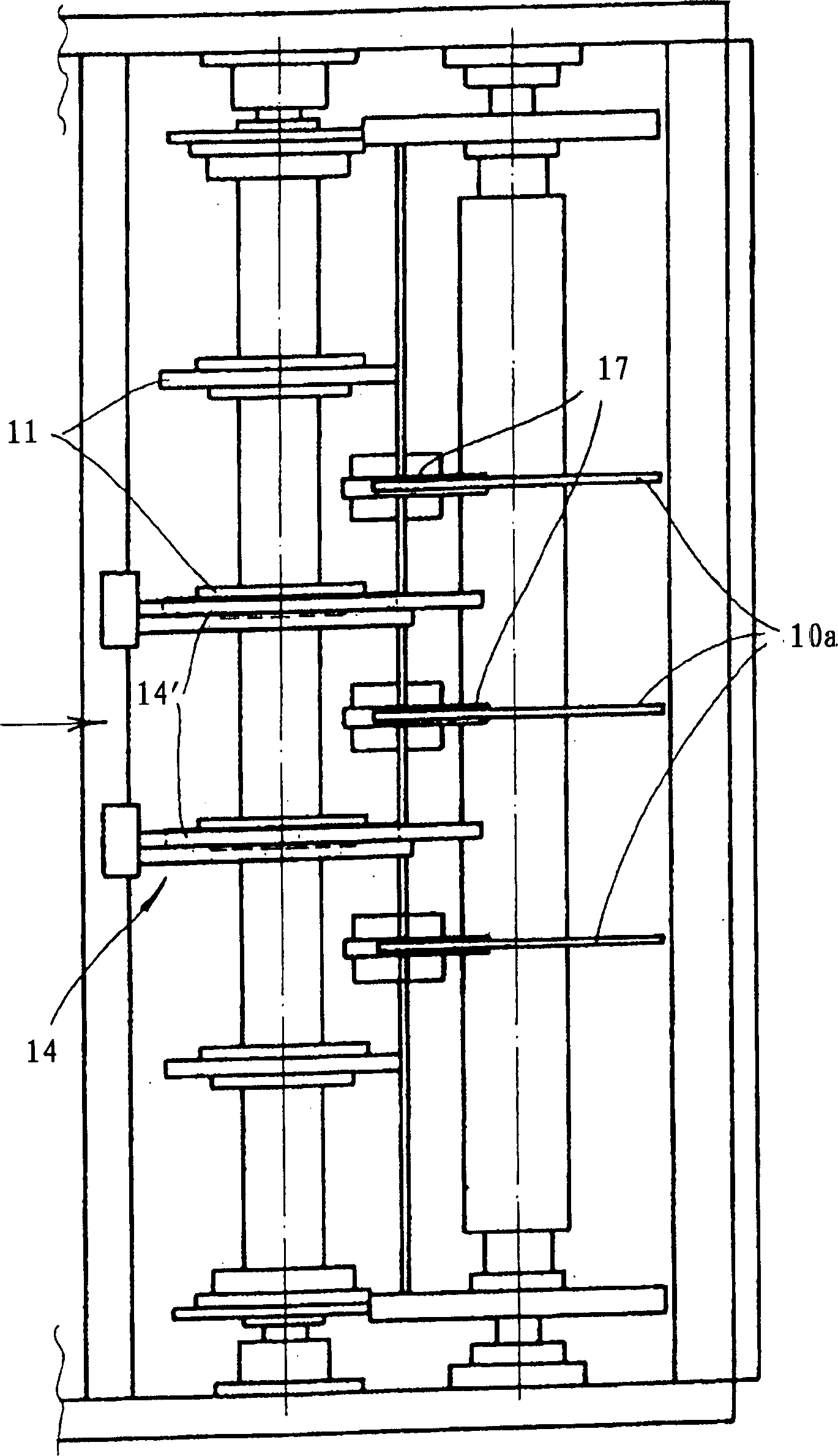

[0025] In the drawing there is shown a continuous press for pressing mats 1 of extruded material into extruded material boards during the manufacture of particleboard, fibreboard or similar wood-based material boards, which press has in its basic structure: Press lower part 2 ; press upper part 3 ; some extruded steel strips 4 circulating endlessly in press upper part 2 and press lower part 3 ; and feed opening 5 . Arranged in the press lower part 2 and in the press upper part 3 is a heatable press plate 6 to which a heatable feed plate 7 protruding on the feed side is connected and at the same time forms the feed opening . It can be seen that in this embodiment there are separate feed plates 7 which can be formed with a high degree of bending elasticity and some special cylinder-piston arrangements are attached to the feed plates 7, An optimal feed profile can thus be adjusted. However, the invention also includes embodiments in which the feed opening is formed by an extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com