Motionless lens systems and methods

A lens, lens technology, applied in the parts, lenses, instruments, etc. of TV systems, can solve the problem of moving one or more lens parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

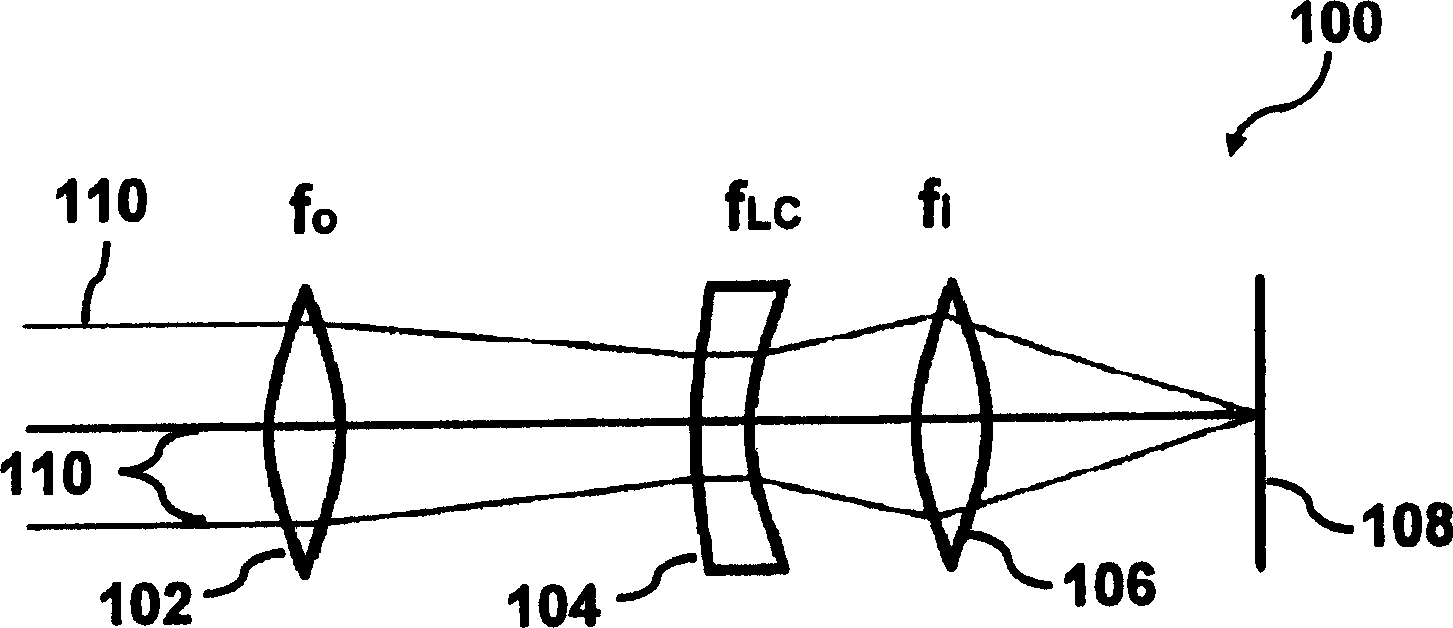

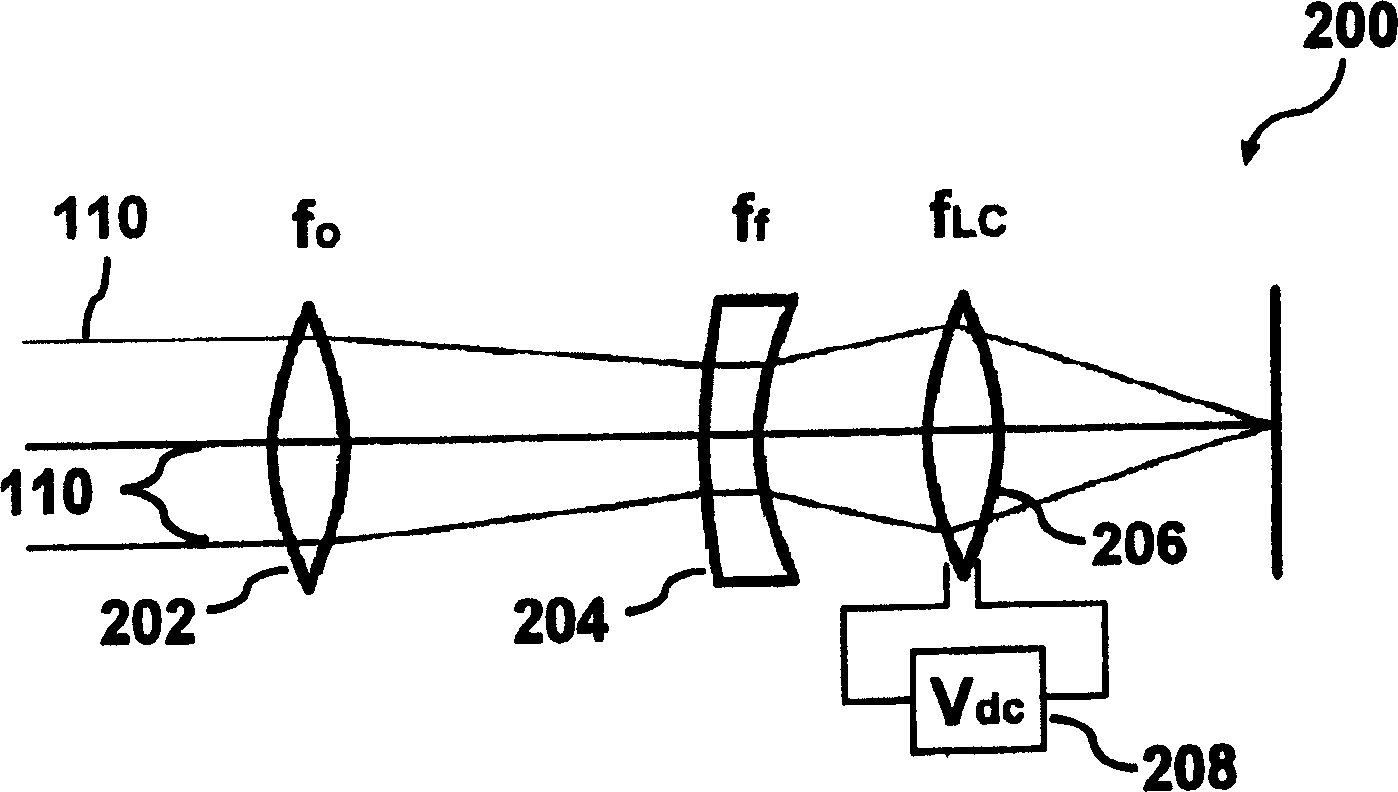

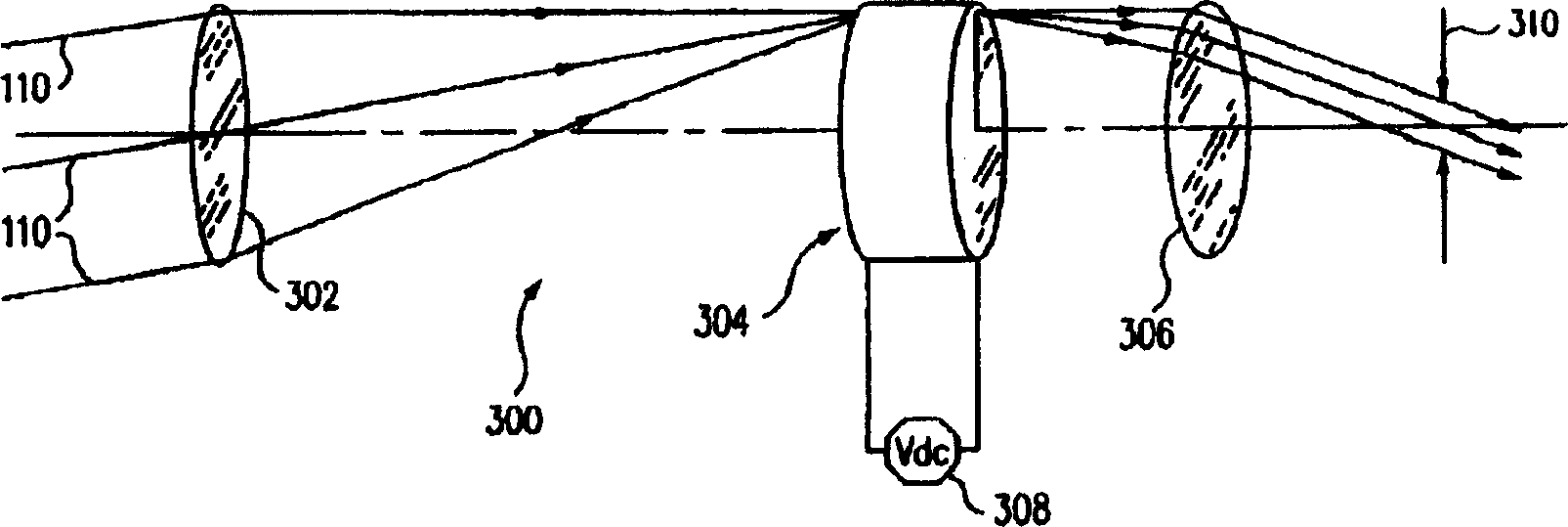

[0031] figure 1 A lens 100 according to an embodiment of the present invention is shown. The lens 100 includes an objective lens 102 , an adjustable field lens 104 , and an imaging lens 106 . Objective lens 102 (with f o Indicated) and imaging lens 106 (with f i denoted) may be a conventional objective lens and a conventional image lens (also referred to as an imaging lens or an eyepiece), respectively, which may be made of glass, plastic, or other known conventional lens materials.

[0032] The imaging lens 106 can be positioned away from, adjacent to, or shaped as an adjustable field lens 104 (with f LC Indicates part of). As will be described in further detail herein, the tunable field lens 104 is a lens whose refractive index is varied, for example, by applying a voltage to the tunable field lens 104 . By changing the refractive index of the tunable field lens 104, the focal length or focal point of the lens 100 can be changed.

[0033] As an example, such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com