Surface light source device

A surface light source, light source technology, applied in the direction of light source, point light source, slender light source, etc., can solve the problems of large light leakage, poor image aesthetics, reduced picture brightness, etc., to achieve high front brightness, improved contrast, Good directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

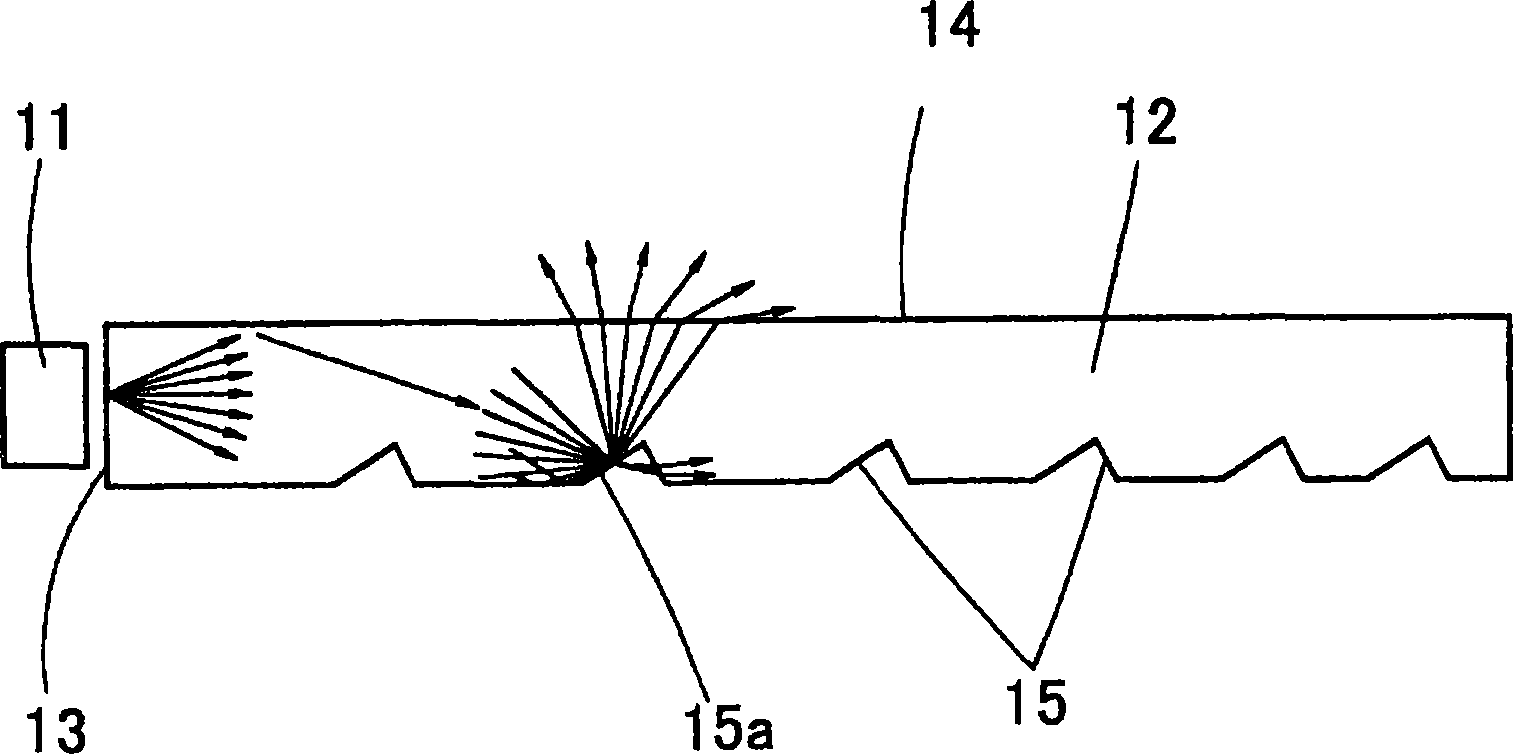

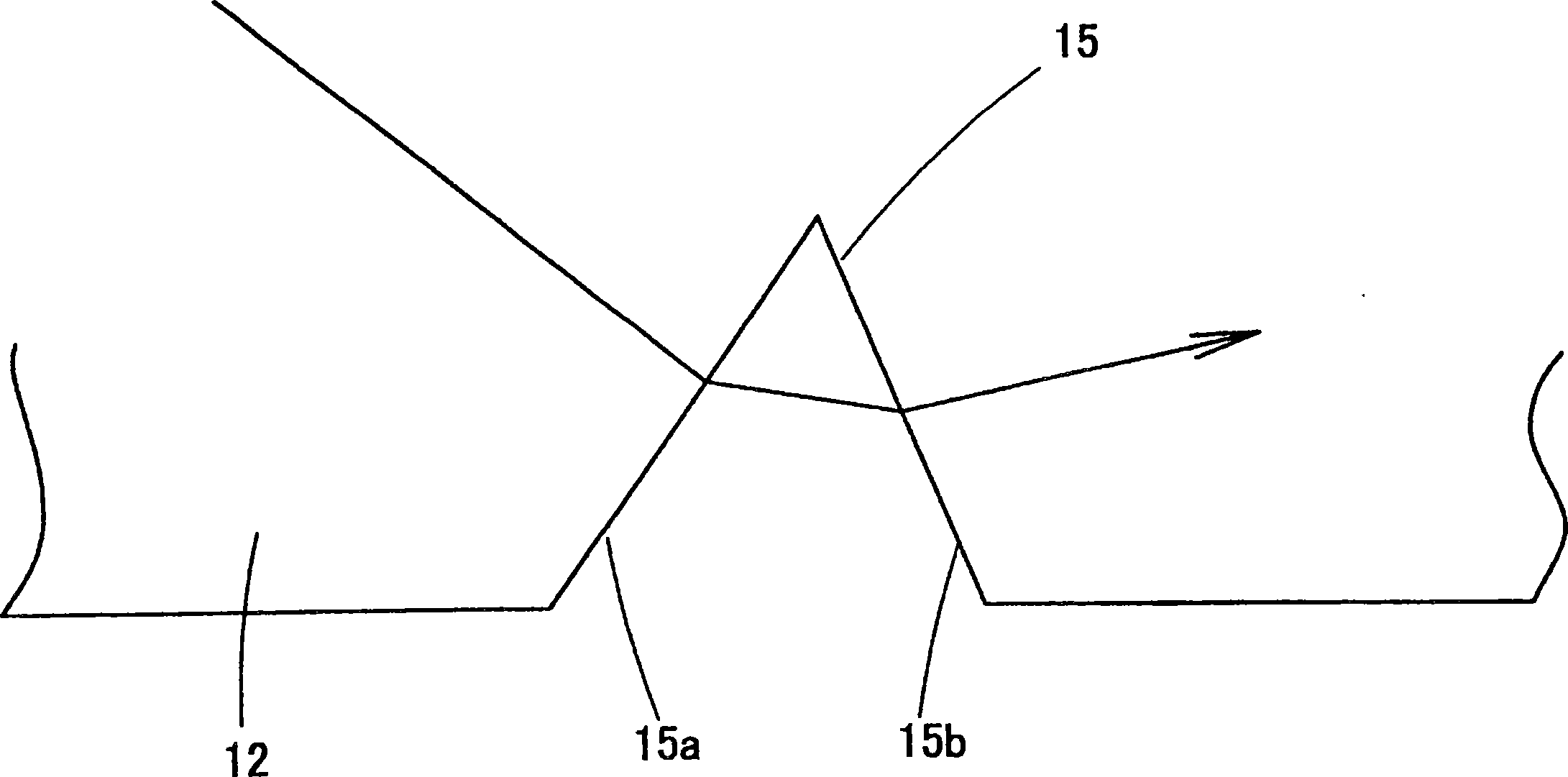

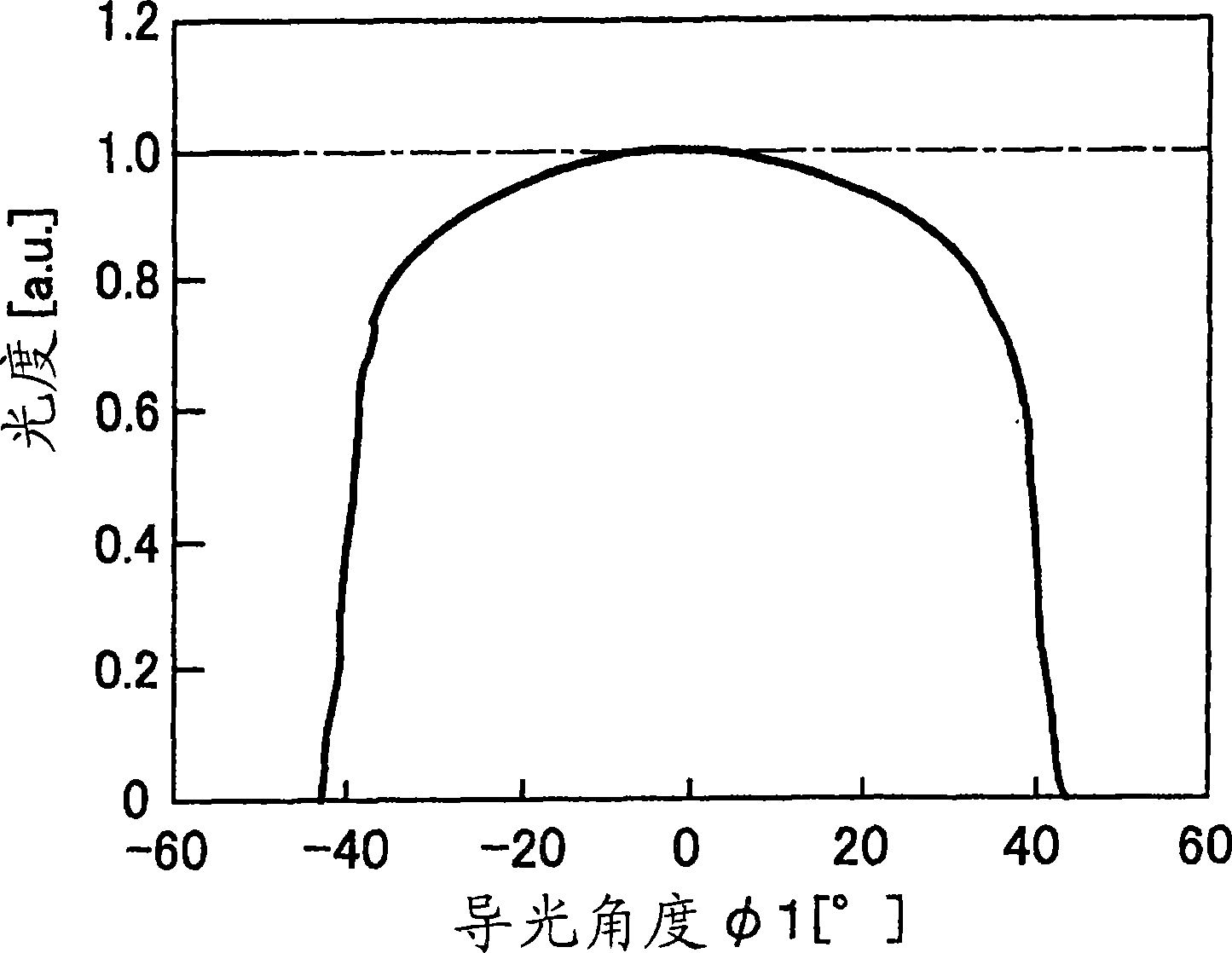

[0108] Figure 13 It is a perspective view showing a surface light source device according to an embodiment of the present invention. Figure 14 It is a schematic cross-sectional view of the surface light source device and a diagram showing the behavior of light in the light guide plate. Figure 15It is an enlarged cross-sectional view of the light guide plate showing the vicinity of the deflection pattern. This surface light source device is composed of a light source 21 and a light guide plate 22 . The light source 21 extends along the longitudinal direction of one side surface (light incident surface 23 ) of the light guide plate 22 to form a so-called linear light source. As such light source 21 , a cold cathode tube may be used, a linear light source may be formed by expanding the light representation of light emitting diodes (LEDs), or a linear light source may be formed by arranging a plurality of LEDs in a line. The light guide plate 22 is formed in a plate shape fr...

Embodiment 2

[0129] Figure 21 It is a perspective view showing a surface light source device according to another embodiment of the present invention. and, Figure 22 is a schematic cross-sectional view of the surface light source device. In this embodiment, between the light reflection portion 25 a and the flat portion 28 of the deflection pattern 25 , the directivity conversion portion 30 is constituted by an inclined surface (first inclined surface). Figure 23 It is an enlarged cross-sectional view showing the shape of the deflection pattern 25 and the directivity conversion part 30 . In this embodiment, the light reflection part 25a (second inclined surface) is also slightly extended to the lower surface side, and the directivity conversion part 30 is formed by providing an inclined surface between the flat part 28 and the extended light reflection part 25a. The inclined surface is formed so that it protrudes further to the lower surface side than the extension of the flat portion...

Embodiment 3

[0148] Figure 34 It is a cross-sectional view showing part of a surface light source device according to still another embodiment of the present invention. In this embodiment, the front end of the re-incident surface 25b protrudes outward from the extension of the flat portion 28, and a re-reflective surface 33 (fourth inclined surface) is formed on the side of the re-incident surface 25b away from the light source. The reflective surface 33 is for reflecting the light re-entered from the re-incident surface 25b toward the light-emitting portion 24 . Furthermore, the flat portion 28 is formed into a flat surface without any level difference by the rereflection surface 33 .

[0149] However, if Figure 34 As shown, according to this embodiment, the light leaked from the light reflection part 25a can be efficiently captured by the re-incident surface 25b, and then re-entered into the light guide plate 22, which can improve the utilization efficiency of light and reduce disturbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com