Inverted type compression molding machine for rubber shoes

An inverted, forming machine technology, applied to household components, household appliances, other household appliances, etc., to achieve the effect of wide application range, firm adhesion, and large pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

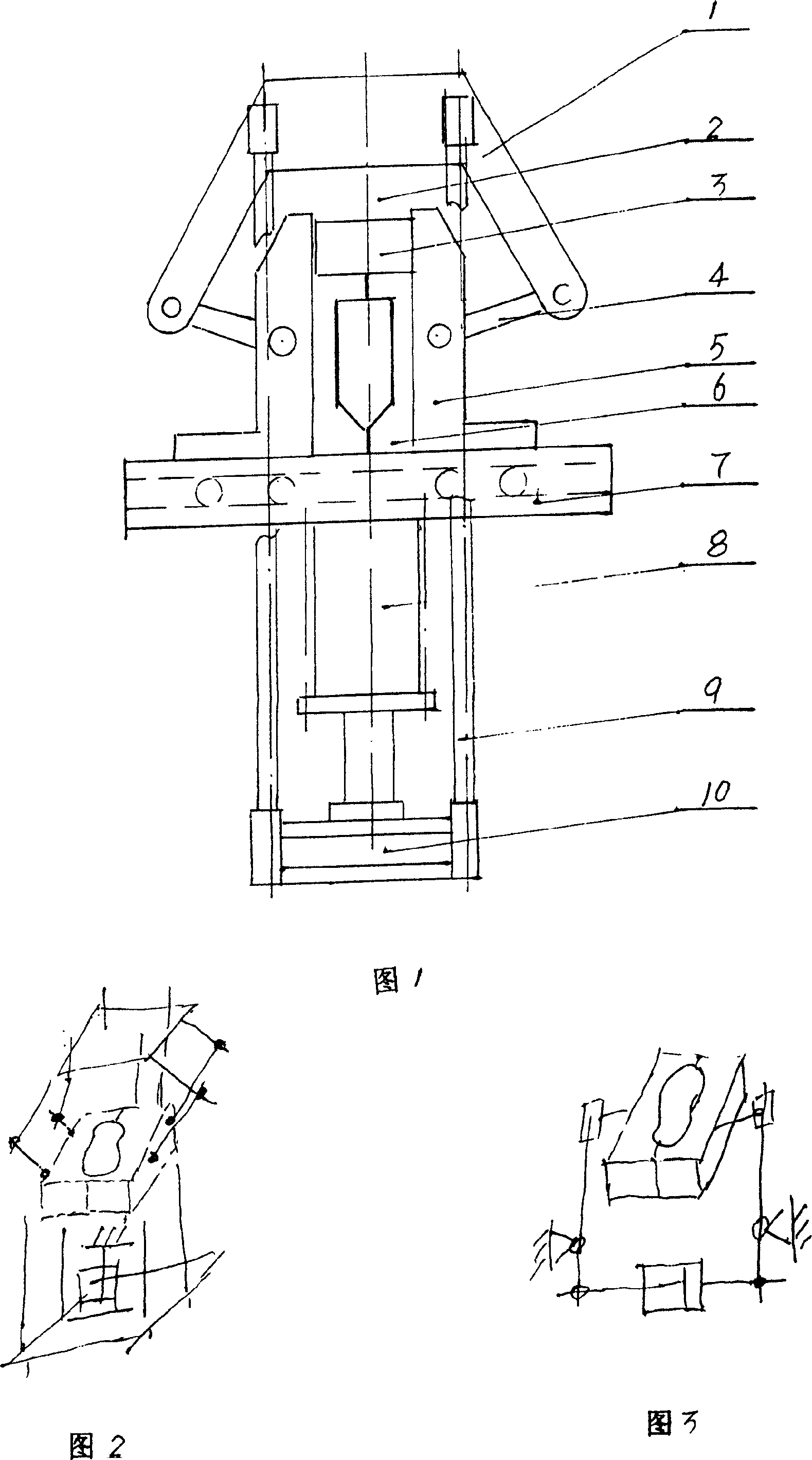

[0011] The present invention is mainly installed on the top of the machine by the item beam 1, connected with the bottom template 2, the shoe mold 3 is fixed at the lower end of the bottom template 2, the two sides of the top beam 1 are connected with the connecting rod 4, and the connecting rod 4 is fixed on the left and right moving plates 5, The left and right moving plate 5 is connected with the mold support 6 and the slideway 7, the lower end of the slideway 7 is fixed with the oil cylinder 8, the lower end of the oil cylinder 8 is connected with the base plate 10, and there are four columns 9 on the base plate 10. When working, the lower port of the oil cylinder 8 enters the oil, and the four columns go up , the heating mechanism works, the shoe mold is preheated, the work shoes are placed, vulcanized material is added, the temperature reaches the working requirements, the oil cylinder goes down, and the four columns are moved down, and the four columns are connected with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap