Gas generator

A generator and gas technology, applied in the manufacture of combustible gas, petroleum industry, combined combustion mitigation, etc., can solve the problems of increasing the cost of gas production, gas escape, distribution, etc., so as to improve the efficiency and effect of gas production and improve production. Speed, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

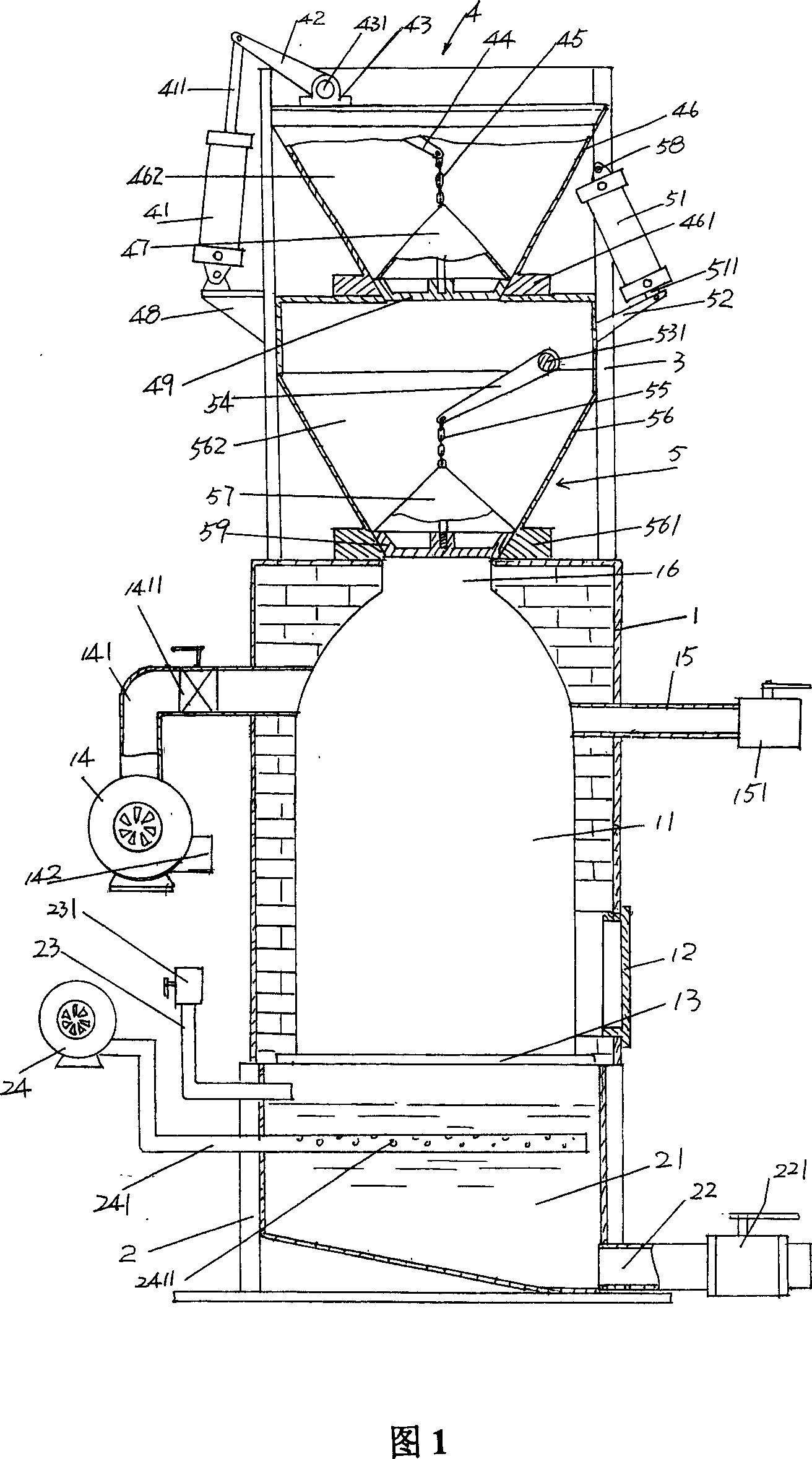

[0021] Referring to FIG. 1 , refractory bricks or other similar materials can be used as a heat insulation layer between the furnace 11 and the furnace body 1 . The upper portion of the furnace body 1 is respectively connected with a gas outlet pipe 15 and a smoke exhauster 14 communicated with the furnace 11 , and a control valve is arranged on the pipeline of the gas outlet pipe 15 . The water gas generated in the furnace 11 is led to corresponding devices by the gas outlet pipe 15 for use, for example, to the ovens of production devices such as the aforementioned spray-bonded cotton, hard cotton, non-glued cotton, and tenter setting machines. Combustion for heating. And the smoke exhaust machine 14 is only used when igniting the coal seam on the grate 13, because it needs to be ignited by means of materials such as firewood that are heterogeneous with coal when igniting the initial stage, so smoke can be produced, by opening the smoke exhaust pipe The valve 1411 is led out...

Embodiment 2

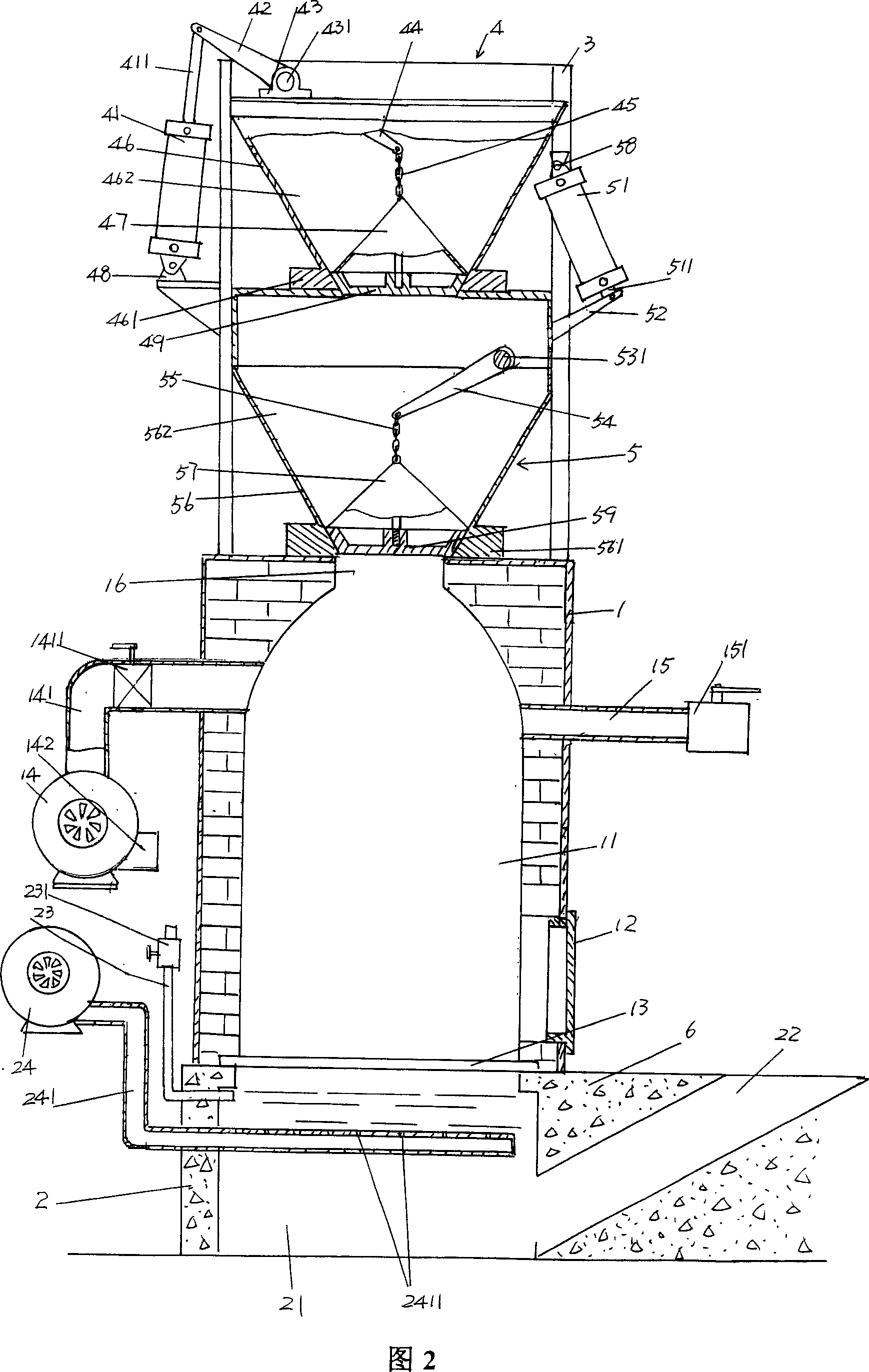

[0024] Please refer to Fig. 2, the sealing body 2 provided in this embodiment is a structural form cast by concrete 6, and the ash discharge port 22 is arranged obliquely, and the ash discharge port 22 can reflect the function of ash discharge while the furnace 11 is working. The effect, therefore, is superior to that shown by the ash outlet 22 in FIG. 1 . All the other are the same as the description of embodiment 1.

Embodiment 3

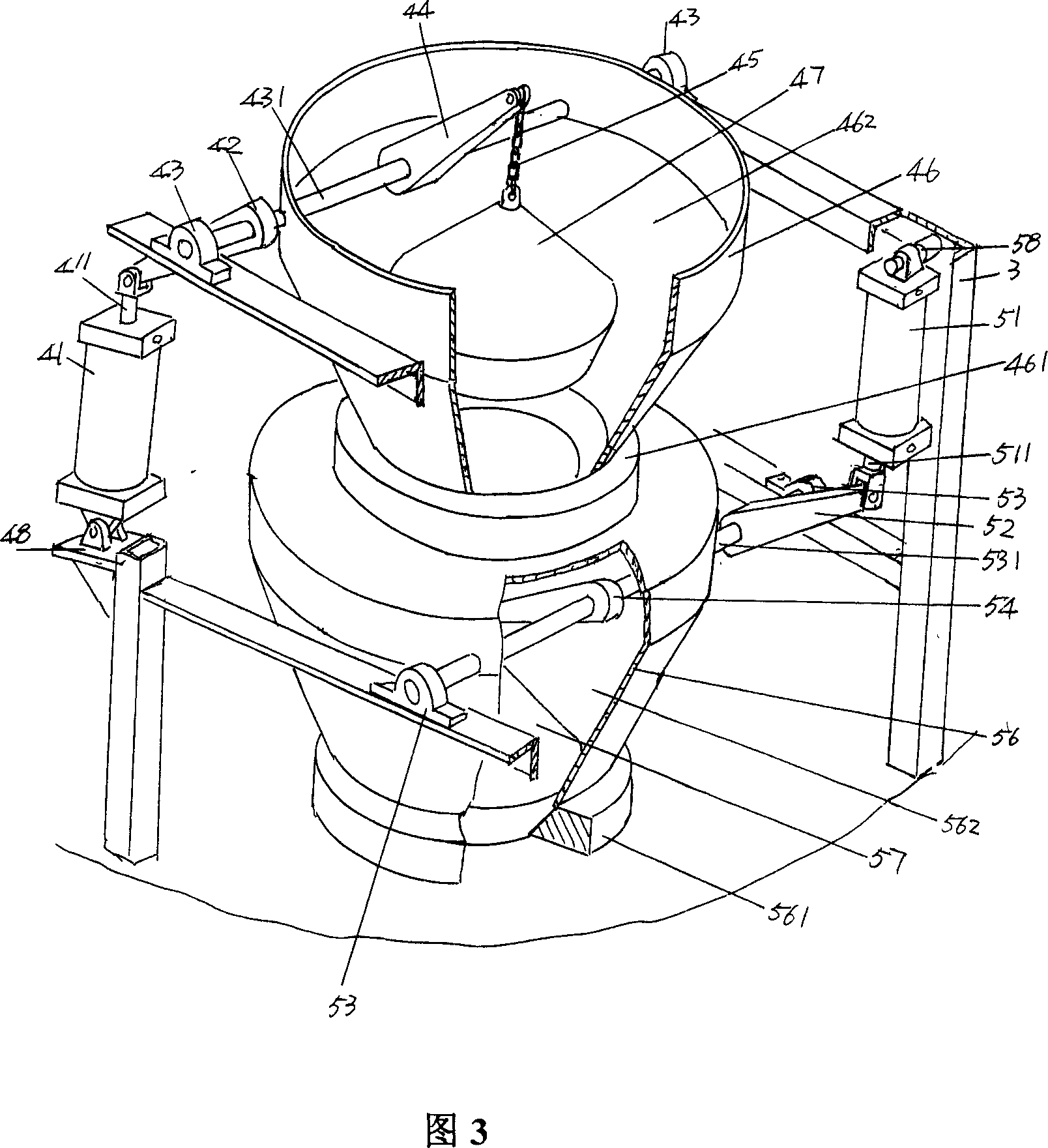

[0026] Please refer to Fig. 3 and in conjunction with Fig. 1, as the first bucket body 56 of the lower coal guiding mechanism 5 of the present invention, it is sealed and fixed on the top of the furnace body 1 through the lower cover plate 561 extending at the bottom of the coal drawing mechanism 5 of the present invention. Cavity 562 communicates with the coal inlet 16 on furnace 11 top or is closed by first cone block cover 57 to take on. The bottom of the first cone retaining cover 57 is fixedly connected with the lower cover 59 by bolts, and the lower cover 59 is formed with a conical surface, which just matches with the inner conical surface of the upper cover plate 561, so as to reflect the impact of coal-feeding. Excellent sealing effect of port 16.

[0027]Seen from Fig. 3, the first cylinder 51 is arranged on the grate 3 by the first cylinder block 58, the cylinder column 511 of the first cylinder block 58 is hinged with one end of the crank arm 52 of the first cylind...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap