decorative material

A technology for decorative materials and decorative layers, applied in the field of decorative materials, can solve problems such as inability to use stably, poor water resistance, and warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

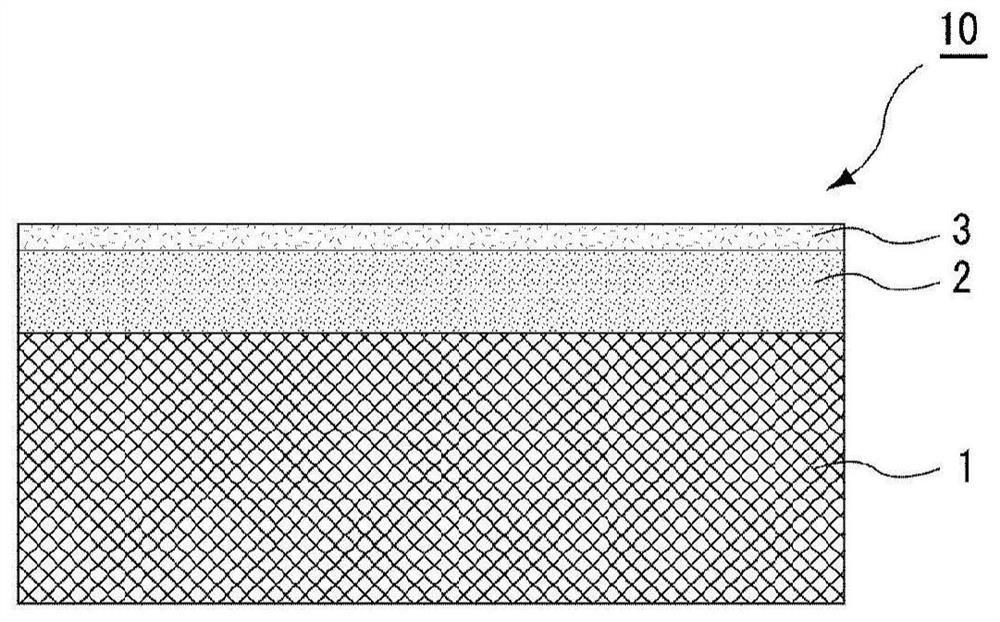

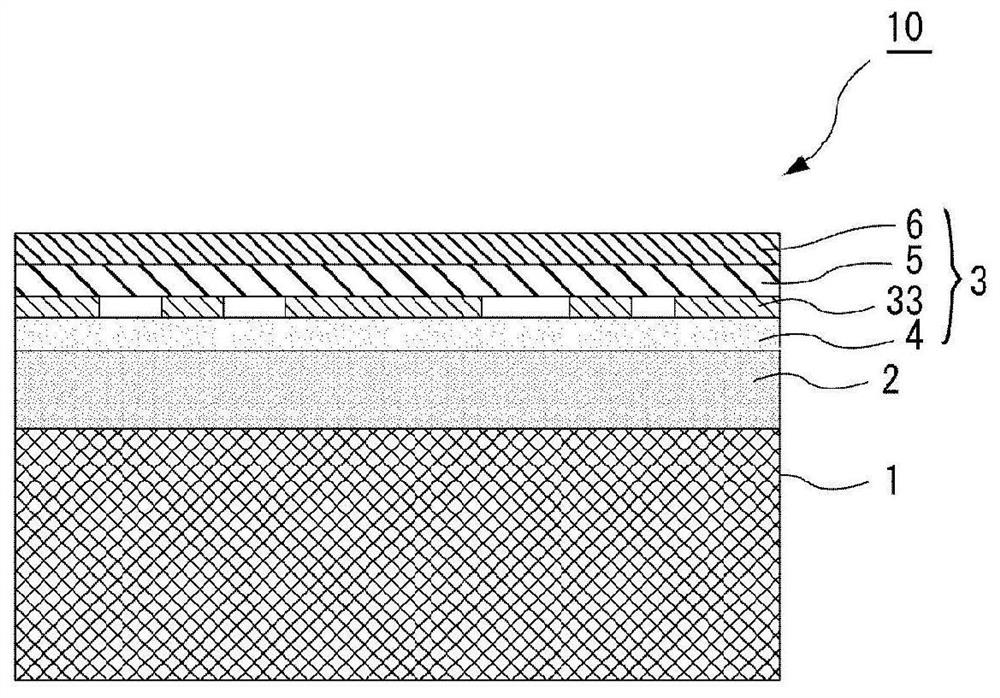

Image

Examples

Embodiment 1

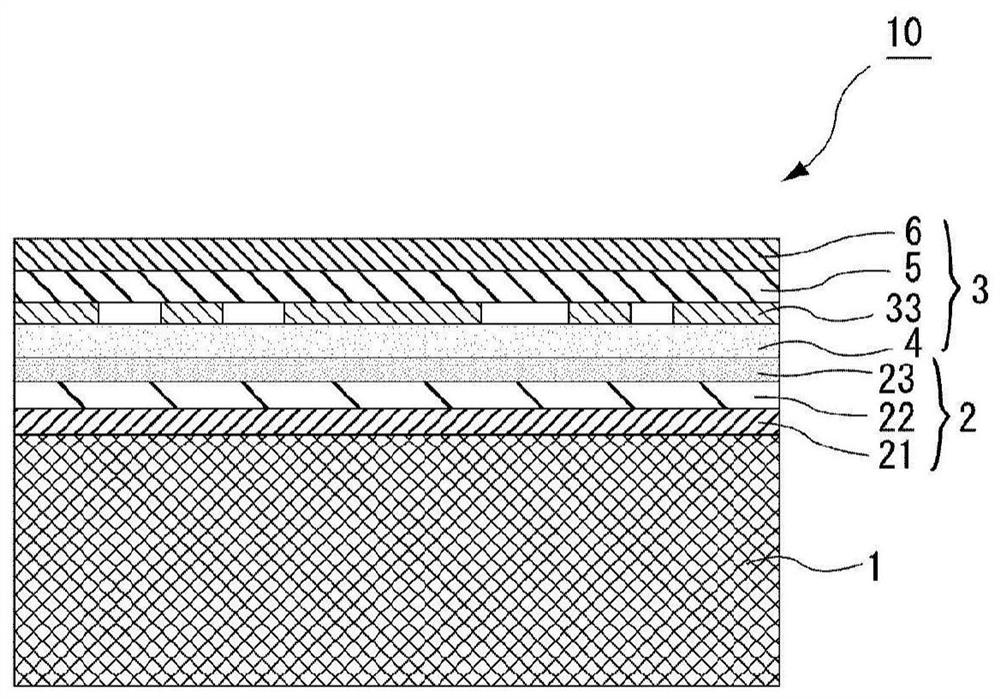

[0260] Using an ink composition (acrylic urethane system), a pattern layer of a stone pattern with a thickness of 2 μm was formed on a colored polypropylene resin film (thickness: 60 μm, color: white system) by gravure printing.

[0261] Next, an adhesive layer with a thickness of 2 μm was formed using a urethane-based adhesive for dry lamination, and a transparent polypropylene resin film (thickness: 80 μm) was provided on the pattern layer by dry lamination.

[0262] On this transparent polypropylene resin film, an undercoat layer having a thickness of 1 μm was formed using a two-component curing type urethane resin. Then, on this primer layer, by gravure printing with coating amount 15g / m 2 Apply an electron beam-curable resin composition (acrylate-based) to form a coating film, irradiate electron beams to crosslink and cure the coating film, form a surface protection layer (thickness: 15 μm), and produce a decorative sheet (thickness: 160 μm), as a decorative layer.

[0...

Embodiment 2~6、 comparative example 1~4

[0268] A decorative material was produced in the same manner as in Example 1 except that the foamed resin layer and the non-foamed resin layer shown in Table 1 were replaced.

[0269] Table 1 shows the results of evaluation of the obtained decorative material.

[0270]

[0271]

[0272] In addition, in Table 1, the place described as "not evaluated" means that the sample did not maintain the shape in the adhesion evaluation of the upper layer, and therefore evaluation was not possible.

[0273] As shown in Table 1, the decorative materials of the examples all had a good adhesion state at the bent portion, and were also excellent in the adhesion evaluation of the bent portion.

[0274] On the other hand, since the decorative material of Comparative Example 1 used a solvent-based rubber adhesive as the first adhesive and the second adhesive, the foamed resin layer was dissolved. The decorative material of Comparative Example 2 uses alcohol-based rubber adhesives as the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com