Combined driving cross seedling set

A unit and motor gear technology is applied in the field of agricultural machinery equipment for seedling transplanting, which can solve the problems such as failure to realize flow operation and mass production, poor seedling transplanting effect, and influence on the growth of crops, so as to achieve an orderly labor order and save the thinning of seedlings. process, the effect of improving land utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

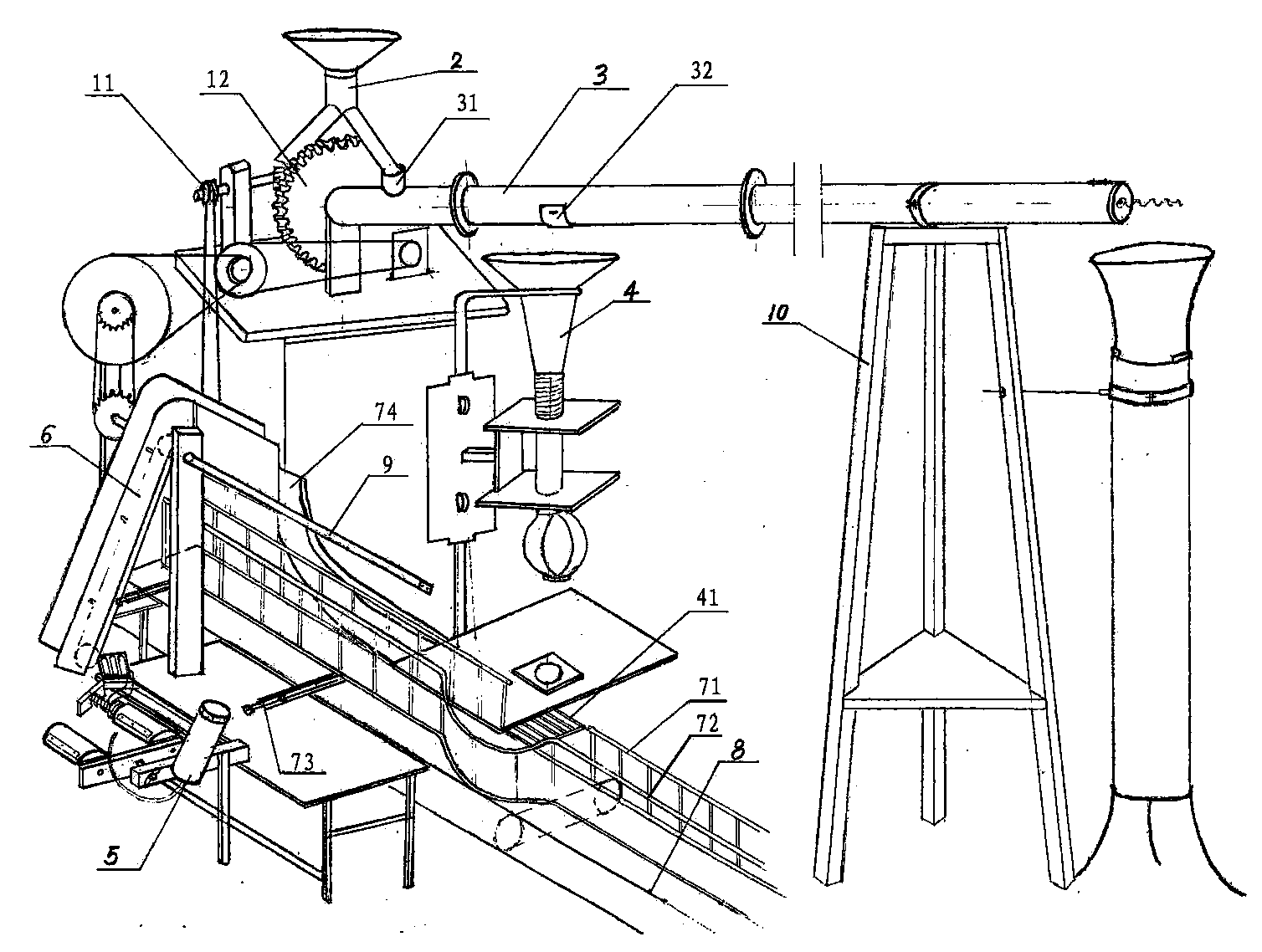

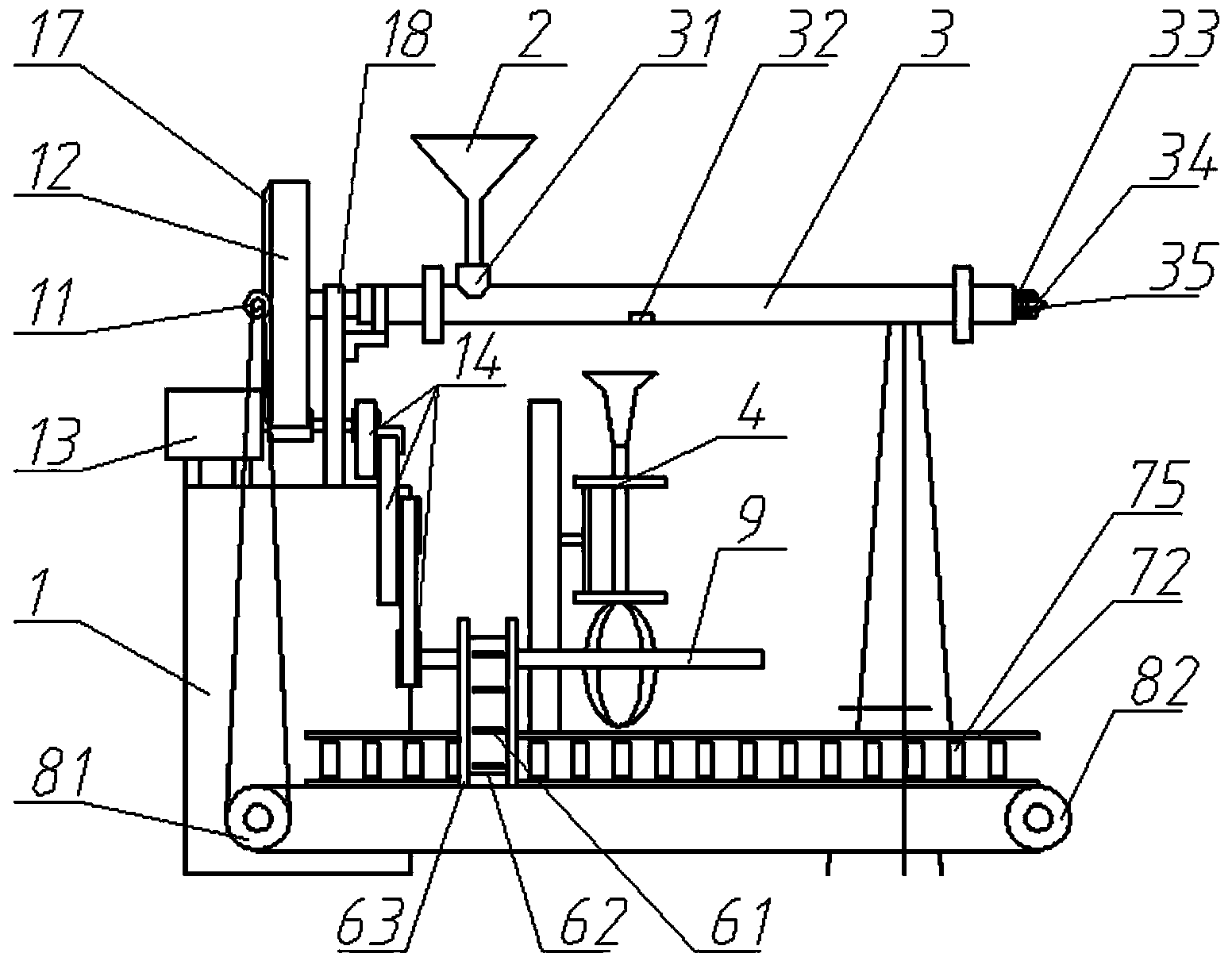

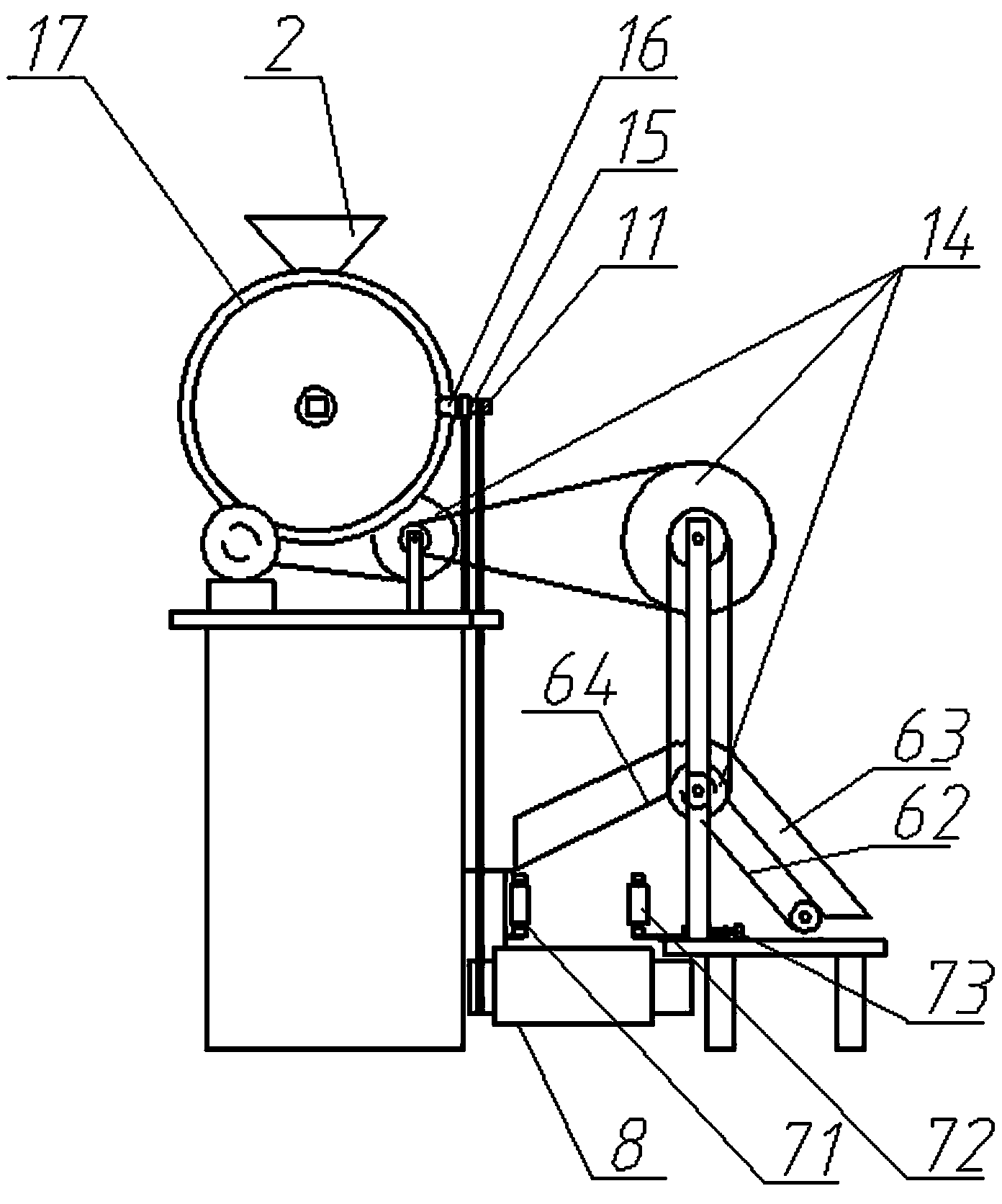

[0015]The combined drive and intertwined seedling raising unit includes a set of power device and several groups of seedling raising units connected in series. The power device and the first-stage seedling raising unit specifically include a main box 1, and a motor 13 is fixed on the main box 1. 13 shafts are fixed with motor gears and motor pulleys, the main box body 1 is provided with a feed pipe 3 supported by a support plate 18 and positioned axially, and a feed pipe bracket 10 is supported under the other end of the feed pipe 3 for supplying There is a feed inlet 31 above the feed pipe 3, a feed hopper 2 is arranged above the feed inlet 31, a feed outlet 32 is provided below the feed pipe 3, flanges are provided at both ends of the feed pipe 3, and inside the feed pipe 3 There is a main shaft 34 supported on the support plate 18, a screw conveying auger 33 is fixed on the main shaft 34, a feeding gear 12 meshing with the motor gear is fixed at the left end of the main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com