Upper air intake type deep internal rotation type burner

A burner and air-type technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of low combustion efficiency and easy generation of exhaust gas, etc., and achieve the effect of less exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

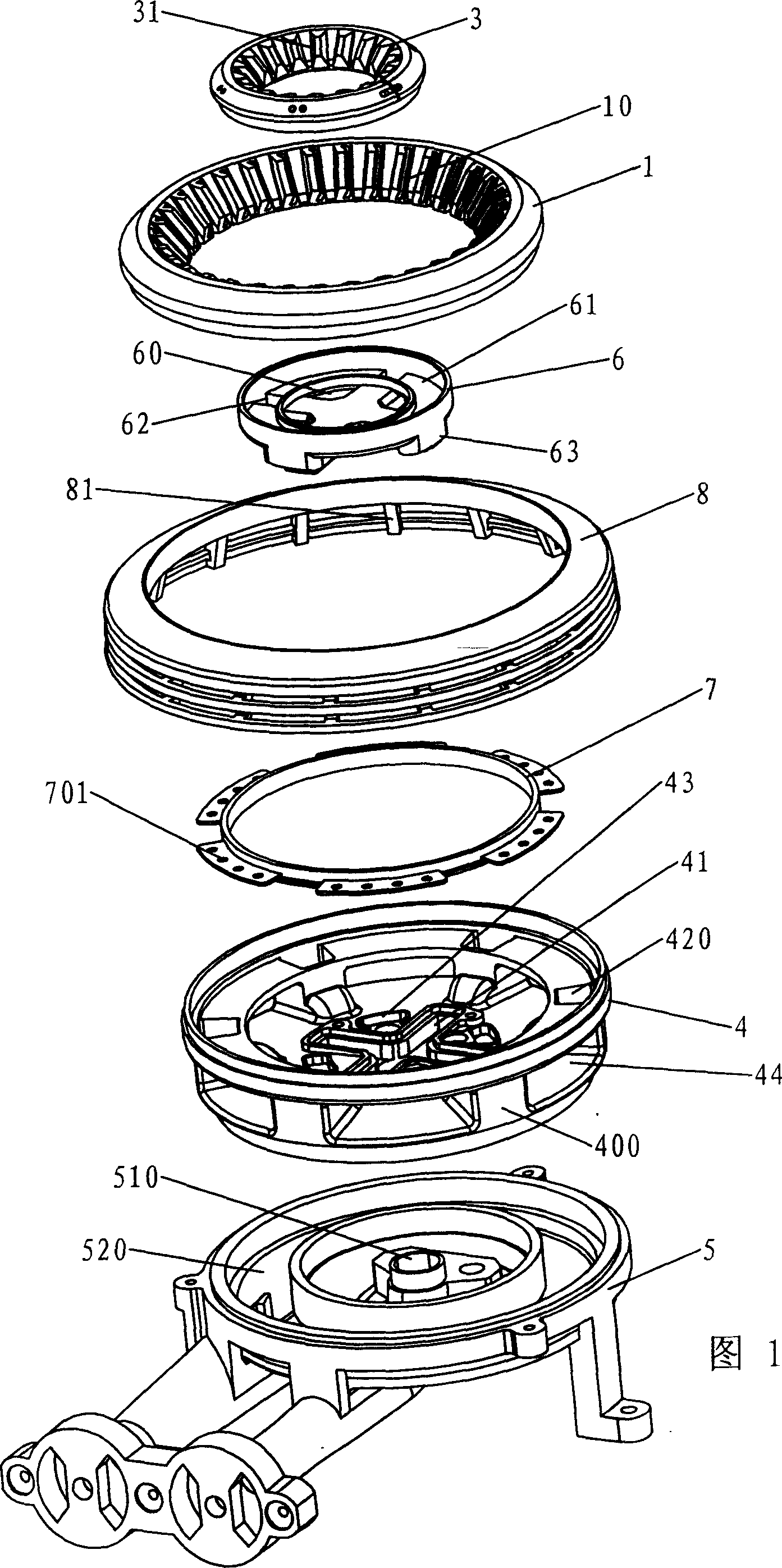

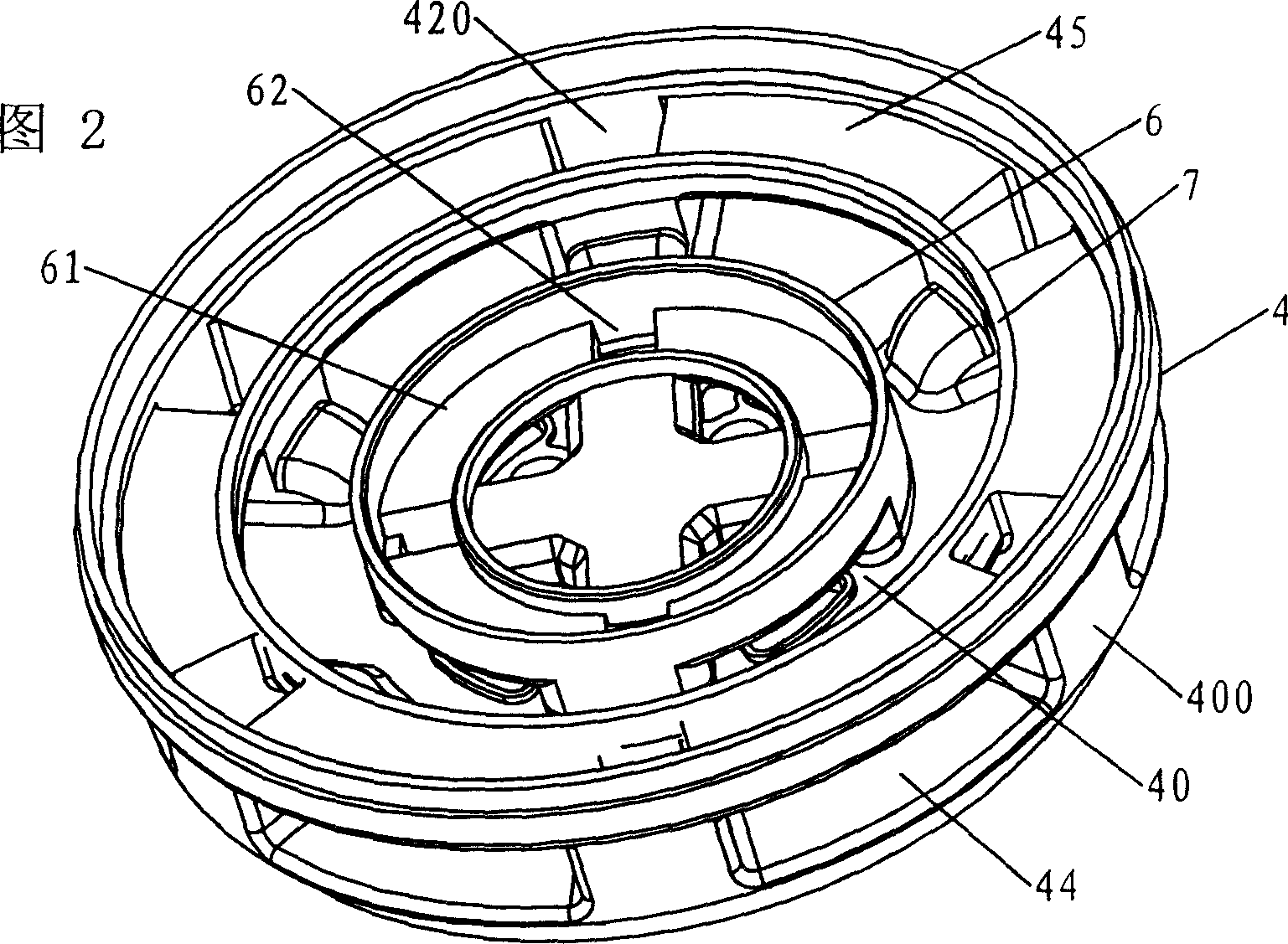

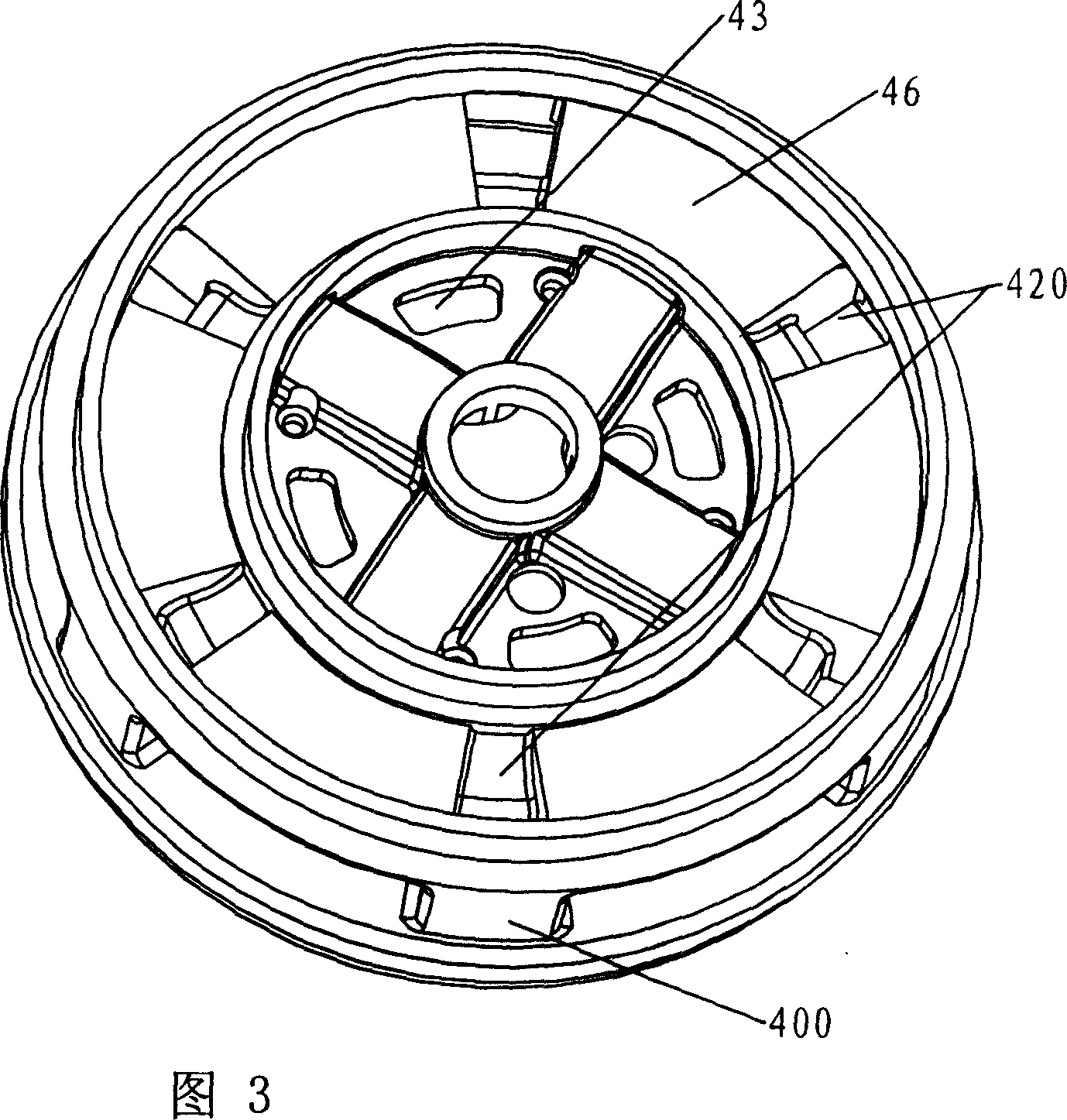

[0032] As shown in Fig. 1, the updraft type deep internal rotation burner includes an inner ring fire cover 3, an outer ring fire cover 1, a chassis 4 and a burner head 5 with inner and outer injection tubes, wherein the inner ring fire cover 3 and the outer ring The fire holes 31 and 10 on the inner ring wall of the fire cover 1 are strip-shaped, and the openings of the fire holes face the same direction. The chassis 5 is an upper layer and a lower layer connected by a connecting pipe 400. The upper layer is ring-shaped and embedded in its inner ring. There is an annular heat insulating ring 7, and several through holes 701 are respectively opened on the six wings of the heat insulating ring 7, and an outer ring air groove 45 matching the outer ring fire cover 1 is formed between the heat insulating ring 7 and the outer periphery of the upper layer (see Fig. 2), the lower side of the lower floor is provided with annular air groove 46 (see Fig. 3), and this annular air groove 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com