Patents

Literature

64results about How to "Enough air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

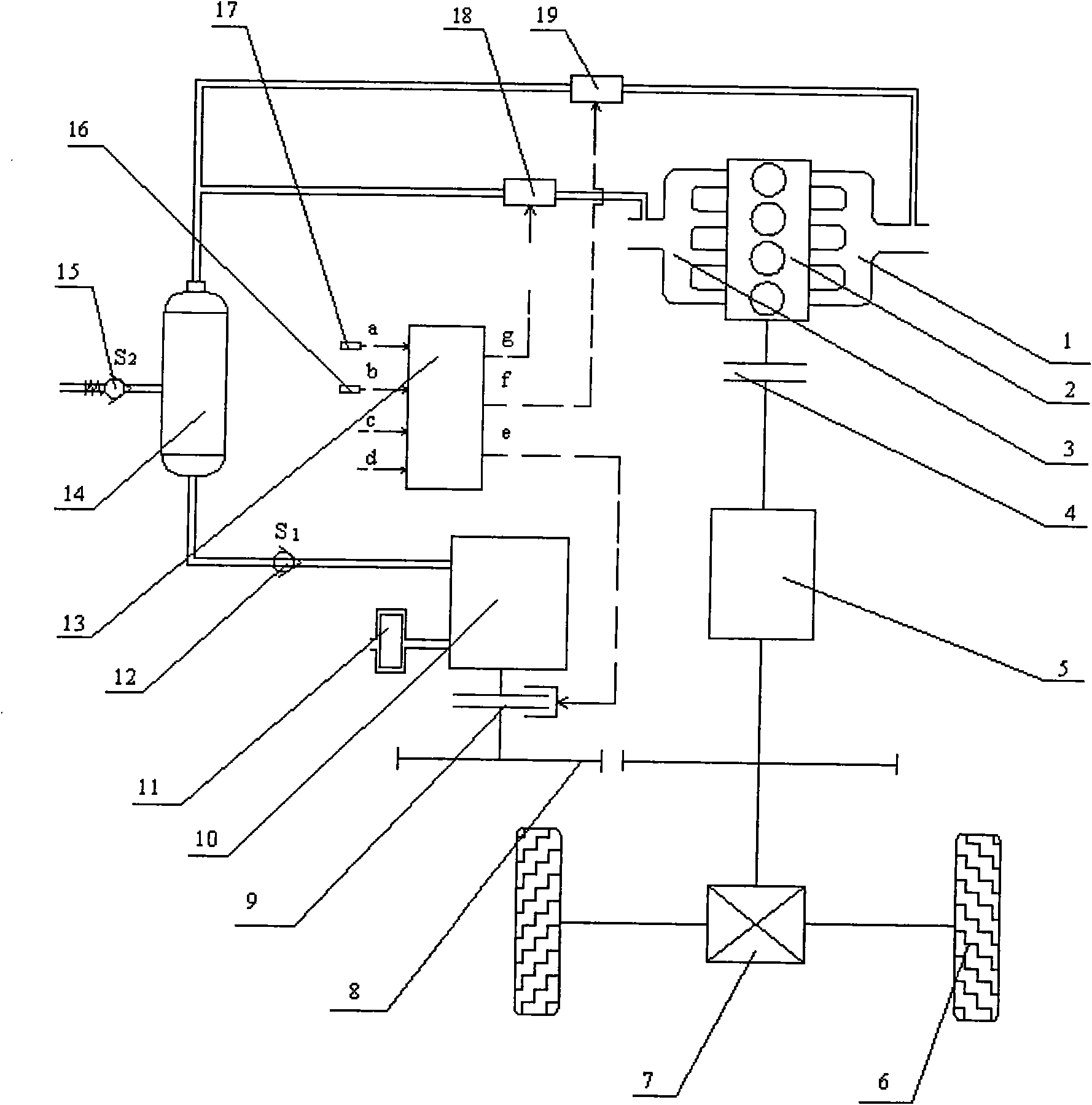

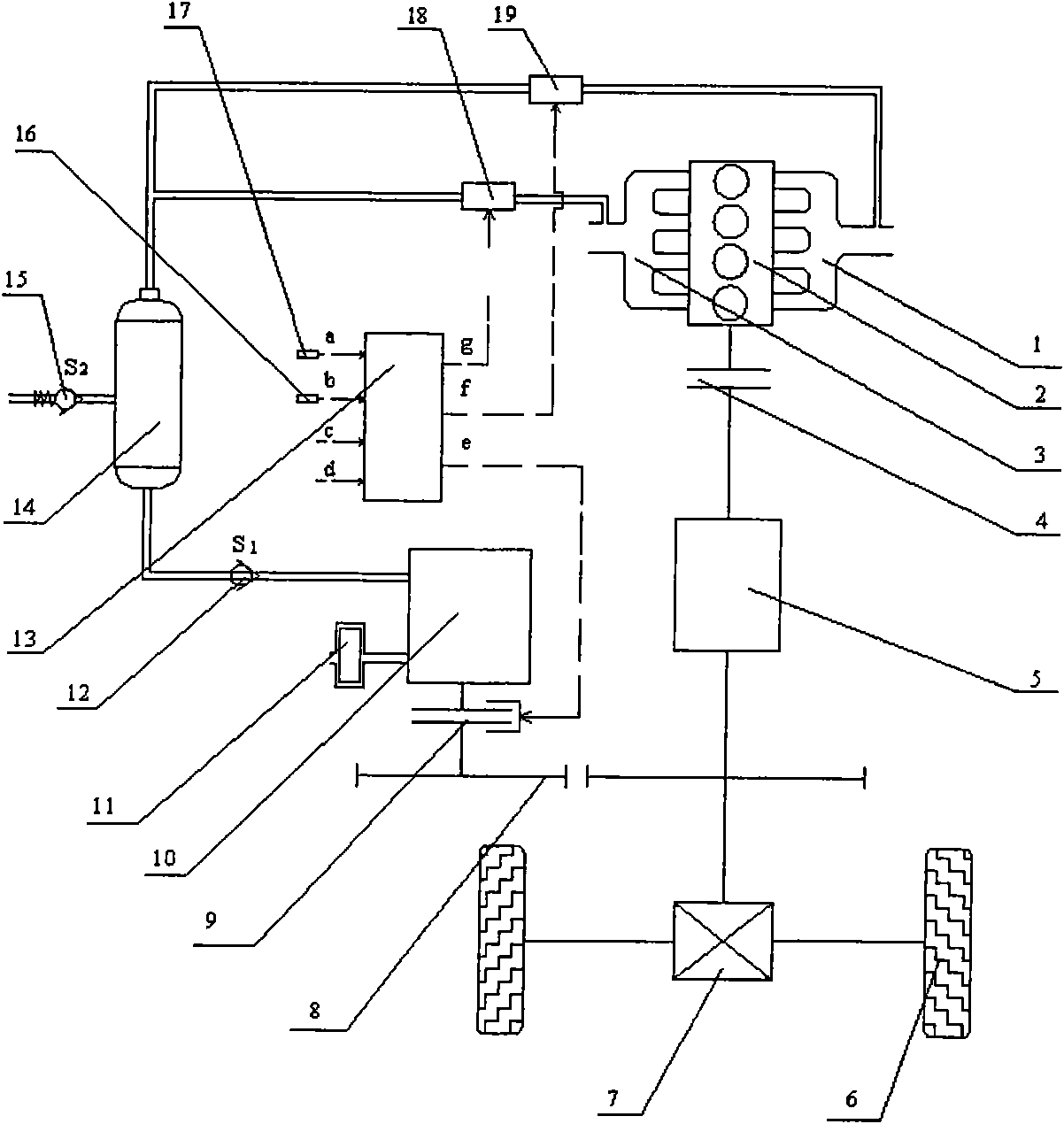

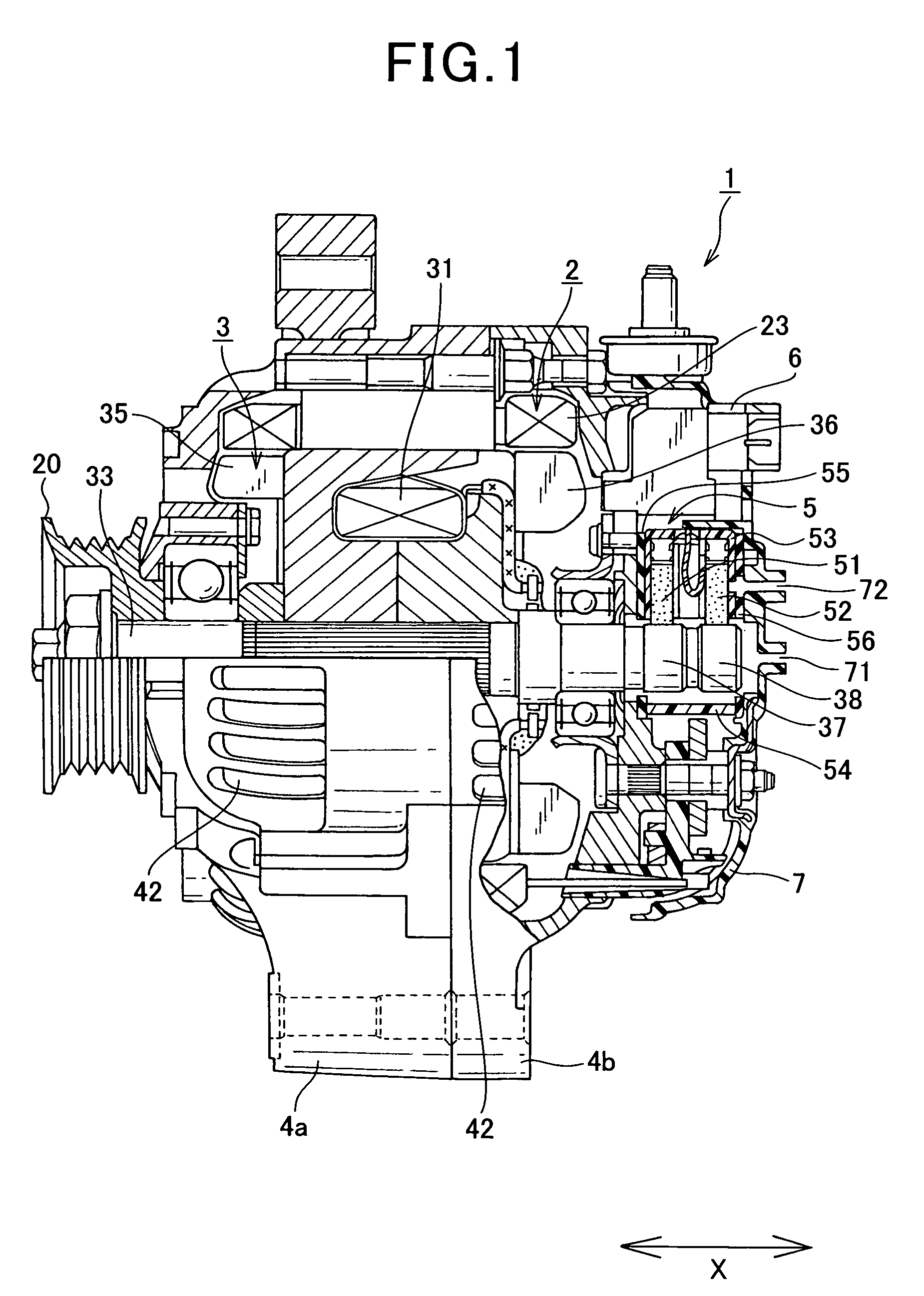

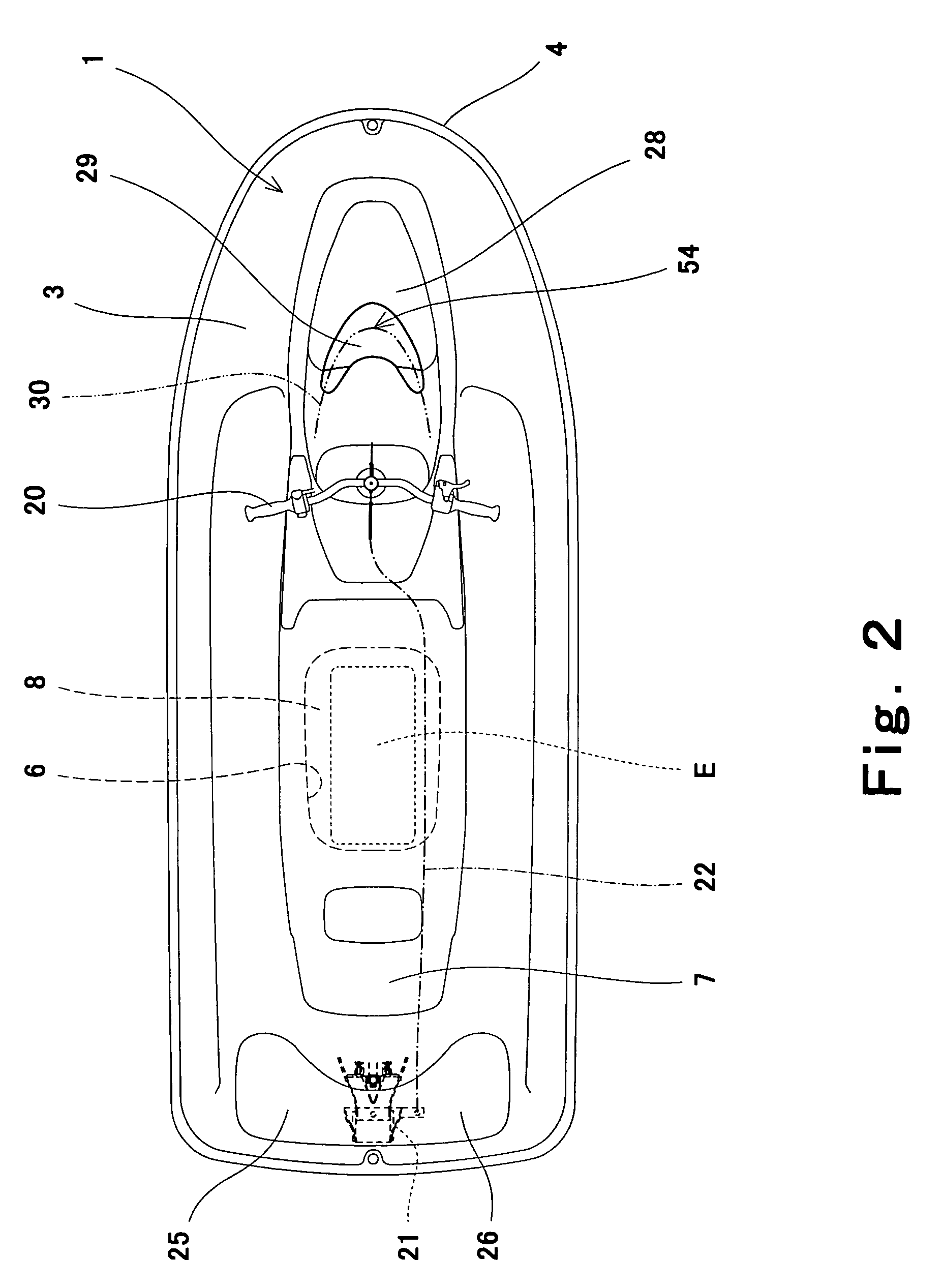

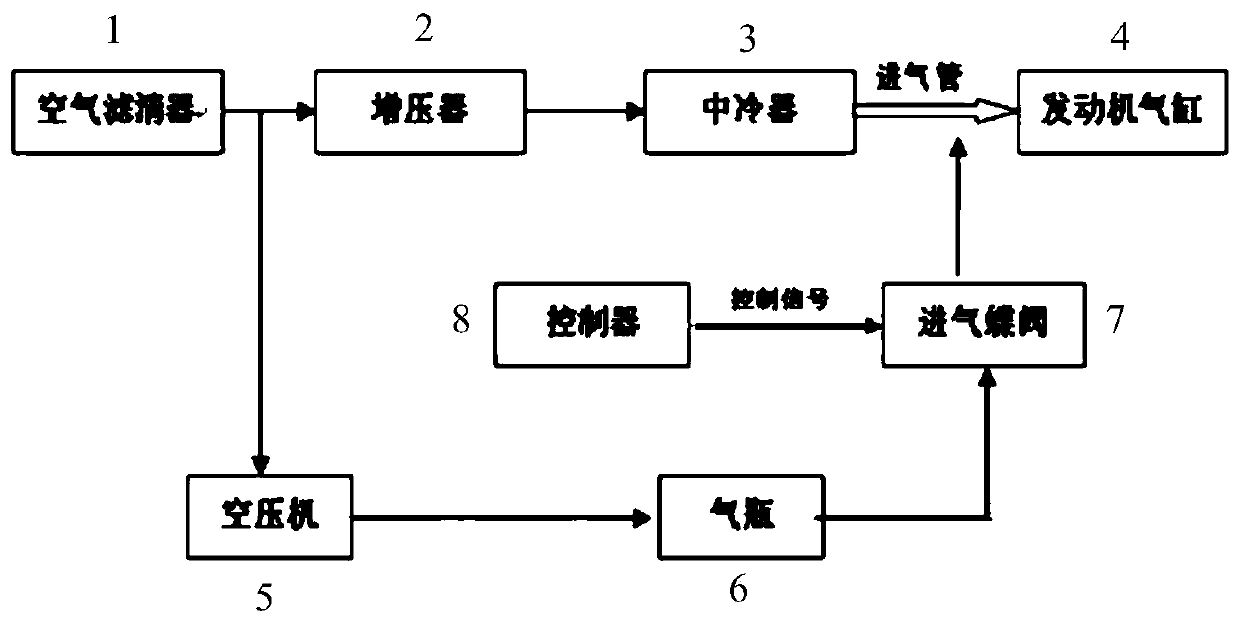

Pneumatic vehicular braking energy recovery and recycling device and control method

InactiveCN102069788AImprove powerImprove acceleration performanceBraking action transmissionExhaust apparatusDrivetrainGas cylinder

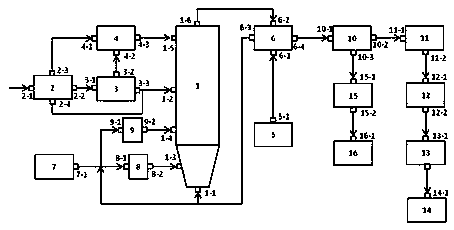

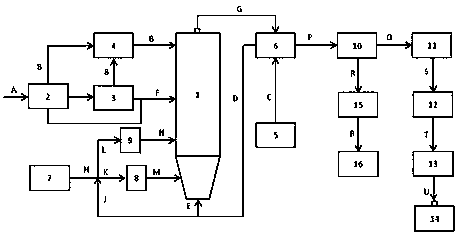

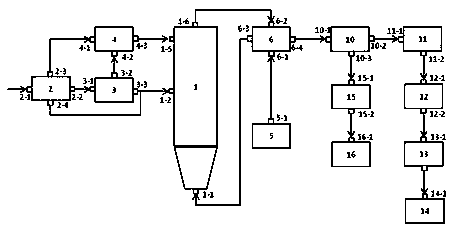

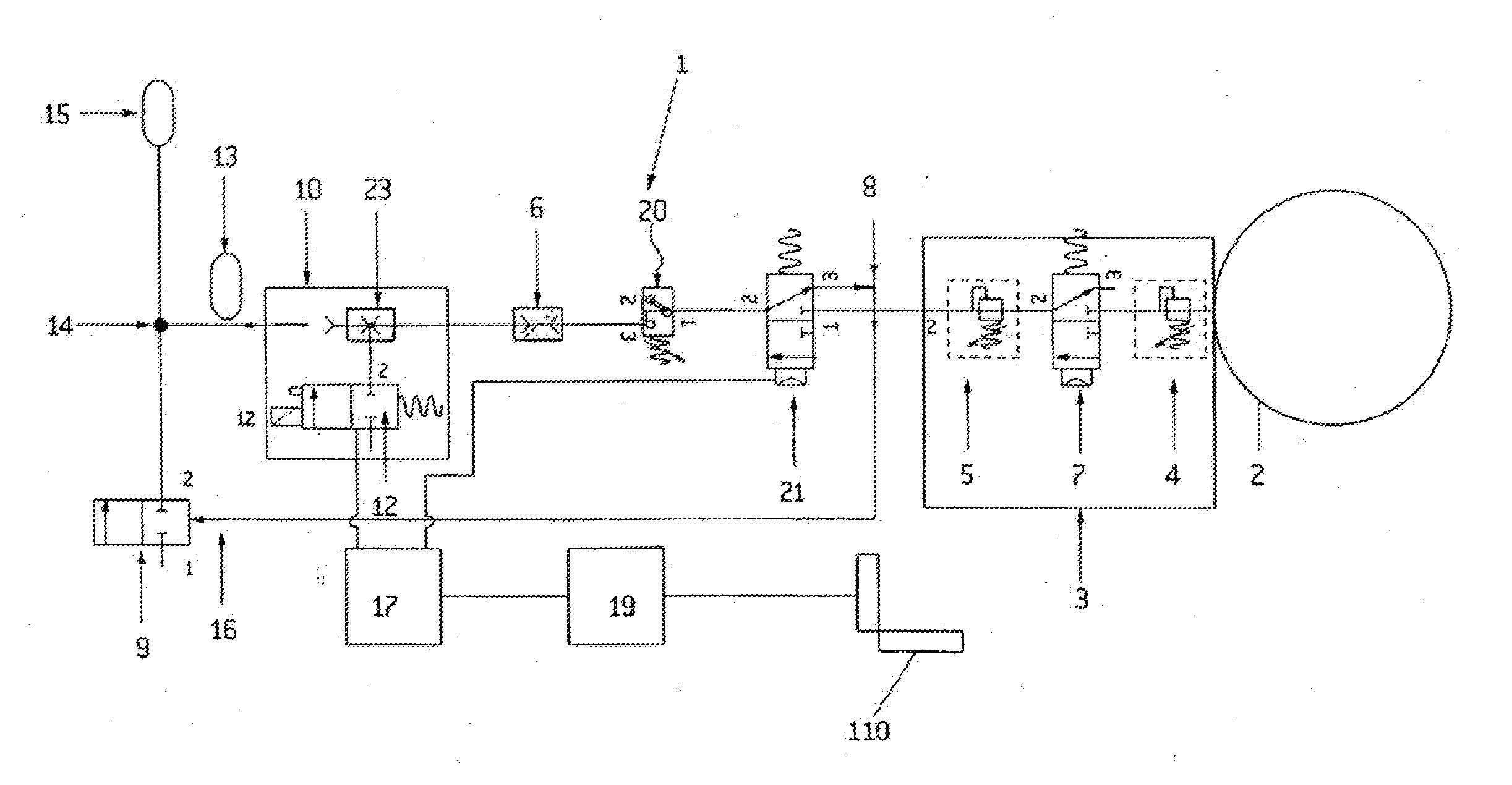

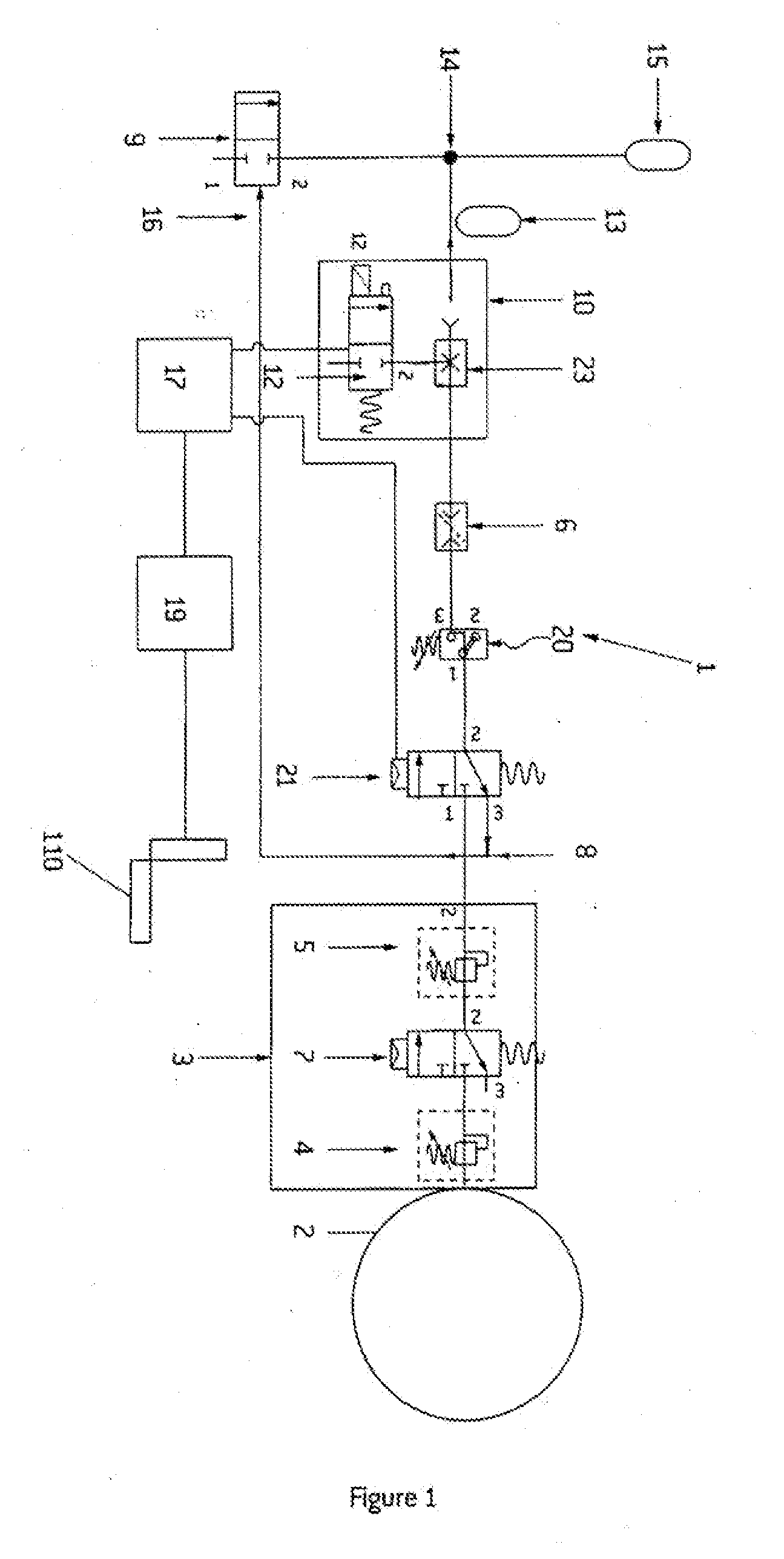

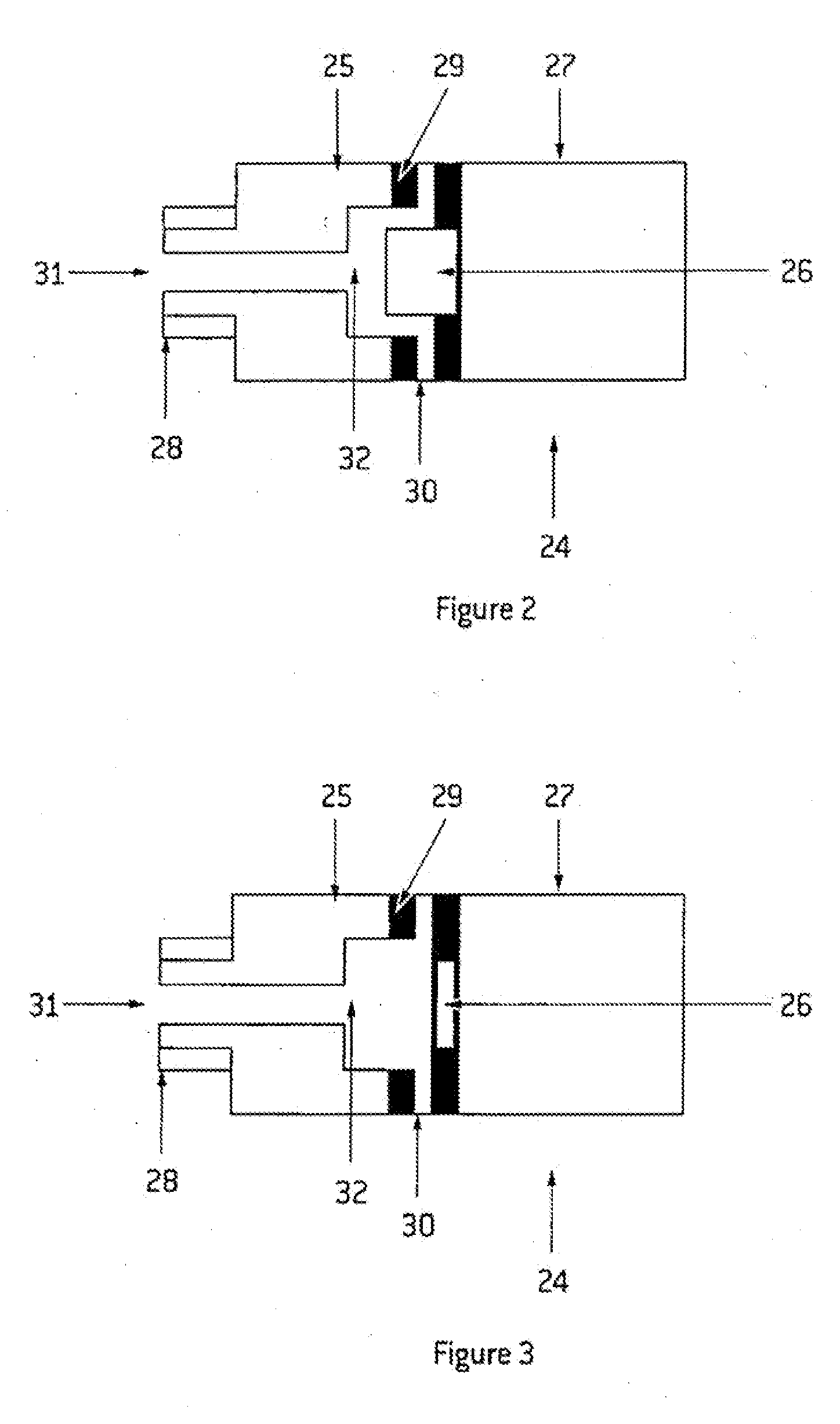

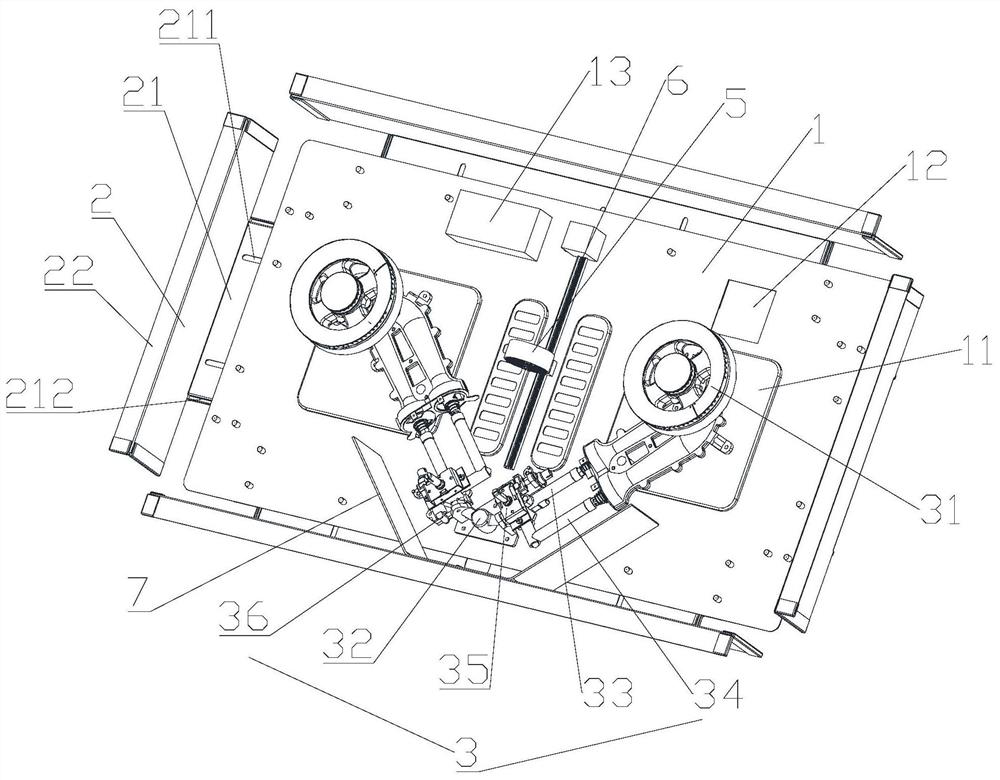

The invention provides a pneumatic vehicular braking energy recovery and recycling device and a control method, which belong to the technical field of energy conservation and emission reduction of vehicles. The device provided by the invention is characterized in that in the checking brake process of a vehicle, an air compressor is connected with a drivetrain system of the vehicle by an electromagnetic clutch, the air compressor is driven to operate by using the inertia of the vehicle so as to recover the braking energy of the vehicle, and the high pressure air produced by the air compressor is stored in a high pressure gas cylinder; when a vehicle is accelerated, the high pressure air stored in the high pressure gas cylinder can carry out air-intake compensation on an internal-combustion engine, which facilitates the sufficient air acquisition of the internal-combustion engine under instantaneous conditions, and improves the dynamic property and acceleration performance of the internal-combustion engine, especially can shorten the air-intake response delay of a turbocharged internal-combustion engine when the internal-combustion engine is accelerated; and when the internal-combustion engine is started, the high pressure air can carry out additional air compensation on the air exhaust of the internal-combustion engine (in particular to a hybrid electric vehicle with an internal-combustion engine frequently controlled to start and stop) so as to reduce the discharge of noxious substances in a starting process of the internal-combustion engine.

Owner:BEIJING UNIV OF TECH

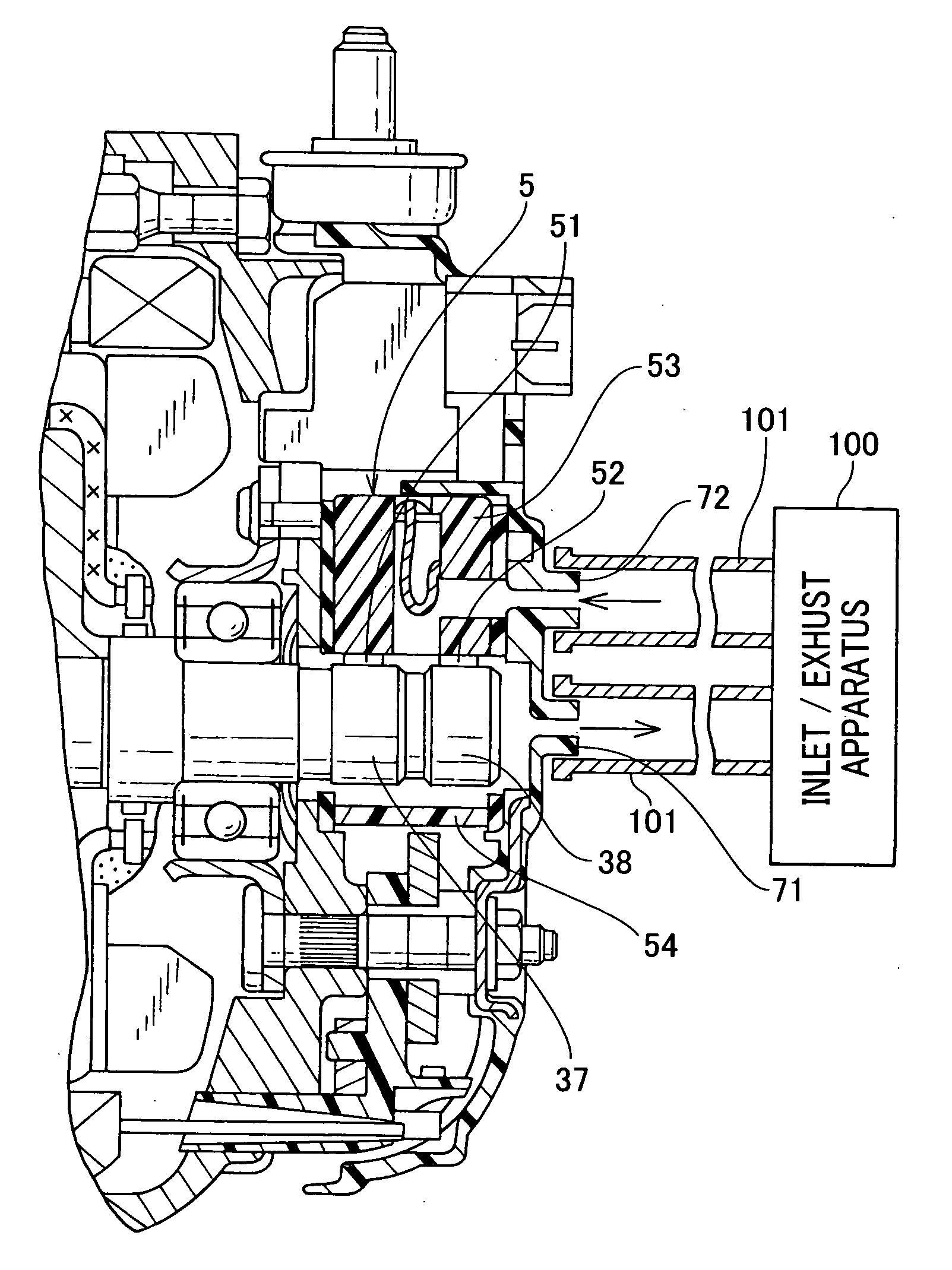

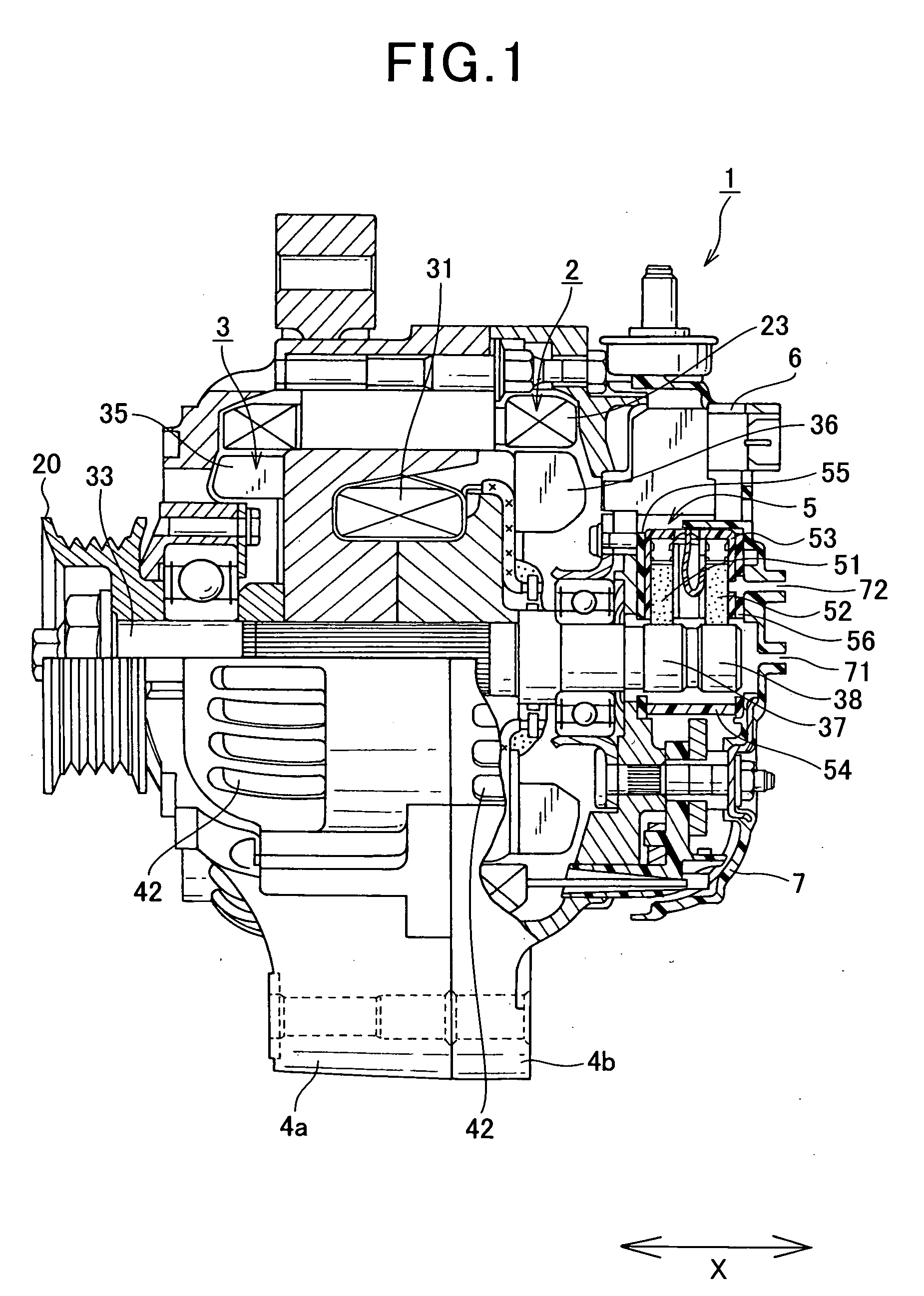

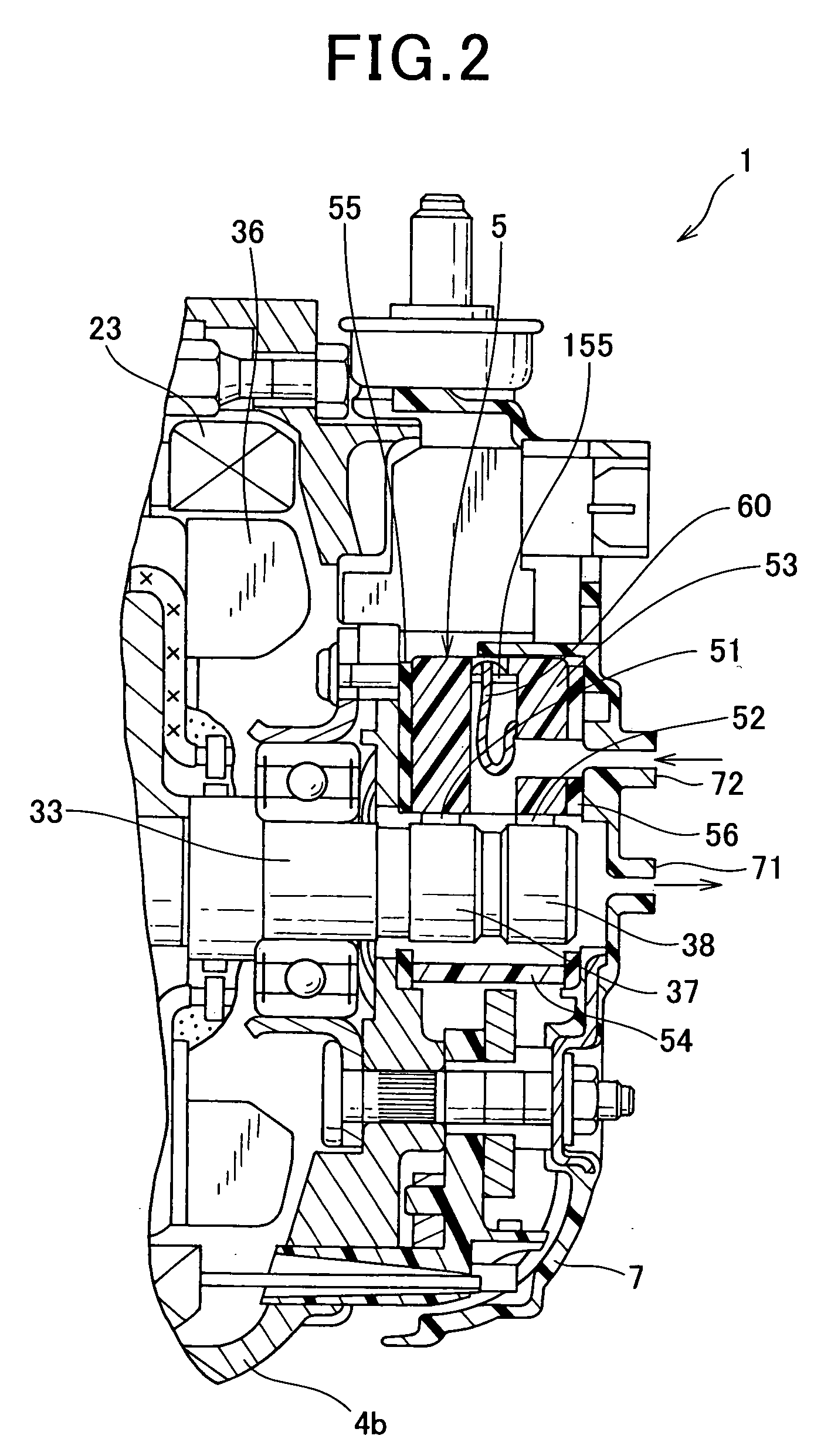

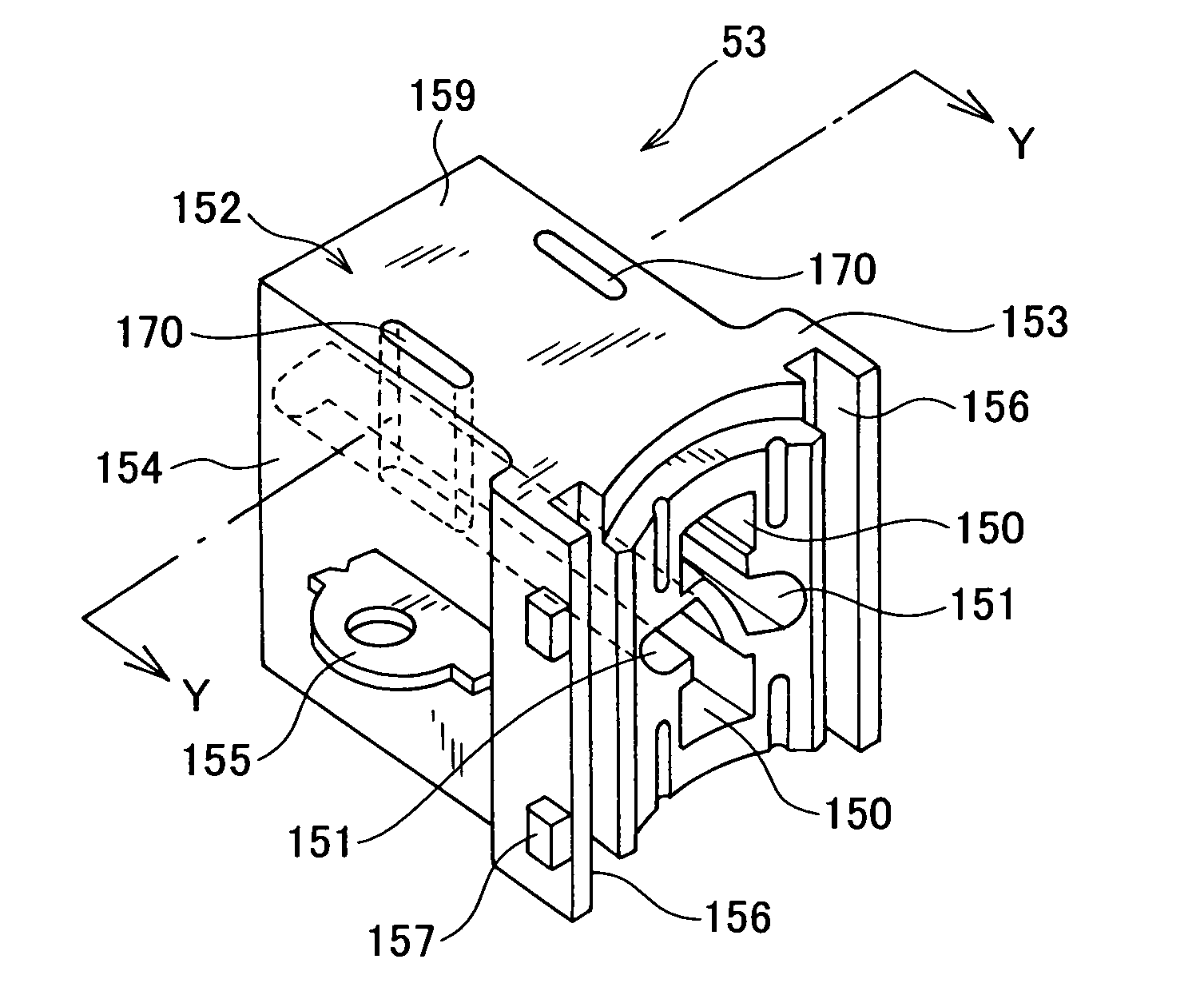

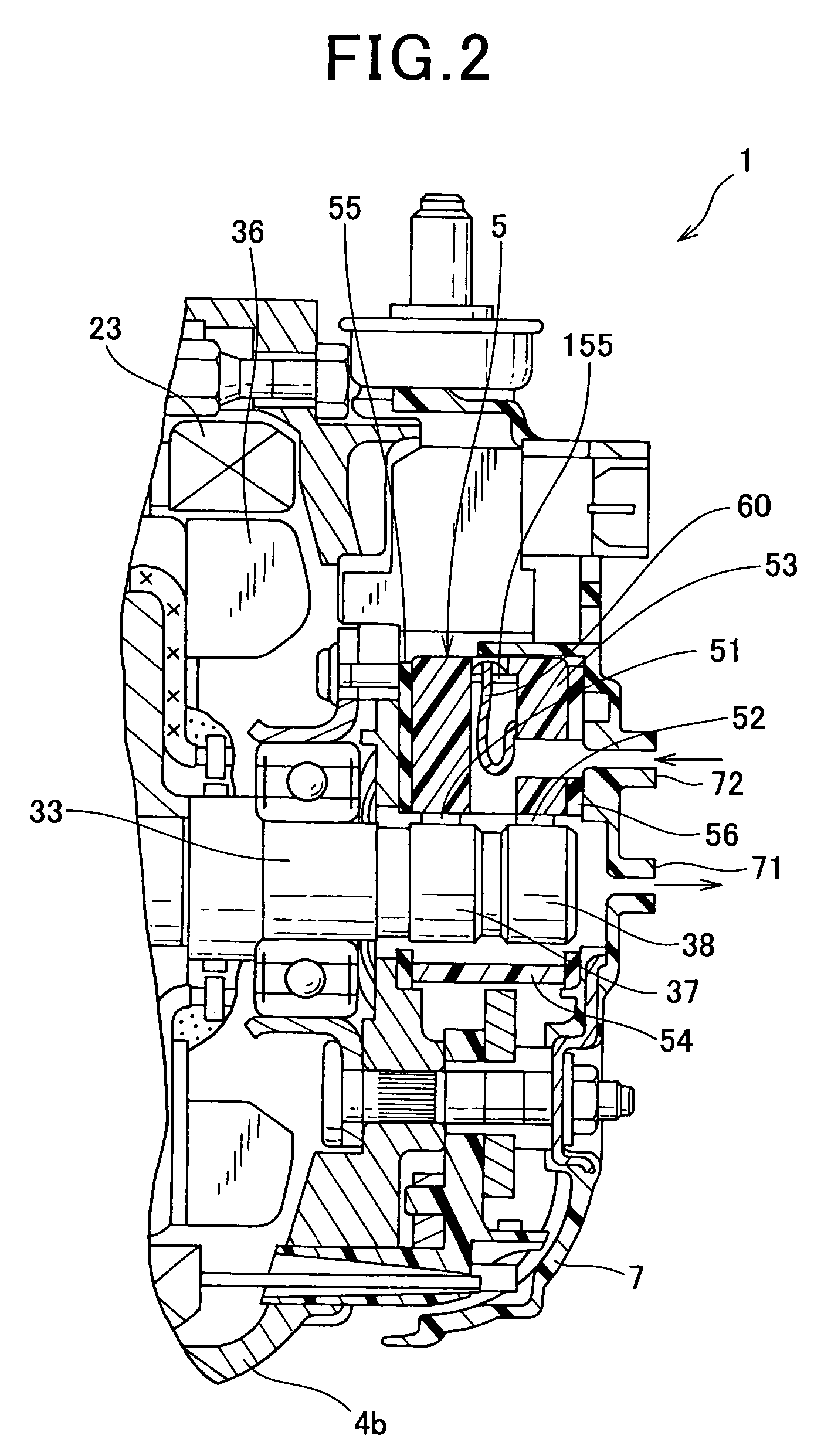

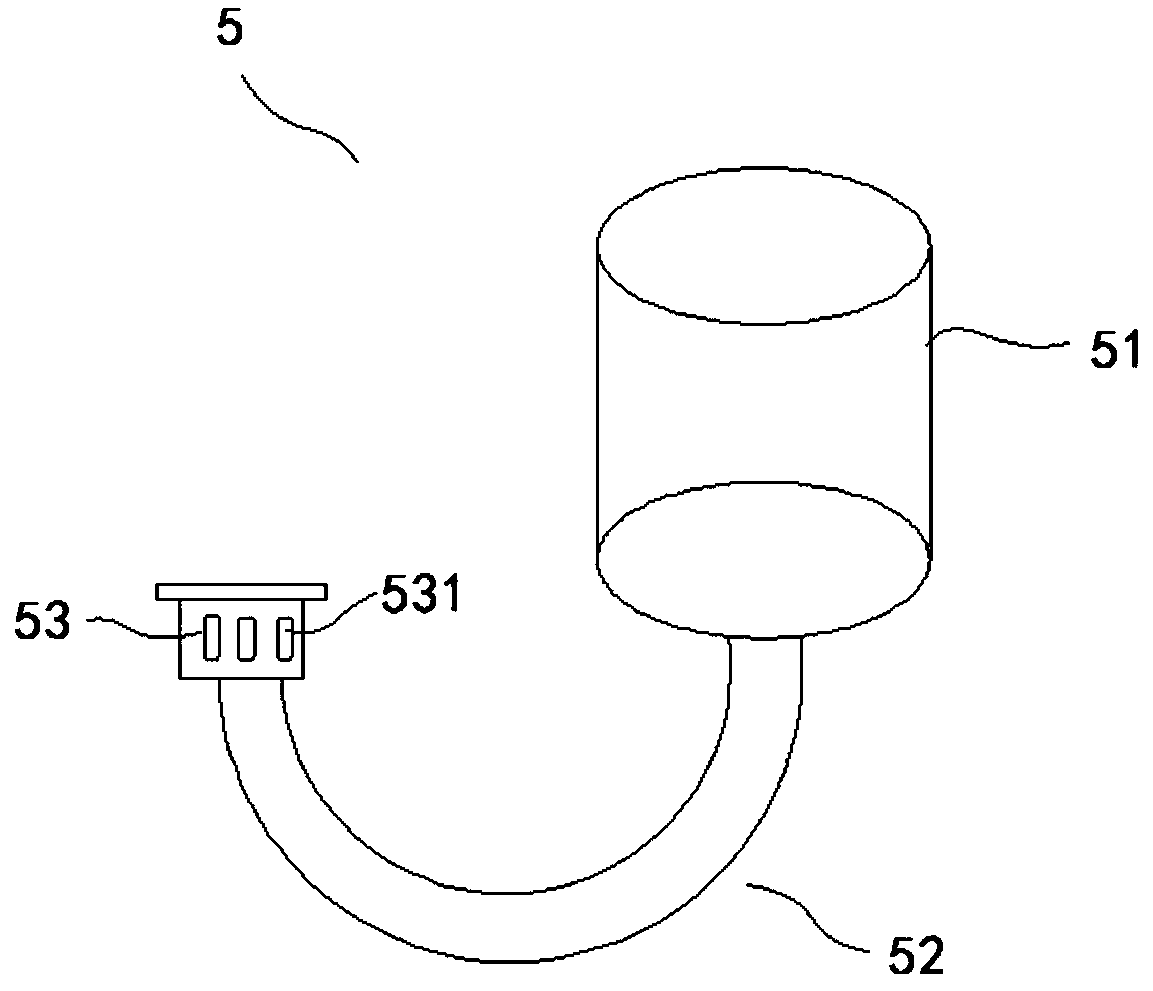

Vehicle alternator provided with brushes and slip rings

ActiveUS20090189478A1Extended service lifeImprove the mechanical environmentRotary current collectorCooling/ventillation arrangementAlternatorEngineering

An alternator for vehicles, the alternator being provided with a rotary shaft, comprising slip rings fixed to a rotary shaft to be rotated with the rotary shaft, brushes being placed to be in slide contact with the slip rings a brush holder that accommodates the brushes to be held therein; connection terminals fixed to the brush holder, brush leads electrically connecting the brushes to the connection terminals respectively, and a slip ring cover that covers the slip rings in cooperation with the brush holder, wherein the brush holder comprises first chambers in which the bushes are fixedly accommodated second chambers in which the brush leads are accommodated, the second combers communicating with the first chambers, and first air holes formed to open outside of the housing and formed as inlet / exhaust passages communicating with the second chambers.

Owner:DENSO CORP

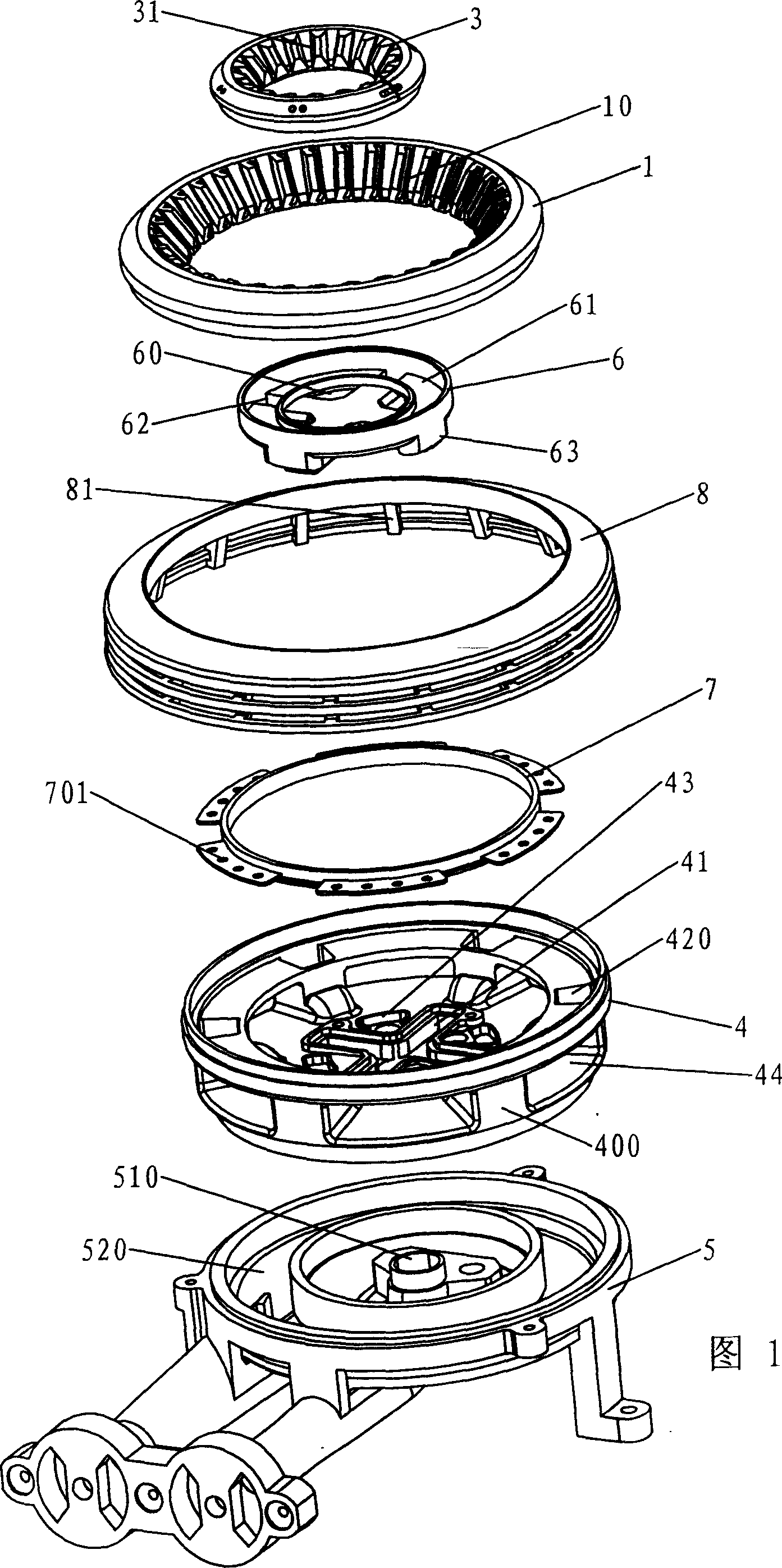

Upper air intake type deep internal rotation type burner

The invention relates to an upper wind inlet deep-cyclone burner, with simple structure and high burning efficiency, wherein it comprises: an outer annular fiber cover, chassis, and the jamb with ejection tube; the chassis is divided into upper and lower layers; the upper layer is annular whose inner ring is embedded with thermal-insulated ring; the thermal-insulated ring and the upper circumference form the external annular gas groove matched with external annular fiber cover; the lower side of lower layer and the external gas inlet groove of jamb form the external annular fuel gas chamber through to the ejection tube; the connecting tube fixes the upper and lower layers; the channel of connecting tube connects the external annular fuel chamber and the external annular gas groove; the upper side of lower layer has the divert gas groove through to the ejection tube of central gas channel; the lower side of inner fire cover base has flange connected to the flange of divert gas groove; the inner fire cover base has connecting hole to connect the divert gas groove and the inner annular gas groove at the upper side of inner fiber cover base; and the inner annular gas groove has inner annular fire cover.

Owner:GUANGDONG HORISUN METALS MFG CO LTD

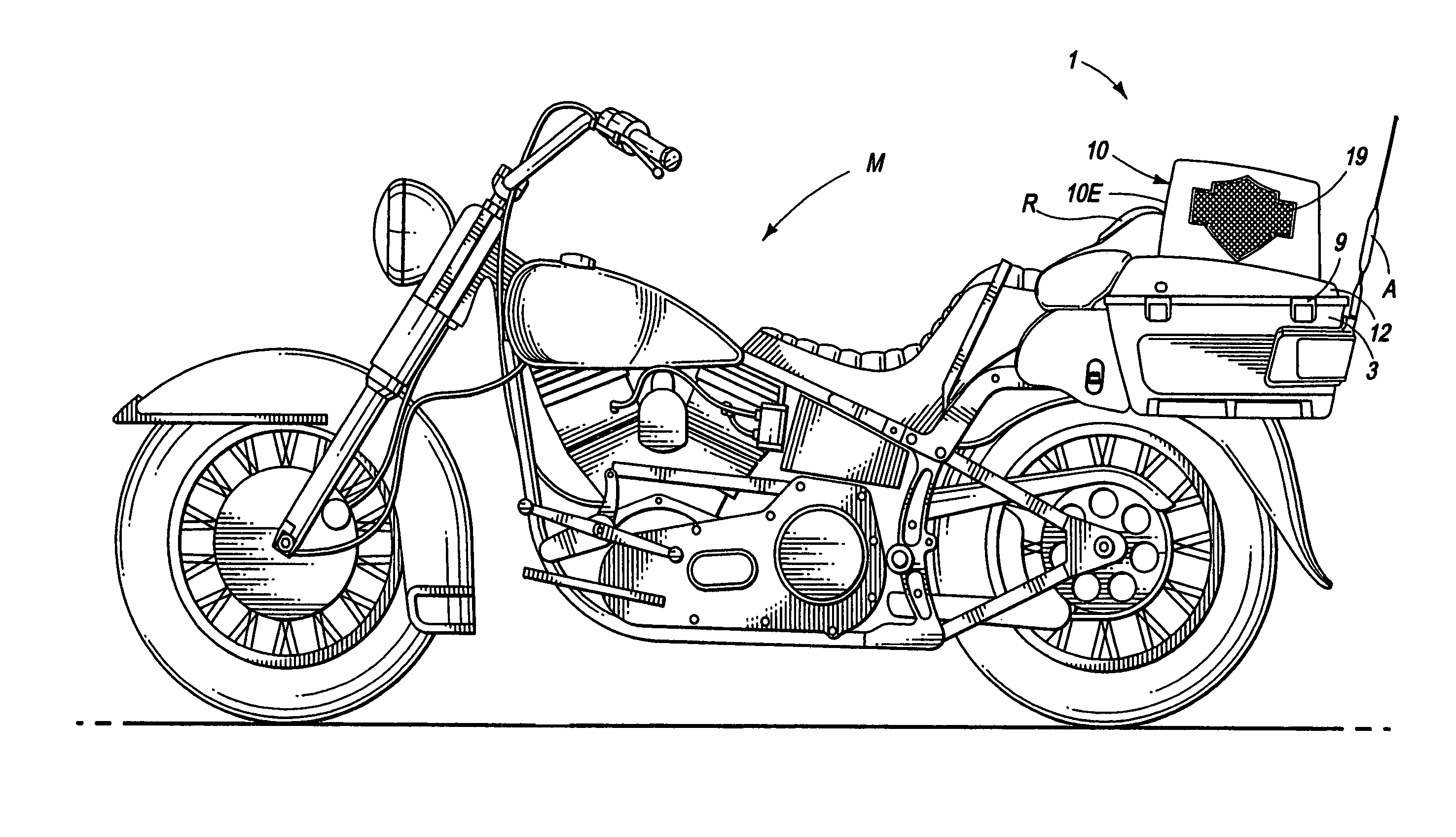

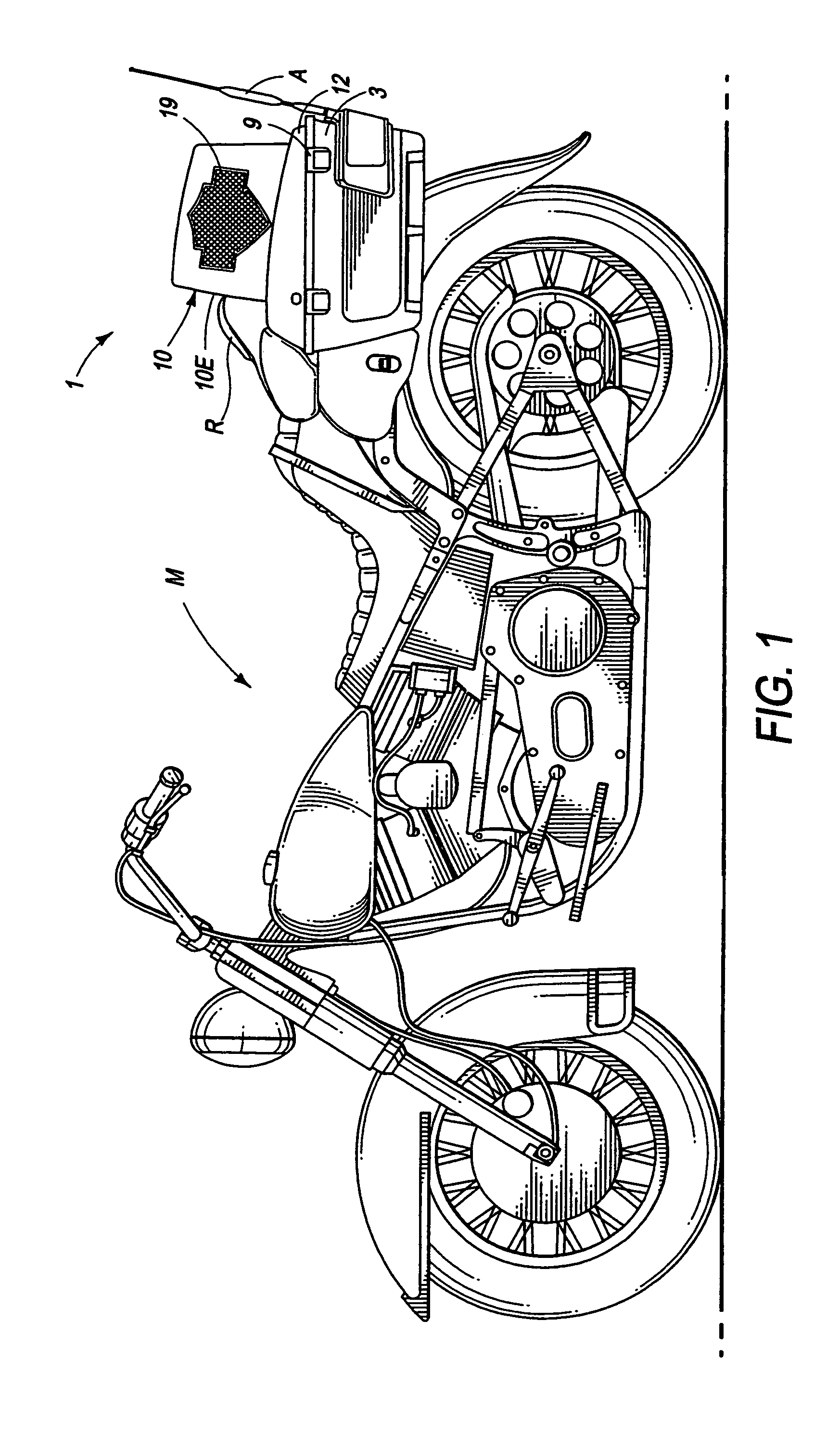

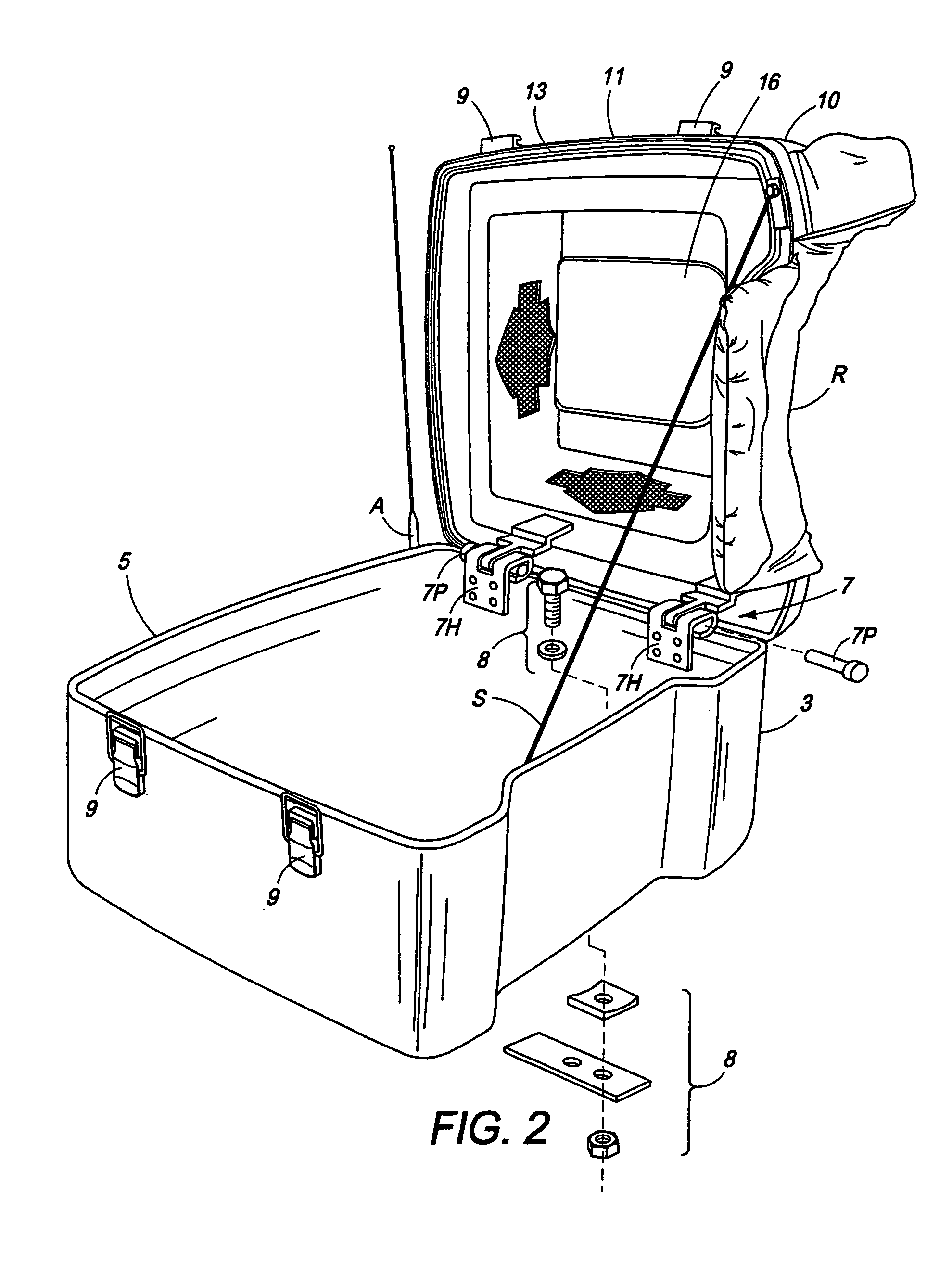

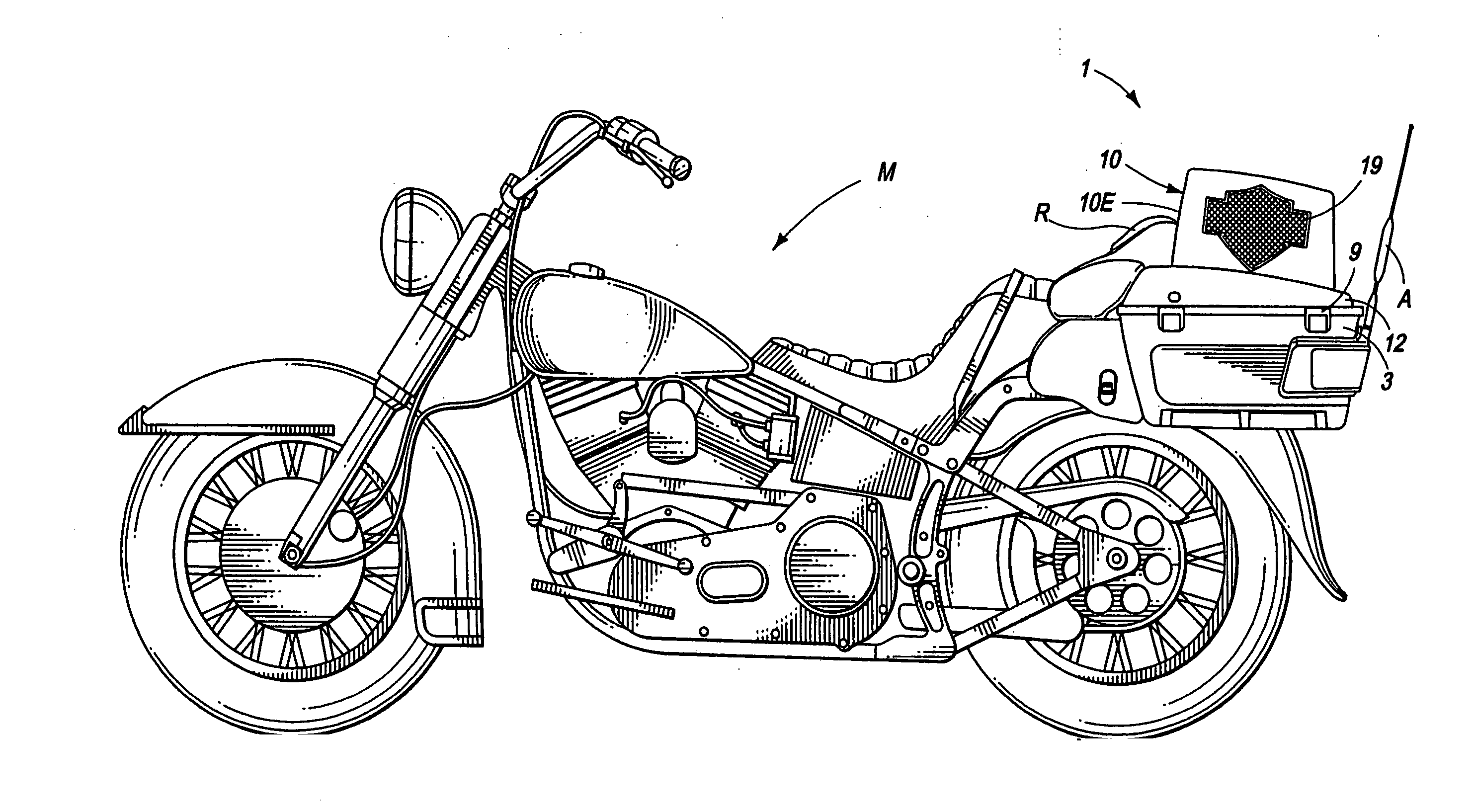

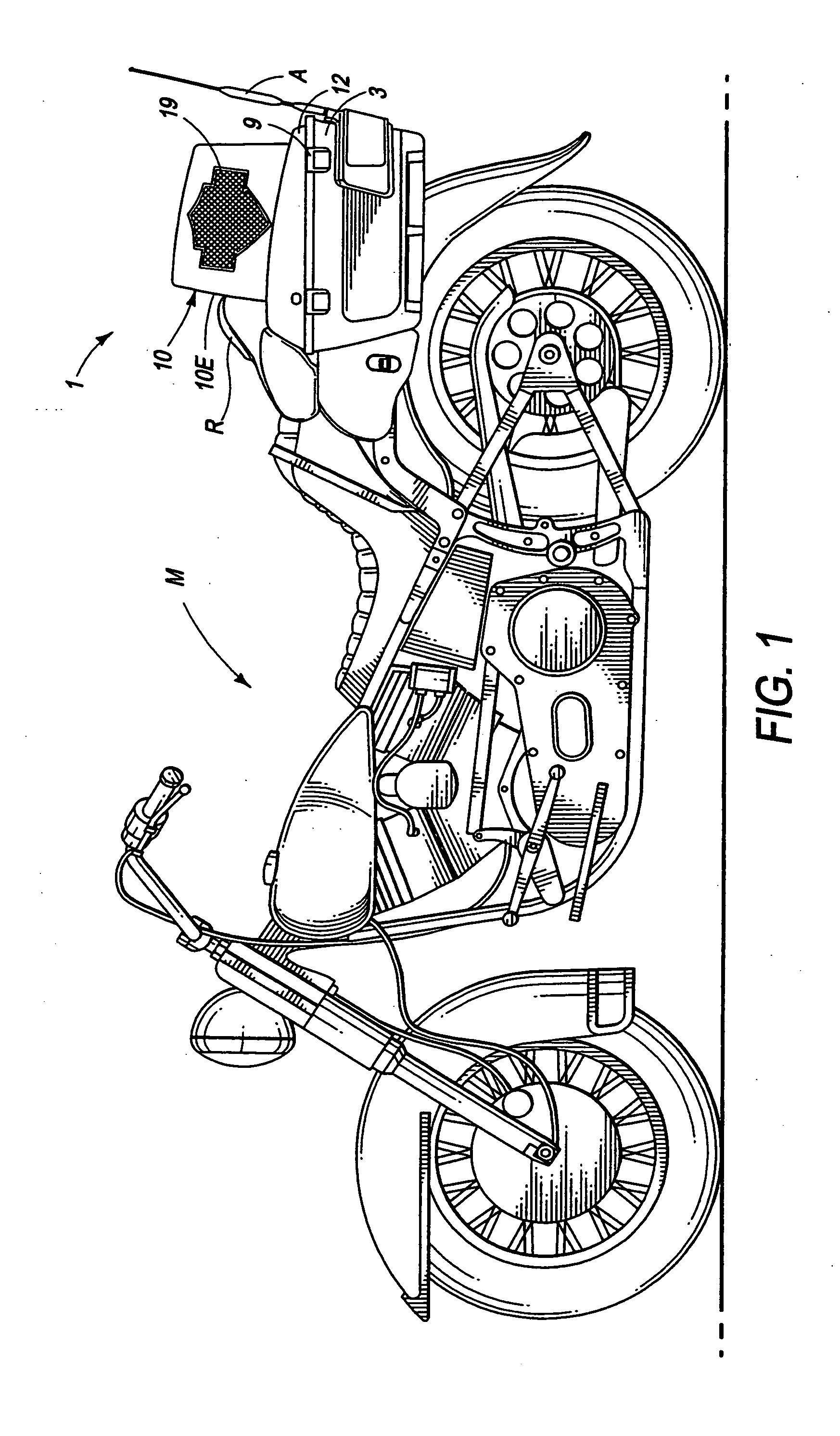

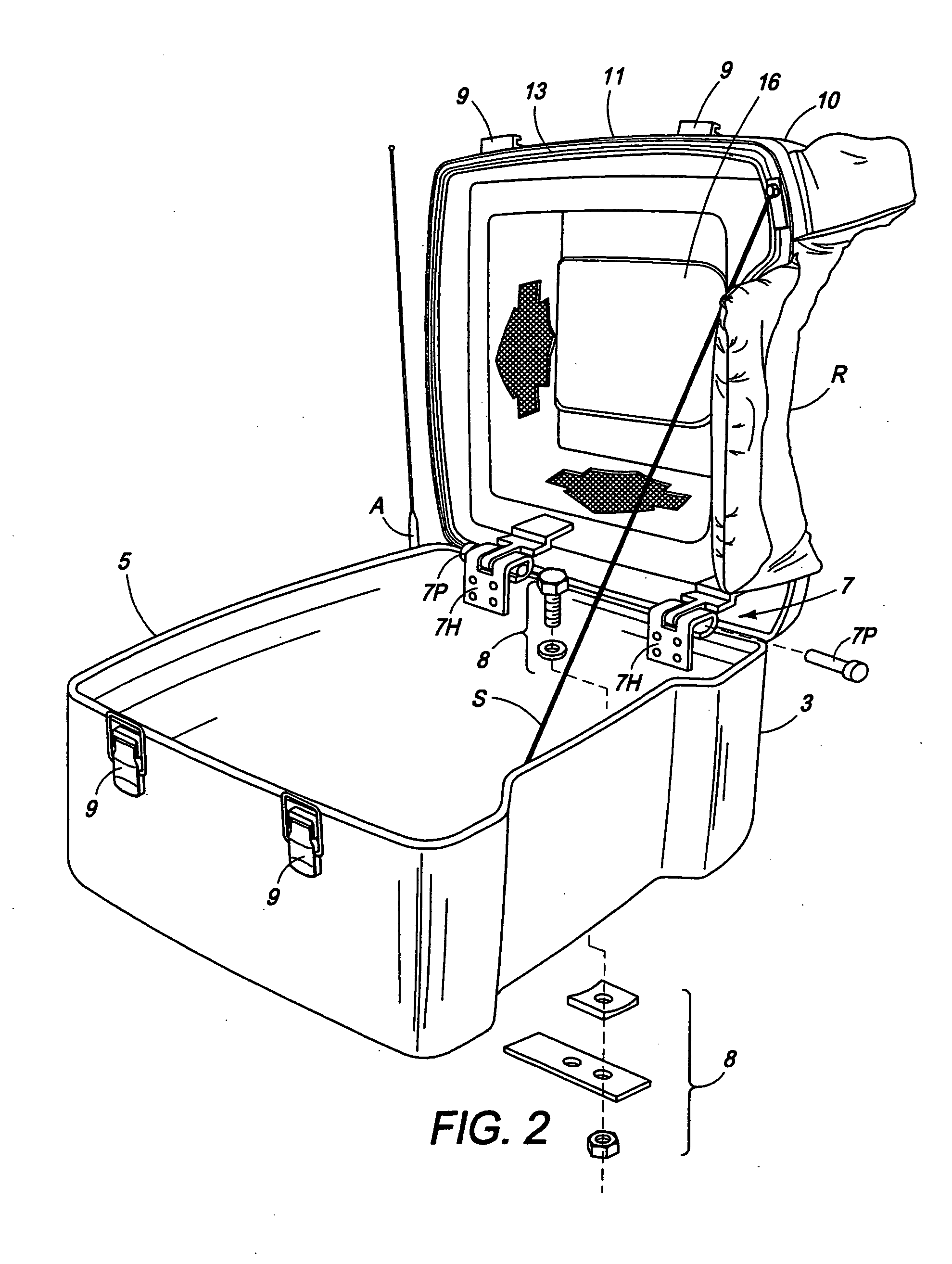

Animal carrier accessory

InactiveUS7628120B2Not adversely affect operational stability and aerodynamicsSufficient head roomLighting and heating apparatusLuggage carriersIndividual animalElectrical and Electronics engineering

An animal carrier for mounting above the rear wheel of a cycle such as a motorcycle may be obtained by converting a motorcycle luggage carrier to an animal carrier. The motorcycle carrier mounts and bottom section may be equipped with a detachable top section equipped with extended sidewalls ported with ventilating ports and roofed canopy to protect the transported animal from the elements.

Owner:BEELER WILLIAM J

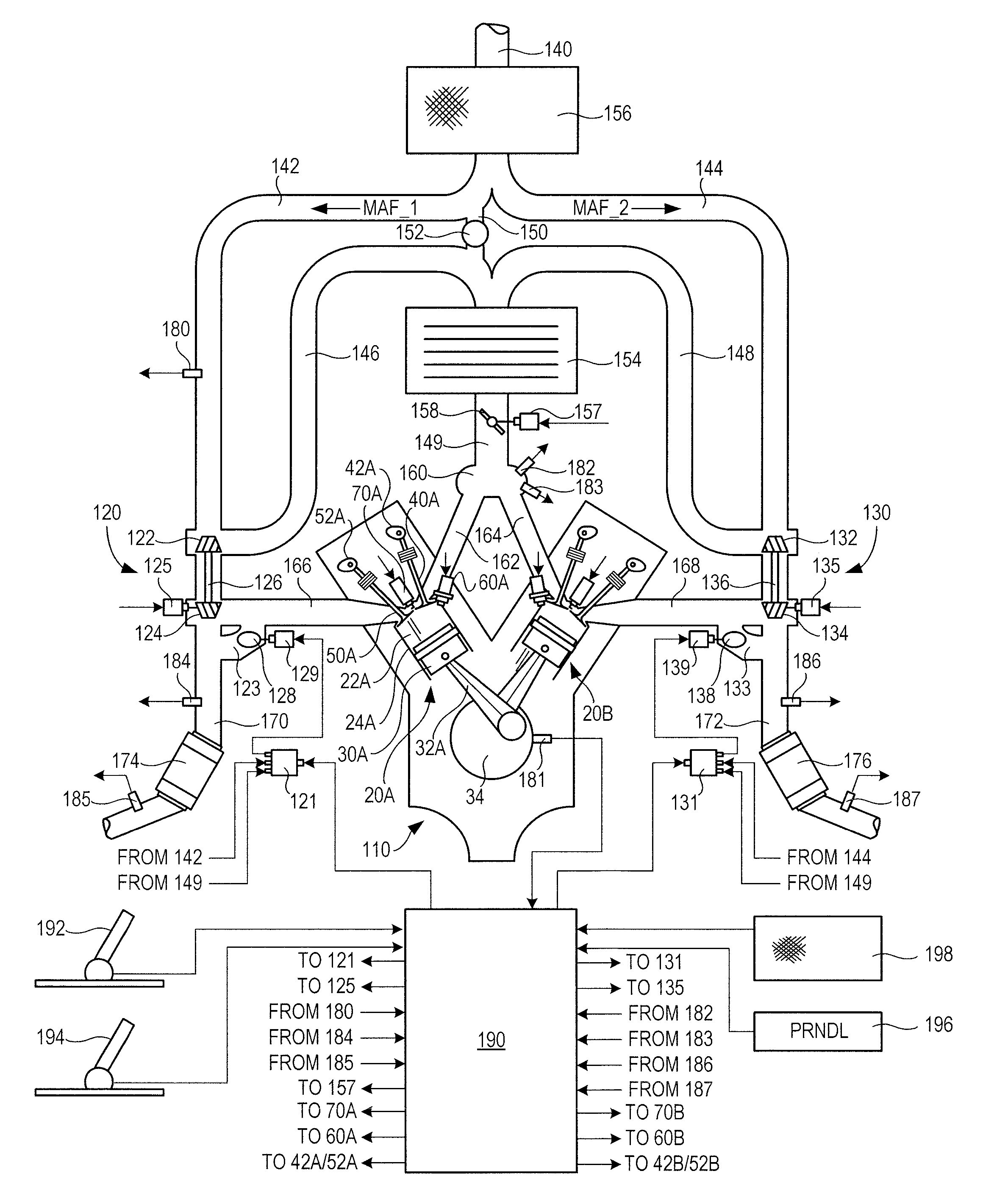

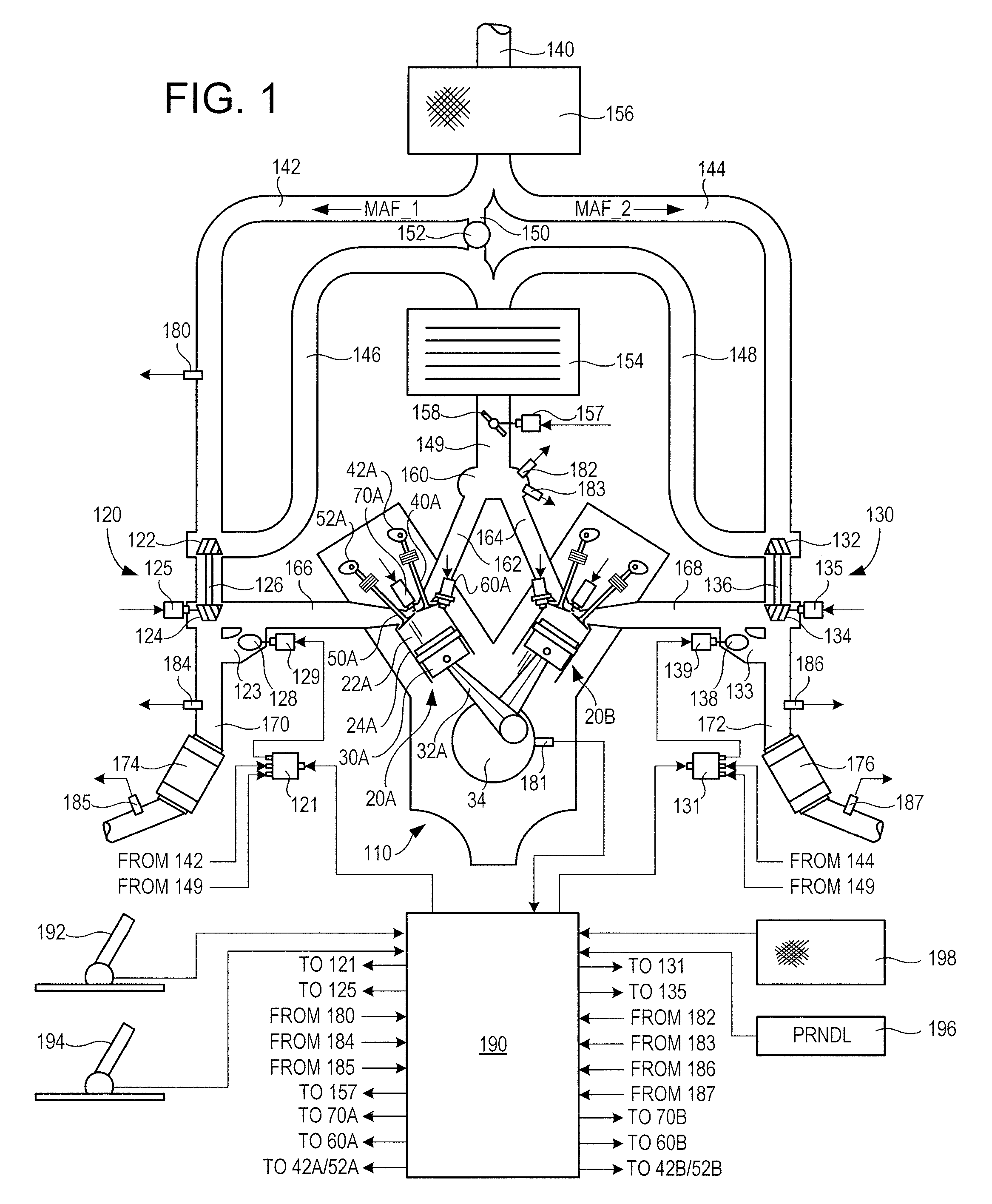

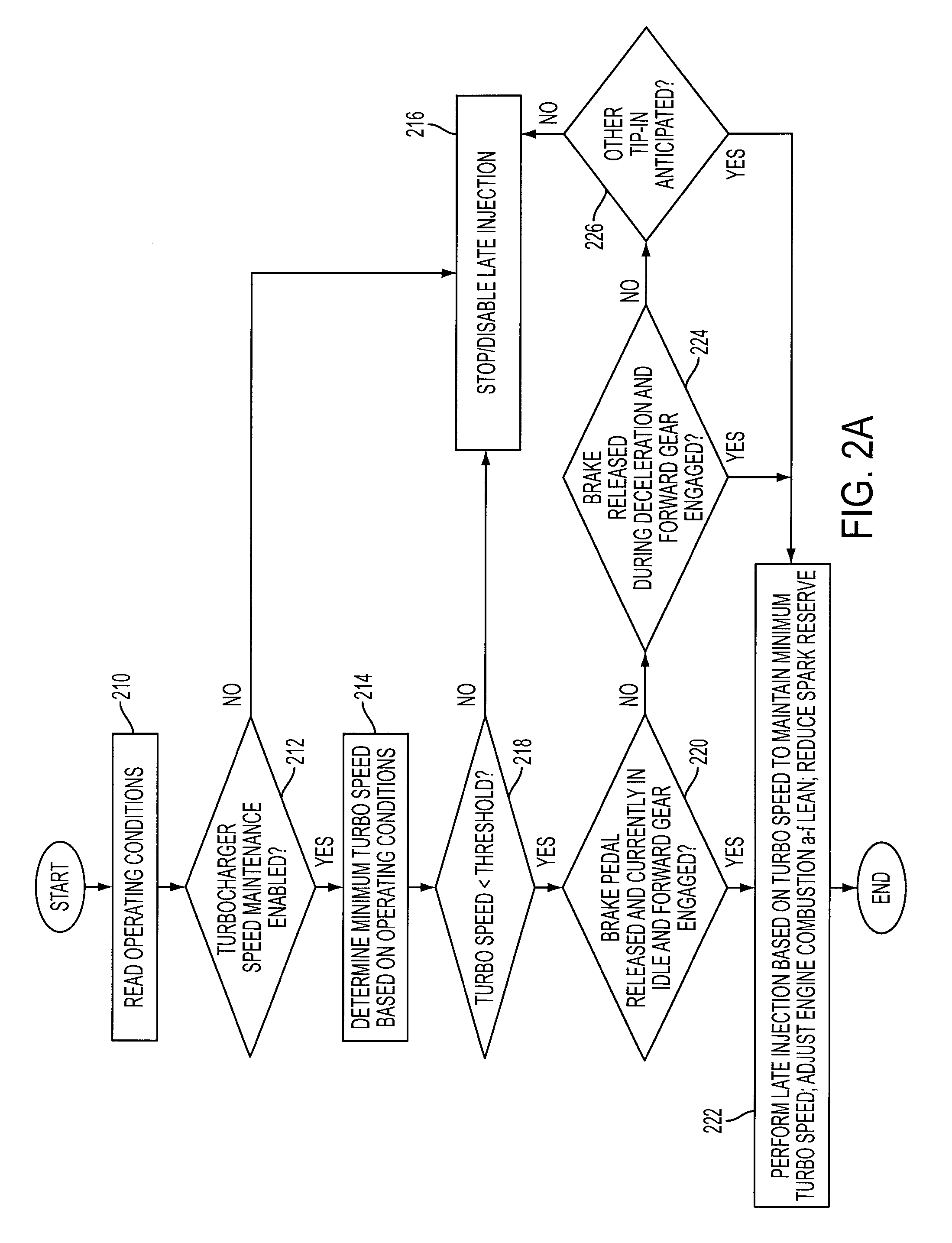

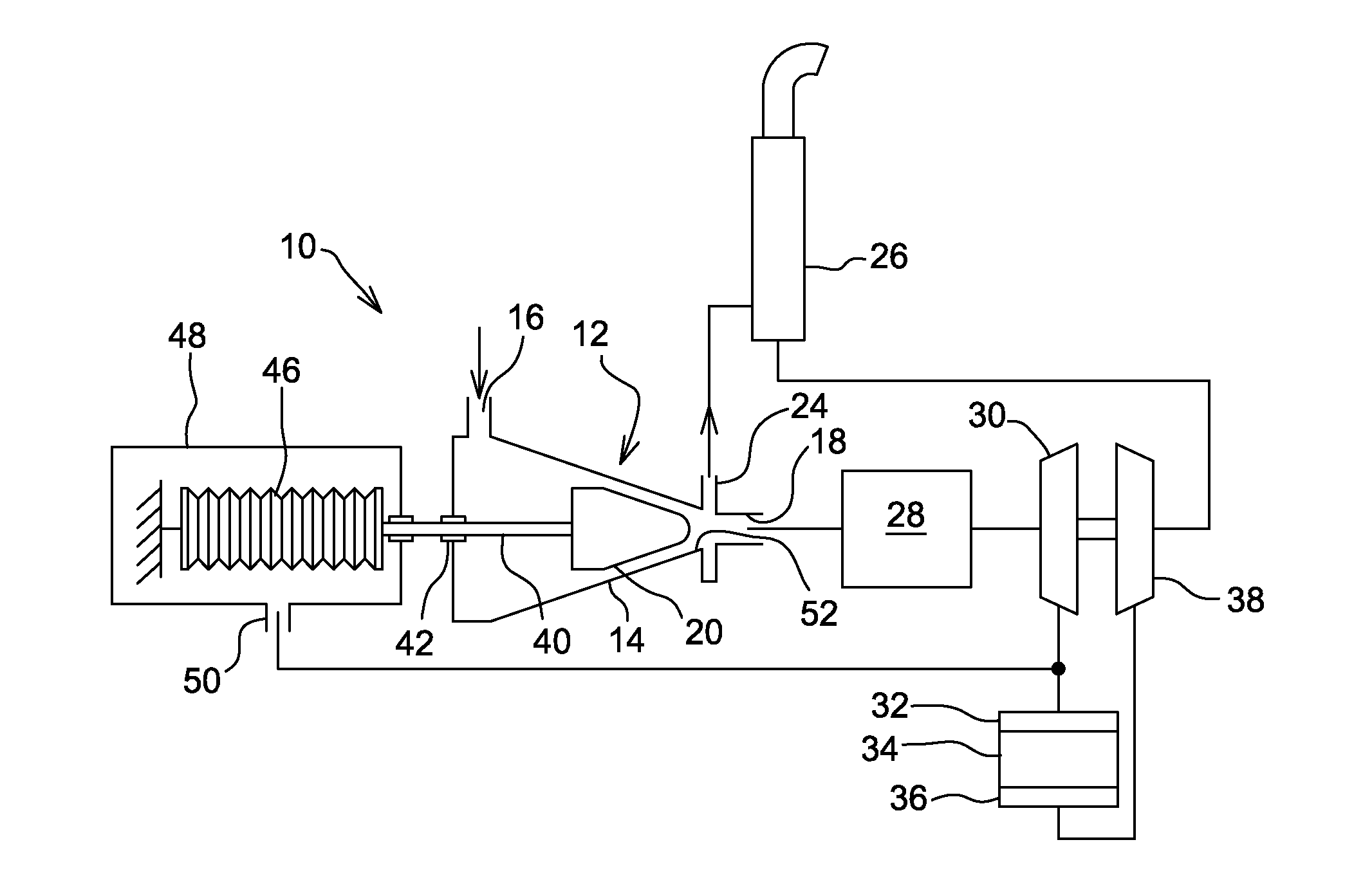

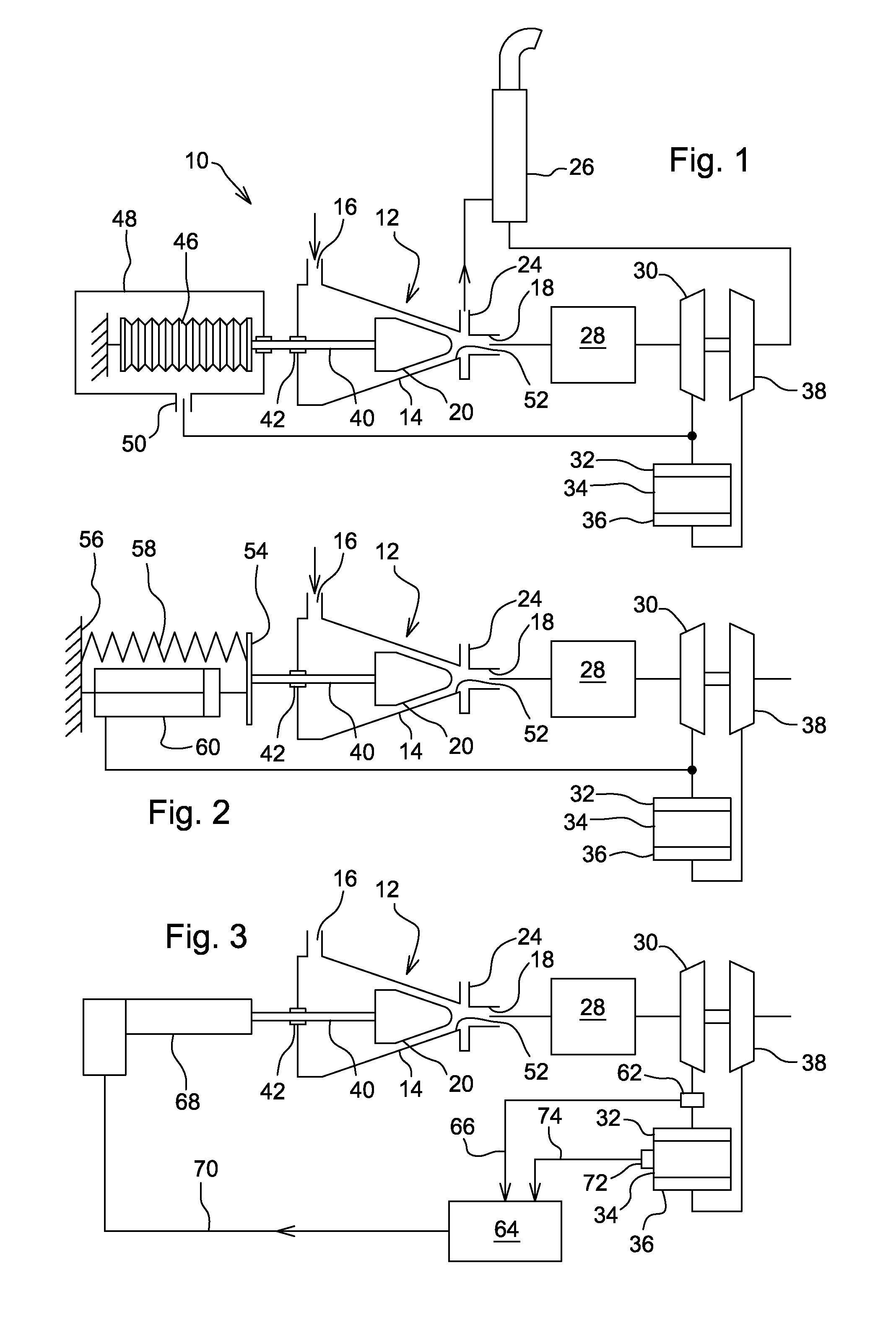

Engine idle speed and turbocharger speed control

ActiveUS8126632B2Improve power densityImprove fuel efficiencyElectrical controlInternal combustion piston enginesTurbochargerIdle speed

Various methods are described for controlling engine operation for an engine having a turbocharger and direct injection. One example method includes performing a first and second injection during a cylinder cycle, the first injection generating a lean combustion and the second injection exiting the cylinder unburned into the exhaust upstream of a turbine of the turbocharger.

Owner:FORD GLOBAL TECH LLC

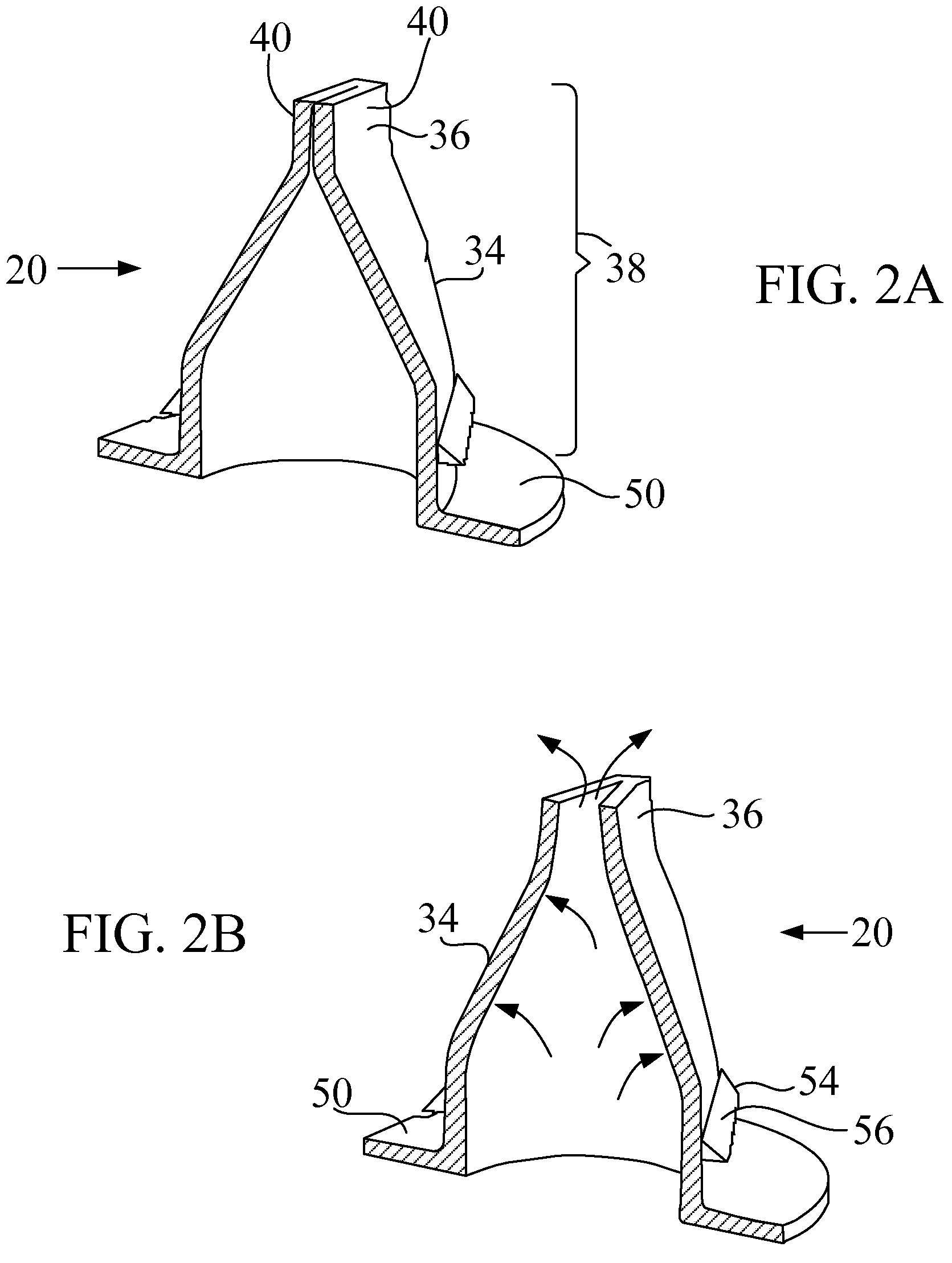

Air cleaner with snow bypass valve

ActiveUS8048179B2Clear obstructionEnough airCombination devicesAuxillary pretreatmentRam-air intakeAir filter

An air cleaner for a motor vehicle includes a housing having an air inlet opening, an air outlet opening, a secondary air inlet opening and at least one peripheral wall defining a chamber therein. An air filter element is provided and received into the chamber and positioned to separate the air inlet opening from the air outlet opening. A vacuum actuated valve is provided in the secondary air inlet opening of the housing and is in communication with a secondary air portion of a dirty face of the filter element. The valve configured and adapted to automatically change from a closed to an open state when a vacuum in the housing increases to a predetermined vacuum value and then to close when the vacuum decreases below the predetermined value, thereby permitting the vehicle engine to continue to operate even though airflow in the primary air intake may be obstructed.

Owner:MANN HUMMEL GMBH

Method for promoting sprouting of rosa multibracteata seeds

InactiveCN103988608AKeep moistEnough airSeed immunisationGerminating apparatusWarm waterSterile water

The invention discloses a method for promoting rosa multibracteata seeds to sprout. The method comprises the following steps including (1) rosa multibracteata fruit fermentation treatment; (2) seed drying in the air; (3) warm lamination: sphagna is sterilized in an autoclave sterilizer for 30 minutes, seeds are soaked for 24 hours in warm water and are mixed with the sterilized sphagna, meanwhile, sterile water is added, the sphagna mixed with the seeds is squeezed to a dry state by hand, the sphagna and the seeds are put into a reclosable bag, and the reclosable bag is placed into a 25 DEG C incubator for 8 to 16 weeks; (4) low-temperature lamination: the reclosable bag containing the sphagna and the seeds and subjected to warm lamination is placed into a 5 DEG C refrigerator, and the standing time is 4 to 16 weeks; and (5) seed sprouting. According to the method, measures of fruit fermentation, seed variable-temperature lamination and the like are adopted, the problems of low sprouting rate, long sprouting time and the like of the rosa multibracteata seeds are effectively solved, and the method has the advantages of simple process, low cost and the like. Through the implementation of the method, the sprouting rate is improved from 0 percent to 70 percents to 81.4 percents.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

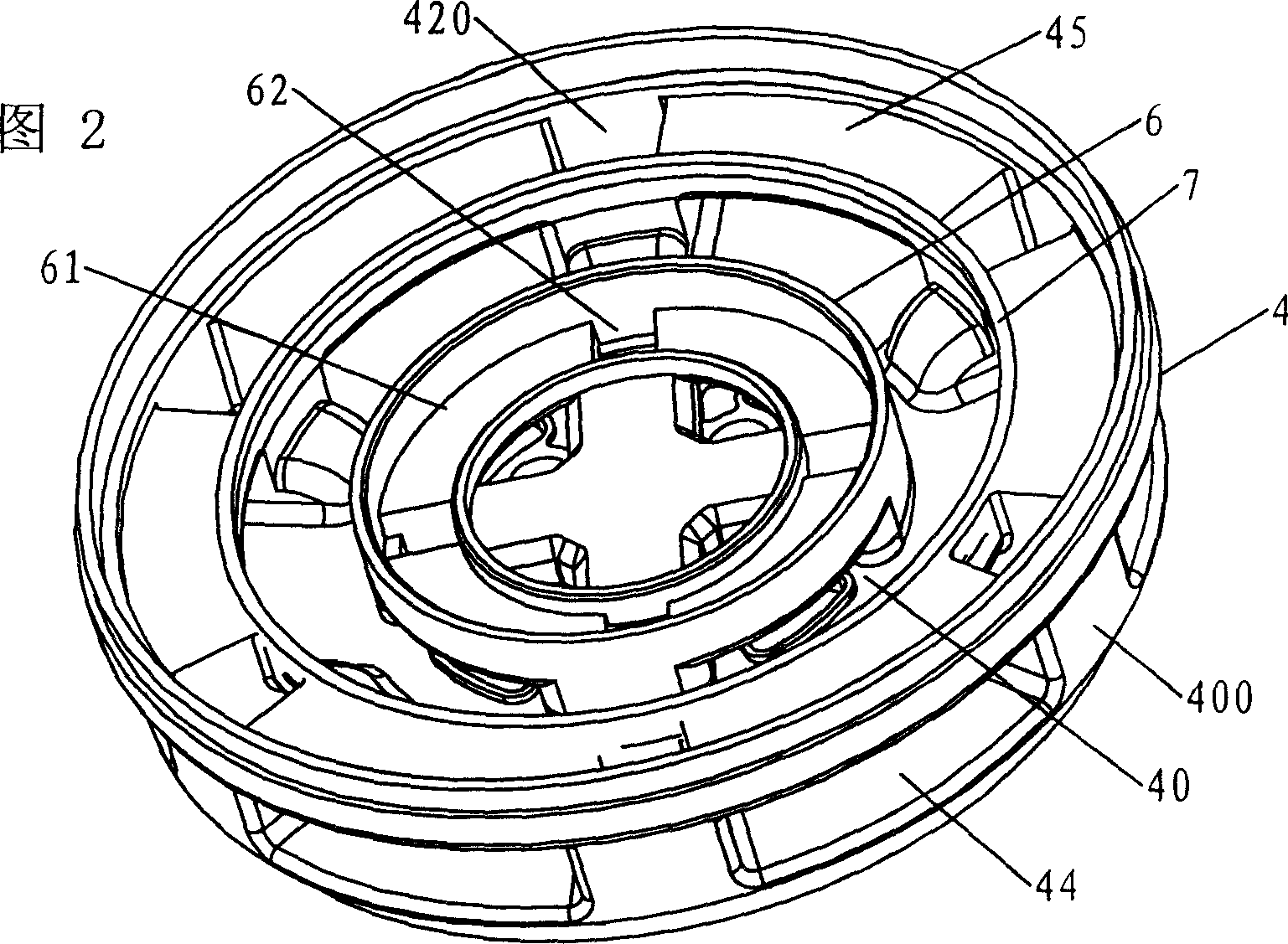

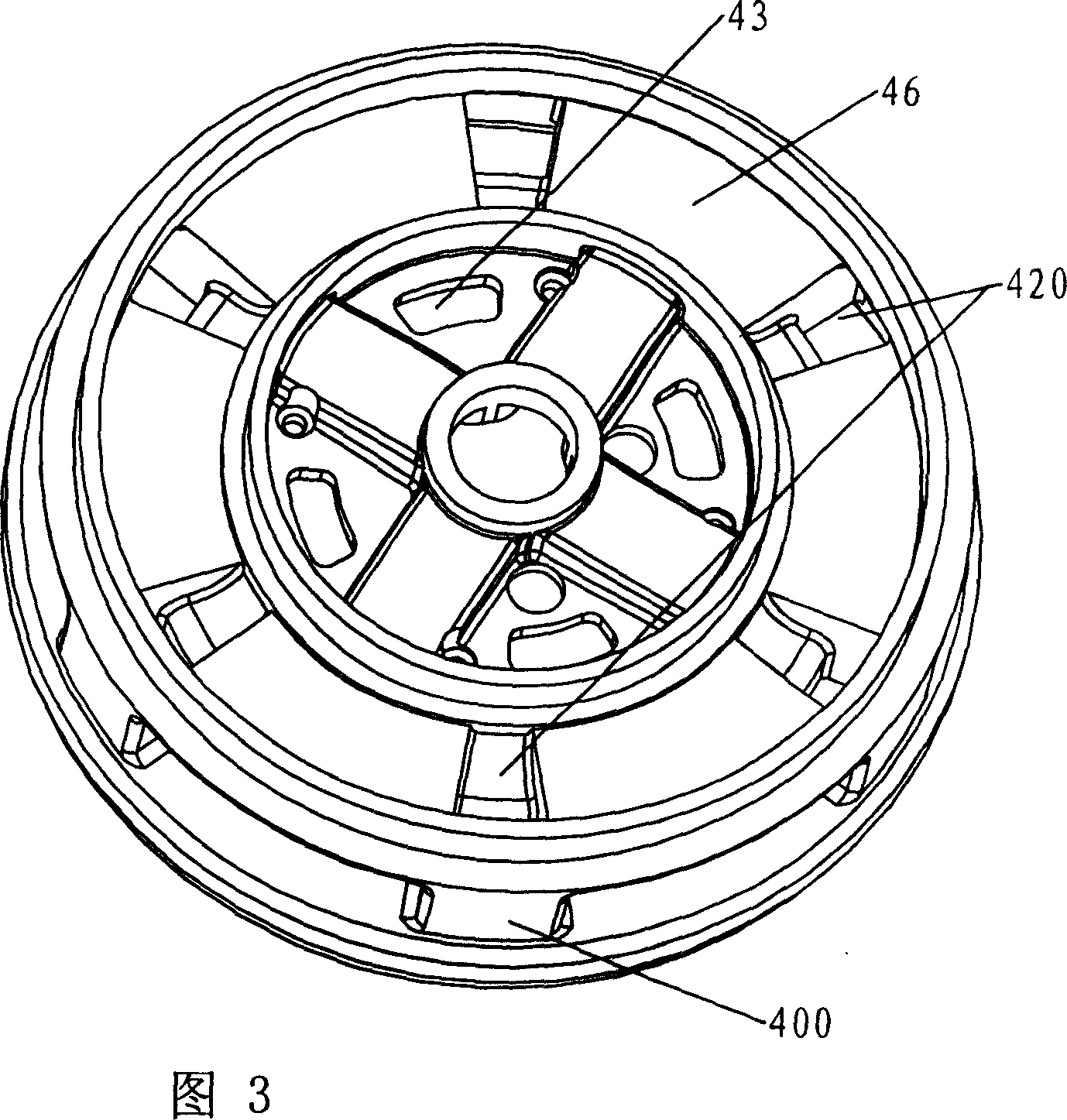

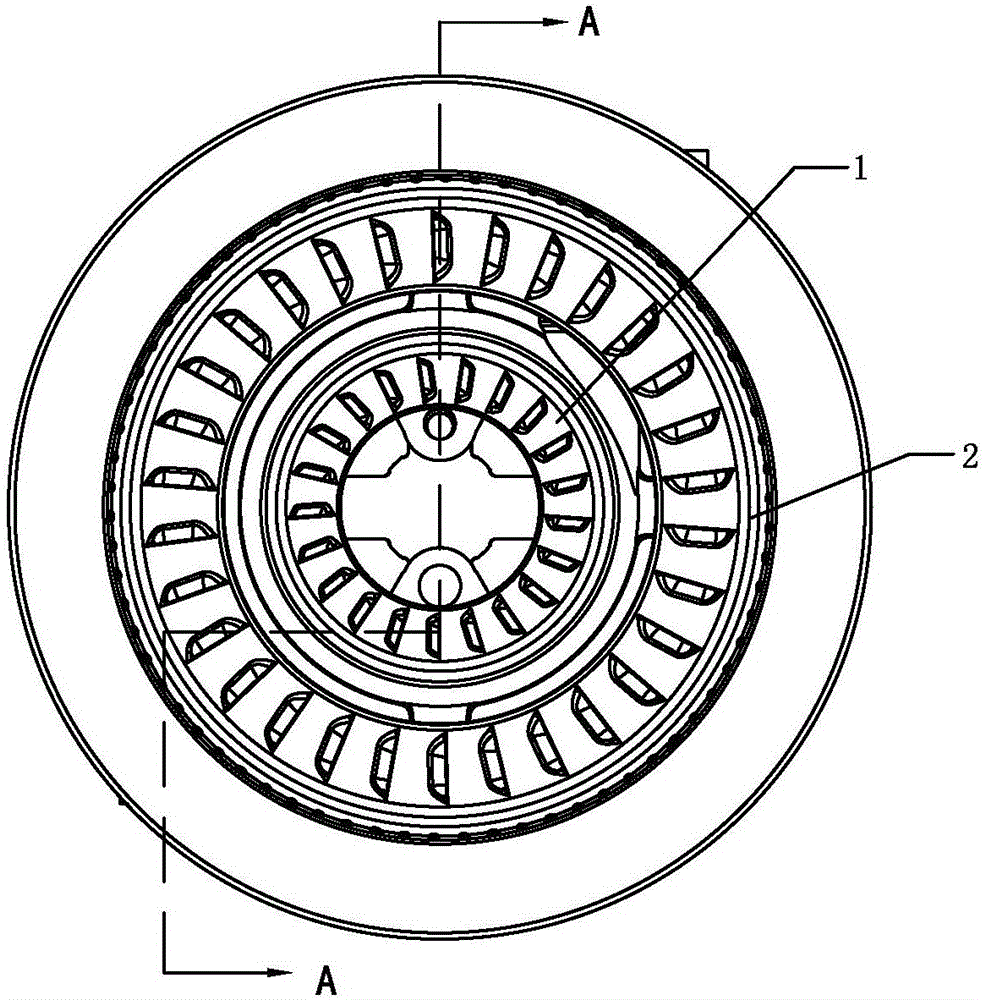

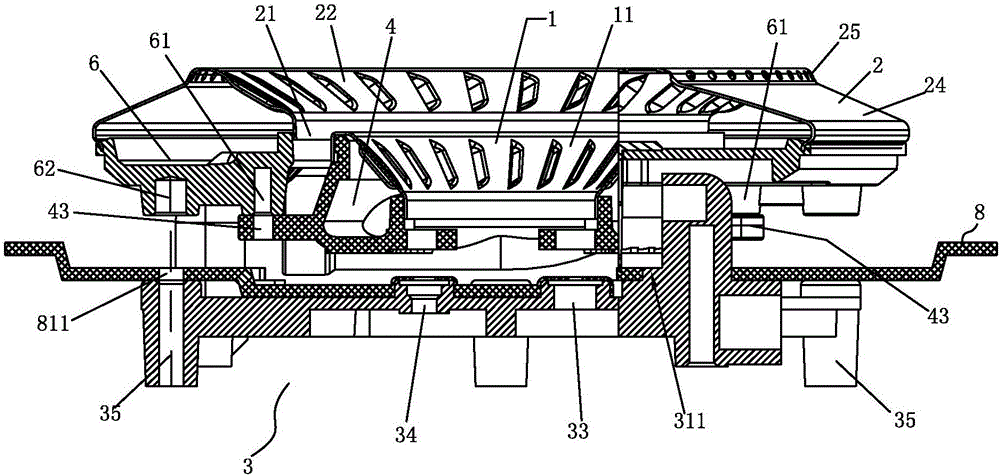

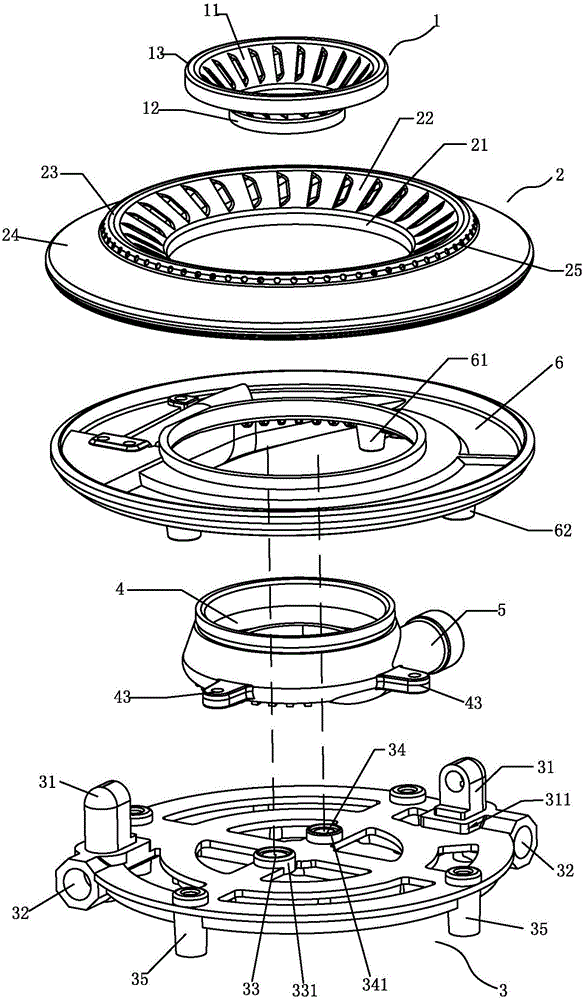

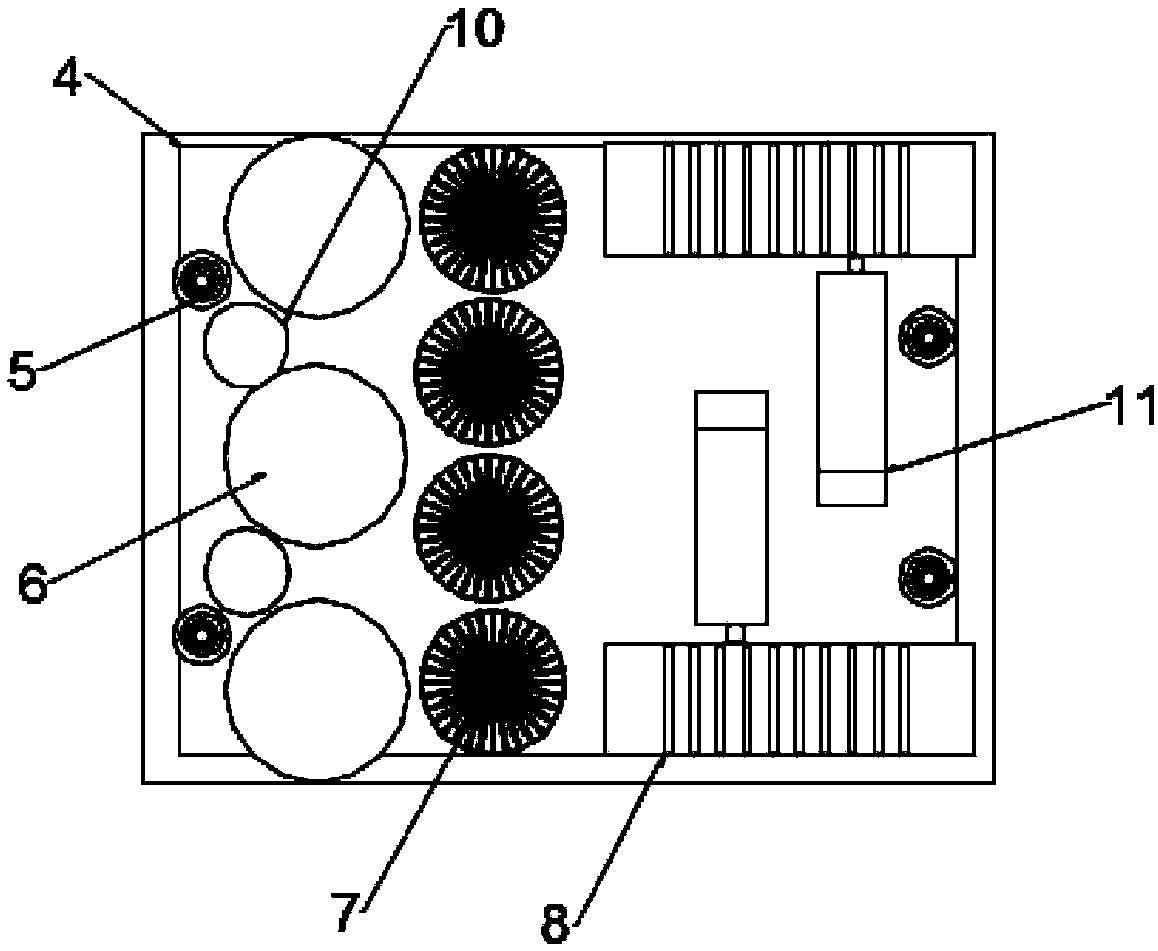

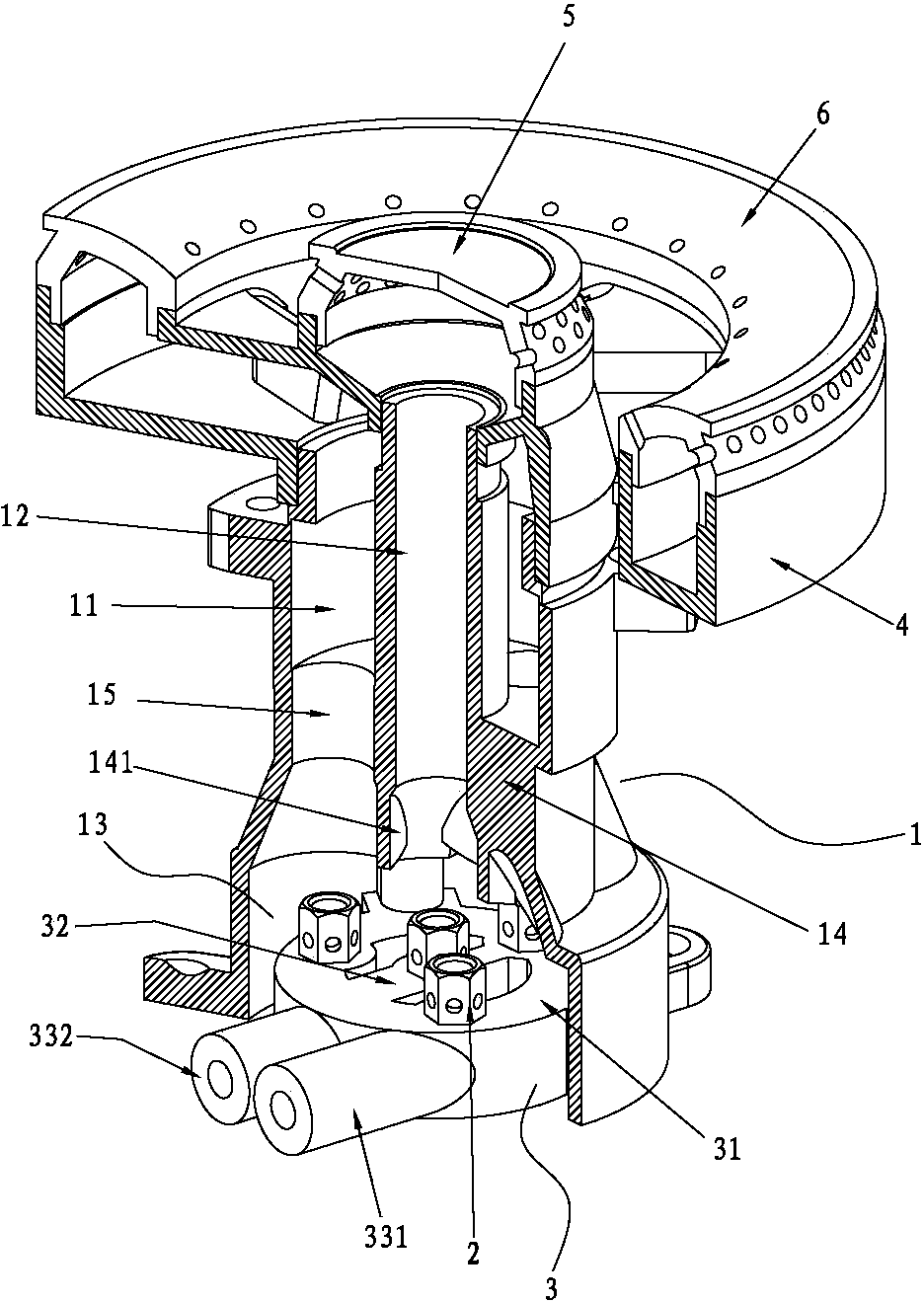

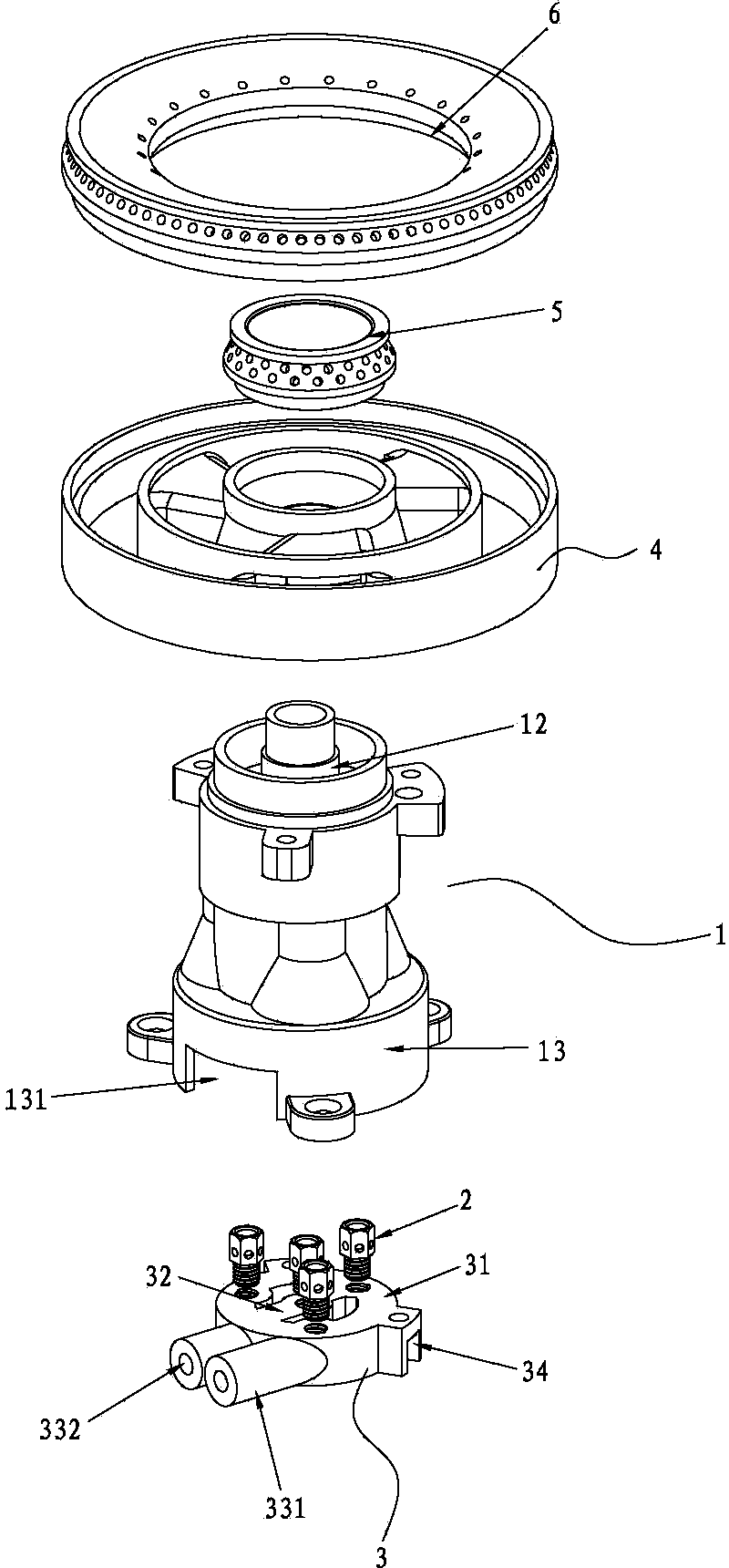

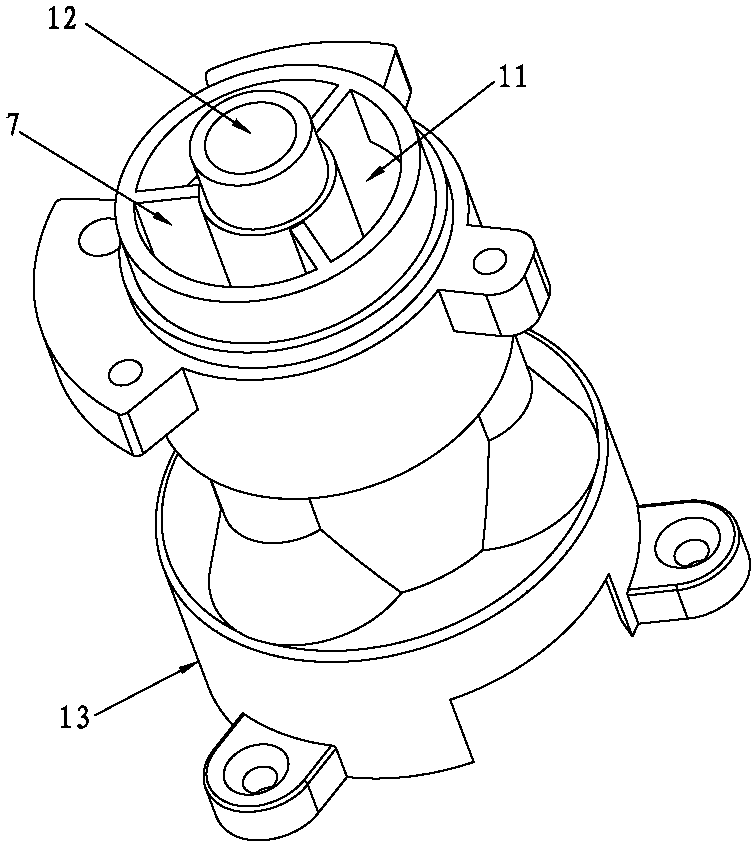

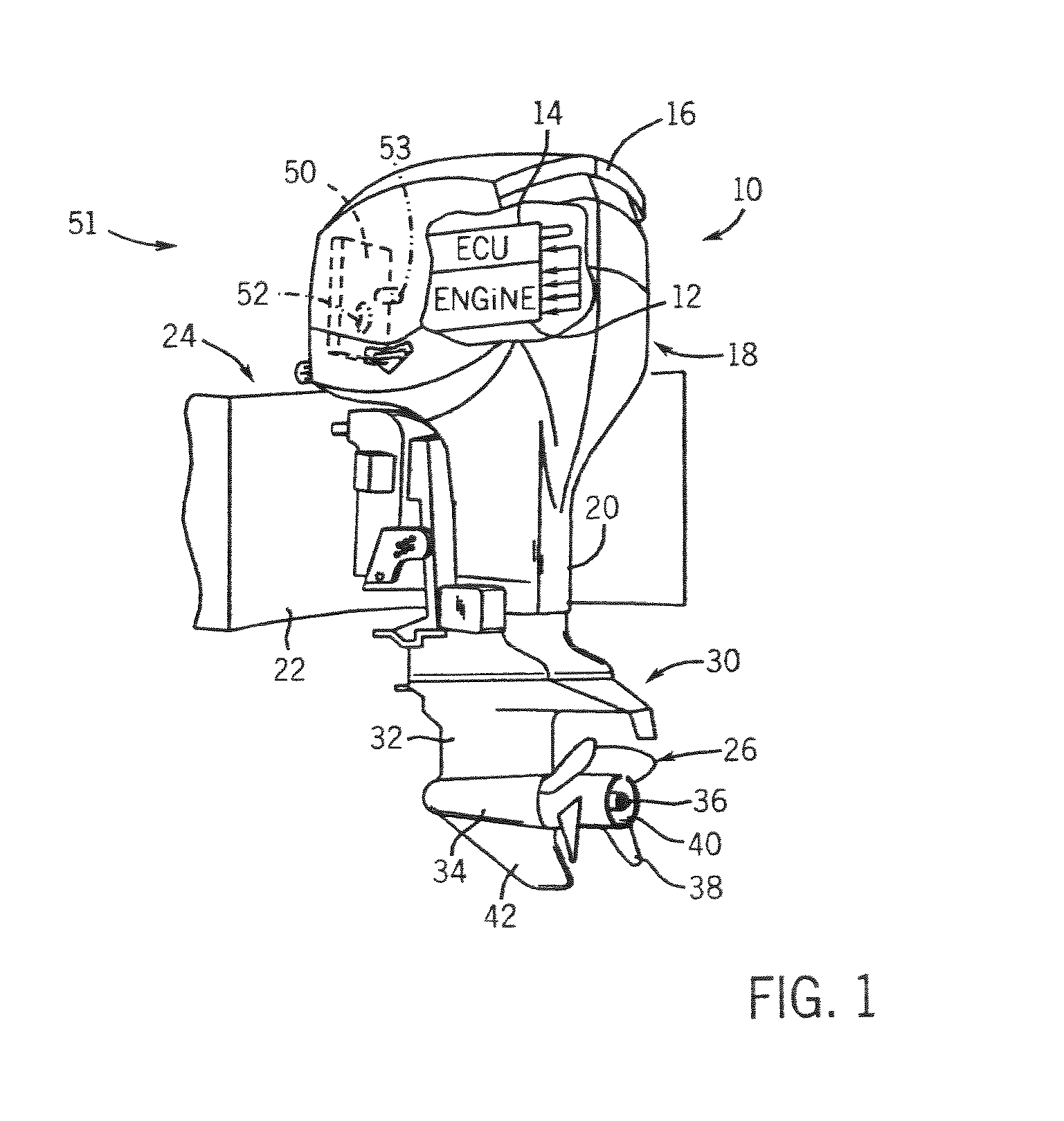

Complete top air inlet type kitchen range combustor and kitchen range

PendingCN106765083AEnough airImprove energy efficiency ratioDomestic stoves or rangesGaseous fuel burnerCombustorBusiness efficiency

The invention discloses a complete top air inlet type kitchen range combustor which comprises an inner fire cover and an outer fire cover and further comprises a seat frame, an inner ring gas mixing groove, an inner injection pipe, an outer ring gas mixing groove and an outer injection pipe. A connecting pillar is supported by a connecting seat. A screw penetrates a connecting hole in the connecting seat to be connected with the connecting pillar in a spiral manner. A gap exists between the inner ring gas mixing groove and the outer ring gas mixing groove, and an air gap exists between the bottoms of the inner ring gas mixing groove and the outer ring gas mixing groove and the seat frame. The inner injection pipe and the outer injection pipe are opposite to gas outlet holes of two gas outlet heads correspondingly. The fuel gas kitchen range comprises the combustor, a water bearing disc and a kitchen range bottom shell and is characterized in that the combustor further comprises the seat frame, the inner ring gas mixing groove, the inner injection pipe, the outer ring gas mixing groove, the injection pipe, the inner fire cover, the outer fire cover and the supporting connecting pillar. According to the combustor, complete top air inlet of primary air and secondary air of the kitchen range can be achieved, air is sufficient, and the energy efficiency ratio is high; and according to the stove, complete top air inlet is achieved, the defect of negative pressure is overcome, and the height of a bottom shell is reduced compared with that of a bottom plate shell in the prior art.

Owner:中山金木楠智能家居有限公司

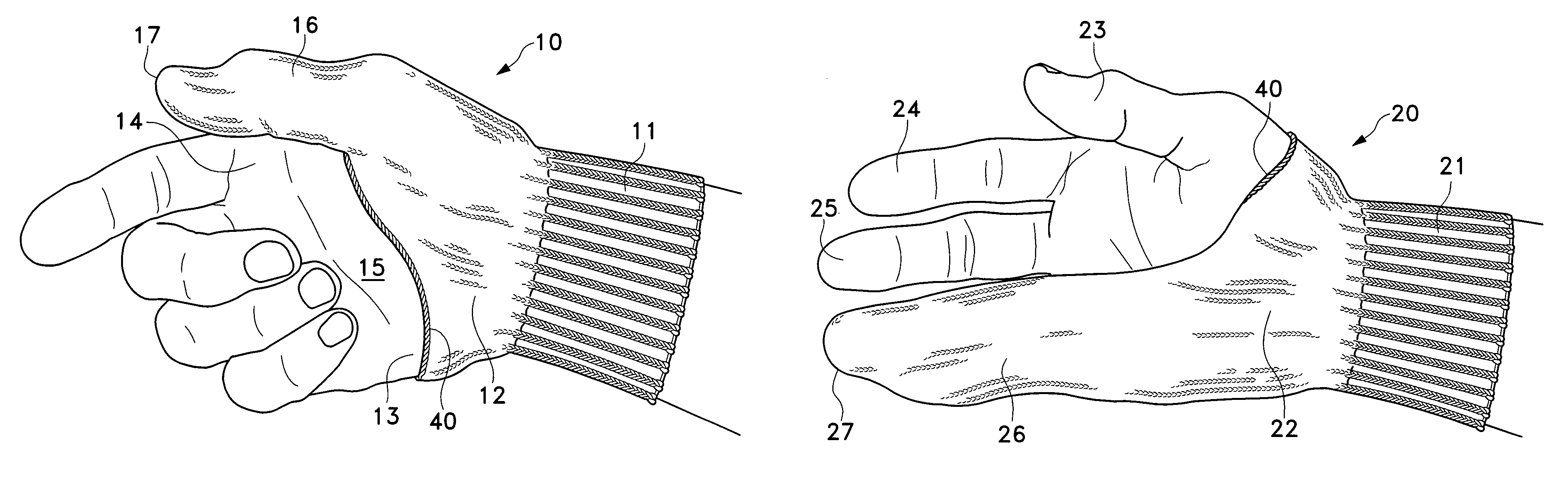

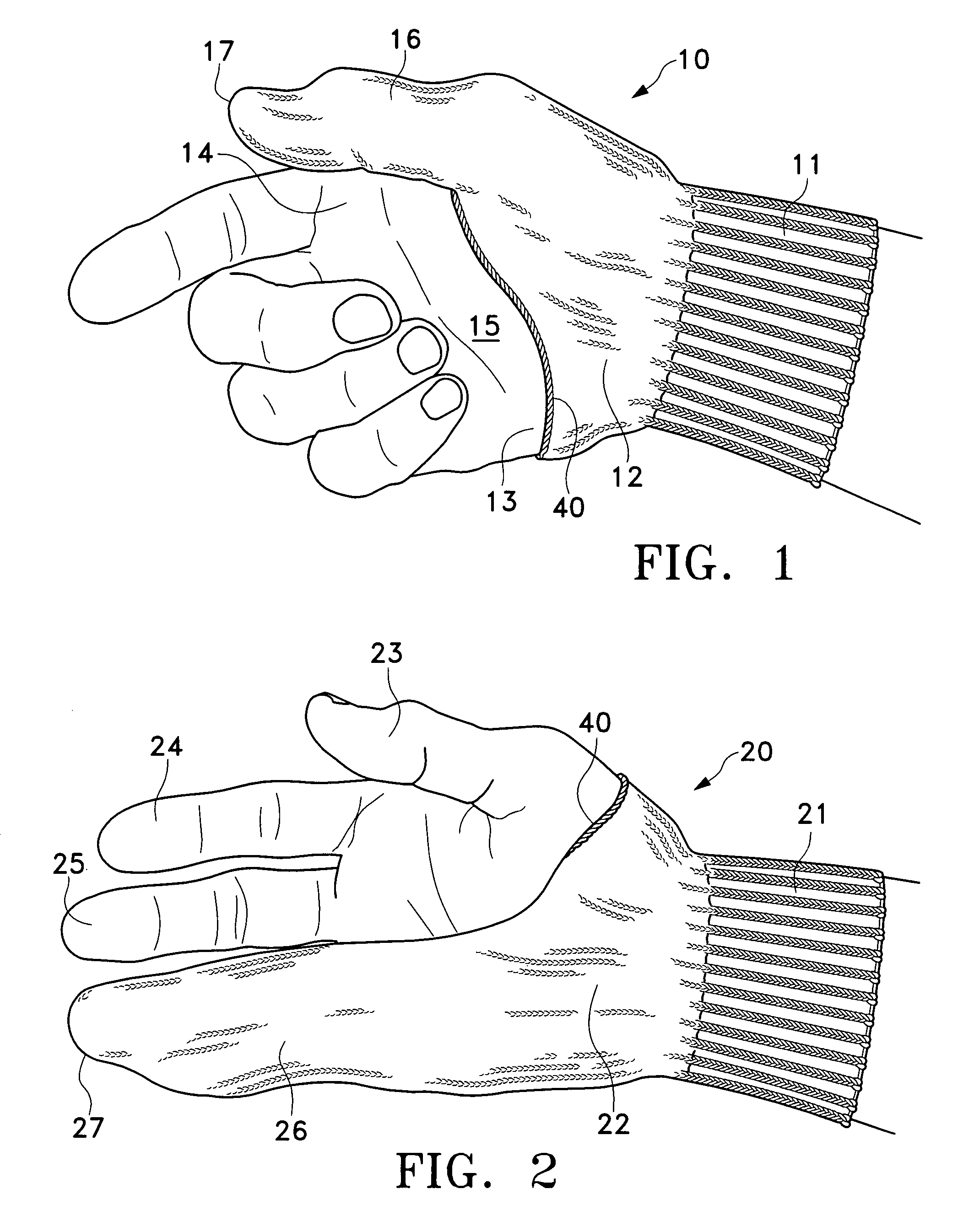

Finger sucking deterrent devise and method of use of same

InactiveUS7900636B1Unpleasant mouth feelingInhibition formationRestraining devicesGlovesFinger-stallEngineering

A device to deter finger sucking is a partial cover for the hand with at least one finger stall encompassing the finger or fingers usually sucked. The device can also have individual finger stalls, each accommodating one finger. The device has a ribbed cuff that is elastic so the child can put the device on and take it off himself. The device is made of a knitted fabric that is stretchable throughout. This characteristic makes it possible for the child to remove his finger or fingers from the one or more finger stalls and move the device upward on his arm and out of the way when eating, washing, for personal hygiene and certain school activities and thereafter quickly replace it on the hand with the finger or fingers in the one or more finger stalls. The child has complete control over its use. This device should be maintained on the hand or arm at all times except when bathing. The device can be colorful and decorated in a manner that is attractive to the child. The knitted fabric provides a dry unpleasant mouth feel and allows air to pass through the fibers so that no suction is attained during sucking. Without suction there is no satisfaction and the child is deterred from sucking his finger or fingers until he stops altogether.

Owner:NASTRO APRIL

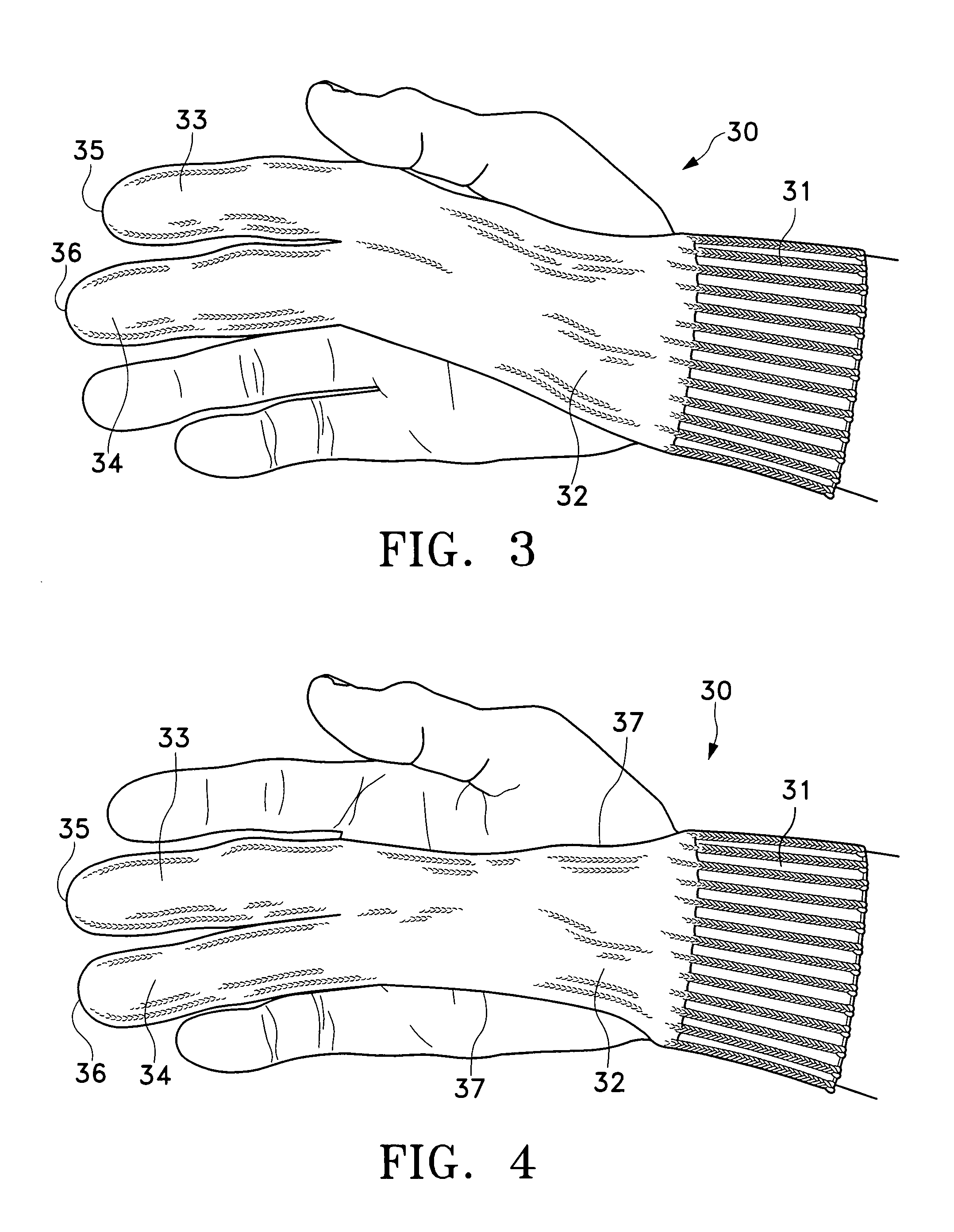

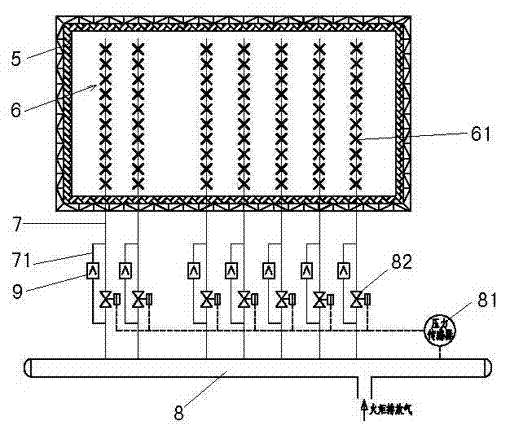

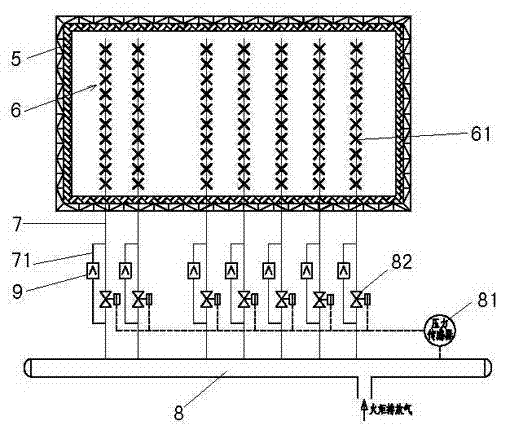

New large-capacity enclosed ground flare

InactiveCN102297417AGood technical effectFlexible partitionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

The invention discloses a new large-capacity enclosed ground flare, which includes a combustion chamber, a plurality of burners arranged in the combustion chamber, exhaust gas branch pipes connected with the plurality of burners, and an ignition control system; the exhaust gas The branch pipe is connected through the gas collecting main pipe; the characteristic is that the cross-section of the combustion chamber is rectangular, and the burners are arranged in rows in the combustion chamber. Since the combustion chamber is designed as a rectangular combustion chamber, it can be designed according to the shape of the site plot, reducing the floor space and saving land resources, so as to meet the requirements of multiple production devices or multiple factories sharing the torch system, thus adapting to various designs of processing capacity. The processing capacity of a single seat can reach 300t / h~1000t / h, far exceeding the processing capacity of the cylindrical combustion chamber. Combined with the arrangement of burners in rows and rows, the arrangement of burners is simpler, which is beneficial to simplify the hierarchical pipeline and control, facilitate inspection and maintenance, and ensure that each burner gets enough air to improve the combustion effect.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

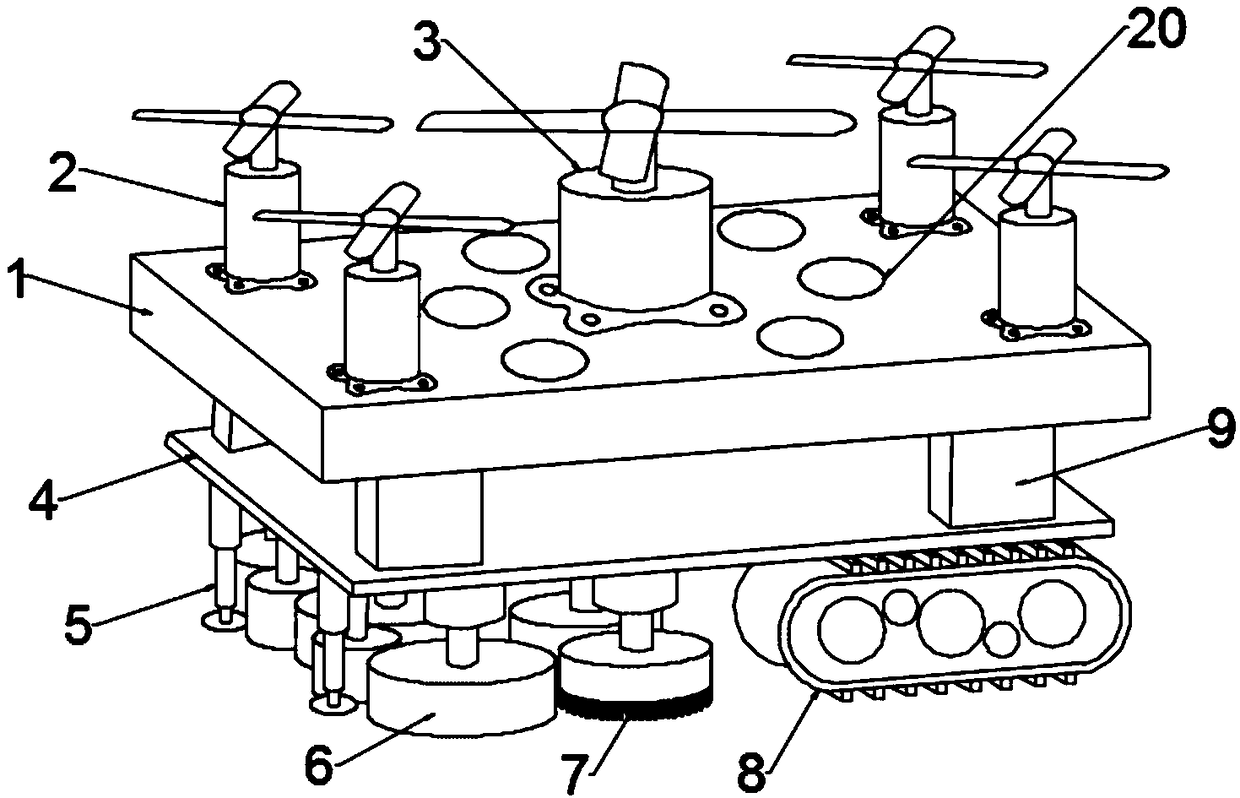

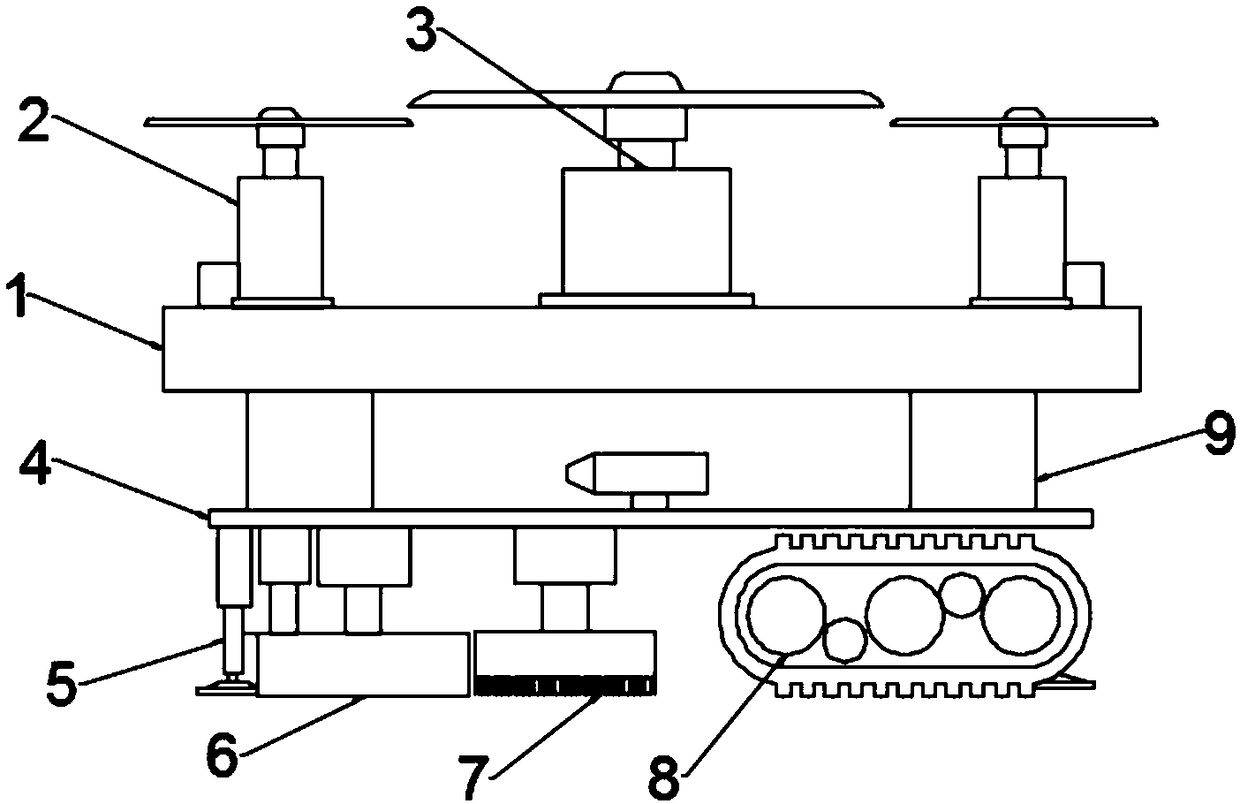

Intelligent outer wall cleaning machine

InactiveCN108798050AHeat dissipation fastSolve the problem of suction cup slippingBuilding repairsManipulatorRemote controlSteel frame

The invention discloses an intelligent outer wall cleaning machine which comprises a robot body, a controller and a winch. The intelligent outer wall cleaning machine is novel in design, gas exhaustedwhen a primary fan and secondary fans work generates counter-acting force on the robot body, and thus the robot body is attached to outer wall glass; when starting, the four secondary fans are responsible for preventing the robot body from rotating around a composite cable during operating; the primary fan starts to provide the stable pressure; formed through holes have the effect that enough airexists below the primary fan and the secondary fans, and meanwhile a fan circuit of the robot body is cooled quickly; the winch pulls the composite cable to drive the robot body to move to achieve washing, and the problems that as for a washing machine of a suction cup structure, a suction cup slides due to dust, and materials are wasted due to a fixed steel frame are effectively solved; a user can conduct remote control through a mobile client; and meanwhile through an arranged crawler, the defect that an ordinary washing machine cannot cross the floor is effectively overcome.

Owner:安徽特芯电子科技有限公司

Burner of direct-injection type cooker combustor

The invention provides a burner of a direct-injection type cooker combustor. The burner of the direct-injection type cooker combustor comprises a burner body and nozzles. An outer annular mixed gas cavity, a center gas inlet tube and a pre-mixed cavity are formed in the burner body. The outer annular mixed gas cavity is communicated with the pre-mixed cavity through a gas guiding hole formed in a partition plate. The lower end of the center gas inlet tube is fixedly connected with a center gas inlet hole in the partition plate. The gas guiding hole surrounds the center gas inlet hole. The lower end of the center gas inlet tube is communicated with the pre-mixed cavity. The nozzles are opposite to the center gas inlet hole and the gas guiding hole. The gas guiding hole is of a circular truncated cone shape. The nozzles are arranged on gas outlet holes formed in a nozzle base. The portion, located on the center of an annular gas inlet cavity, of a direct gas inlet tube is provided with gas outlet holes. The nozzle base is arranged in the pre-mixed cavity or the nozzle base is arranged below the pre-mixed cavity. Gas and air are mixed in advance in the pre-mixed cavity. Sufficient air is guaranteed. The gas and the air enter the outer annular mixed gas cavity to be further mixed after being compressed and released by the gas guiding hole, and therefore the purposes that the gas and the air are completely mixed, the gas is burned completely, and energy is saved are achieved.

Owner:ZHONGSHAN QIAO TAITAI KITCHEN & ELECTRICAL APPLIANCES CO LTD

Oil-containing sludge incineration system for pressurized fluidized bed and incineration treatment method

PendingCN110375310AHarmlessAchieve reductionFuel feedersIndirect carbon-dioxide mitigationCombustionHazardous substance

The invention discloses an oil-containing sludge incineration system for a pressurized fluidized bed and an incineration treatment method. The process comprises the following steps: introducing preheated pressurized air into a fluidized bed incinerator, adding oil-containing sludge into the incinerator to pressurize and combust under a fluidized state, and supplementing auxiliary fuels to keep a combustion state stable if combustion heat is insufficient; enabling high-temperature pressurized wet flue gas generated in the incinerator to preheat pressurized air for combustion of the fluidized bed incinerator, preliminarily cooling the pressurized air into medium-temperature pressurized wet flue gas; continuously performing dust-removal denitration treatment on the flue gas to obtain medium-temperature pressurized clean wet flue gas, and recycling separated fly ash; recycling sensible heat of the medium-temperature pressurized clean wet flue gas through a waste heat recycling system, andrealizing up-to-standard emission through treatment such as a follow-up decompression system and a dehumidifying system. Reduction, harmless and resource utilization as well as energy conservation andemission reduction are realized on the oil-containing sludge, so that combustion efficiency can be greatly improved, equipment unit area processing ability is improved, and emission of harmful substances in flue gas is reduced.

Owner:陕西正本环境工程有限公司

Animal carrier accessory

InactiveUS20090114688A1Not adversely affect operational stability and aerodynamicsSufficient head roomLuggage carriersLighting and heating apparatusIndividual animalElectrical and Electronics engineering

An animal carrier for mounting above the rear wheel of a cycle such as a motorcycle may be obtained by converting a motorcycle luggage carrier to an animal carrier. The motorcycle carrier mounts and bottom section may be equipped with a detachable top section equipped with extended sidewalls ported with ventilating ports and roofed canopy to protect the transported animal from the elements.

Owner:BEELER WILLIAM J

Vehicle alternator provided with brushes, brush holder, and slip rings

ActiveUS8193682B2Extended service lifeImprove performanceRotary current collectorCooling/ventillation arrangementAlternatorEngineering

Owner:DENSO CORP

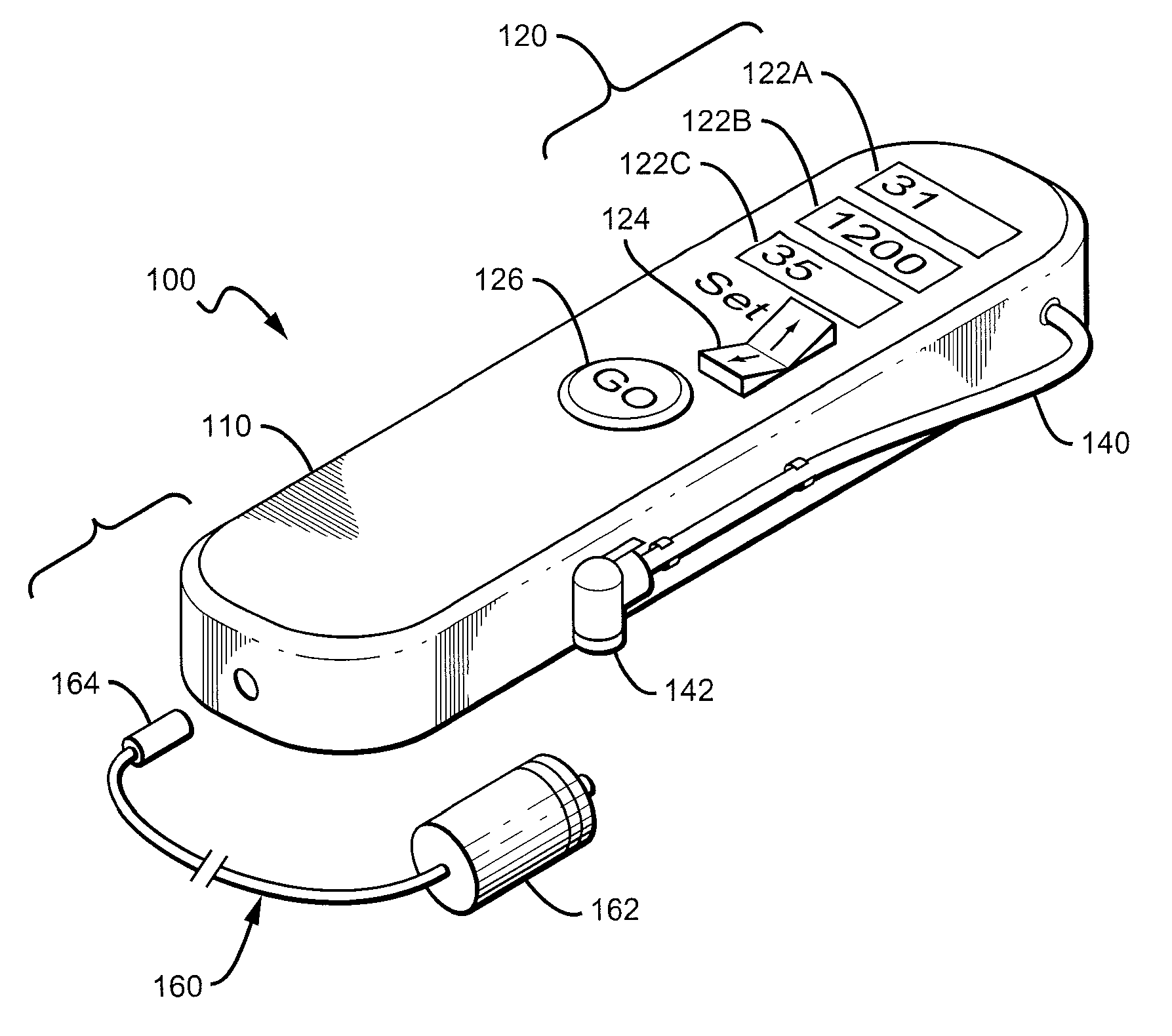

Air Compressor and Reservoir For Topping Off Low Pressure Tires

InactiveUS20090010774A1Considerable air pressureEnough airRotary piston pumpsRotary piston liquid enginesControlled releaseEngineering

A small volume capacity pump is used to pressurize a small air tank, and the tank is used to top off pressure in an automobile tire or other receptacle. The tank preferably has a reservoir measuring 200-300 cc, and is pressurized to at least 500 psi. The pump preferably has a low volume capacity of 200-300 cc / min, thus requiring at least 15-45 minutes to refill the reservoir to its full operating pressure when empty. A pump can be operated by a DC or AC motor, which can be housed along with, or separately, from the pump. Especially preferred embodiments also include an automatic pressure regulator that can be set to deliver a desired pressure to a receiving device, and a trigger that controls release of air from the tank to the regulator.

Owner:FISH ROBERT D

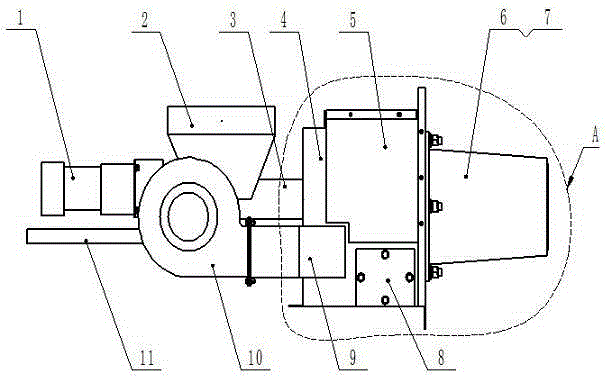

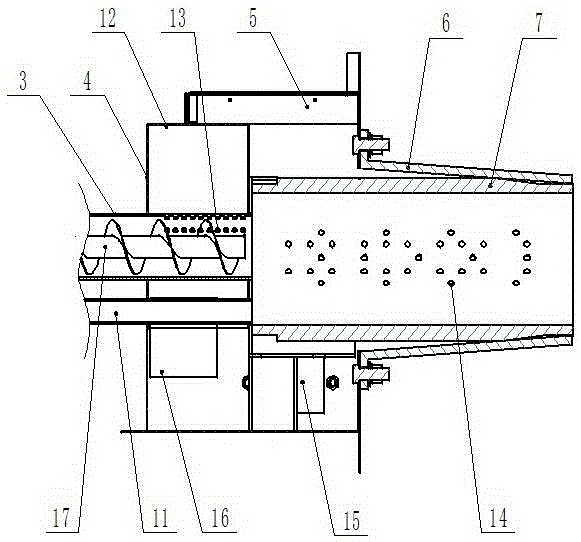

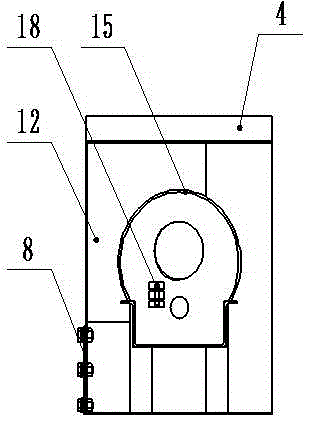

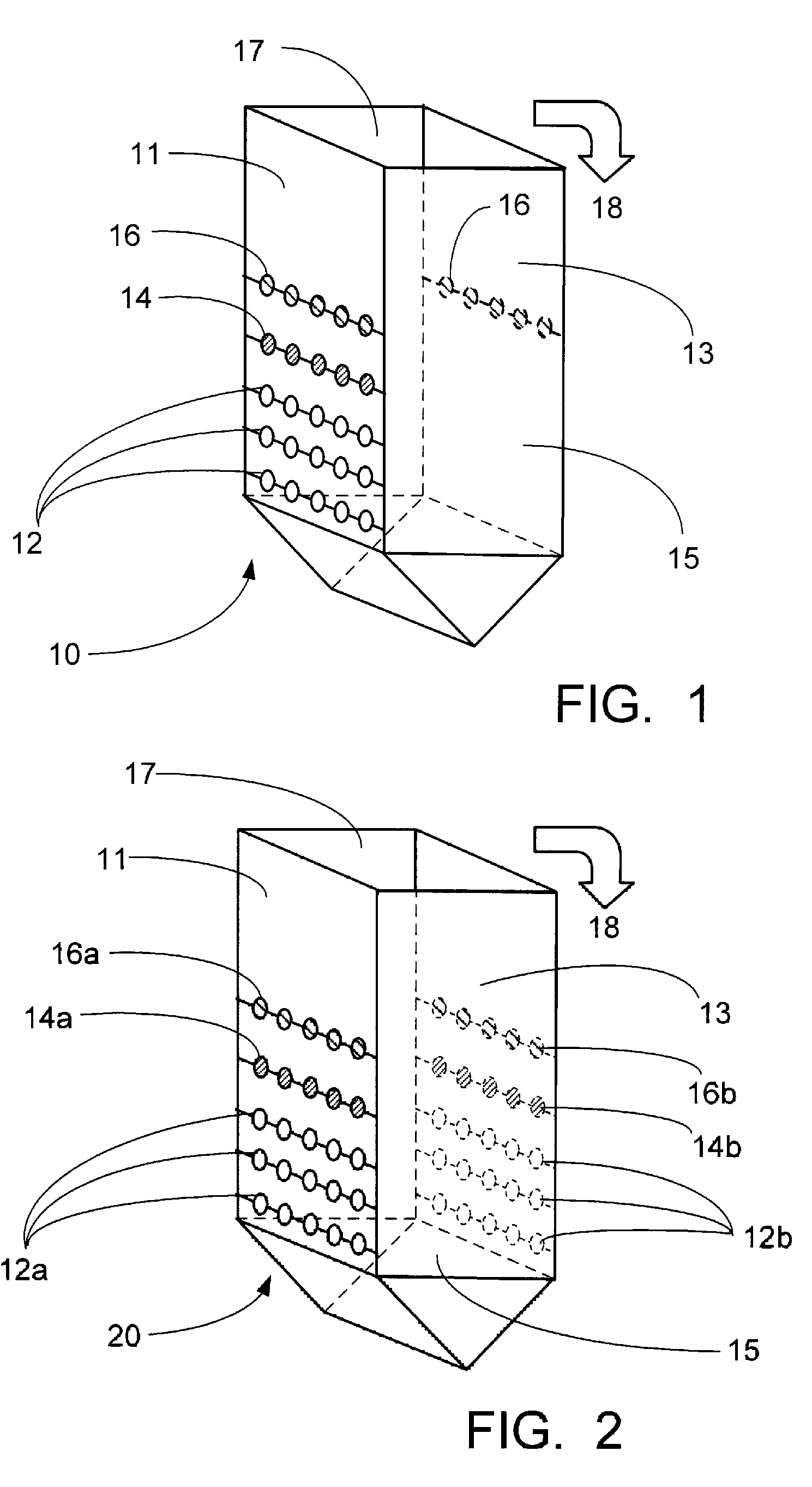

Biomass particle combustor

InactiveCN105240840ANo burning phenomenonFully dispersedSolid fuel combustionBlast-producing apparatusCombustorBiomass particle

The invention provides a biomass particle combustor. The biomass particle combustor comprises feeding equipment, combustion equipment and blast air supply equipment, wherein the feeding equipment comprises a material pipe; the combustion equipment comprises an inner fire outlet pipe and an outlet fire guide pipe; the blast air supply equipment comprises a blast pipe, an outer air box and an inner air box; the inner air box is arranged inside the outer air box, and the blast pipe is communicated with the outer air box and the inner air box; the material pipe penetrates through the inner air box to be communicated with the inner fire outlet pipe; the inner fire outlet pipe is arranged on the outer wall of the inner air box and penetrates through the outer air box, and vent holes are formed in the inner fire outlet pipe; the outlet fire guide pipe is fixed to the outside of the outer air box to sleeve the part, outside the outer air box, of the inner fire outlet pipe, and a gap is reserved between the outlet fire guide pipe and the inner fire outlet pipe and communicated with the outer air box. The biomass particle combustor is reasonable in structural design, low in cost and high in combustion efficiency.

Owner:广西节得乐生物质能源科技有限公司

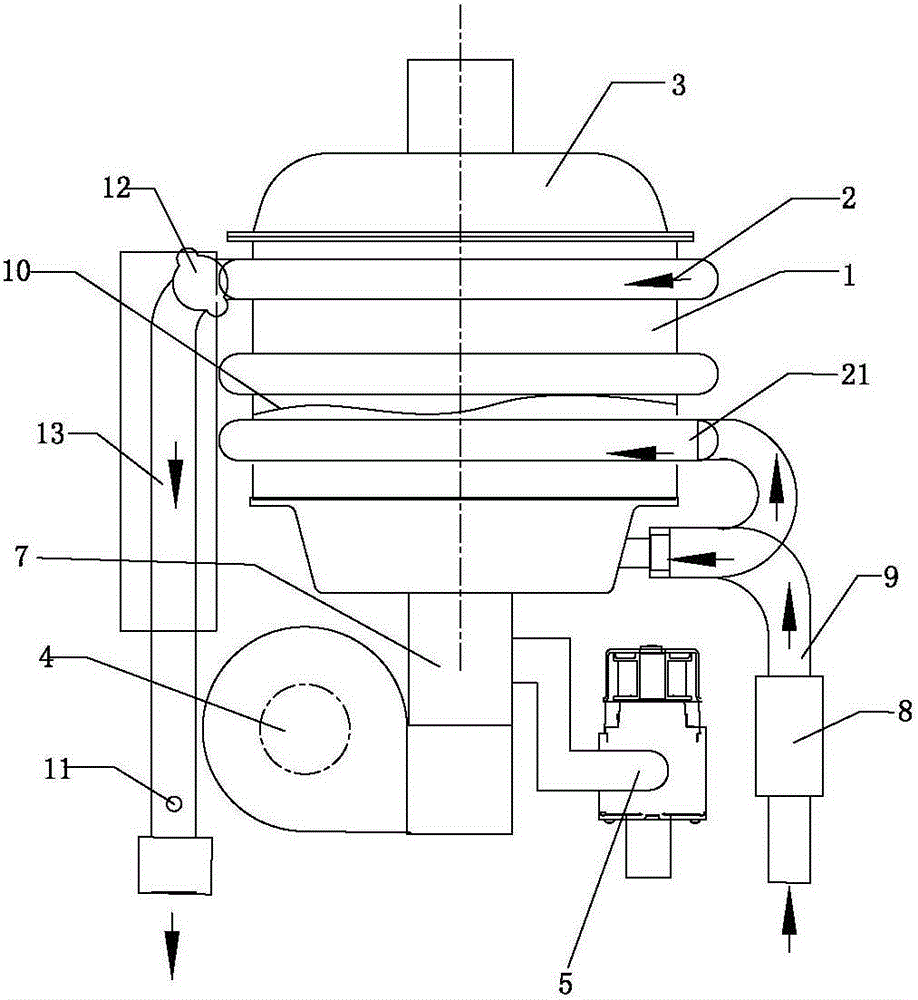

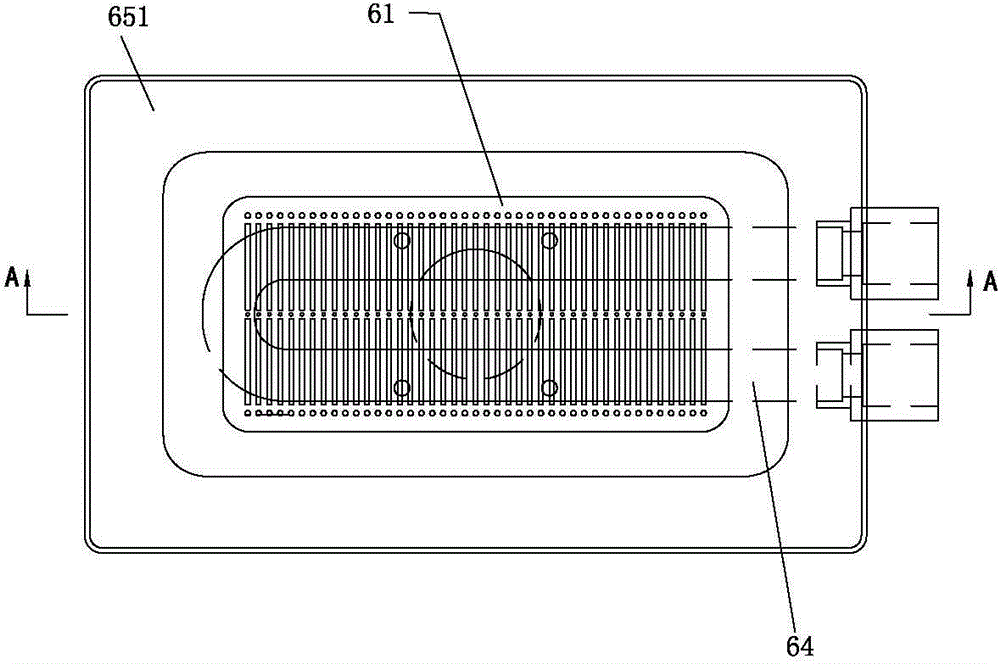

Water-cooled full-premixing gas water heater

The invention discloses a water-cooled full-premixing gas water heater. The water-cooled full-premixing gas water heater comprises a main heat exchanger, a cylindrical heat exchange coil pipe, a burner, a fume collecting hood and a main controller. The main heat exchanger is arranged on the upper portion of the cylindrical heat exchange coil pipe. The water-cooled full-premixing gas water heater further comprises a draught fan and a gas proportional valve. A gas mixing pipe is arranged at a gas inlet in a bottom plate of a burner base. The gas inlet end of the gas proportional valve is communicated with a gas source. The gas outlet end of the gas proportional valve is communicated with a radial gas inlet of the gas mixing pipe. The air outlet end of the draught fan is communicated with the axial lower end of the gas mixing pipe. A preheating heat exchanger is communicated with the heat exchange coil pipe and also communicated with a water source. By the adoption of the structure, cold water is preheated in the water-cooled burner through the preheating heat exchanger, heat energy is fully utilized on one hand, and it is guaranteed that flames are stable on the other hand; the cold water preheated through the preheating heat exchanger then enters the main heat exchanger, heat energy is fully utilized, and the purpose of saving energy is realized. Through the arrangement of the draught fan, it is guaranteed that primary air is sufficient, the primary air and fuel gas are fully premixed, the fuel gas is fully burnt, and energy is saved.

Owner:ZHONGSHAN CITY HENG YUE ELECTRICAL APPLIANCE CO LTD

Stevia two-section floating plate cutting seedling culture method

InactiveCN106171907APromote photosynthesisPromote absorptionAgriculture gas emission reductionCultivating equipmentsSeedlingCulture plates

The invention discloses a stevia two-section floating plate cutting seedling culture method. Floating plates are used for stevia cutting seedling culture; one floating plate seedling culture plate water pool is arranged in the tree shade, and the other floating plate seedling culture plate water pool is arranged in the sunshine; firstly, the stem sections of the stevia are cut in the floating seedling culture plate in the tree shade; after the rooting and survival, the stem sections and the floating plate are jointly transferred into a sunshine water pool for culture and seedling strengthening. The seedling culture method has the advantages that the cutting survival rate can be improved; the strengthening seedling can be cultured; meanwhile, the seedling culture management work quantity can be reduced; the work efficiency is improved.

Owner:张玉玲

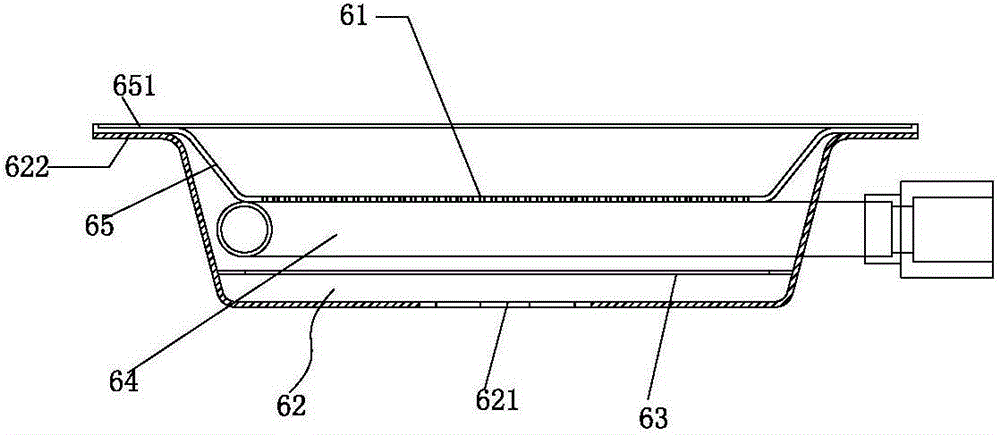

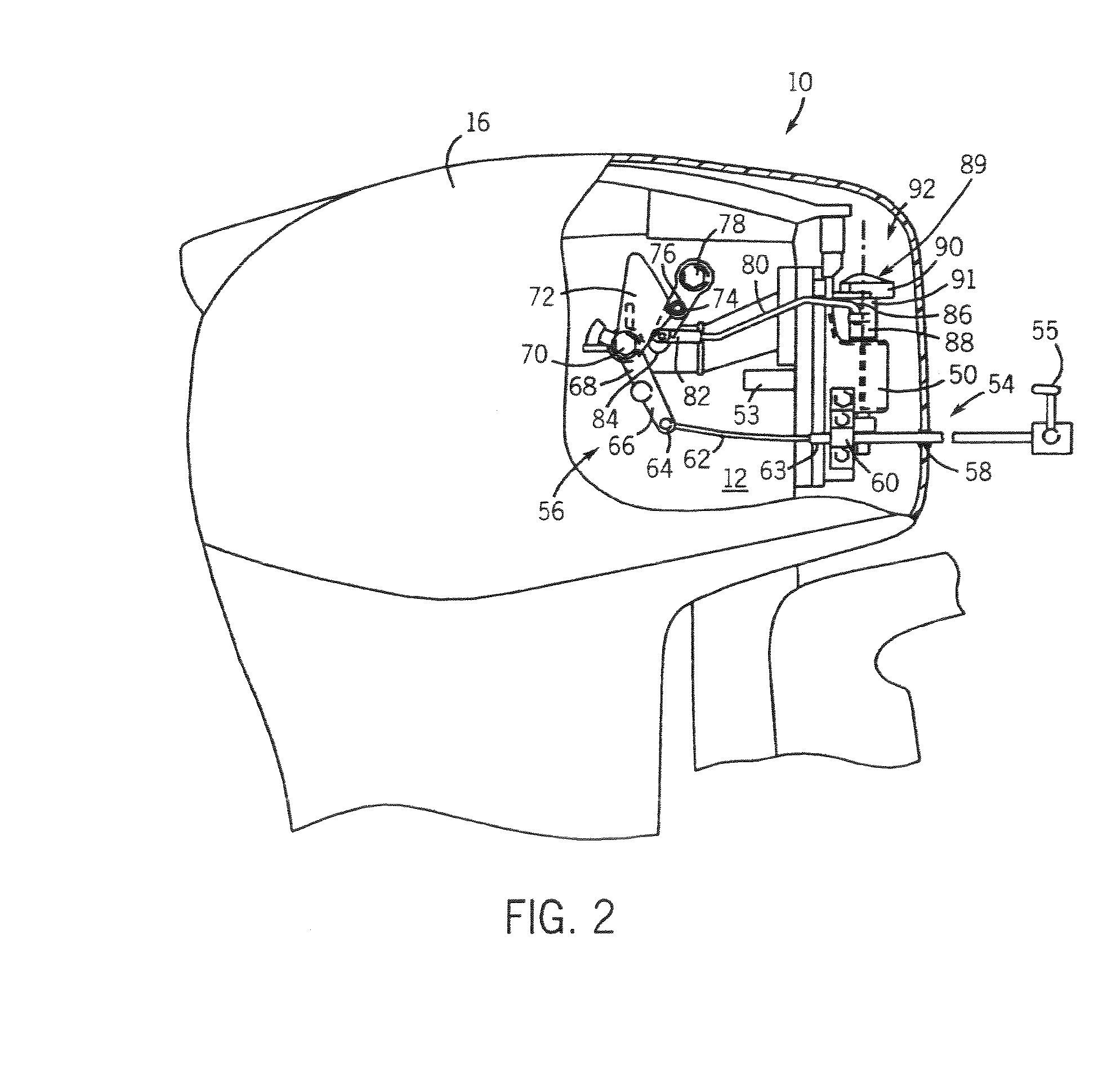

Throttle assembly having deadband linkage

ActiveUS7000591B1Minimizes noise emissionMinimize noise travelSpeed sensing governorsMachines/enginesExternal combustion engineMonobloc engine

An apparatus and method for adjusting a throttle plate of a throttle assembly of an internal combustion engine is disclosed. A throttle linkage mechanically connects a throttle actuator to the throttle assembly with a deadband therebetween. The deadband allows the throttle plate to remain in a closed position during initial movement of the throttle actuator and initial acceleration, thereby reducing overall engine noise.

Owner:BRP US

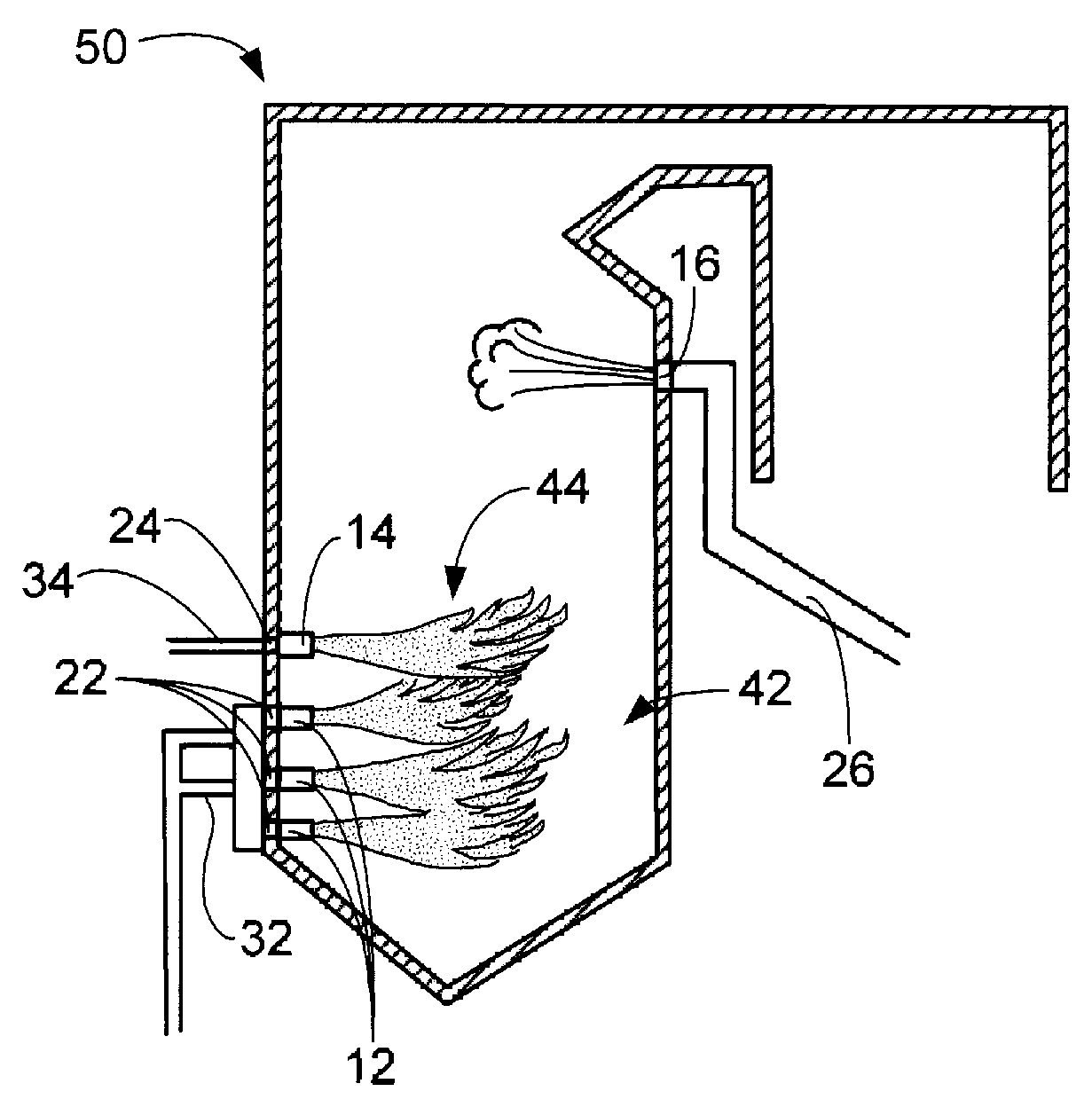

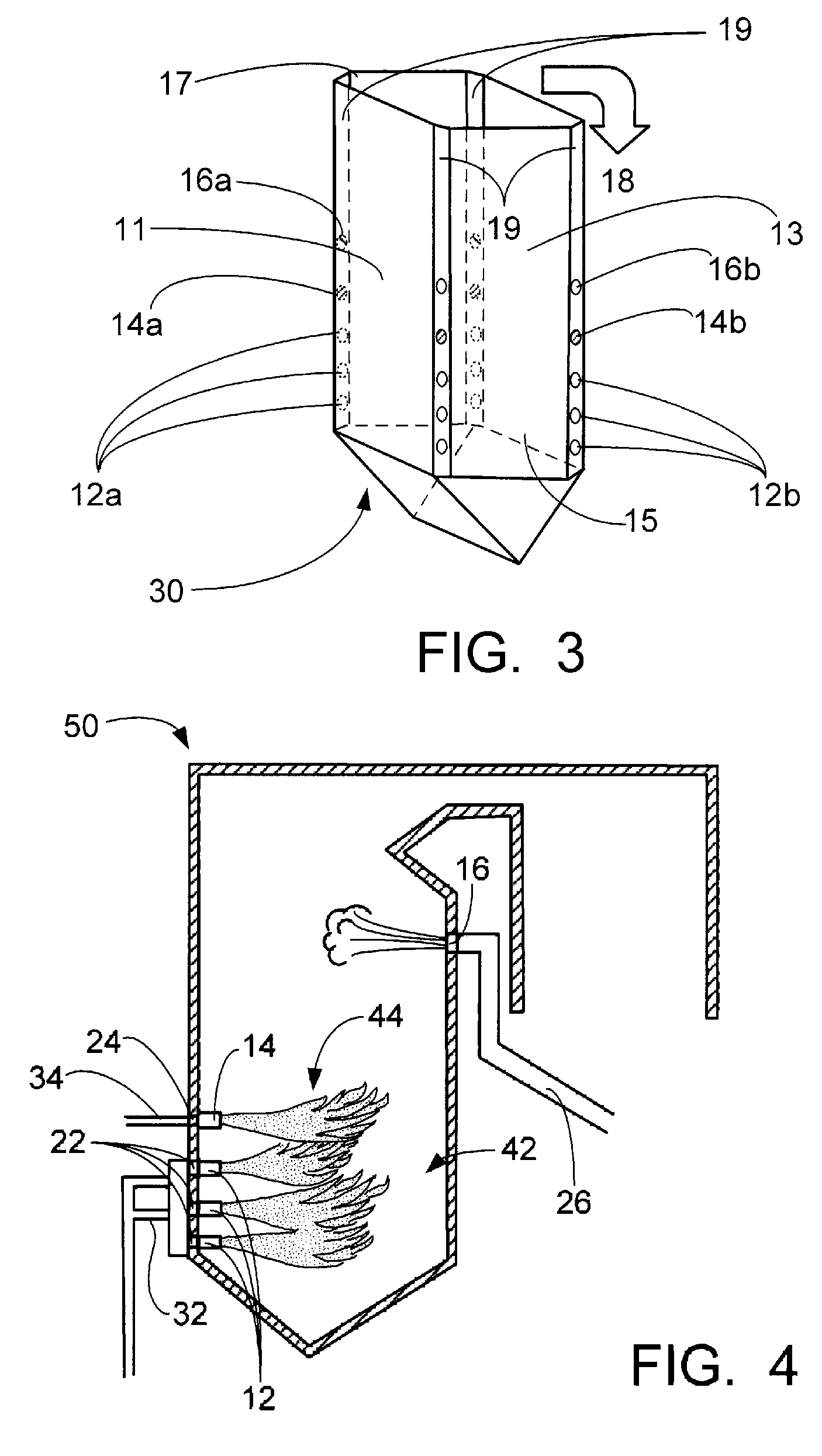

Combustion System and Process

InactiveUS20090084294A1Eliminate needReduce formationPilot flame ignitersIndirect carbon-dioxide mitigationCombustion systemPower station

A method and apparatus for reducing NOx emissions in a coal burning furnace of a power plant without utilizing techniques downstream of the furnace, such as SCR and SNCR, is provided. In a primary combustion zone, a fuel is combusted in the presence of a first oxidant gas comprised substantially of N2, to produce a first effluent gas that include one or more NOx species. Downstream a re-burn zone is operated in a sub-stoichiometric manner, combusting a second fuel in presence of the first effluent gas and a second oxidant wherein the second oxidant gas comprises a stream of oxygen. The effluent gas from the re-burn zone is introduced to overfire airflow so as to establish a super-stoichiometric zone prior to discharged from the furnace.

Owner:BABCOCK & WILCOX POWER GENERATION GRP INC

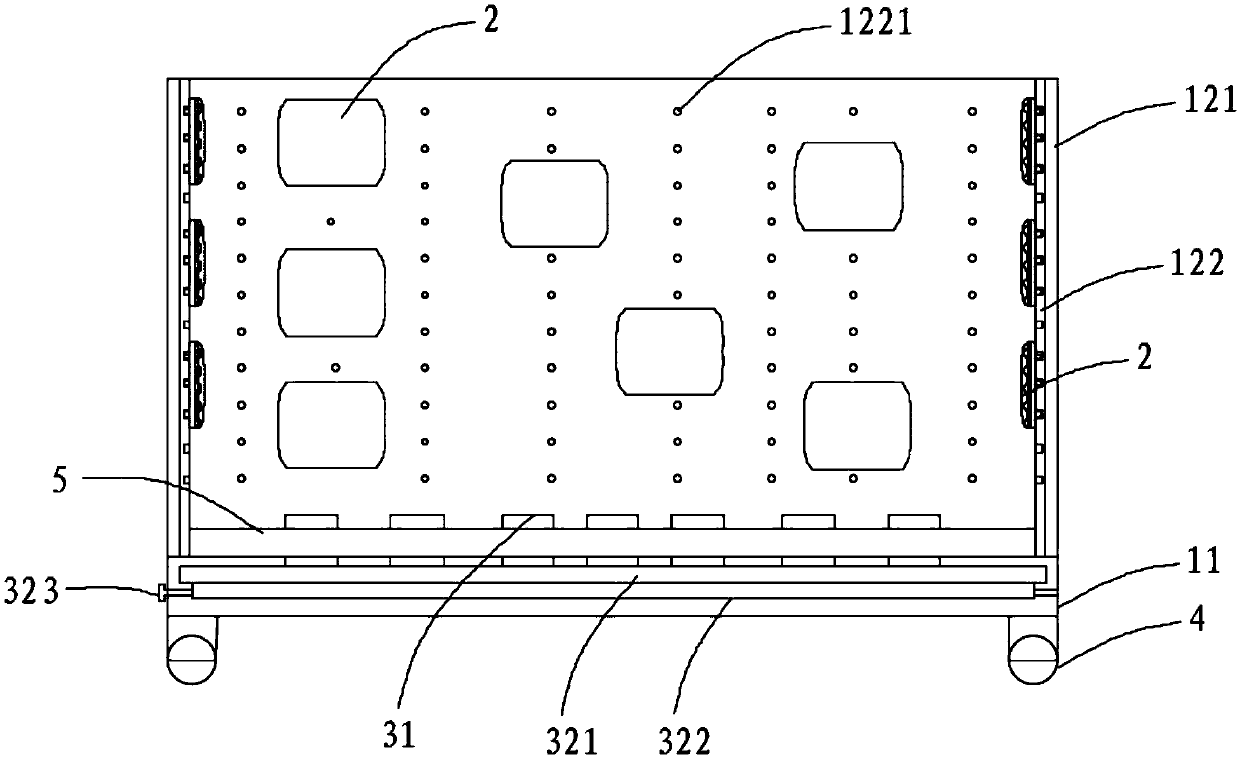

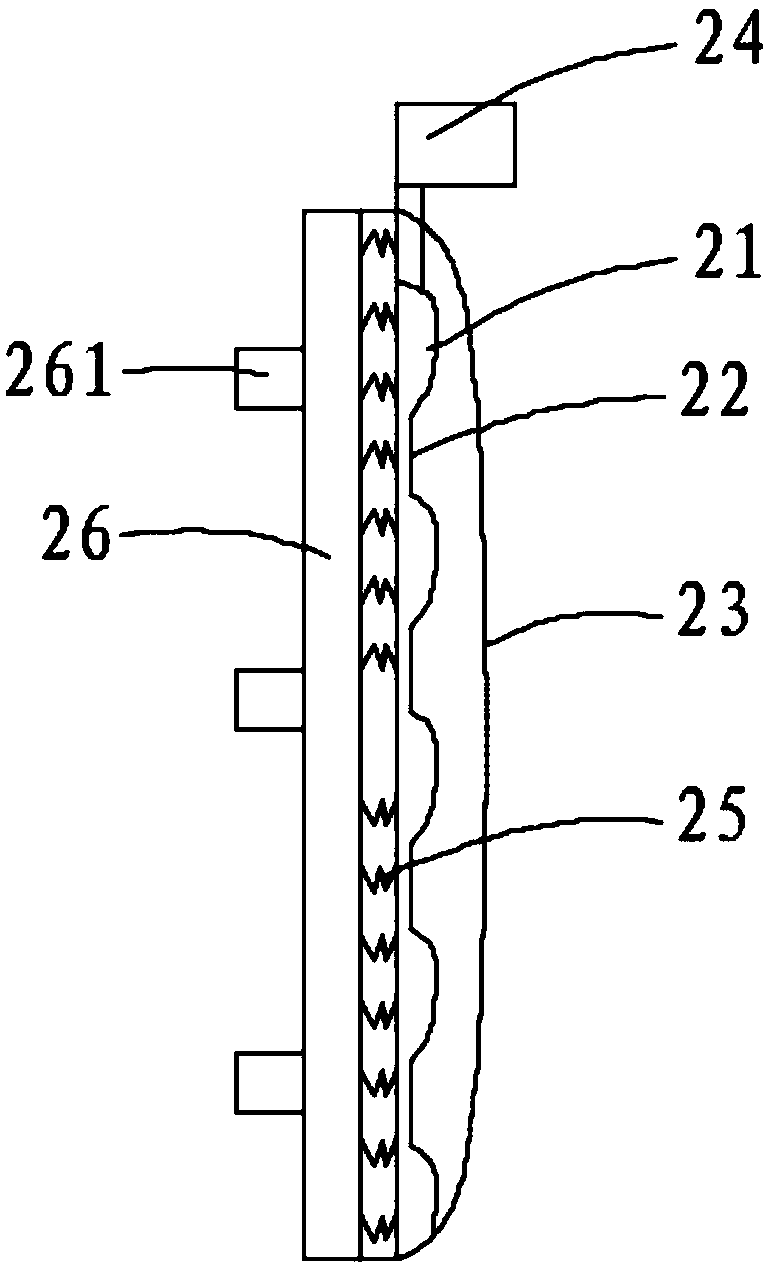

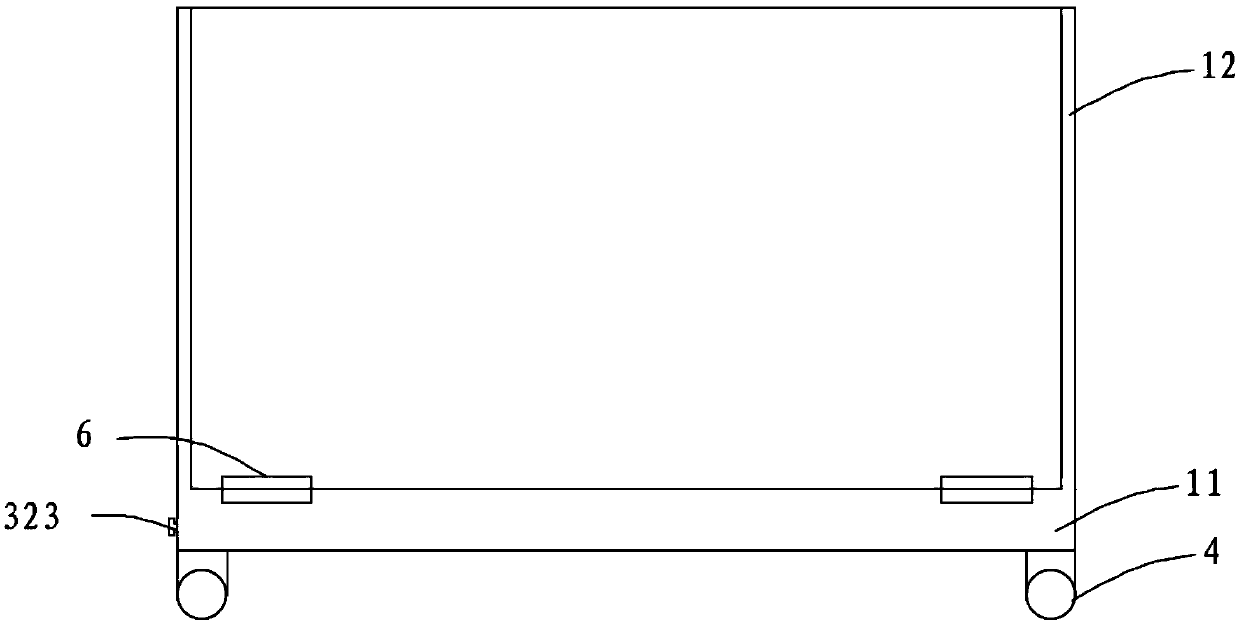

Anti-collision carrying frame

ActiveCN110962896AAdjustable positionAvoid breakingHand carts with multiple axesHand cart accessoriesStructural engineeringMechanical engineering

The invention relates to an anti-collision carrying frame. The carrying frame comprises a carrying frame body, a buffer component and a rolling assembly, wherein the buffer component is magnetically connected with the carrying frame body; the mounting position of the buffer component can be selected according to actual requirements; the buffer component comprises a plurality of bags filled with fluid; the bags are arranged on the inner side of the frame in a spaced mode; the bags filled with the fluid can deform and have a certain resilience characteristic; impact force generated by collisionof furniture can be effectively buffered; and the furniture is prevented from being damaged by collision in the carrying process.

Owner:台山市森美家居有限公司

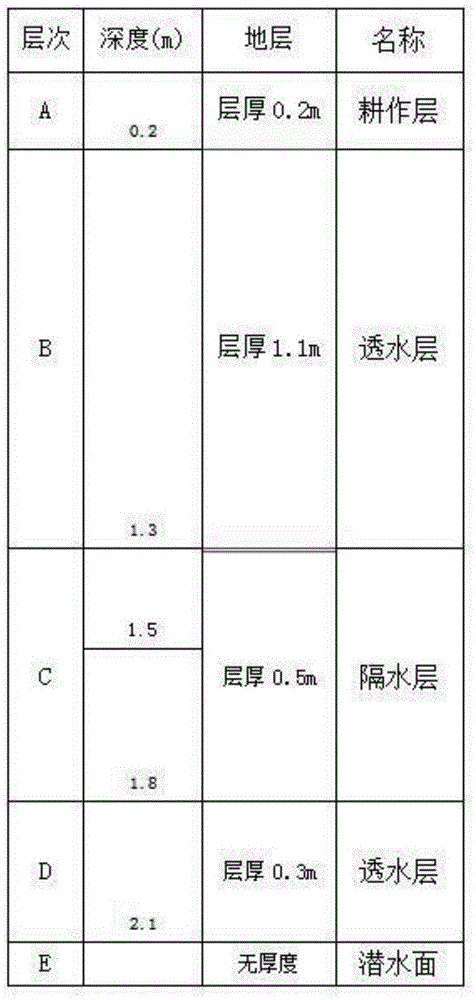

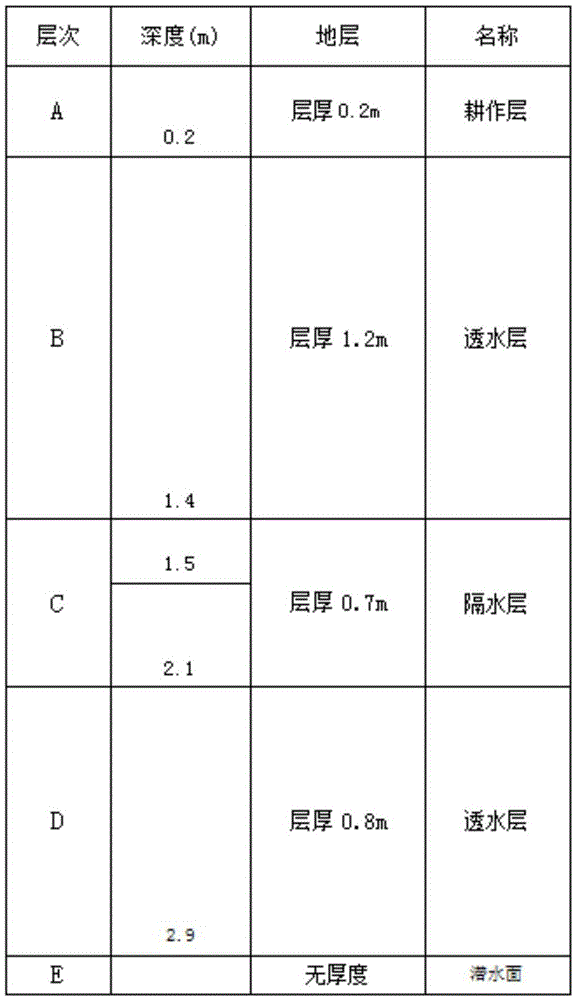

Shallow shaft side infiltrating irrigation water saving irrigation method

InactiveCN105532368AHigh technical contentSmall amount of workWatering devicesCultivating equipmentsEvaporationEngineering

The invention discloses a shallow shaft side infiltrating irrigation water saving irrigation method. Compared with the prior art, the method is high in technical content, low in work amount, low in facility cost, and small in floor space of a main facility, and ground operation is not influenced. Equipment is not needed to move in a production process, and manpower and energy are saved. No pipeline exists underground, and ploughing and turning up soil are not influenced. A self-flowing method is used, and almost not power is needed in an irrigation process. Water is irrigated from the lower part of a plough layer, irrigated water does not infiltrate through a soil surface, so surface soil continuous permeability is maintained, and breath of roots of plants is not interrupted, and development of the plants is not inhibited. The method would not make nutrition be washed away. The surface of soil keeps a dried state all along, and the soil layer is loose, air and optothermal are sufficient, biochemical action is active, and large amount of nutrient contents and carbon dioxide are generated, so plant growth is flourishing. The method keeps the surface of the soil layer dry and loose, and stops underground water evaporation, so water saving effect is more obvious. The method is worthy of popularizing and using.

Owner:王晨煜

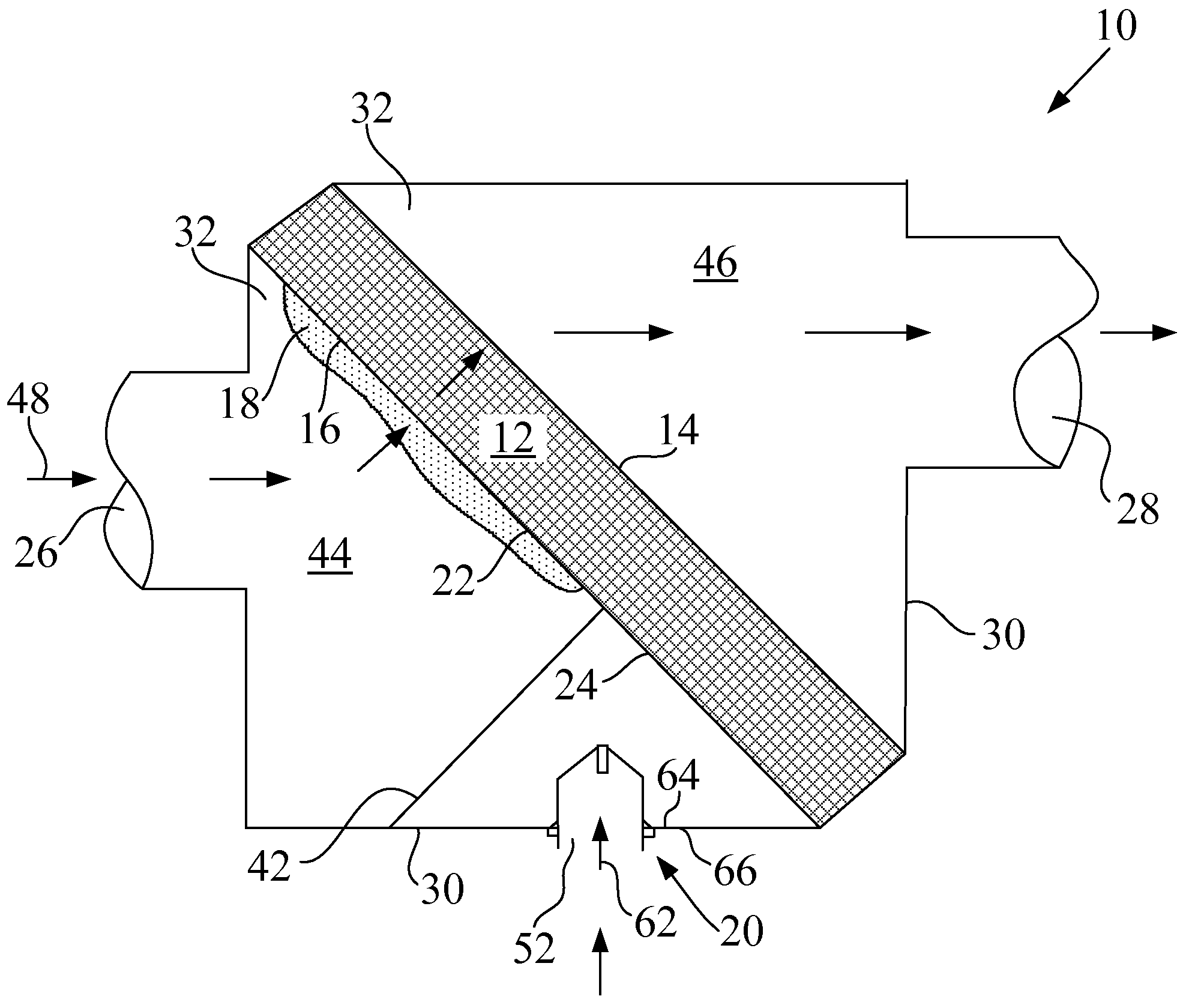

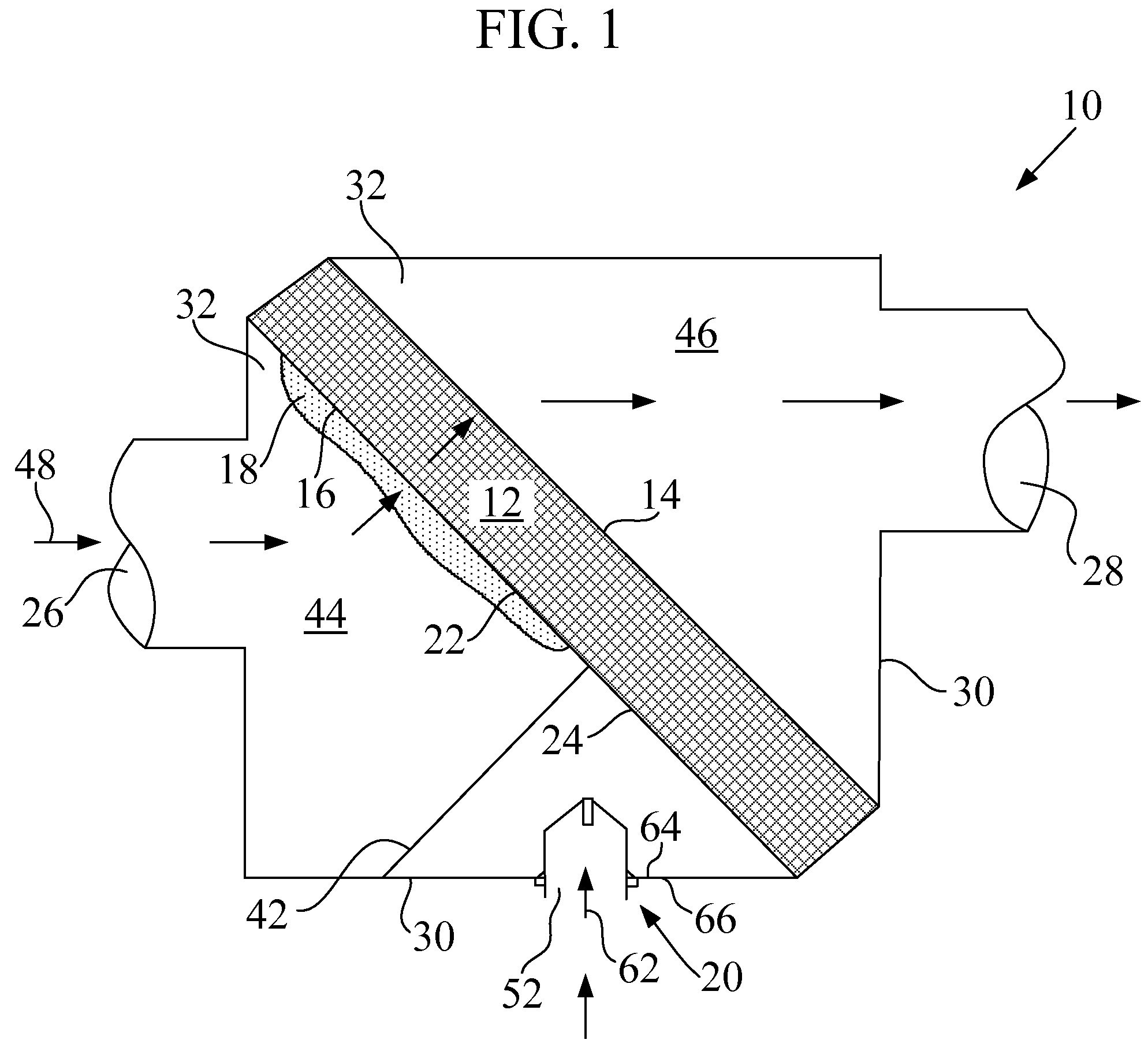

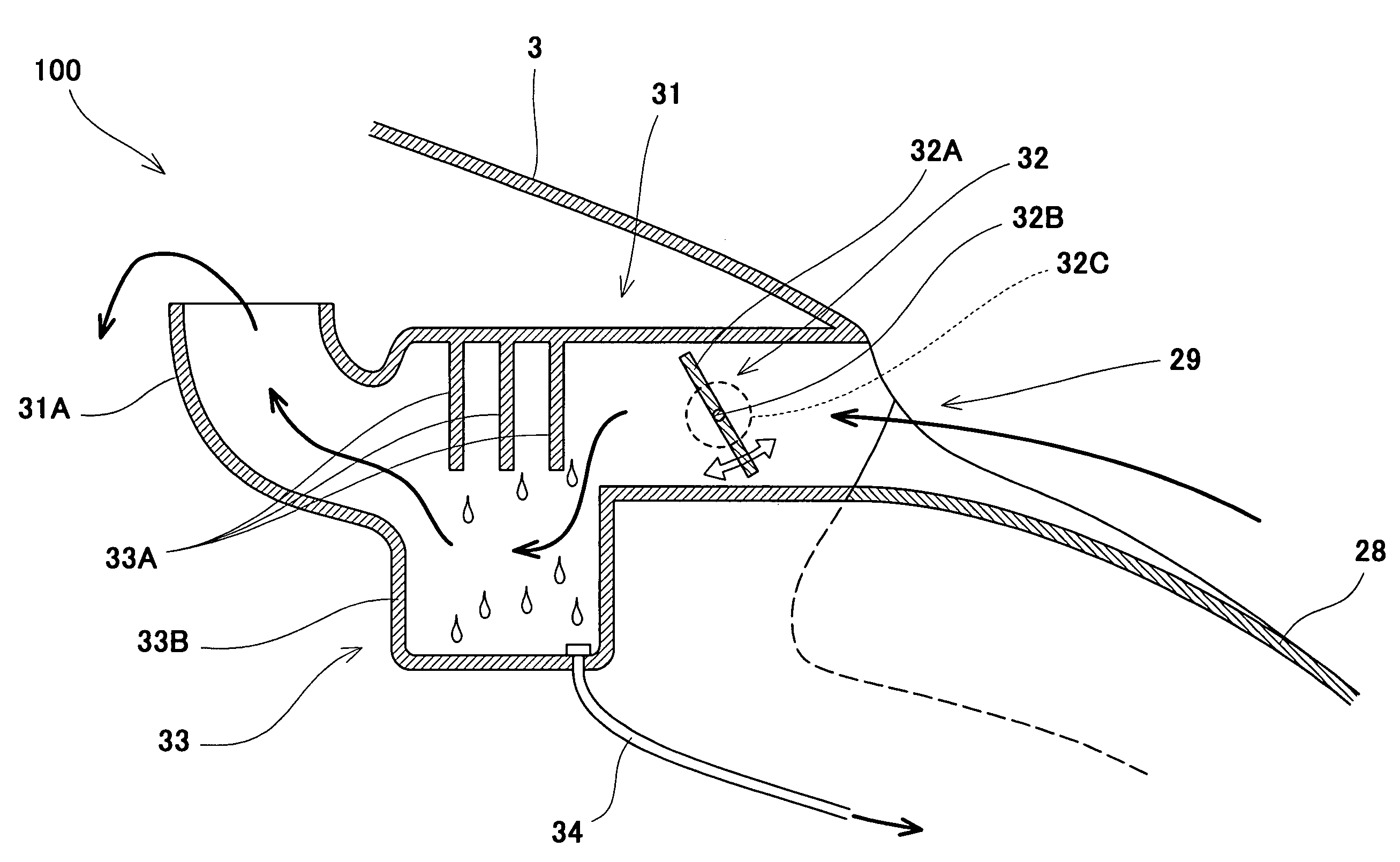

Engine combustion air cyclonic pre-cleaner embodying throttling member adjusted in accordance with engine load

ActiveUS8151774B2Wide in engine load requirementIncrease pressureCombination devicesElectrical controlCombustionLoad regulation

An engine combustion air pre-cleaner includes a body shaped for effecting cyclonic air flow between an inlet and an outlet of the body. Located along a longitudinal axis of the body is a conical throttling member which is coupled to a control device which operates in response to increasing engine load, as represented by increasing boost pressure, torque and / or speed, to shift the throttling member so as to cause an increasing air flow with increasing engine load.

Owner:DEERE & CO

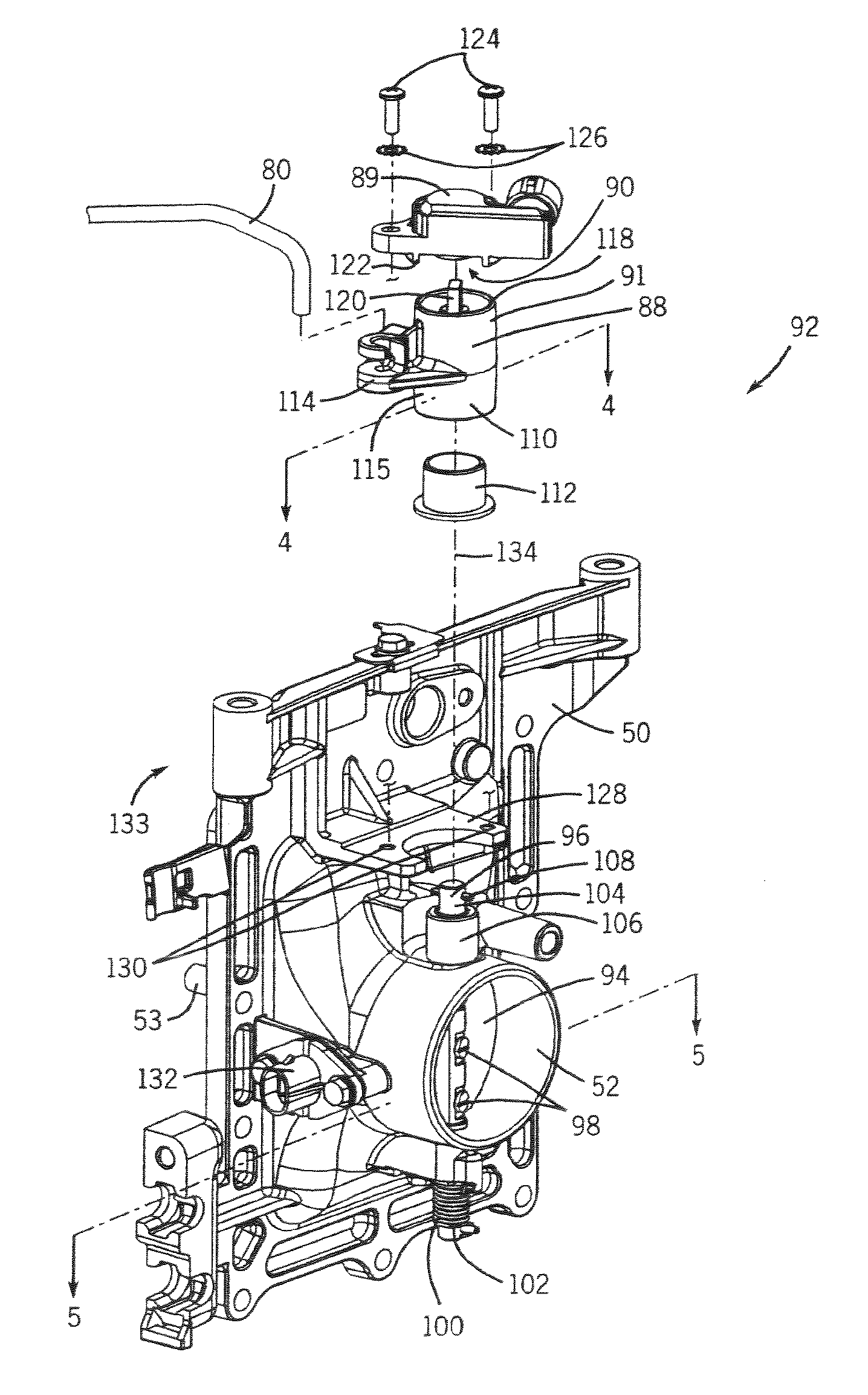

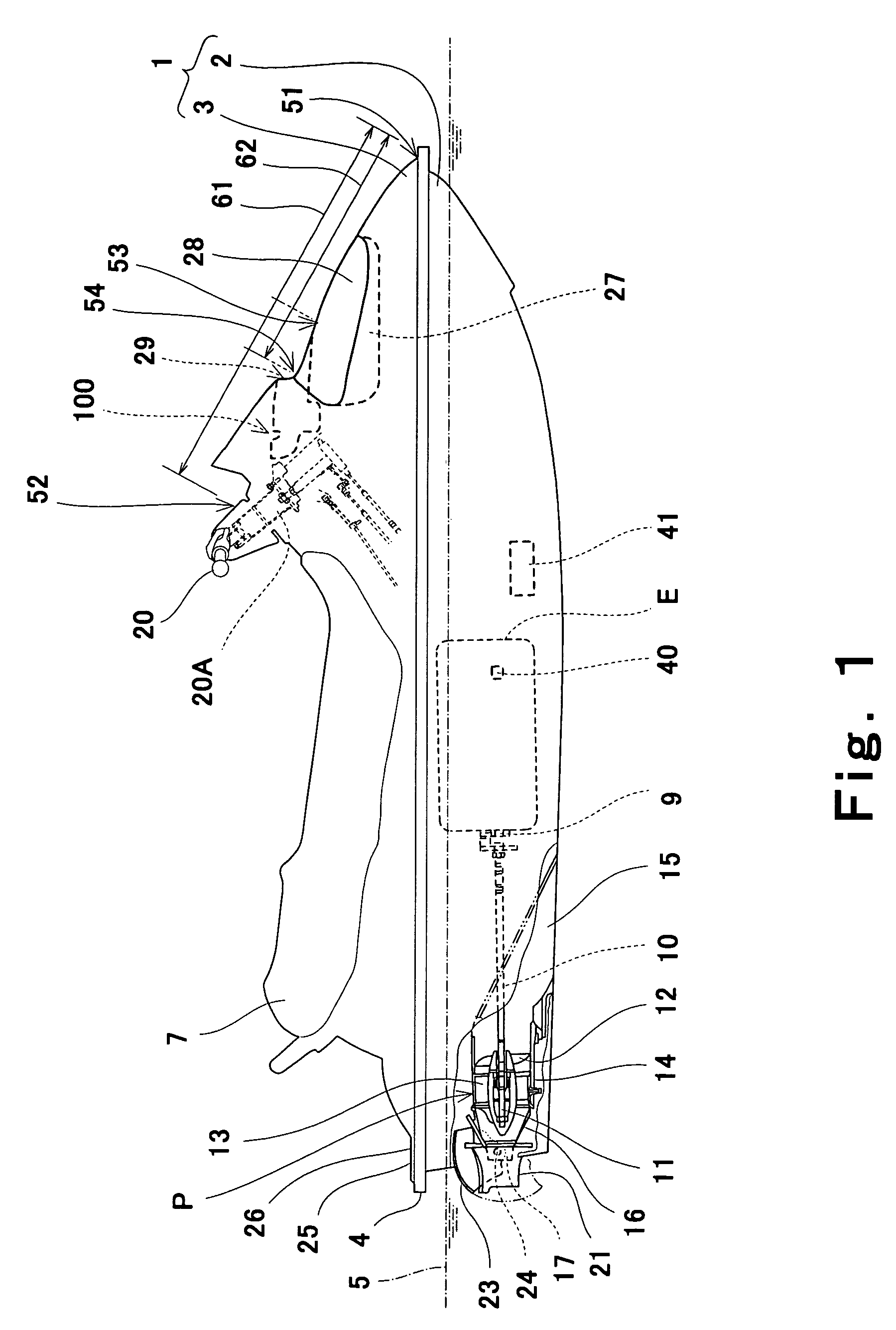

Personal watercraft

InactiveUS7056171B2Smoothly taking large amount of airEnough airPower plants using condensersAuxillariesWatercraftEngine room

A water-jet personal watercraft comprises a body including a hull and a deck covering the hull from above, the body being configured to form an engine room inside thereof in which an engine is mounted, and the deck being provided with a first opening configured to guide air from outside into the engine room, and a steering handle provided on an upper portion of the body, the steering handle including a steering shaft having a base portion where the steering shaft intersects an upper surface of the deck, wherein the first opening is provided on the upper surface of the deck at a position defined between the base portion of the steering shaft and a substantially center position between a front end portion of the body and the base portion of the steering shaft.

Owner:KAWASAKI HEAVY IND LTD

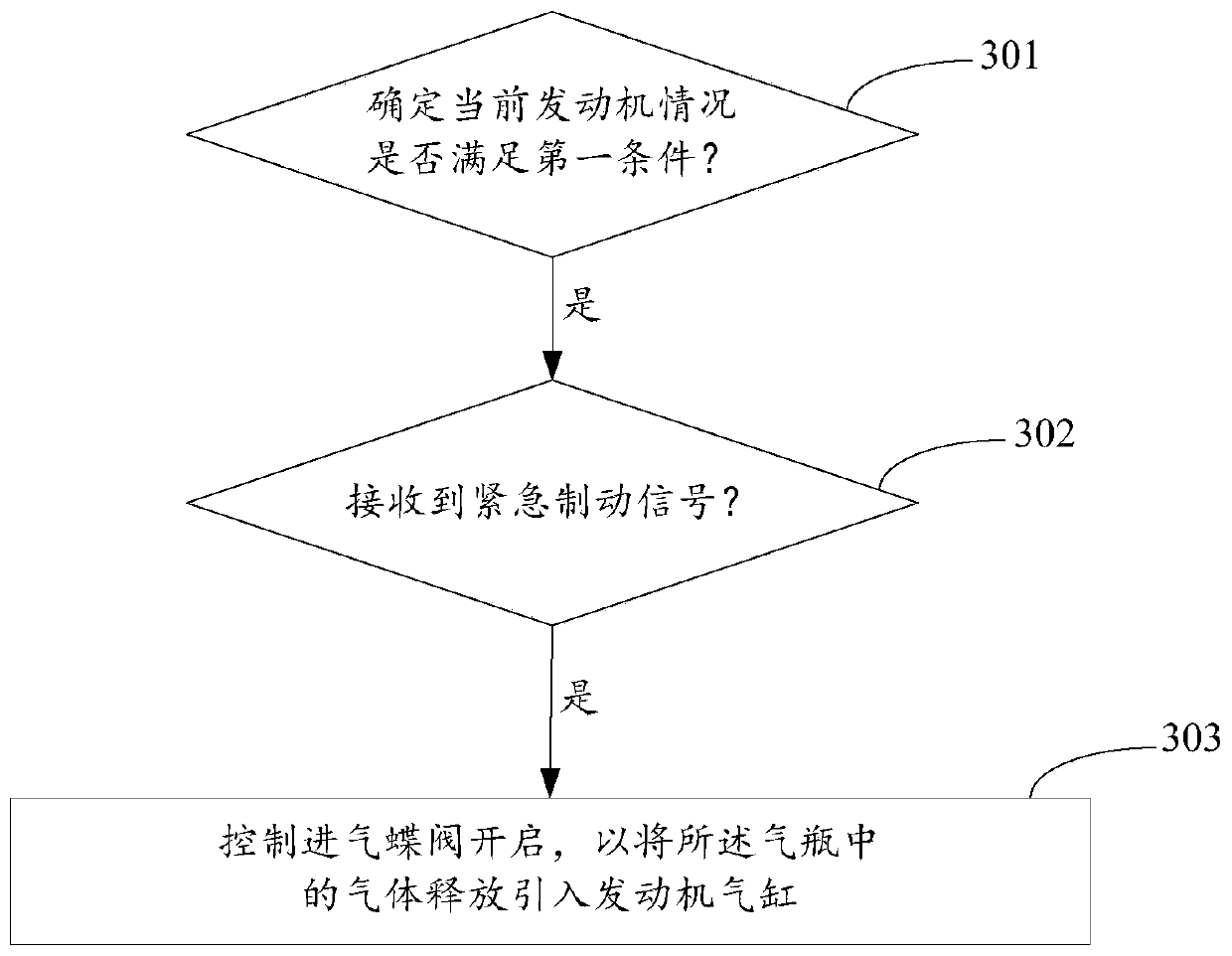

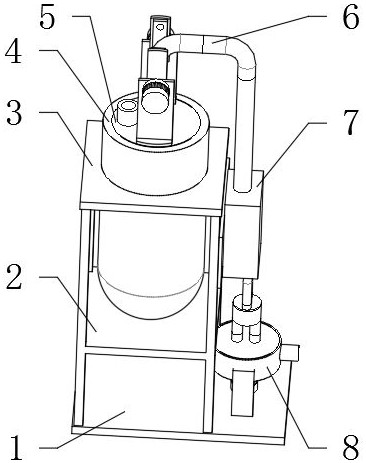

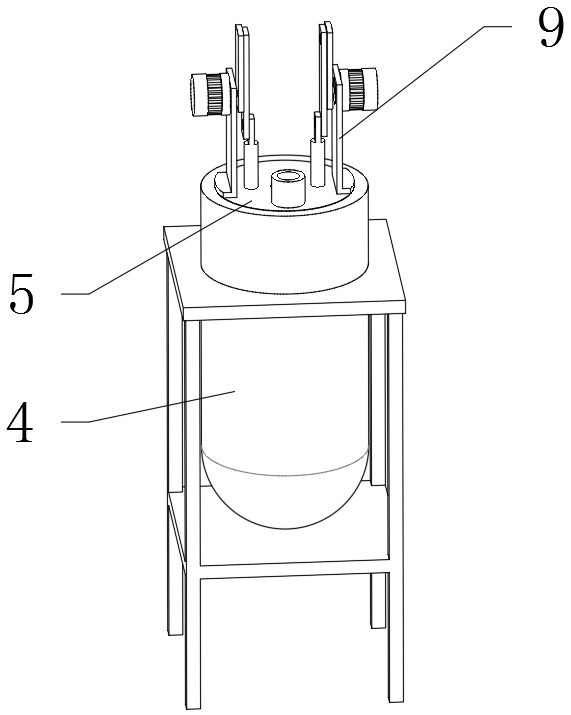

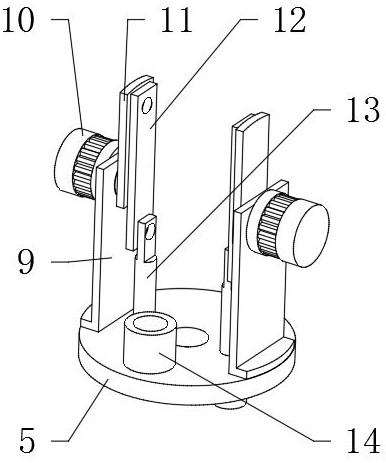

Engine air inlet structure, engine air inlet control method and device

InactiveCN110552779AEnough airGuaranteed braking powerCombustion enginesEngine controllersAir volumeGas cylinder

The invention discloses an engine air inlet structure and an engine air inlet control method and device. The method comprises the following steps that whether a current condition meets a first condition or not is determined, wherein the first condition includes that the braking force of an engine can be effectively transferred to a wheel and the air volume in an air cylinder can reach a first preset value; whether an emergency brake signal is received or not is judged under the condition that the condition items in the first condition are met; and if yes, an air inlet butterfly valve is controlled to open so as to release and introduce air in the air cylinder into an engine cylinder. According to the engine air inlet control method, after a whole vehicle is started, compressed air can be stored in the air cylinder, when the vehicle has an emergency brake state, the air in the air cylinder can be controlled to release and introduce into an air inlet pipe in front of the engine cylinder,so that in the case of emergency braking, the air in the engine cylinder is sufficient, and the braking power is ensured.

Owner:WEICHAI POWER CO LTD

Rice rapid crushing equipment for rice processing

ActiveCN112264126BSeparation in timePromote absorptionGrain treatmentsAgricultural engineeringRice grain

The invention discloses a rice rapid crushing device for rice processing, which relates to the field of rice processing; in order to solve the problem that the crushed rice cannot be separated in time; The inner wall in the middle of the frame is fixedly connected with a supporting plate, the outer wall at the top of the support frame is fixedly connected with a clamping plate, the inner wall of the clamping plate is fixedly connected with a barrel, and the inner wall of the barrel is slidingly connected with a hammer assembly. In the present invention, a hammer body assembly is provided, wherein the rice material enters the inside of the barrel, and then the hammer body assembly is lowered to perform hammer pressing and crushing work on the rice material, and at the same time, the crushed material is pushed to the hammer when the hammer block falls. At this time, the powder enters the inner wall of the hammer block through the filter plate, and then absorbs the powder entering the hammer block through the cone tube and the powder tube through suction, so that the rice grains can be separated from the grinder in time. The powder is separated and easy to absorb.

Owner:深圳市中泰粮油进出口有限公司

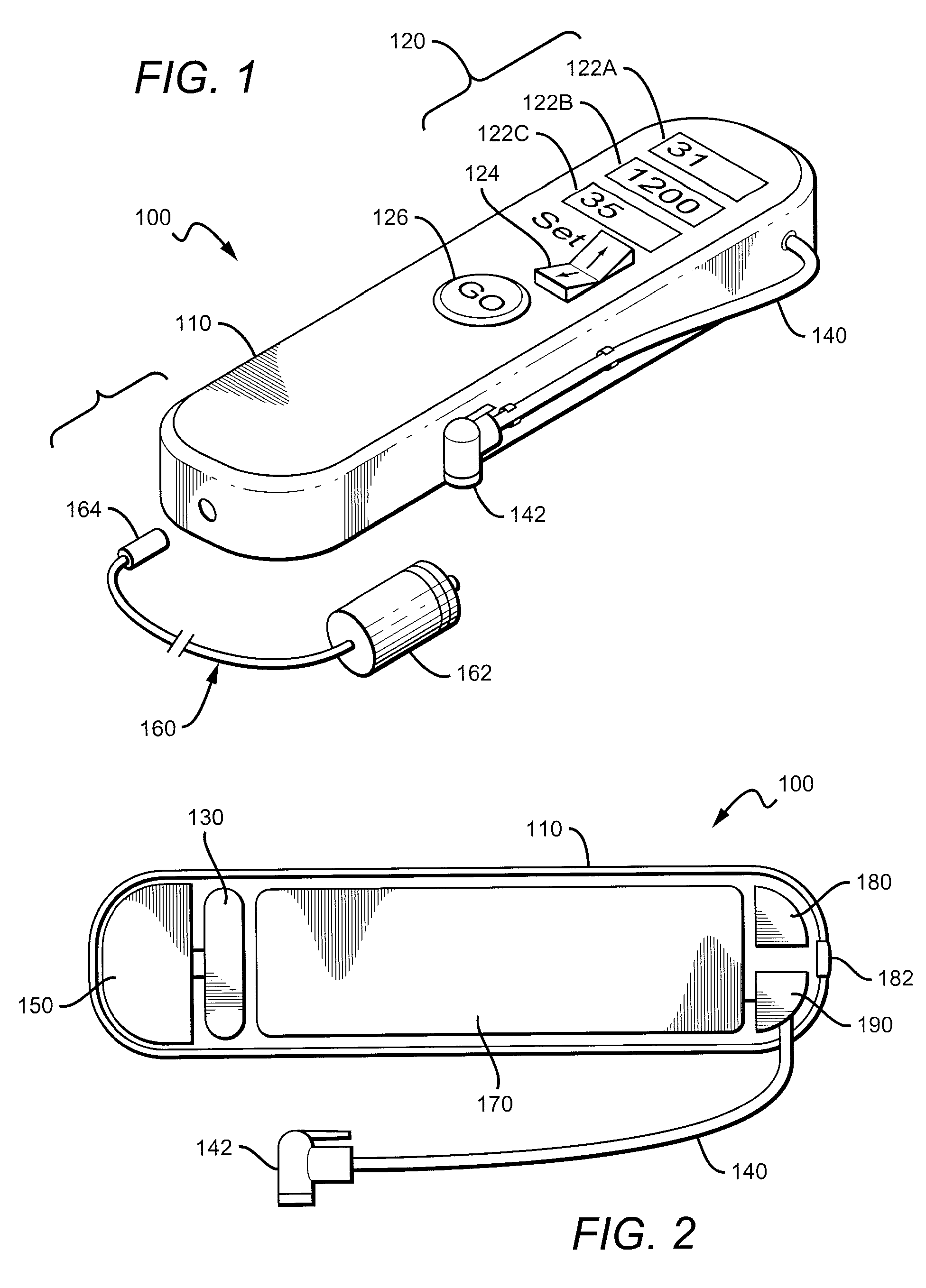

Gas Supply Apparatus With Improved Control

ActiveUS20100297593A1Avoid flowSufficient supplyRespiratorsCosmonautic condition simulationsProcess engineeringGas supply

A gas supply apparatus with improved control is provided. The gas supply apparatus provides gas at an outlet junction. The apparatus includes a gas mixer for gasses from primary and secondary supplies to a given ratio. The apparatus also includes a gas reservoir supplied by the gas mixer. A tertiary supply valve is also included and connected in parallel with the reservoir. The tertiary supply valve is adapted to connect the outlet junction to a tertiary gas supply when gas is not being supplied to a mixer by the primary and / or secondary supply.

Owner:DEVX TECH IP

Embedded gas cooker

PendingCN112032766AHigh thermal efficiencyReduce the chance of not being able to put it in and not being able to use itDomestic stoves or rangesBlast-producing apparatusEngineeringAir blower

The invention discloses an embedded gas cooker. The cooker comprises a bottom shell and a burner, wherein the bottom shell comprises a face plate and side plates arranged around the face plate, the burner is fixed to the face plate and communicates with an injection pipe for conveying gas, and the face plate is provided with an air supply device for supplying air to an injection port of the injection pipe, so that the gas and air are sufficiently premixed. According to the embedded gas cooker, the primary air coefficient of a combustor of the gas cooker is increased, the heat efficiency of thegas cooker is effectively improved, and meanwhile the emission of harmful gas is reduced; the bottom shell is designed to be of an open structure with the adjustable size, so that on one hand, air can easily enter the bottom shell, and it is guaranteed that the air amount in the bottom shell is sufficient; and the primary air coefficient can be easily increased through an air blower, and the gasand air can be well premixed.

Owner:GREE ELECTRIC APPLIANCES INC

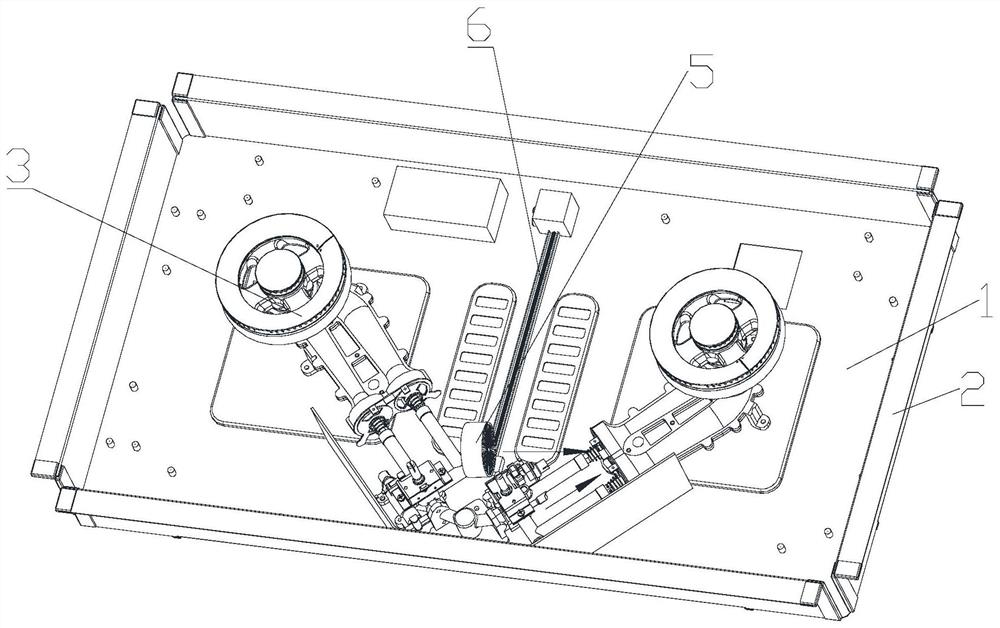

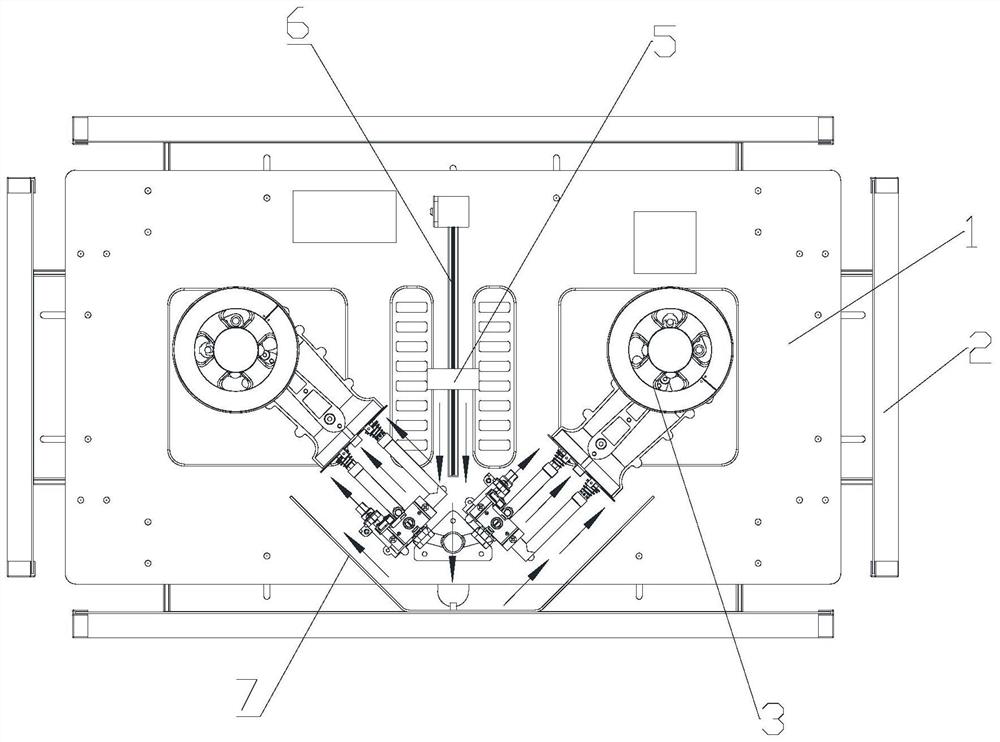

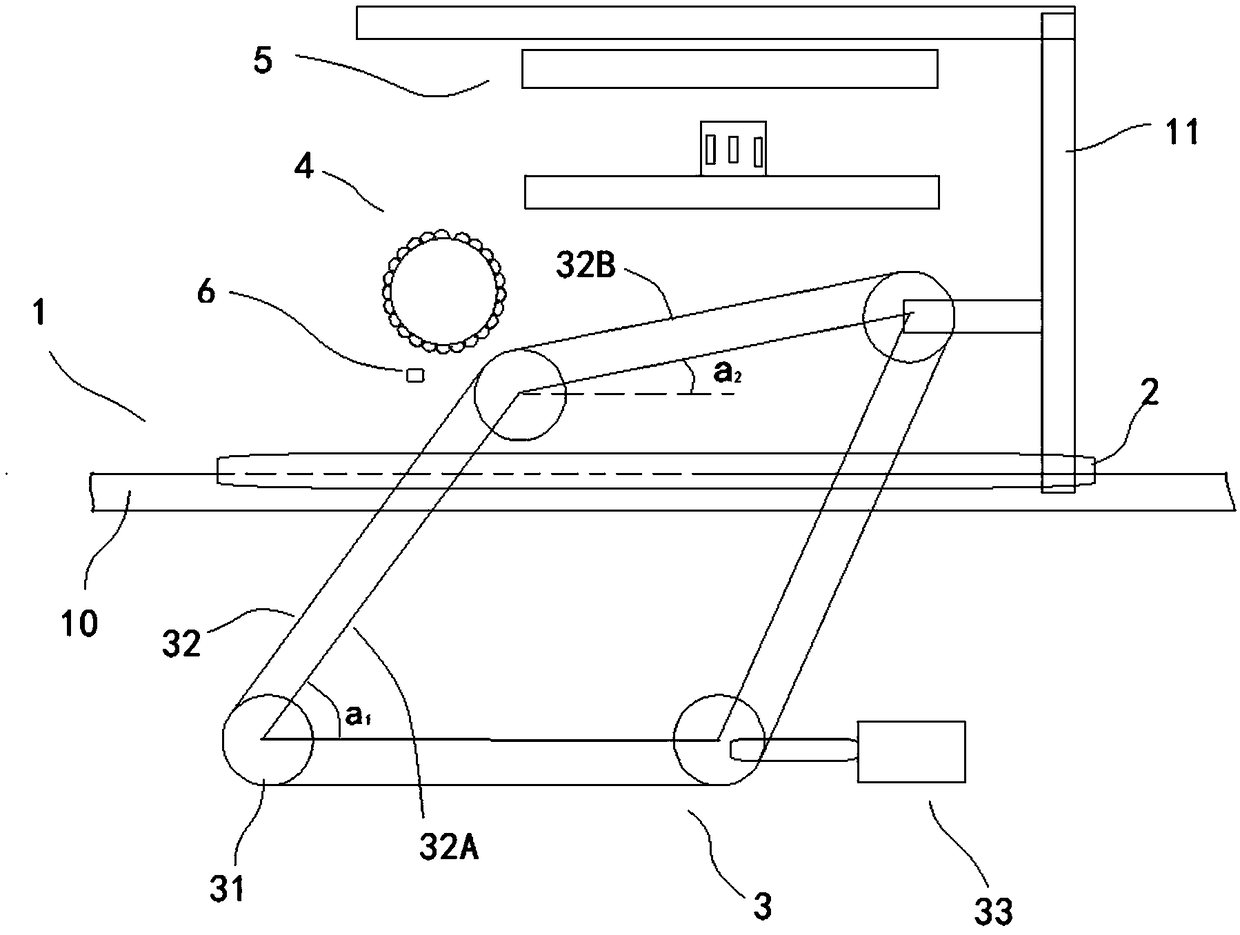

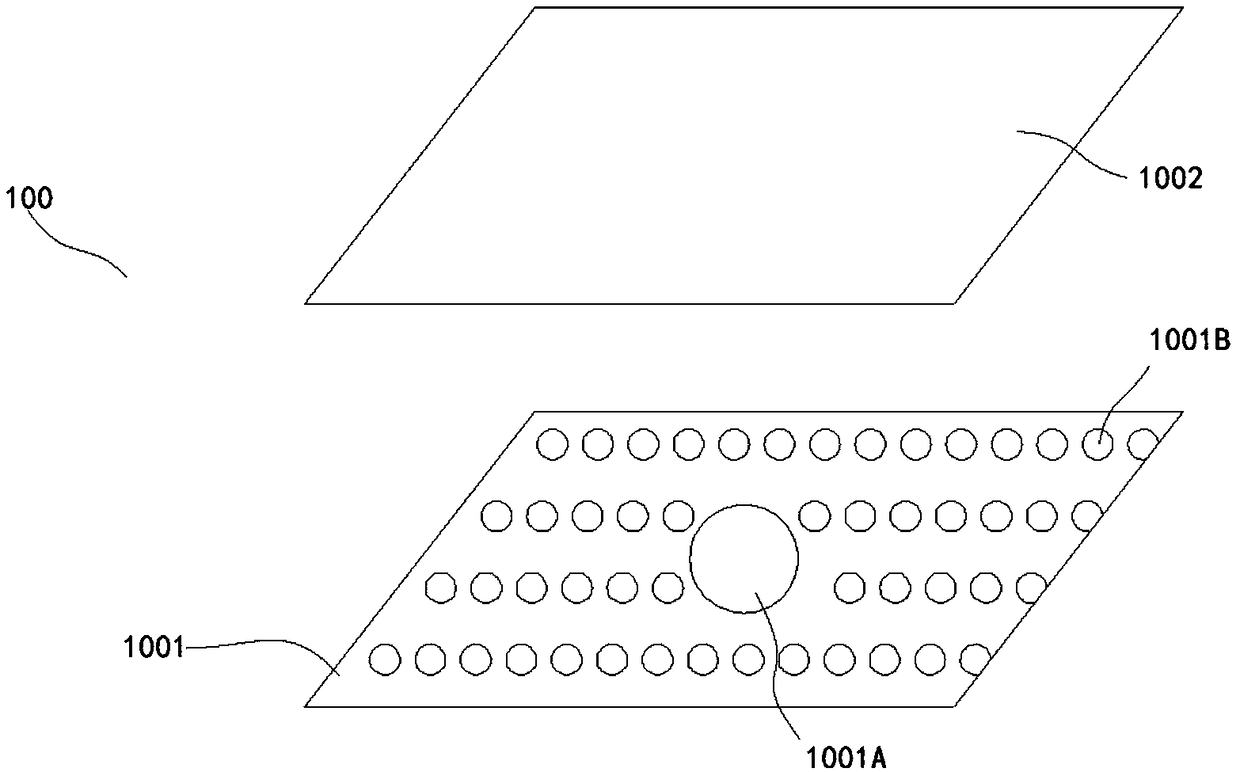

Chain plate type turner

InactiveCN108821820AAdd bacteriaIncrease waterOrganic fertiliser preparationAcute angleAnaerobic bacteria

The invention relates to a chain plate type turner, comprising a frame, a travelling mechanism, a turning mechanism, a crushing mechanism, a fresh air mechanism and a spraying mechanism. The turning mechanism comprises supporting rollers, chain plates laid on the supporting rollers and a turning driving mechanism driving the chain plates to move; the supporting rollers are slidably arranged on theframe along a vertical direction; the chain plates form a first inclined surface, a second inclined surface and a third inclined surface along the moving directions of the chain plates; and an inclination angle alpha1 between the first inclined surface and the horizontal plane is an acute angle and is larger than the inclination angle alpha2 between the second inclined surface and the horizontalplane. The crushing mechanism is arranged above the joint of the first inclined surface and the second inclined surface and used for crushing fermented materials passing through the crushing mechanism. The air outlet of the fresh air mechanism is arranged above the second inclined surface and used for sucking in air from places out of the frame and guiding air in space between a frame body and thechain plates. The chain plate type turner of the invention is additionally provided with the fresh air mechanism, so oxygen supply is more sufficient, anaerobic bacteria are inhibited, and the generation of odor is controlled.

Owner:荆门市佳益机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com