New large-capacity enclosed ground flare

A ground torch and processing capacity technology, applied in the combustion type, combustion method, lighting and heating equipment, etc., can solve the problems of insufficient air, low metal fence, high requirements for grading control system, and achieve simplified grading pipeline and control system, The effect of facilitating maintenance and saving land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The performance and characteristics of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

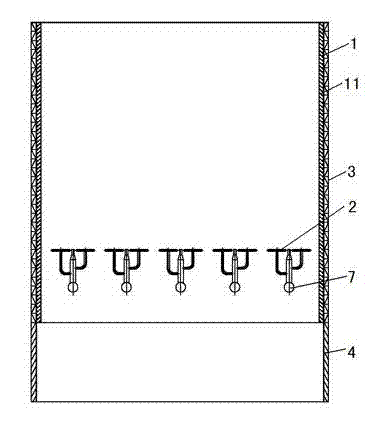

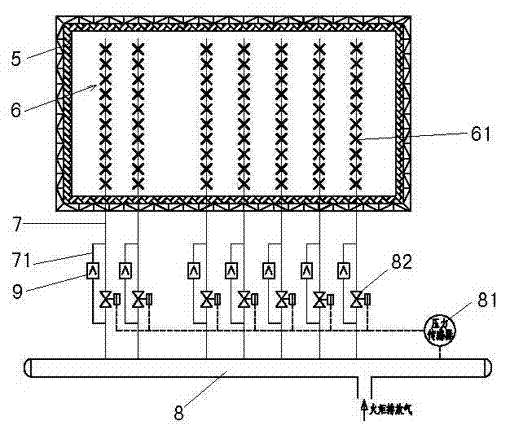

[0033] see figure 1 , figure 1 It is a longitudinal sectional view of the combustion chamber of the novel large-capacity enclosed ground flare of the present invention. The novel large-capacity enclosed ground flare of the present invention comprises a combustion chamber 1 and a plurality of burners 2 arranged in the combustion chamber. The cross section of the combustion chamber is rectangular, and the burners are arranged in rows in the combustion chamber. It also includes a reinforcement frame 3 and a hollow bracket part 4, the reinforcement frame 3 is arranged around the combustion chamber 1, and is fixed integrally with the combustion chamber. The hollow bracket part 4 is arranged at the bottom of the reinforced frame to raise the entire combustion chamber to a certain height. The height of the hollow brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com