Packaging structure for optical sensing assembly and method of manufacture

A technology of packaging structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., and can solve problems such as difficult to remove pollutants and affect the function of light-sensing chip 20

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

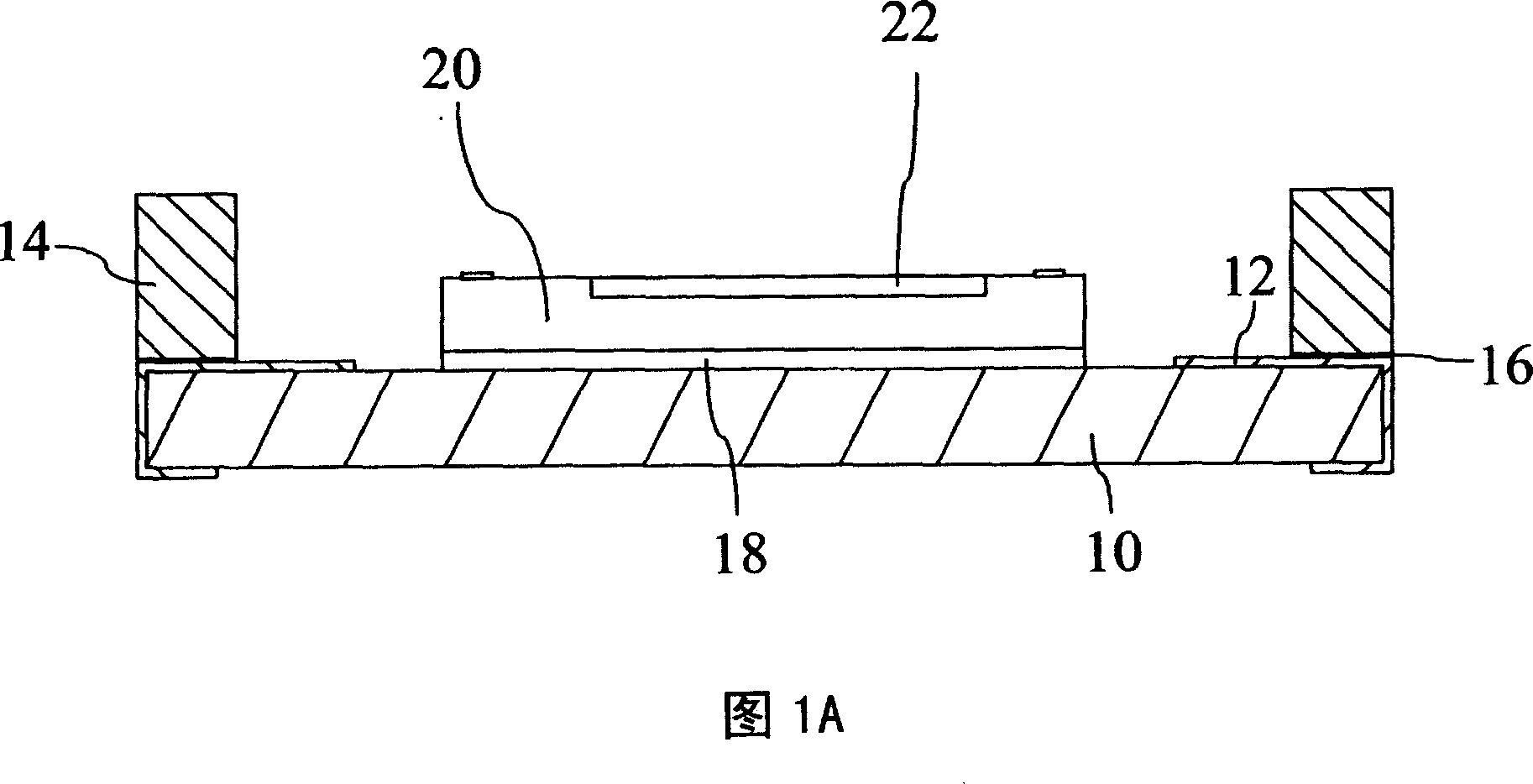

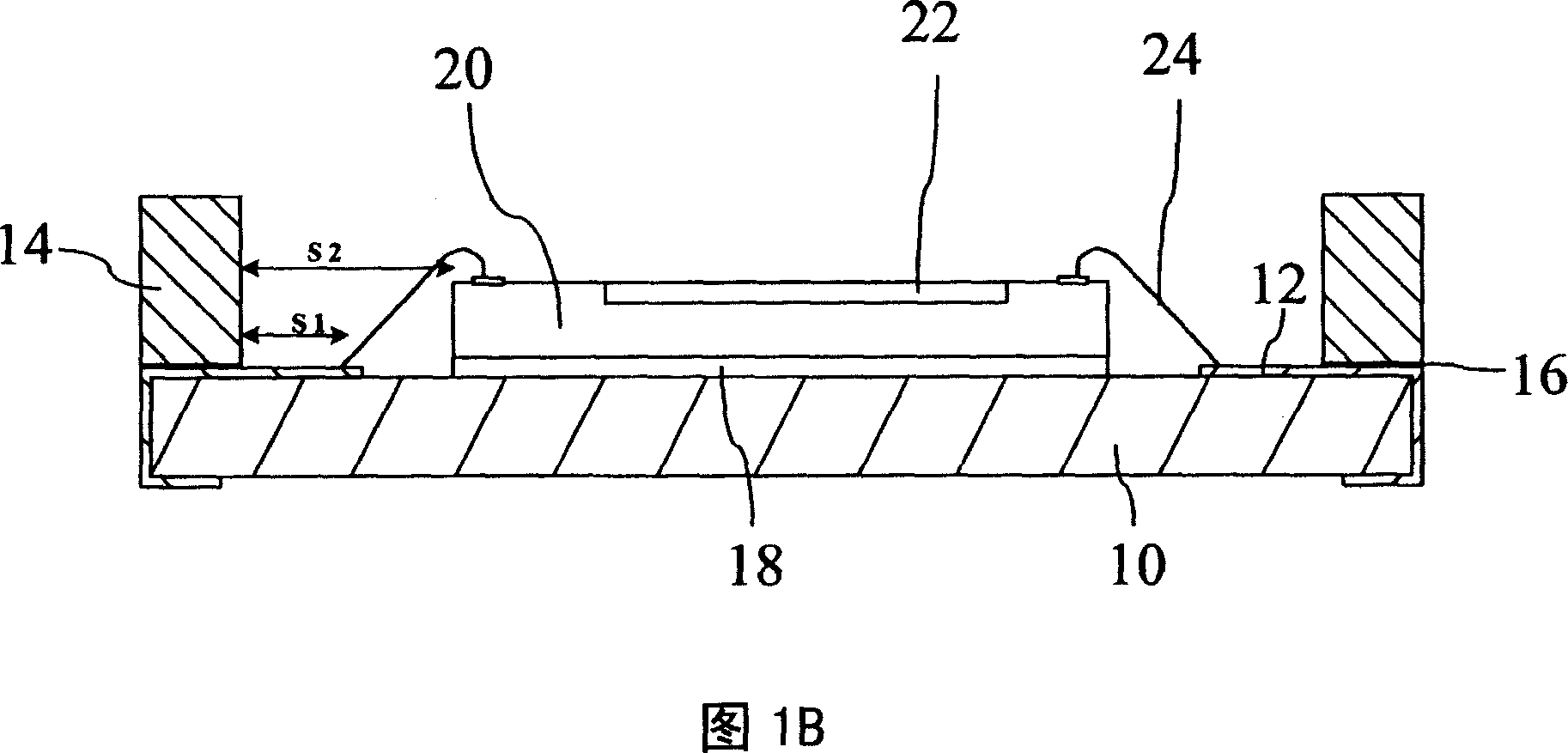

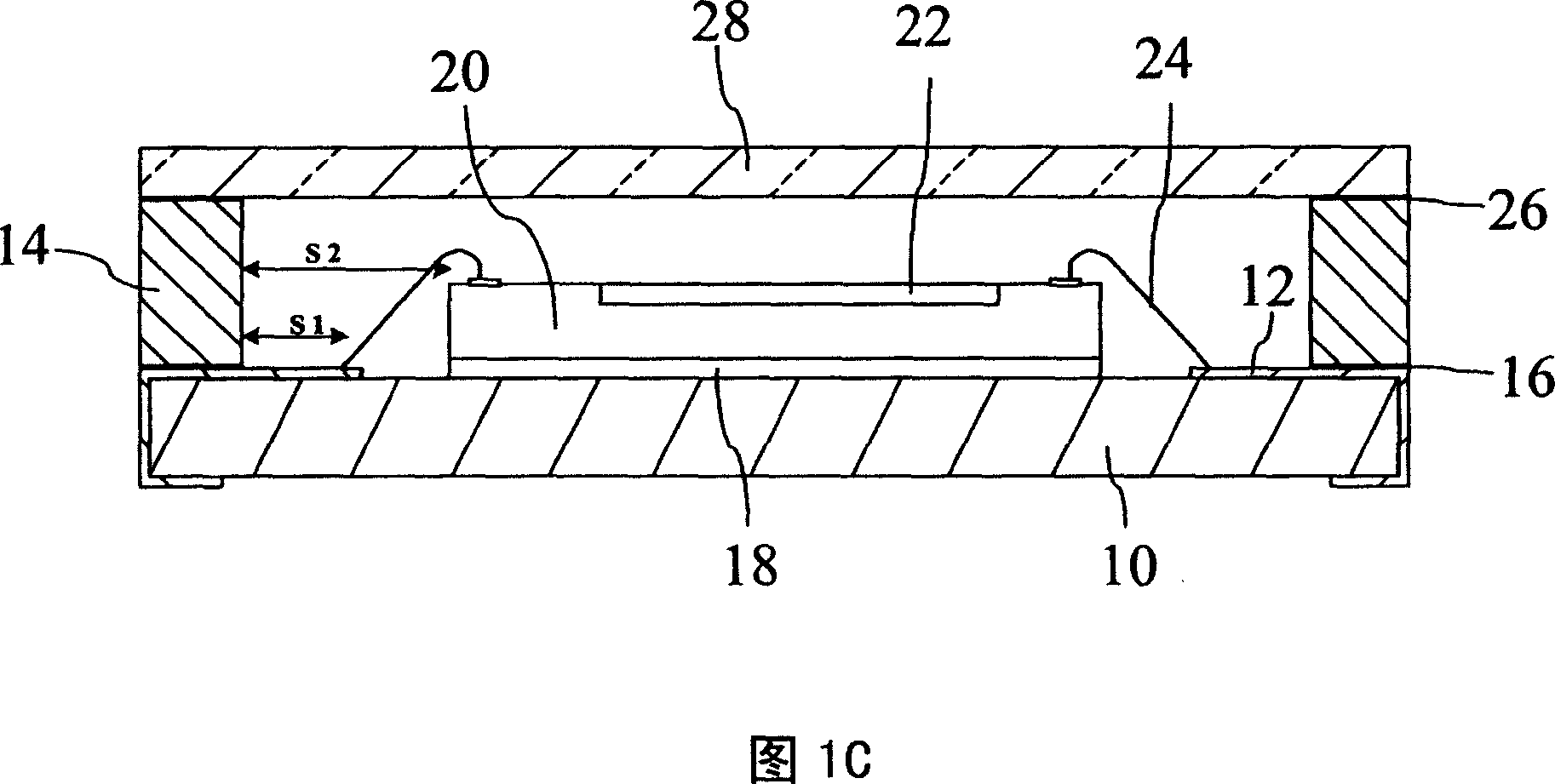

[0042] In the following, specific embodiments are described in detail with reference to the accompanying drawings, so that it is easier to understand the purpose, technical content, features and effects of the present invention.

[0043] The invention relates to a packaging structure of a photo-sensing component and a manufacturing method of the packaging structure, which provide a mechanism for light to penetrate into the photo-sensing component and protect the photo-sensing chip inside from being polluted by external particles.

[0044] The basic structure of the new optical sensor package structure of the present invention is shown in FIG. Adhesive on the substrate 30, the photo-sensing chip 34 has a photo-sensing area (Sensor Area) 38, the electrical communication between the photo-sensing chip 34 and the substrate 30 is connected by metal wires (Bond wires) 40, and there is a A Light transparent cover lid 42 has a cavity design, so that the cover 42 is bonded to the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com