Aging testing apparatus and method

A test board and temperature sensor technology, which is applied in the direction of measuring electricity, measuring devices, measuring heat, etc., can solve the problems of temperature sensor damage, integrated circuit damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A. IC package temperature control device and method

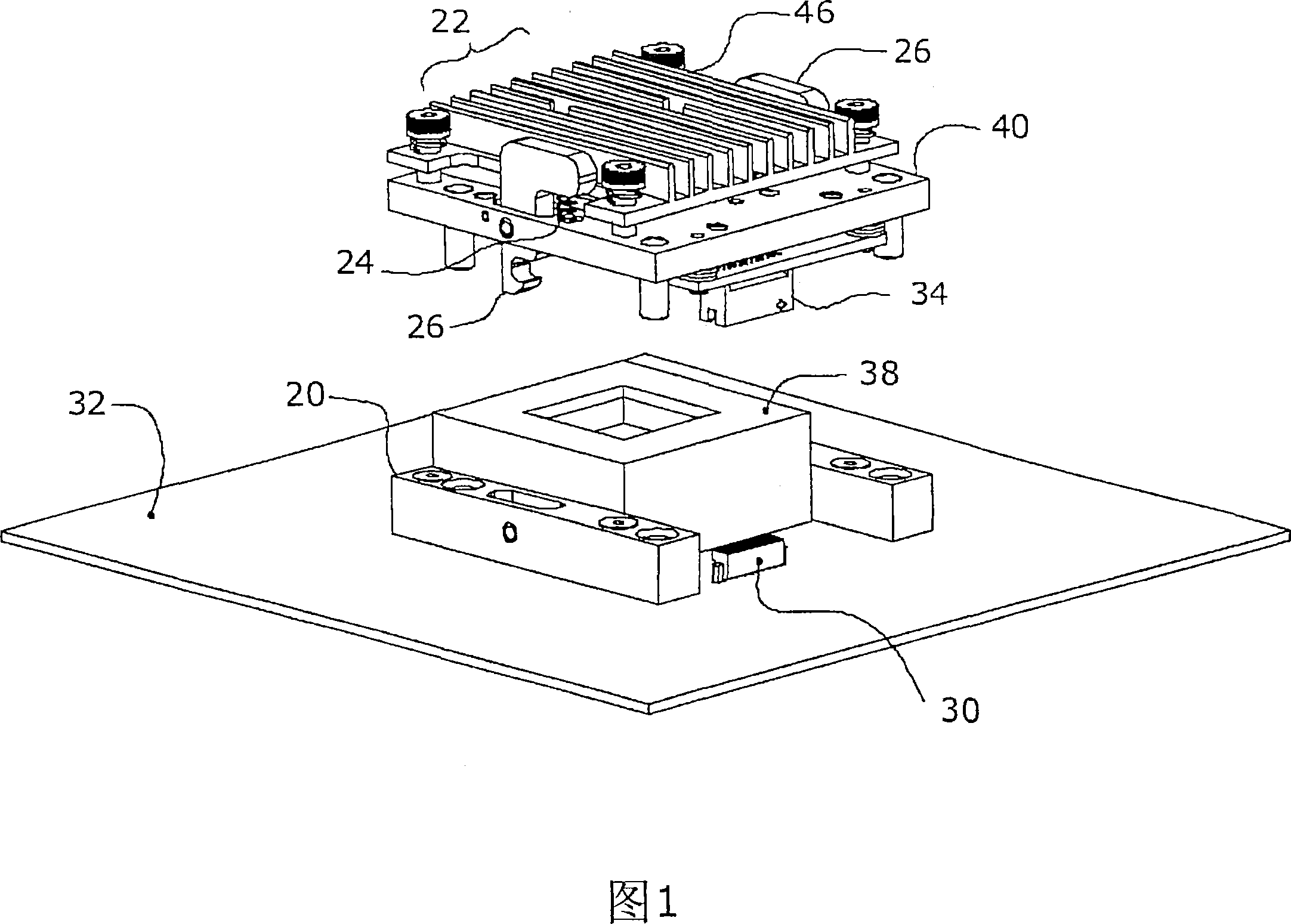

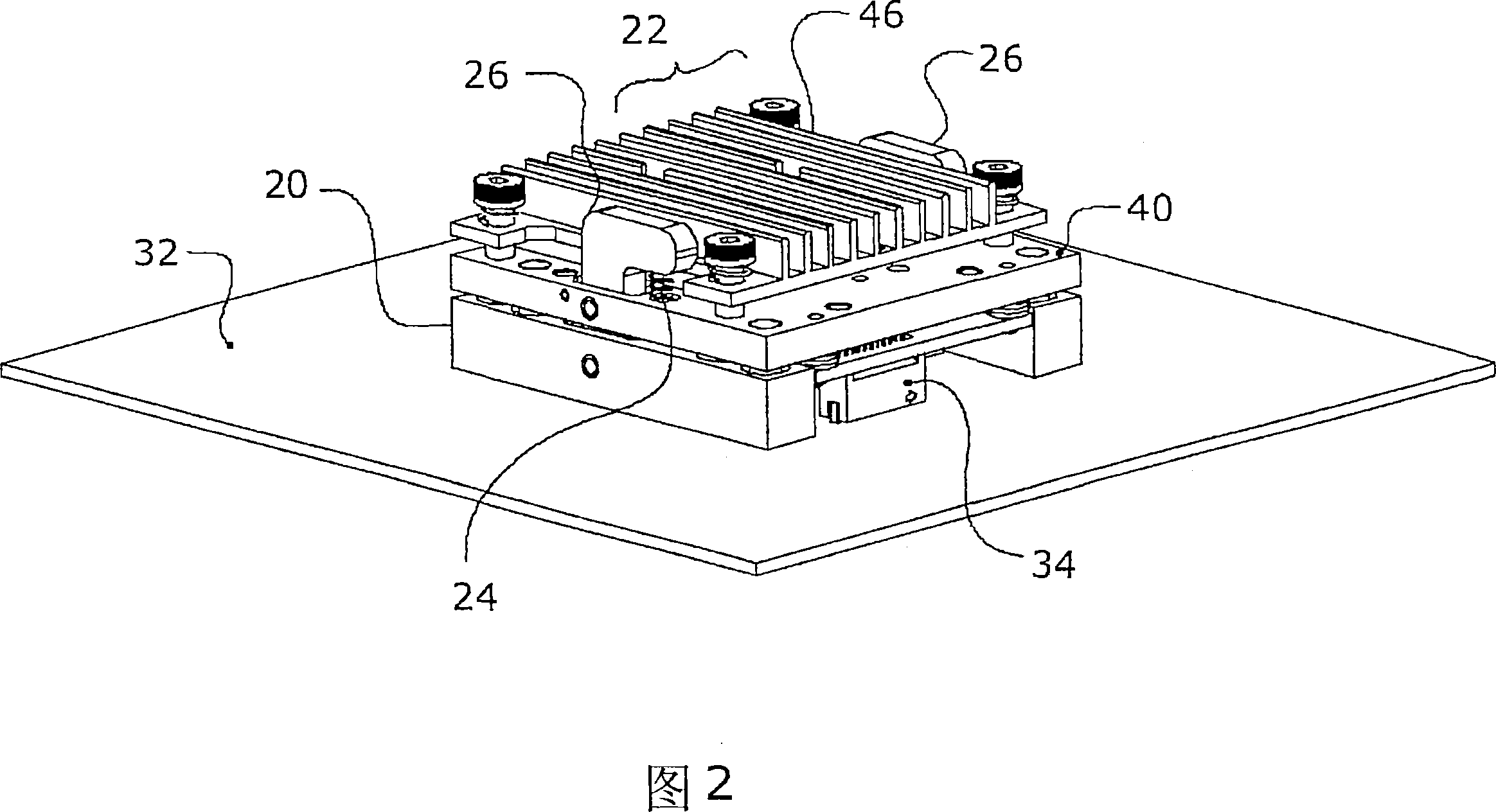

[0031] 1 and 2 show perspective views of a test socket 20 and a module sensor / heater / controller unit 22 according to one embodiment of the present invention. The heater may also be a cooler, but is hereinafter referred to simply as a heater for brevity. The spring 24 on the latch 26 allows easy and quick release of the heater unit 22 from the test socket base 38 . FIG. 2 shows the test socket 20 and the modular unit 22 in the closed position, with the board-side connector 30 on the test board 32 receiving the communication / power connector 34 on the heater unit 22 .

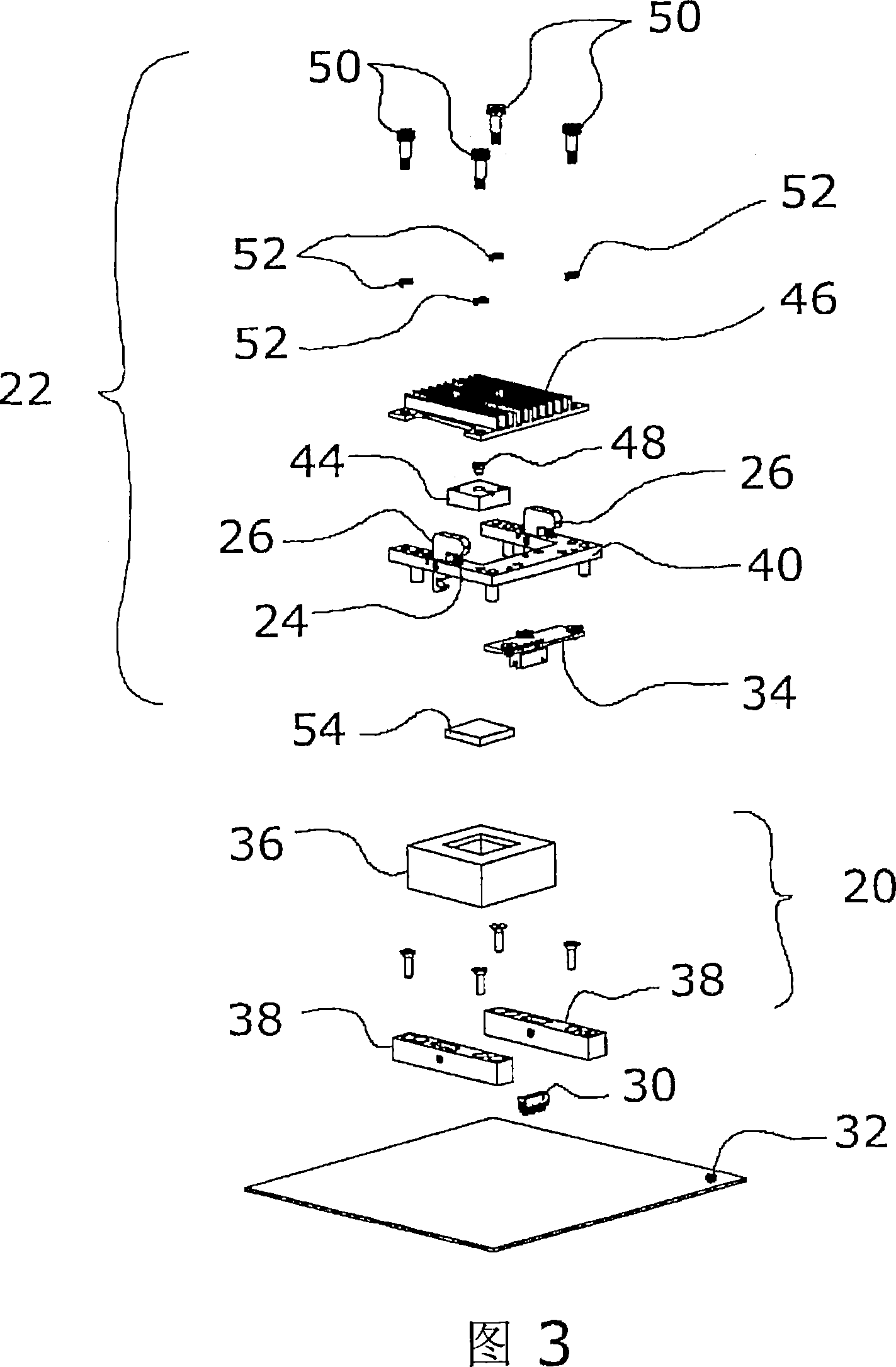

[0032] FIG. 3 shows an exploded perspective view of the test socket 20 , the modular unit 22 and the test board 32 . The test socket 20 utilizes a general open top socket 36 fastened to a base 38 with an alignment pin 41 and two latches 26 . The modular unit 22 has a guide plate 40 for aligning the modular unit 22 onto the base 38 and the board-side c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com