Work-table for forming electric spark working machine

A workbench and processing machine technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as inconvenience, heavy weight, and difficult implementation, and achieve simple adjustment methods, easy operation, and improved processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

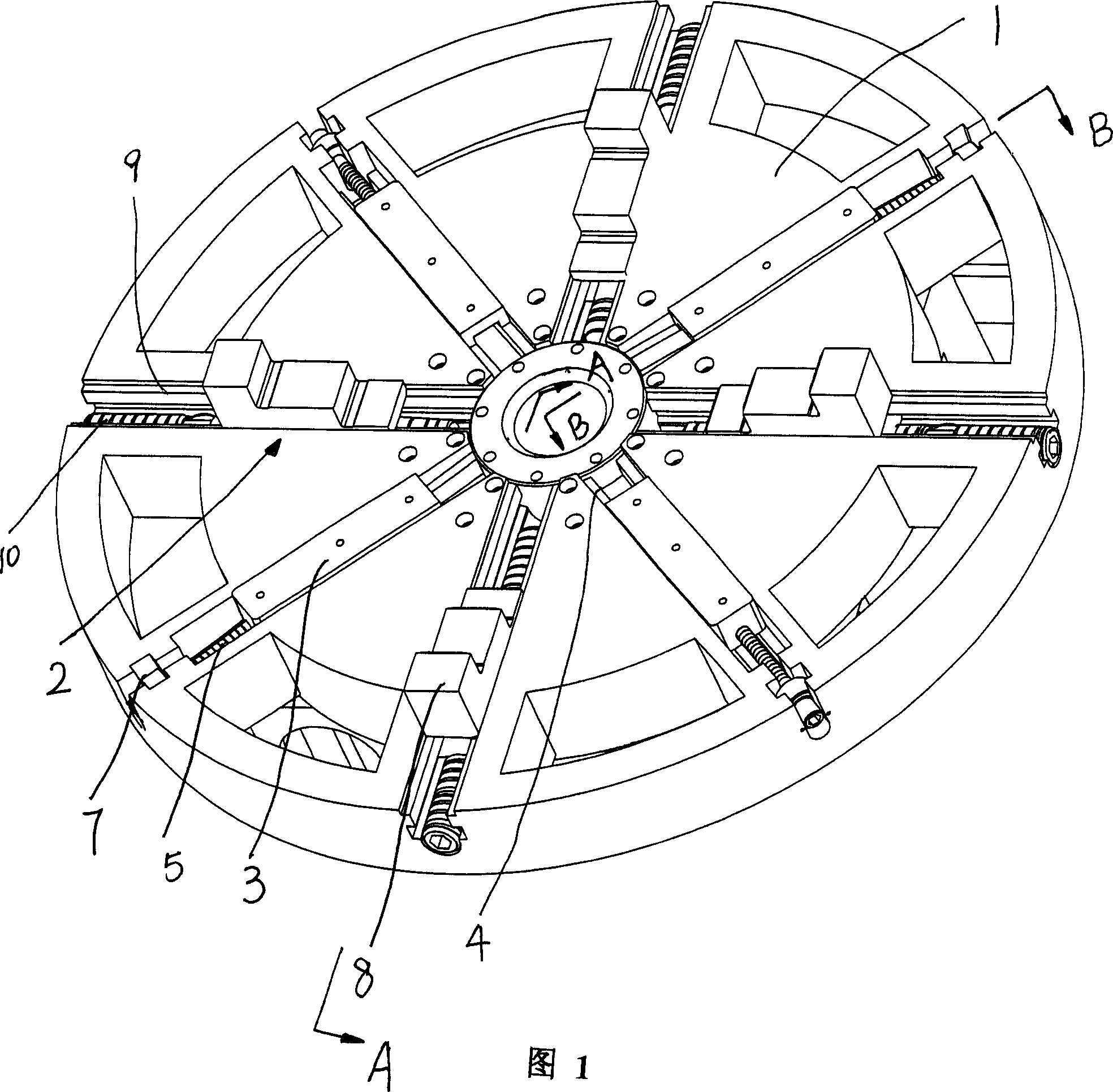

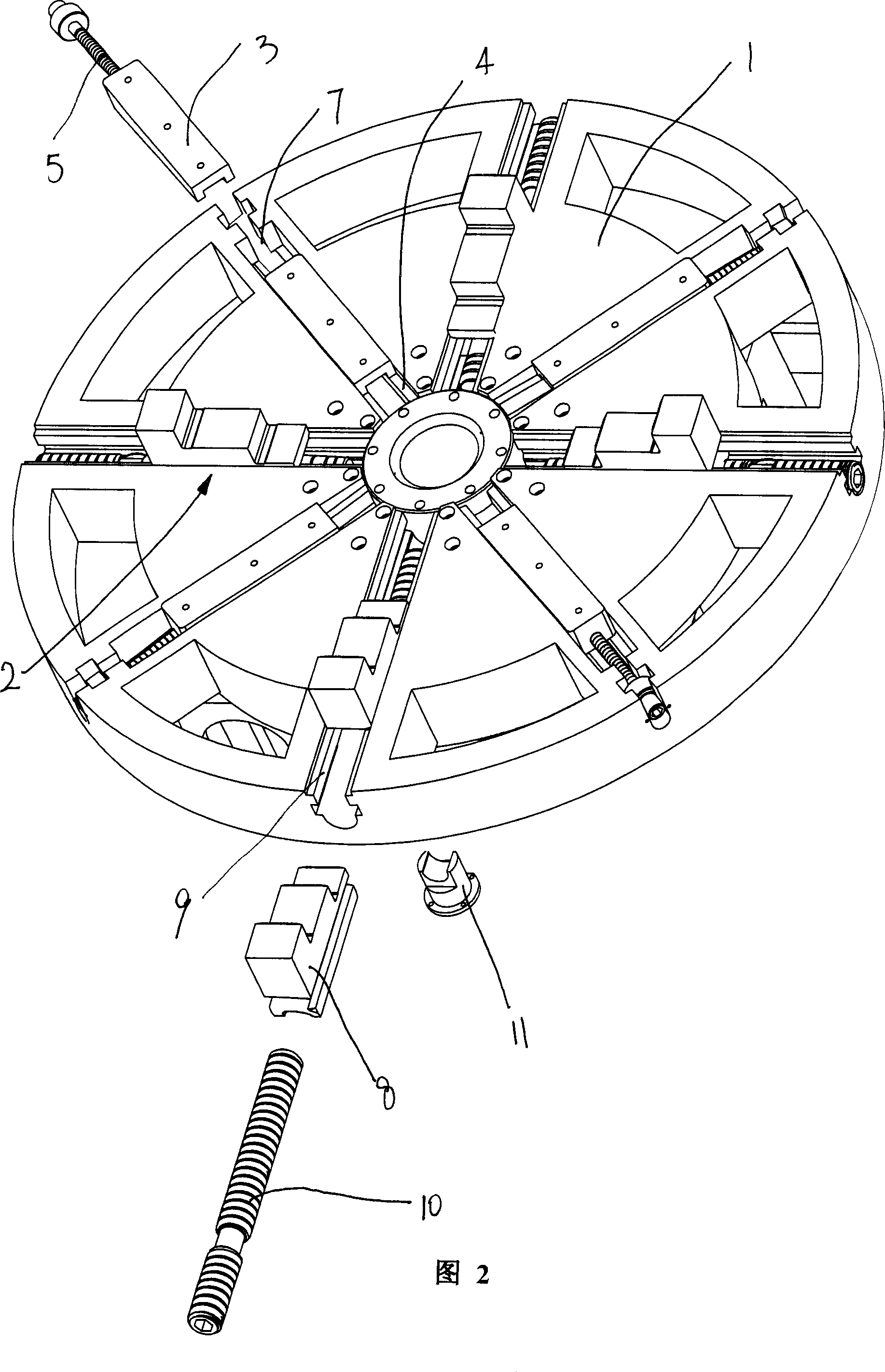

[0017] A workbench of a molding electric discharge machine as shown in Figures 1 to 4, it includes a workbench body 1, a fixing part 2 arranged on the workbench body 1 for fixing workpieces, and each attachment In the embodiment shown in the figure, the fixing part 2 is four clamping blocks, and the four clamping blocks can firmly fix the workpiece on the workbench body 1, and the workbench body 1 is also provided with a support for supporting the workpiece. There are four spacers 3 in the embodiments shown in the accompanying drawings, and the spacers 3 are arranged on the workbench body 1 in a liftable manner.

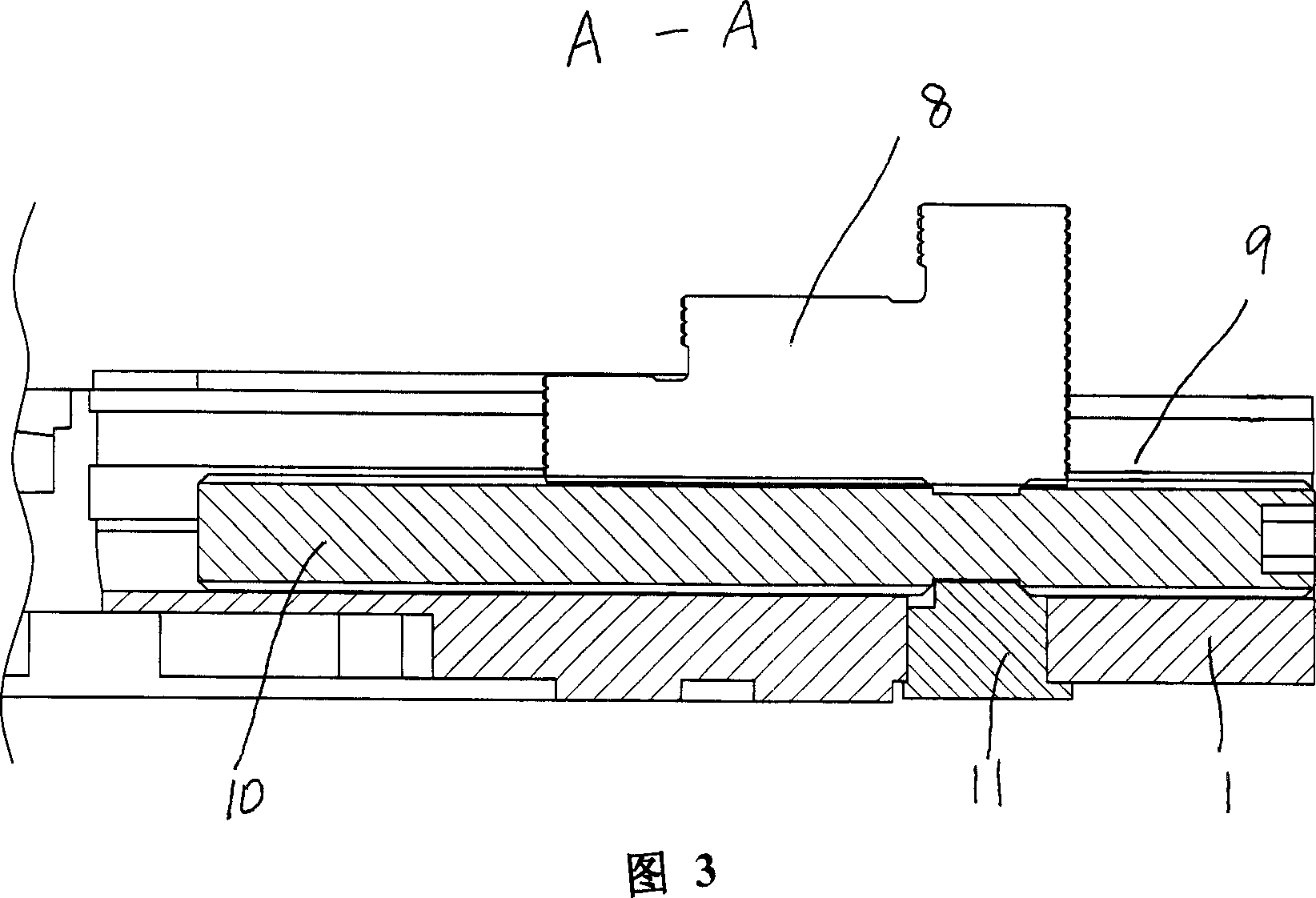

[0018] Said workbench body 1 is provided with rails 4, and in the preferred embodiment generally adopted in the present invention, there are two pairs of rails 4, and each pair of rails 4 is located on the same straight line, and the top of said rails 4 The surface is a wedge-shaped surface 6 inclined relative to the upper surface of the workbench body 1. The four pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com