Liquid ejection apparatus

一种喷射装置、液体喷射头的技术,应用在印刷等方向,能够解决墨水雾化、喷嘴堵塞、印字不良等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

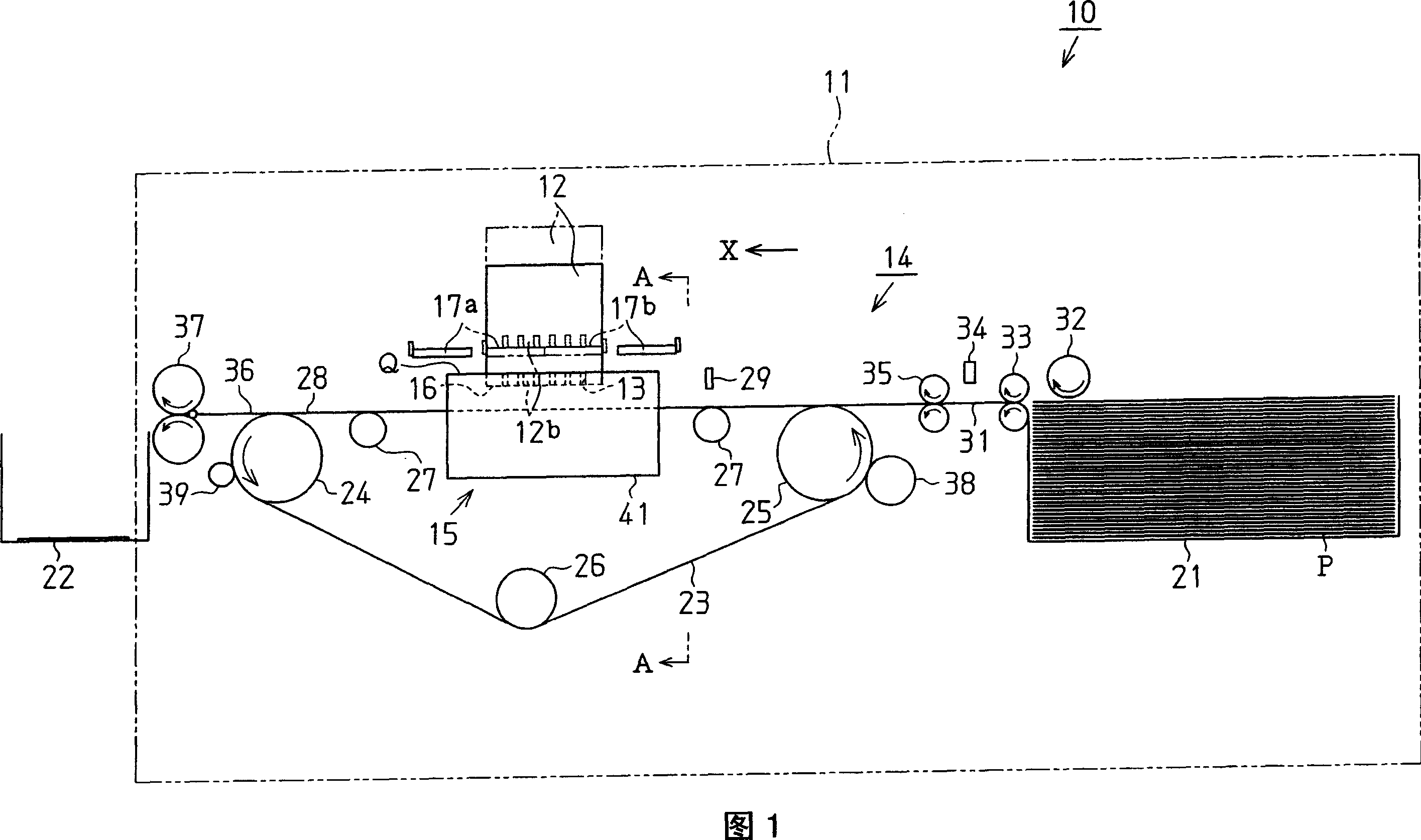

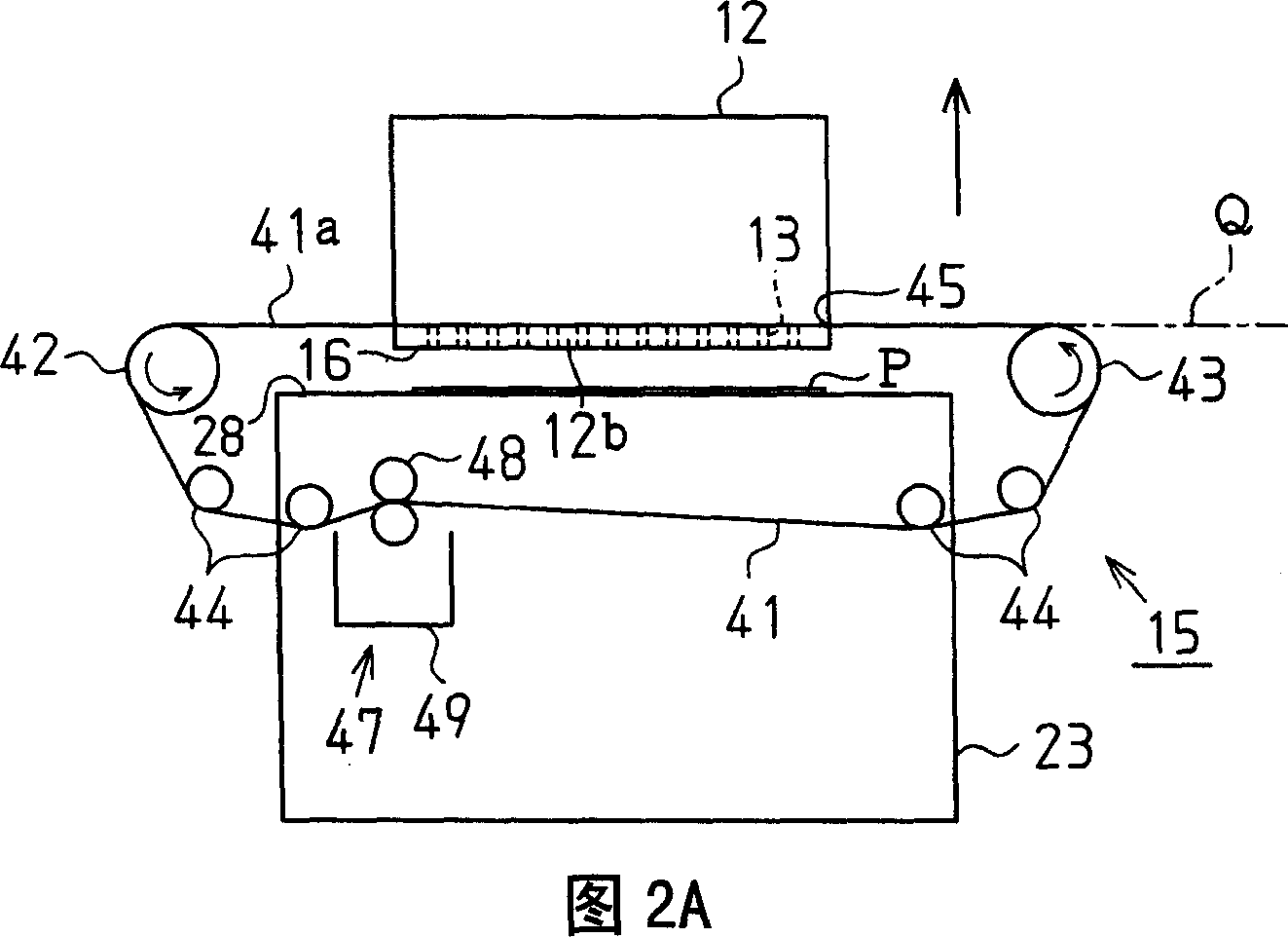

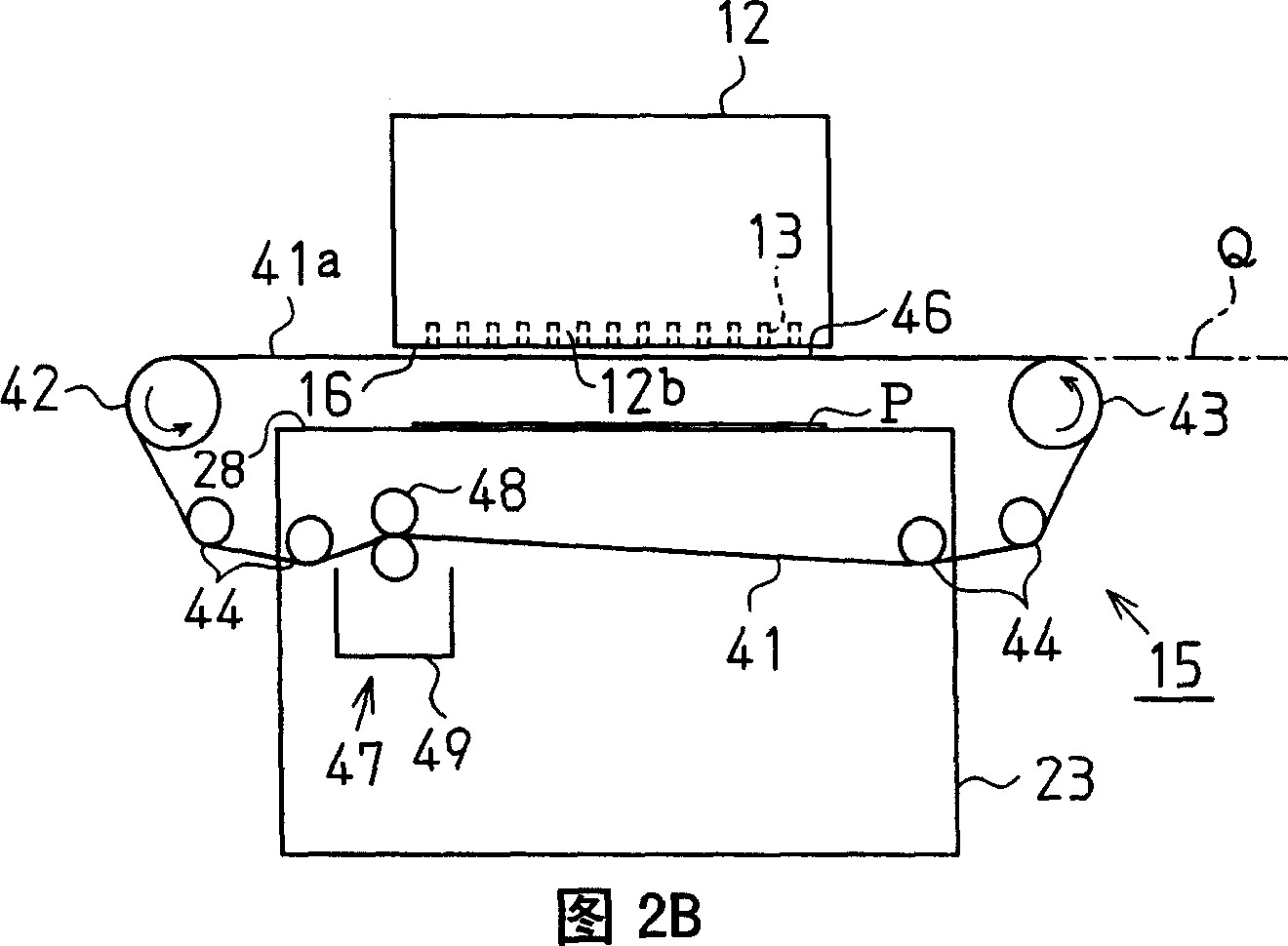

[0014] An embodiment of the present invention will be described below with reference to FIGS. 1 to 4 .

[0015] As shown in FIG. 1 , an inkjet printer (hereinafter referred to as “printer”) 10 as a liquid ejecting device according to the present embodiment includes a substantially box-shaped main body casing 11 . A recording head 12 (liquid ejection head) for ejecting ink (liquid) onto a target paper P is disposed substantially in the center of the main body casing 11 .

[0016] On the nozzle forming surface 16, which is the lower surface of the recording head 12, a plurality of nozzles 13 are formed over the entire width of the printing area of the paper P in a direction intersecting the conveying direction of the paper P (direction X indicated by an arrow in FIG. 1 ). , the recording head 12 does not reciprocate in a direction intersecting the transport direction of the paper P during printing. In this regard, the printer 10 of the present embodiment is not a type in whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com