Independent die cutting apparatus for liquid filling machine

A filling machine and liquid technology, applied in packaging, metal processing, etc., can solve the problems that affect the economic benefits of manufacturers, affect consumers' desire to buy, affect the aesthetics of products, etc., and achieve simple structure, high production efficiency, and reliable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

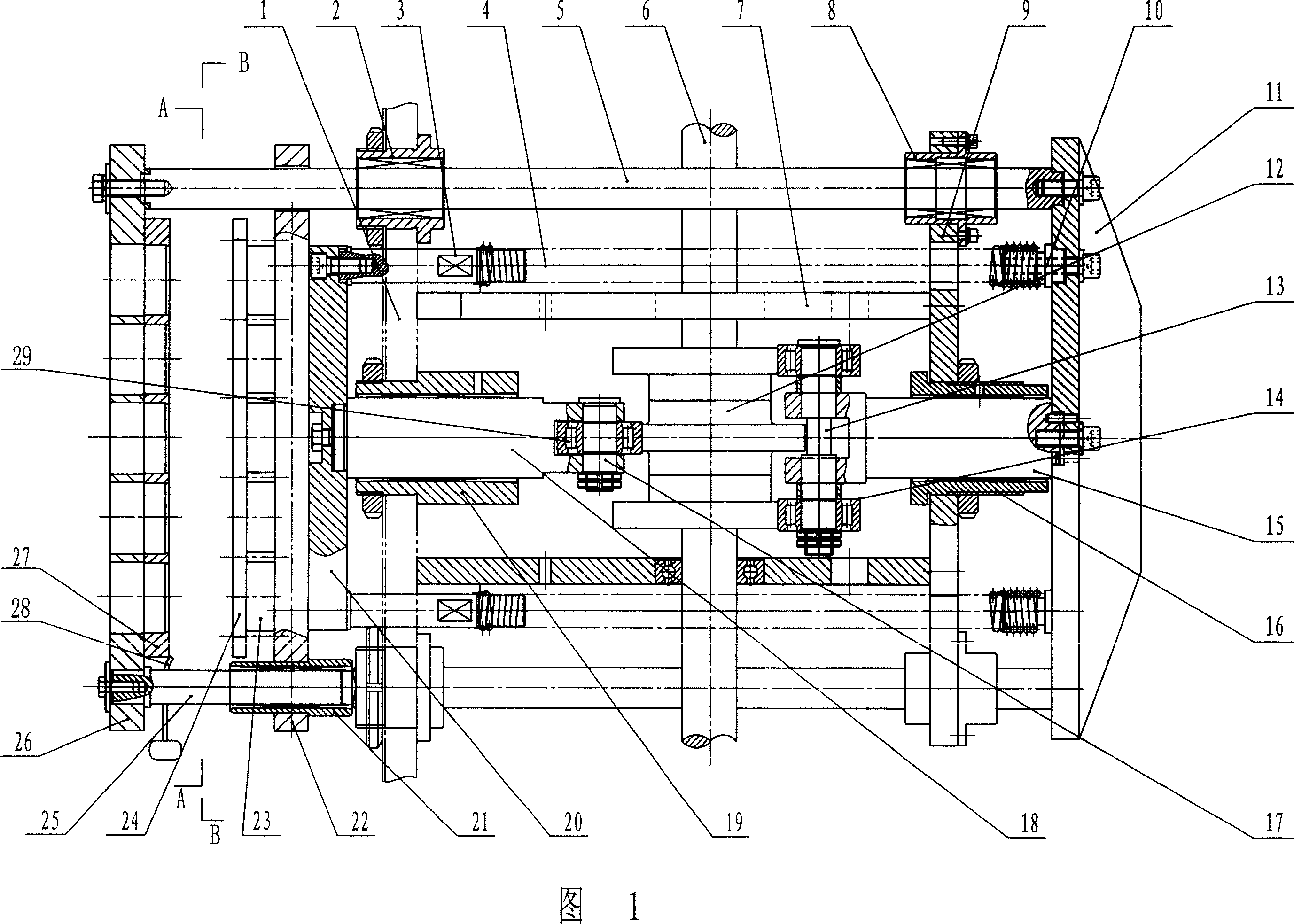

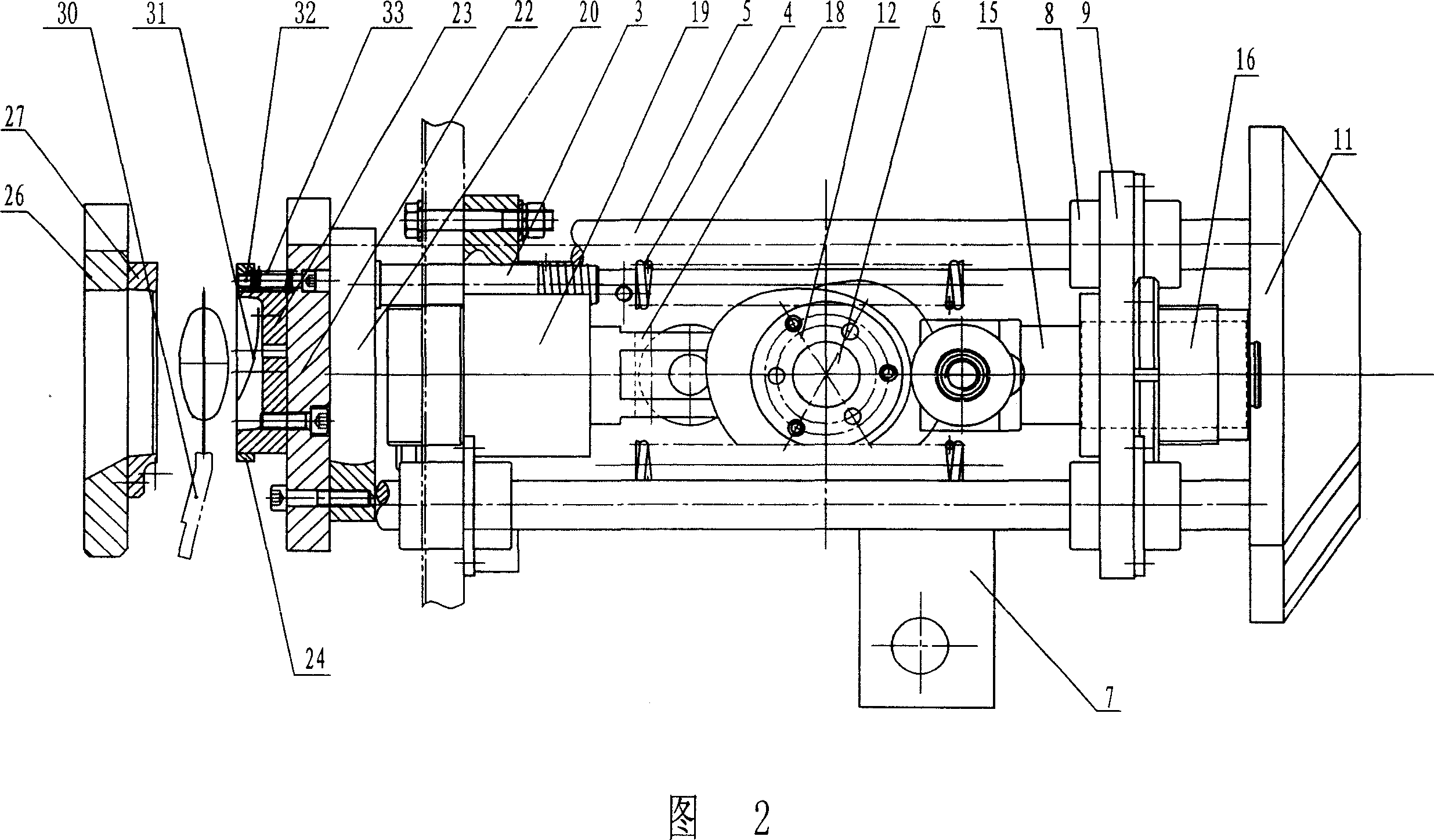

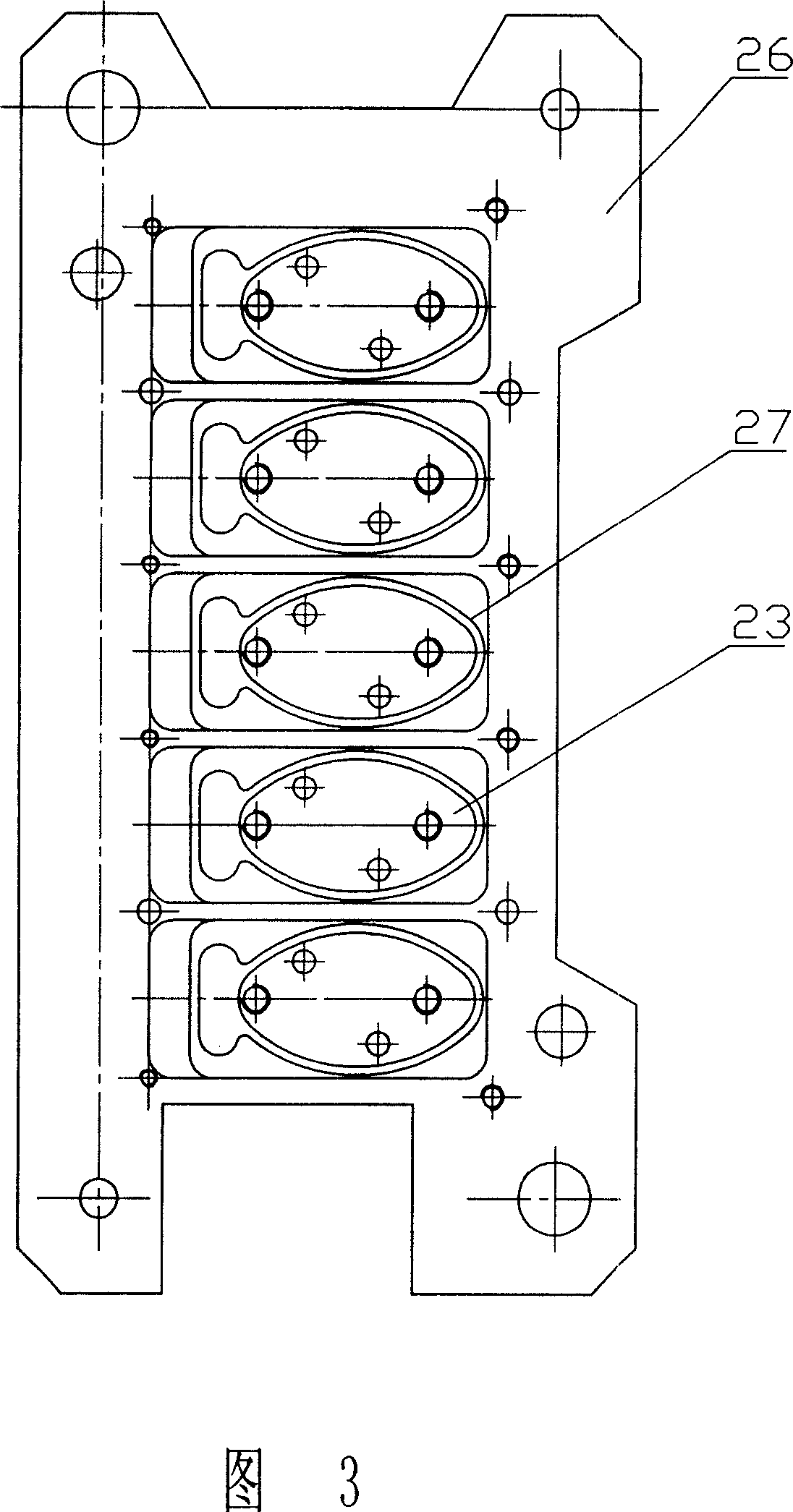

[0017] As shown in the figure, the independent punching device of the liquid filling machine includes a body composed of a body main board 1, a rear fixing plate 9 and two fixing plates 7, and the two fixing plates 7 are symmetrically connected to the body main board 1 and the rear fixing board by bolts. Between the plates 9, a main transmission shaft 6 is installed on the two fixed plates 7 through bearings, and one end of the main transmission shaft 6 is connected with the output end of the reducer of the liquid filling machine. A punching cam group 12 is installed in the middle of the main transmission shaft 6, and the punching cam group 12 is an integral wheel made of three cams, wherein the cam in the middle is eccentrically opposite to the cams on both sides. The middle part of body main board 1 and rear fixed plate 9 is respectively fixed with sliding sleeve 19 and sliding sleeve 16 by nut, and in sliding sleeve 19 and sliding sleeve 16, mobile shaft 18 and bracket shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com