Aluminum electrolytic cell current transfer method and apparatus thereof

An aluminum electrolytic cell and current conversion technology, which is applied in the field of stopping or opening electrolytic cells, can solve problems such as endangering the life of the electrolytic cell, and achieve the effects of prolonging life, simple structure and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

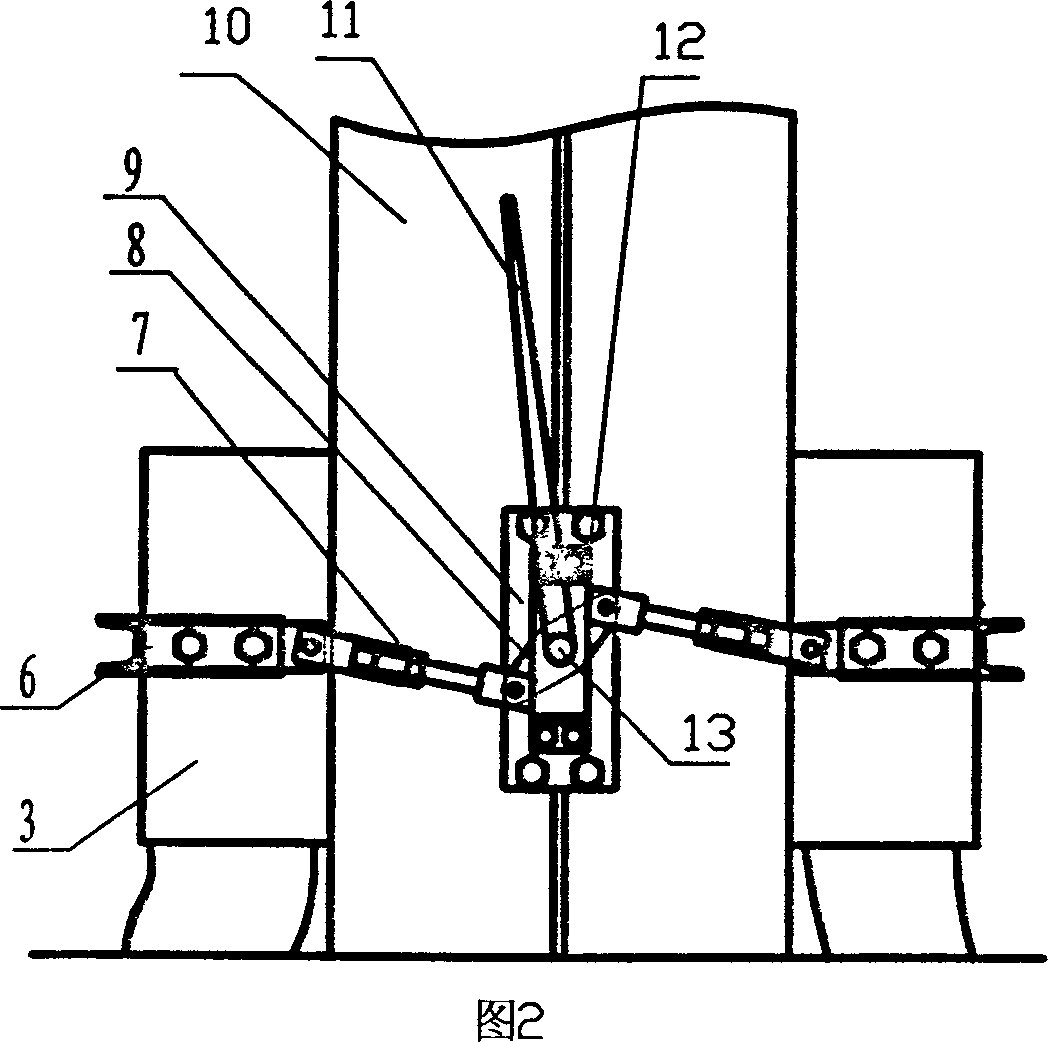

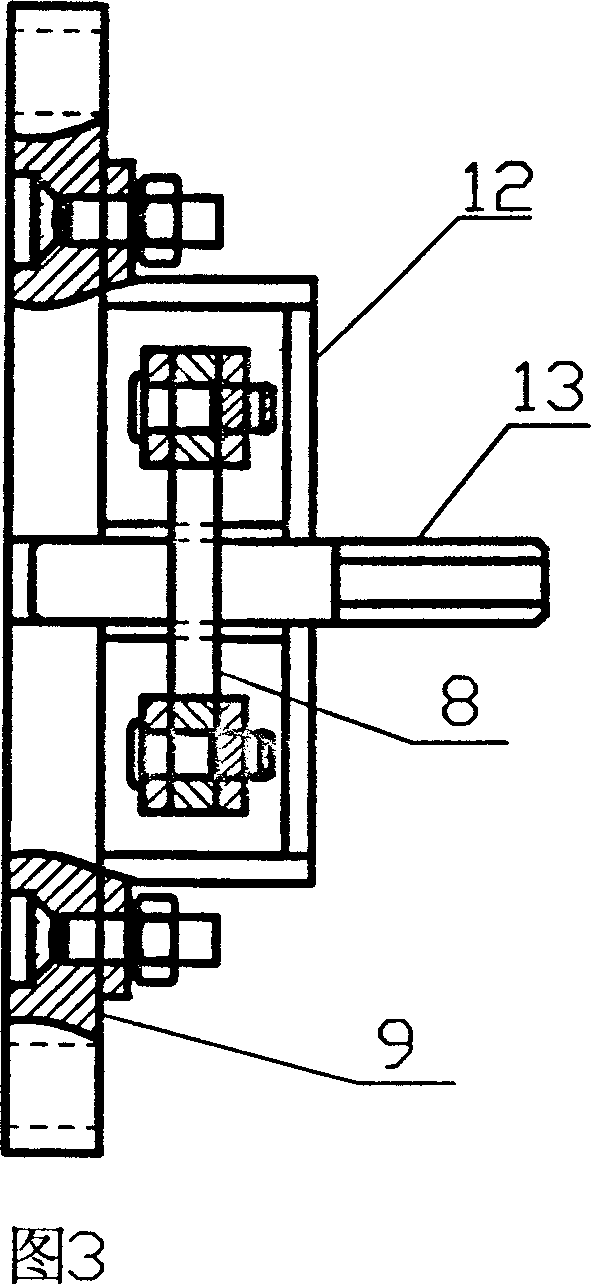

[0027] Below in conjunction with accompanying drawing, the utility model is further described:

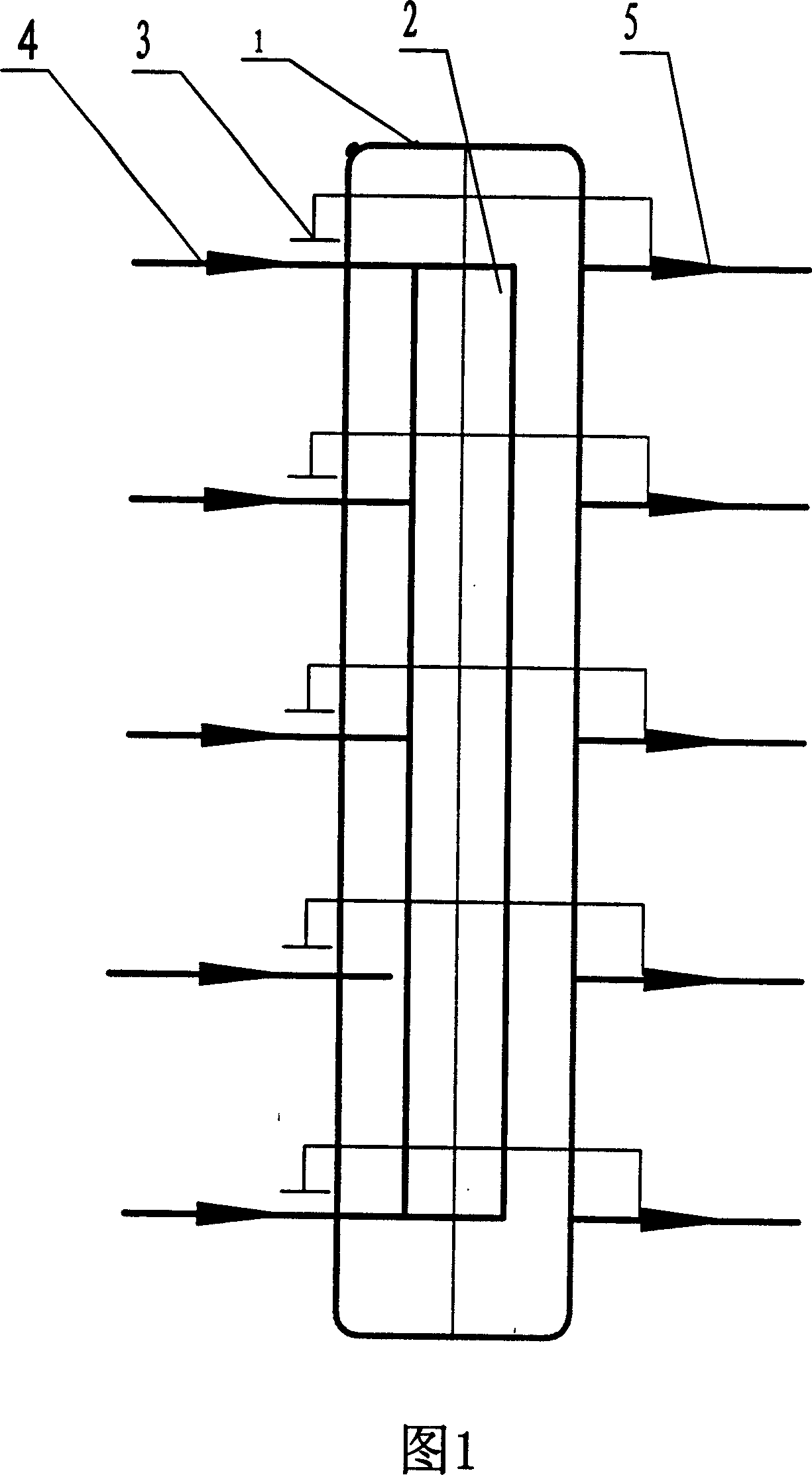

[0028] It can be seen from Figure 1 that the electrolytic cell body 1 is the cathode, the anode bus 2 forms a current path through the anode carbon block and the cathode under it, the short-circuit block 3 is connected to the outlet bus 5 through the short-circuit bus connected to it, and the power-in terminal bus 4 is the column busbar; when the electrolyzer is in production, the current enters 2 from the power-incoming busbar 4, and is introduced into the cathode through the anode carbon block connected with the anode busbar 2, and is output from the cathode busbar 5, and enters the next electrolyzer to form a series series Circuit; when the electrolyzer is stopped, all short-circuit blocks 3 need to be connected with all columns 4, usually in the form of crimping, and the short-circuit blocks 3 are crimped to the columns through bolts, and there are 1 to 2 short-circuits on each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com