Wide voltage energy-saving controller for contactor

A contactor, wide voltage technology, applied in circuits, relays, electrical components, etc., can solve problems such as high operating noise, high power consumption, and narrow operating voltage range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

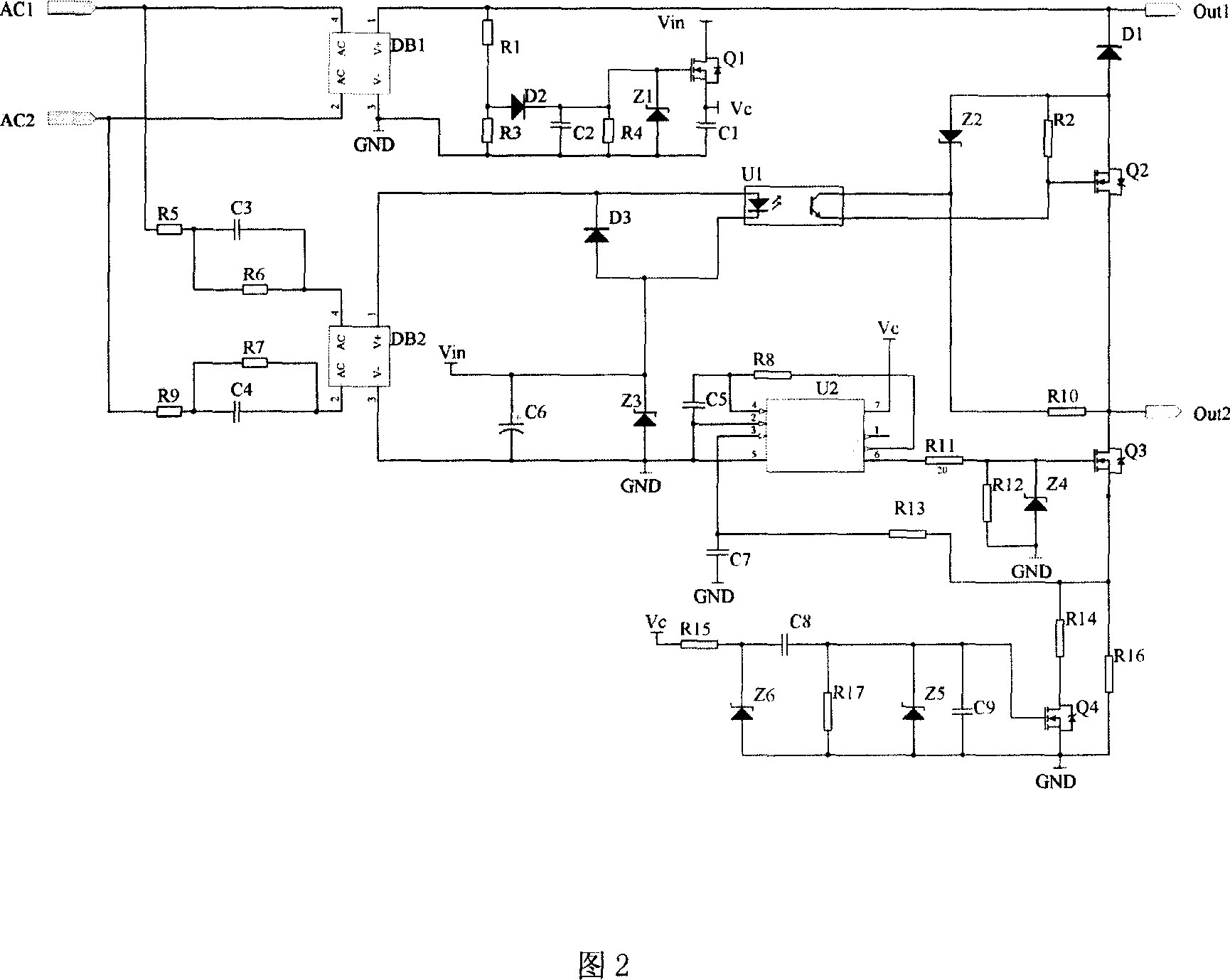

[0008] As shown in Figure 2, AC1 and AC2 are connected to the control power supply of the contactor, and Out1 and Out2 are connected to the coil of the contactor. Adjusting resistor R14 can adjust the pull-in current of the contactor; adjusting resistor R16 can adjust the holding current of the contactor; adjusting resistor R3 can adjust the voltage value of undervoltage protection; when the contactor is opened, the power device Q2 is turned off, Quickly break the current in the coil of the contactor to realize the quick opening of the contactor.

[0009] By controlling the coil voltage of the contactor, the circuit of the present invention makes the contactor pull in and maintain a constant current, and the coil current fluctuates very little with the applied voltage, thereby realizing wide voltage operation of the contactor, low power consumption and no noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com