Methods for the production of sildenafil base and citrate salt

A technology for sildenafil and sildenafil citrate, which is applied in the field of preparing sildenafil base and its citrate, can solve problems such as difficulty in removing by-products, complicated purification, and economic limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

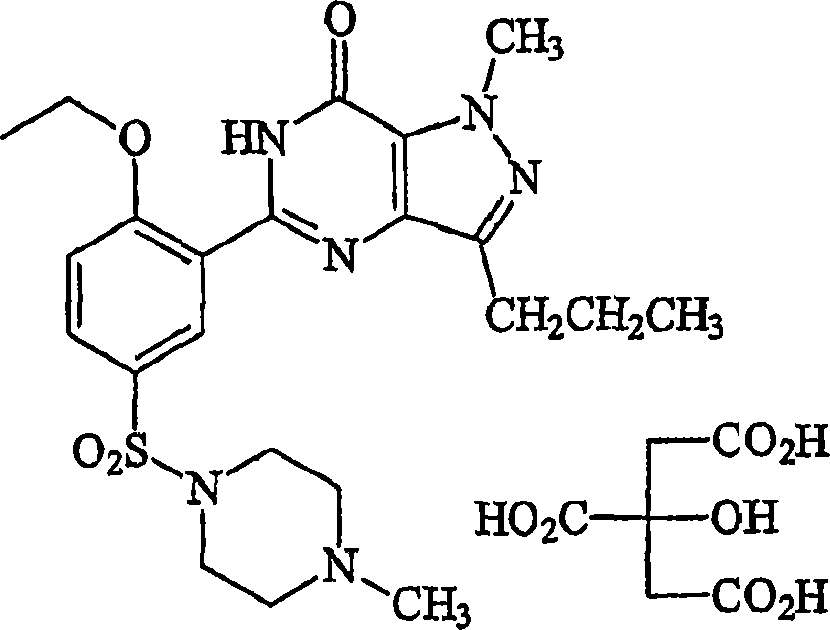

Image

Examples

Embodiment 1

[0051] Embodiment 1: unconventional preparation of sildena

[0052] In a three-necked flask, benzenesulfonyl chloride-3-(4,7-dihydro-1-methyl-7-oxo-3-propyl-1H-pyrazolo(4,3-d )pyrimidin-5-yl)-4-ethoxyphenyl) (5g, 12.2mmol) was mixed with acetone (100ml) followed by the addition of 47% aqueous NaOH (0.487g, 10mmol). N-methylpiperazine (1.34 g, 11 mmol) was added dropwise. The reaction mixture was stirred for 45 min, then cooled to 0 °C and filtered. The precipitate was washed twice with water, and dried at 50° C. and a vacuum of 10 mmHg to obtain sildenafil with a yield of 88.8%.

Embodiment 2-13

[0054] Table 1. The yields of sildenafil synthesized using various solvents

Embodiment 14

[0055] Embodiment 14: the synthesis of sildenafil citrate

[0056] In a three-necked flask, sildenafil (5 g, 10 mmol) was dissolved in acetone (40 ml) at 50°C. In a separate vessel, citric acid (2 g, 10 mmol) was dissolved in acetone (15 ml). Both solutions were filtered. When the citric acid solution was added dropwise to the sildenafil solution, a white precipitate appeared immediately. Thereafter the reaction mixture was heated, maintained at the reflux temperature of the solvent for 1 hour, then cooled at room temperature for 3 hours. The precipitate was collected by filtration and dried at 50° C. and a vacuum of 10 mmHg to obtain sildenafil citrate with a yield of 95.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com