Catalyst for ethylbenzene dehydrogenation-hydroxide reaction

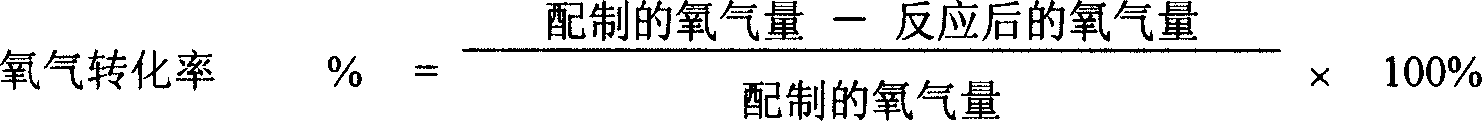

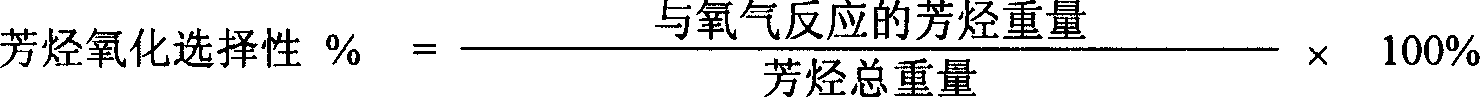

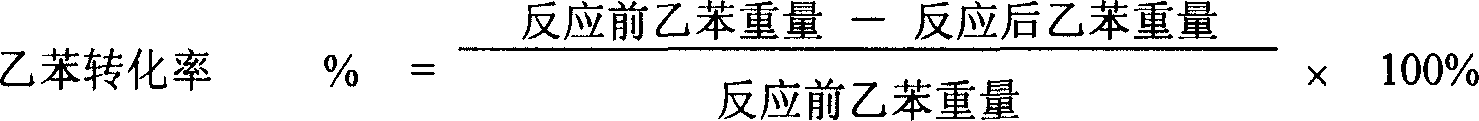

A hydrogen oxidation reaction and ethylbenzene dehydrogenation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrocarbons, etc., can solve low oxygen conversion rate and aromatics oxidation selectivity advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 0.536 g of chloroplatinic acid, 0.347 g of tin chloride, 2.532 g of cerium nitrate and 0.926 g of lithium nitrate in 40 ml of deionized water to prepare an impregnation solution; 5 mm cylindrical α-Al 2 o 3 Put the carrier into a rotatable container, add the impregnating solution, keep the internal temperature of the container at 70-80°C, and dip while rolling until the impregnating solution disappears completely; take it out and put it in an oven, and dry it in the air at 80°C for 4 hours; take it out Put it into a calcination furnace, and calcine it in air at 550° C. for 4 hours to obtain a finished hydrogen oxidation catalyst.

Embodiment 2

[0032] The catalyst was prepared according to the method of Example 1, except that the active precursor was 0.027 gram of chloroplatinic acid, 0.035 gram of tin chloride, 0.253 gram of cerium nitrate and 0.046 gram of lithium nitrate.

Embodiment 3

[0034] Prepare catalyst according to the method for embodiment 1, difference is that active precursor adopts 0.536 gram chloroplatinic acid, 0.868 gram tin chloride, 25.316 gram cerium nitrate and 4.631 gram lithium nitrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com