Railway turnout ballast cleaning-sieving machine(6)

A ballast cleaning machine and turnout technology, which is applied in ballast layers, roads, tracks, etc., can solve the problems of unsatisfactory, increased excavation width, and long time of manual auxiliary operations, etc., and achieves the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

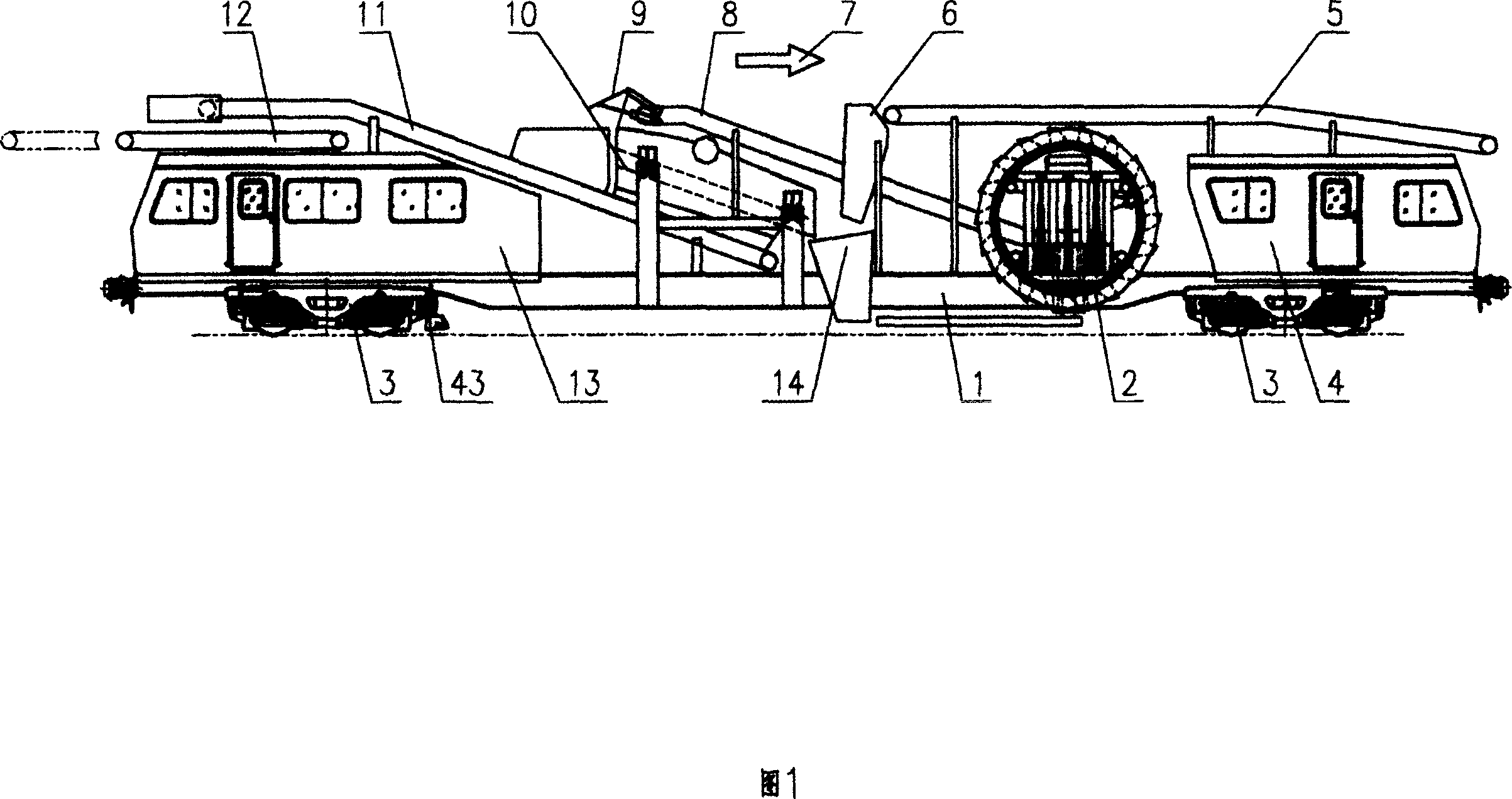

[0026] In Fig. 1, a set of excavating mechanisms 2 are respectively installed on both sides of the main frame 1, and the main frame is also equipped with a driver's cab 4, a new ballast conveying device 5, a ballast dividing bucket 6, a mixed ballast conveying device 8, a vibrating screen 10. Sludge conveying device 11, rotary conveying device 12, machine room 13, slag discharge device 43, backfill slag hopper 14, etc. The whole machine is also provided with two sets of walking driving devices 3, and a Ballast blocking device 9, rotary conveying device 12 can be done ± 180 ° of rotations, can be rotated to the complete machine rear, also can be rotated to complete machine one side. During operation, the whole machine walks in direction 7.

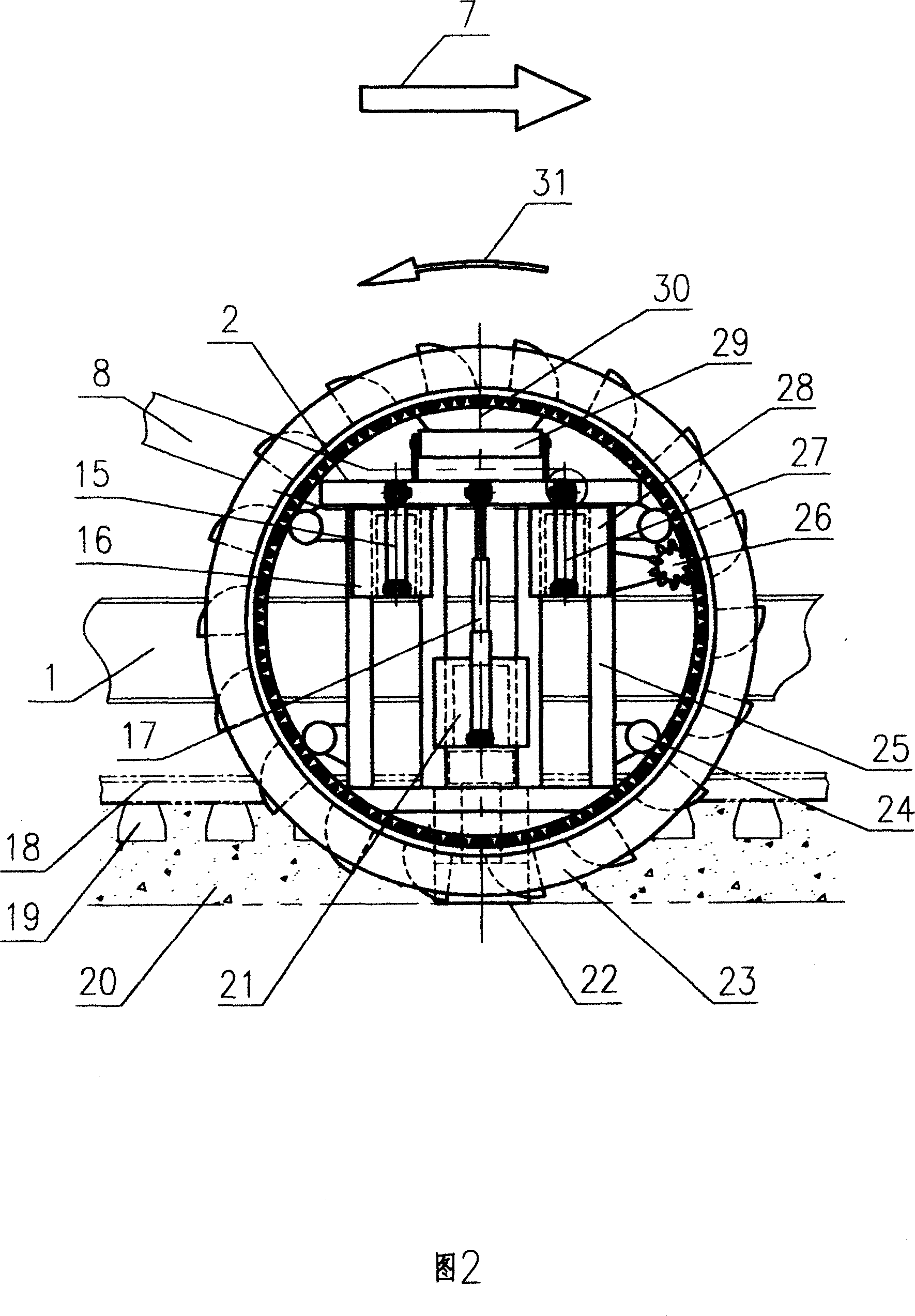

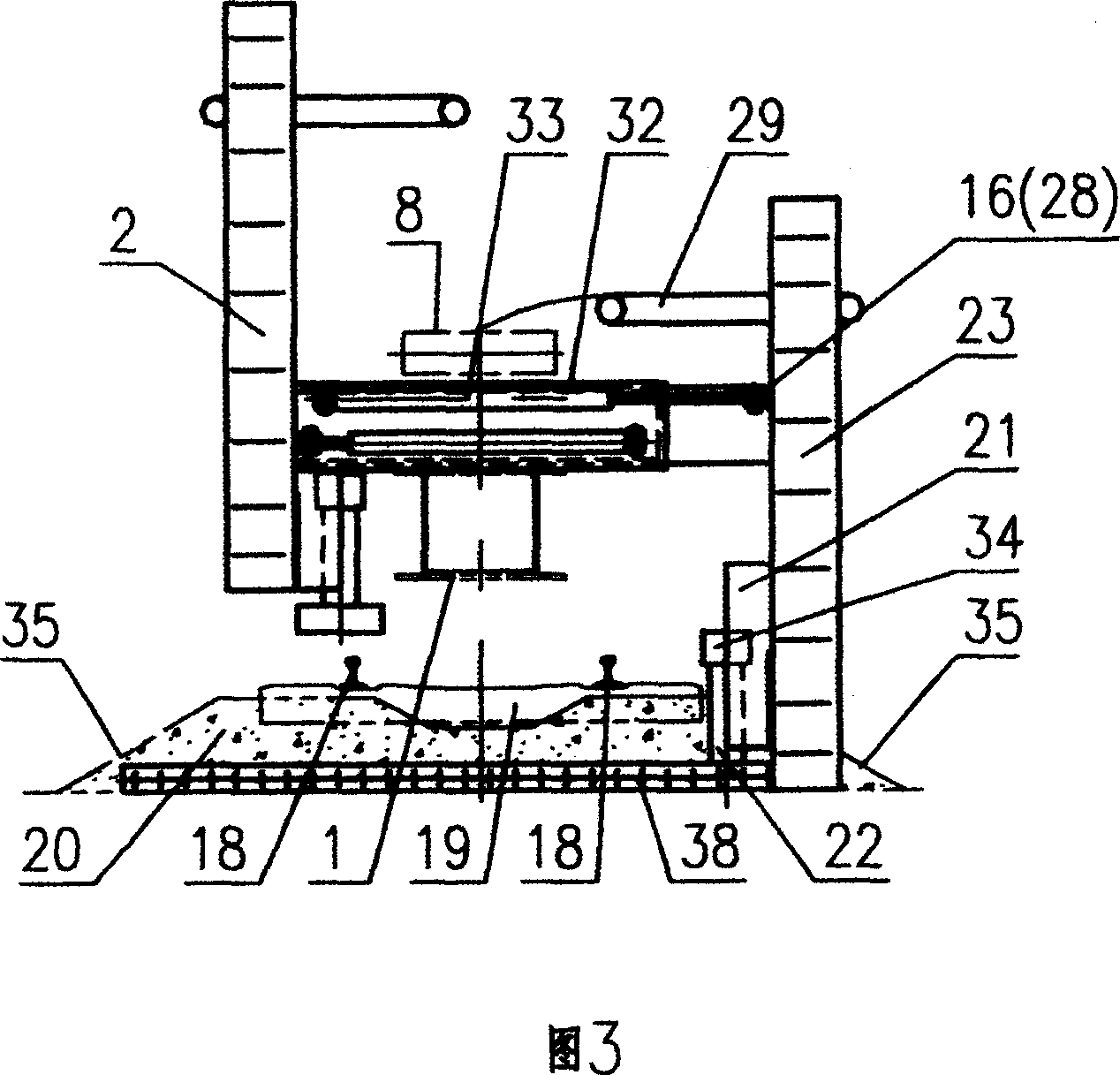

[0027] Among Fig. 2, 2 is a set of digging mechanism. Excavating mechanism 2 is made up of bed scraping device 22, bucket wheel 23, bucket wheel support 25, belt conveyor 29 and the like. The bucket wheel 23 is installed on the bucket whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com