Adsorbing separation preventing rubber grains and cilia convection method and apparatus

A technology of rubber particles and separation method, which is applied to the separation of solids from solids by air flow, solids separation, chemical instruments and methods, etc., can solve the problem of increasing manufacturing difficulty and production cost, high cost of semi-manual operation, and increased maintenance expenditure. and other problems, to achieve the effect of easy production and promotion, easy connection and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

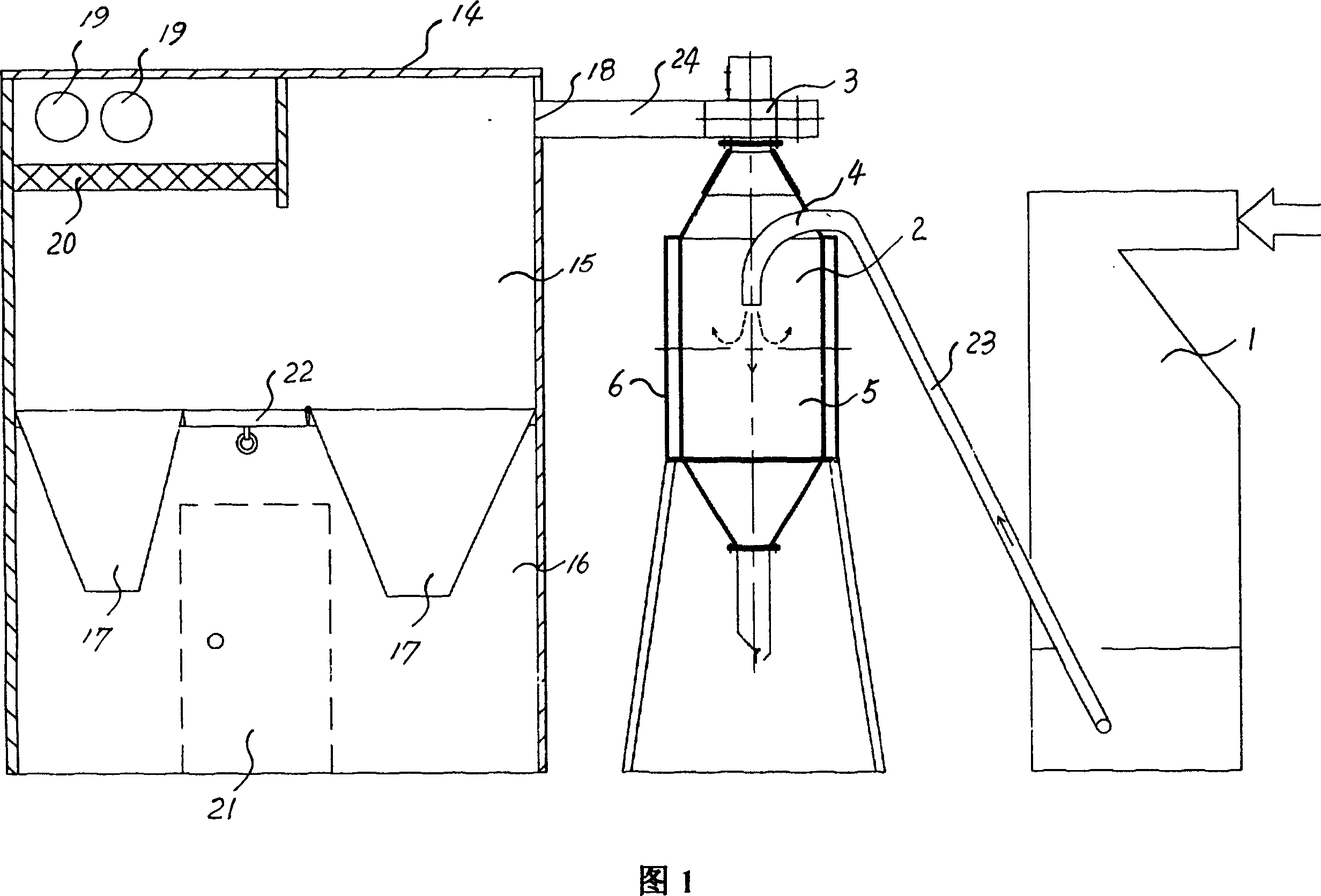

[0024] Special equipment of the present invention comprises:

[0025] A shredder1.

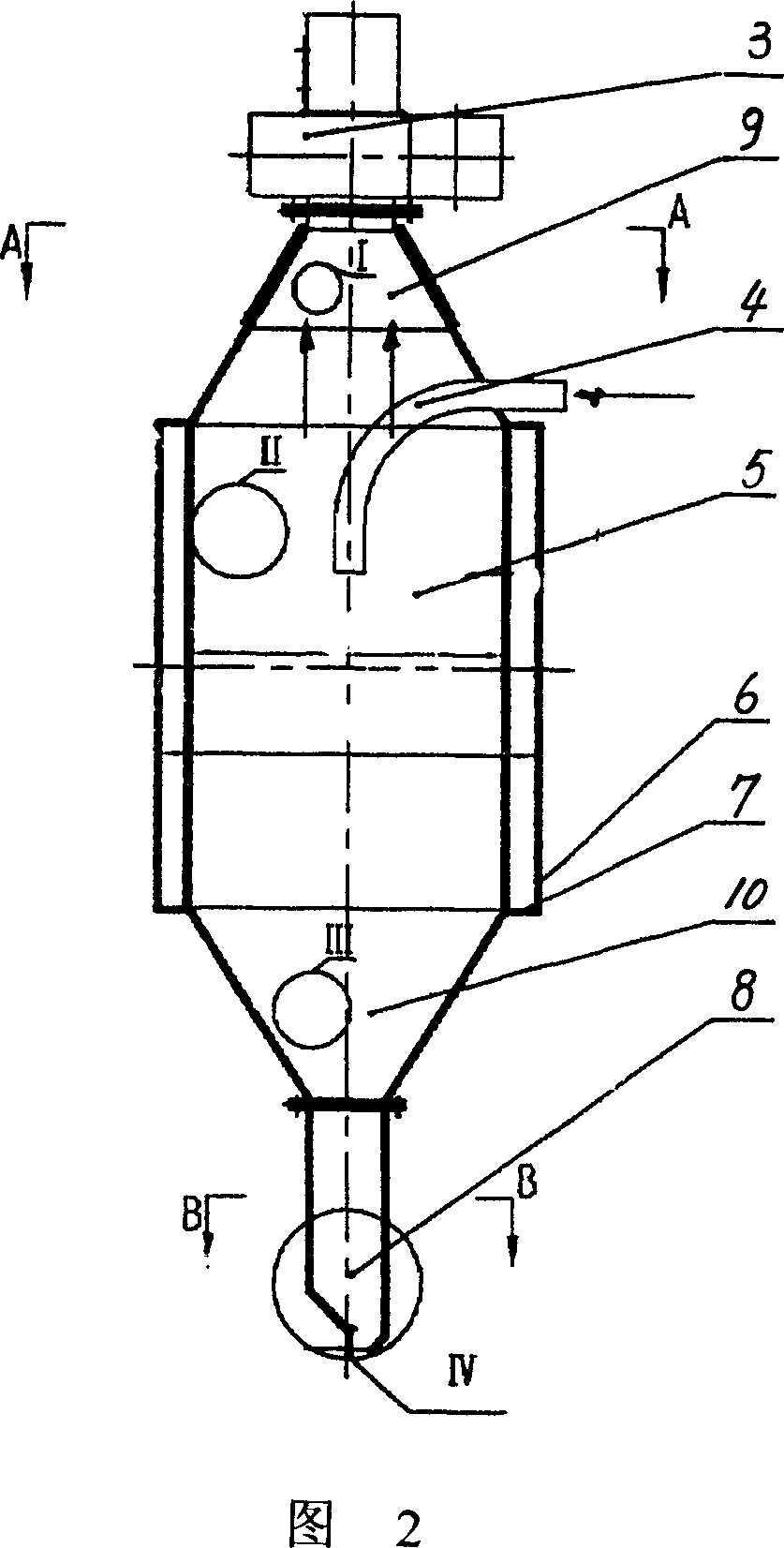

[0026] A convection anti-adsorption separator 2, the convection anti-adsorption separator 2 is a cylindrical structure with tapers at both ends, a centrifugal fan 3 is installed at the top outlet, and a downward feeder is provided on the upper shoulder of the cylinder Tube 4 and outer shell 6 are arranged on the outside of the middle liner 5, and the inner liner 5 and the shell 6 are interlayer structures, with air inlet holes 7 on the upper and lower sides of the interlayer, and a storage barrel 8 with a duckbill-shaped automatic closer at the lower end.

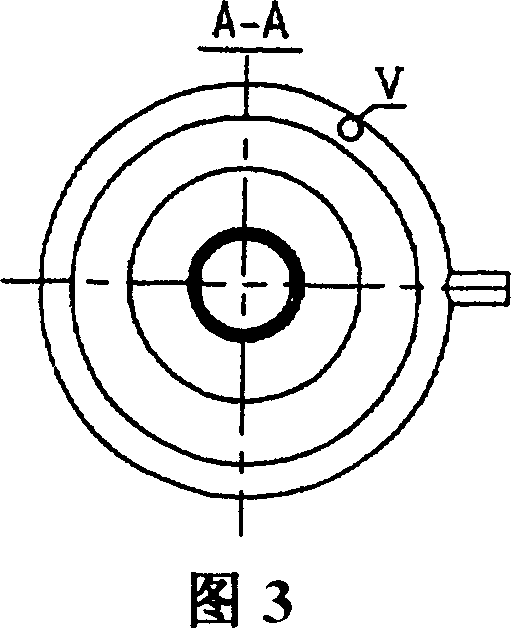

[0027] The middle liner 5 of the convection anti-adsorption separator 2 and the tapered cylinders 9, 10 at both ends are respectively provided with regularly arranged annular air holes 11, 12, 13 with different sizes. The function of the annular air hole 11 of the inner tank is to offset the adsorption force of the inner tank wall by its a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com