Magnetic attraction floor

A floor and magnetic suction technology, applied in the field of magnetic suction floors, can solve the problems of cumbersome installation, lack of modification flexibility, and high cost, and achieve the effects of convenient partial or overall replacement, reduction of regular renovation costs, and easy floor laying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

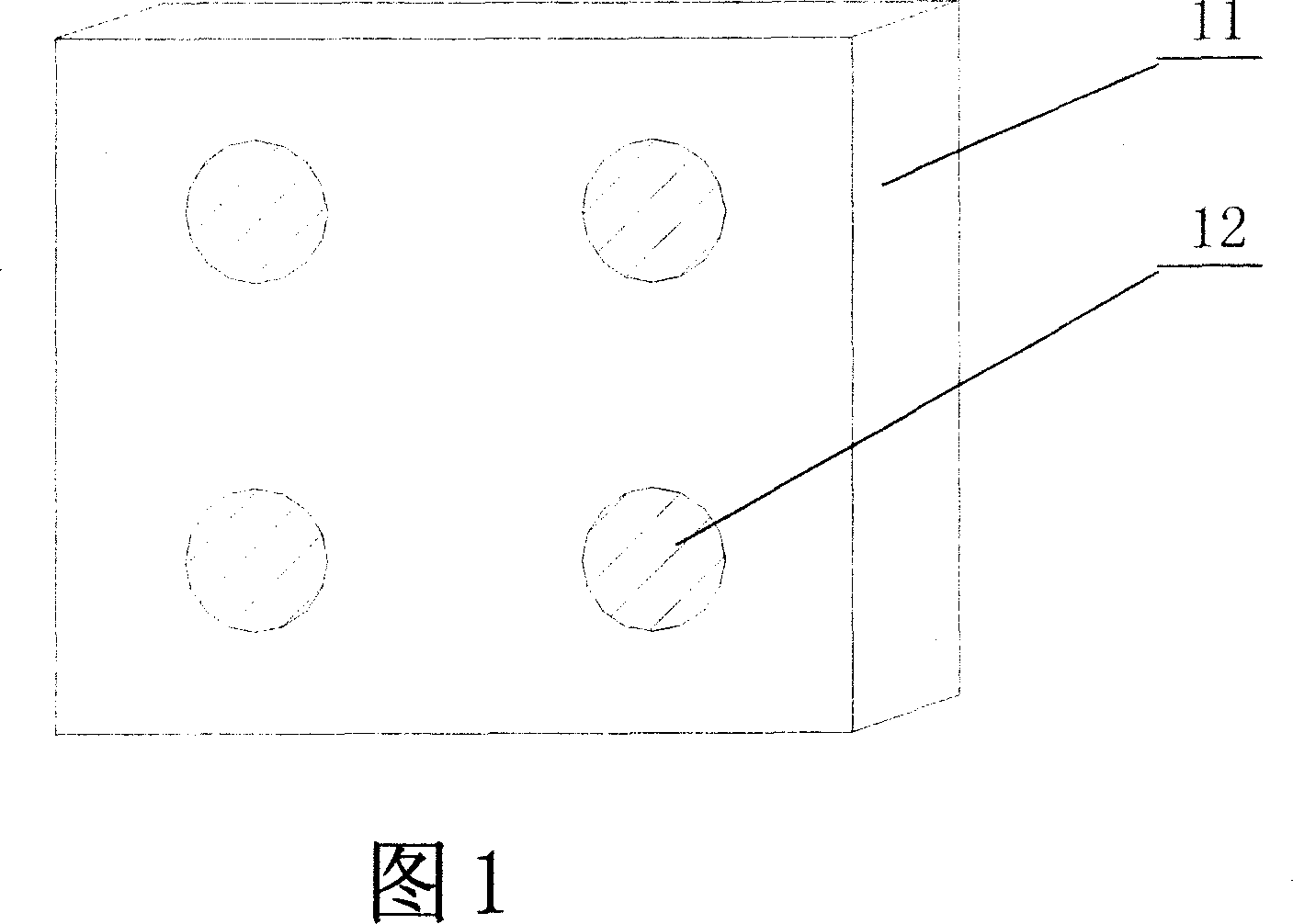

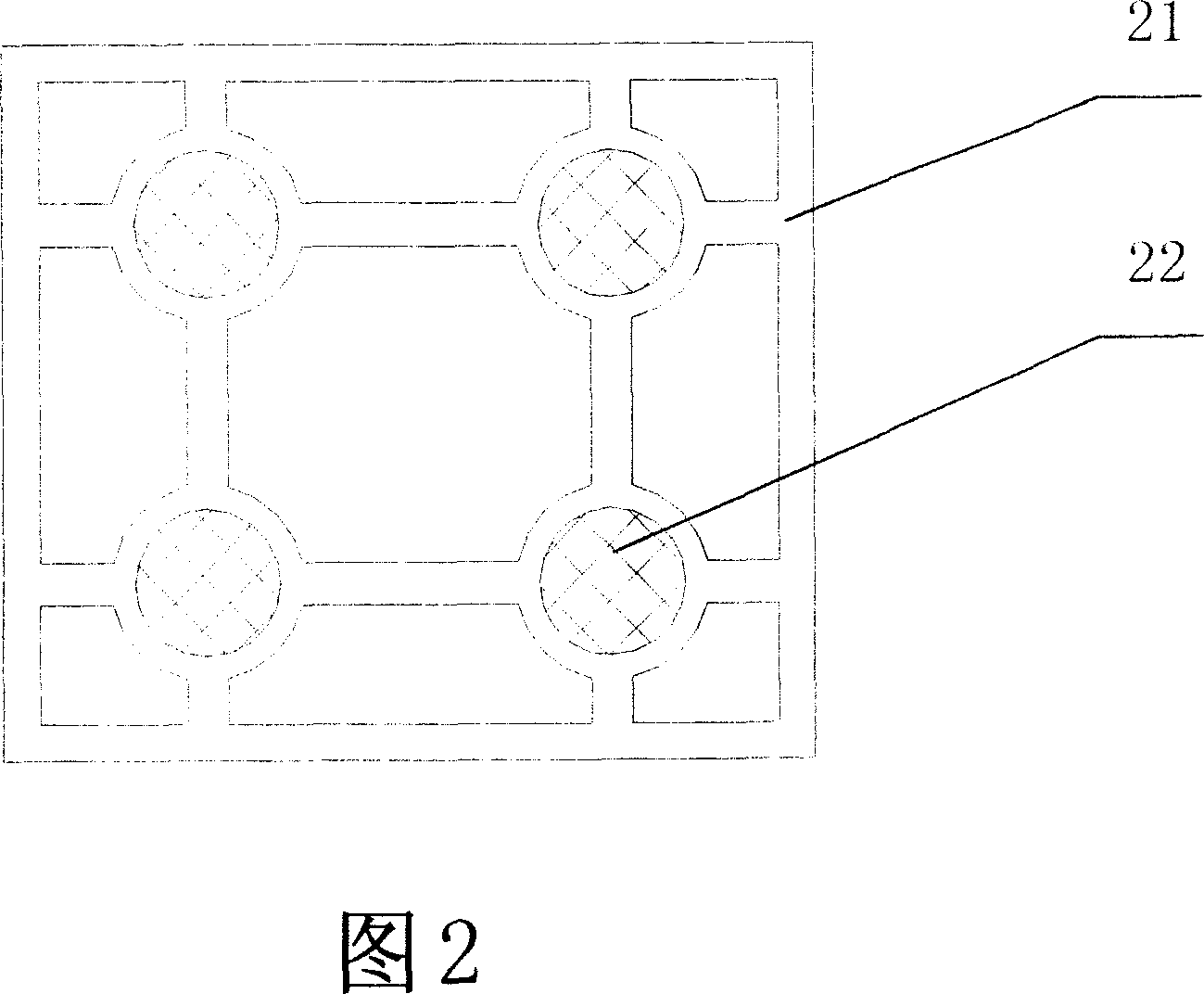

[0034] Please refer to Figure 1 and Figure 2. In Fig. 1, four grooves (φ=32mm, deep H=1.3mm) on the lower plane of the porcelain floor tile 11 with a specification of 200mm×200mm×7mm are equipped with φ=30mm and four iron sheets 12 with a thickness of 1.2mm. The porcelain floor tile 11 is bonded to the iron sheet 12 with an adhesive, and the outer plane of the iron sheet 12 is on the same level as the lower plane of the porcelain floor tile 11 . In Fig. 2, the outer frame specification is 200mm * 200mm * 35mm four grooves (φ = 25mm, deep H = 15mm) on the floor base 21 are equipped with four pieces of said iron sheets that are flat with the porcelain floor tile 11 12 corresponding four permanent magnets 22. The permanent magnet is ferrite with φ=23mm and height h=14.5mm; the skeleton thickness of the floor base 21 is 20mm, and its material is PVC plastic. When laying the floor, the floor base 21 is fixed on the ground smoothly with cement mortar, and then the four iron sheets...

Embodiment 2

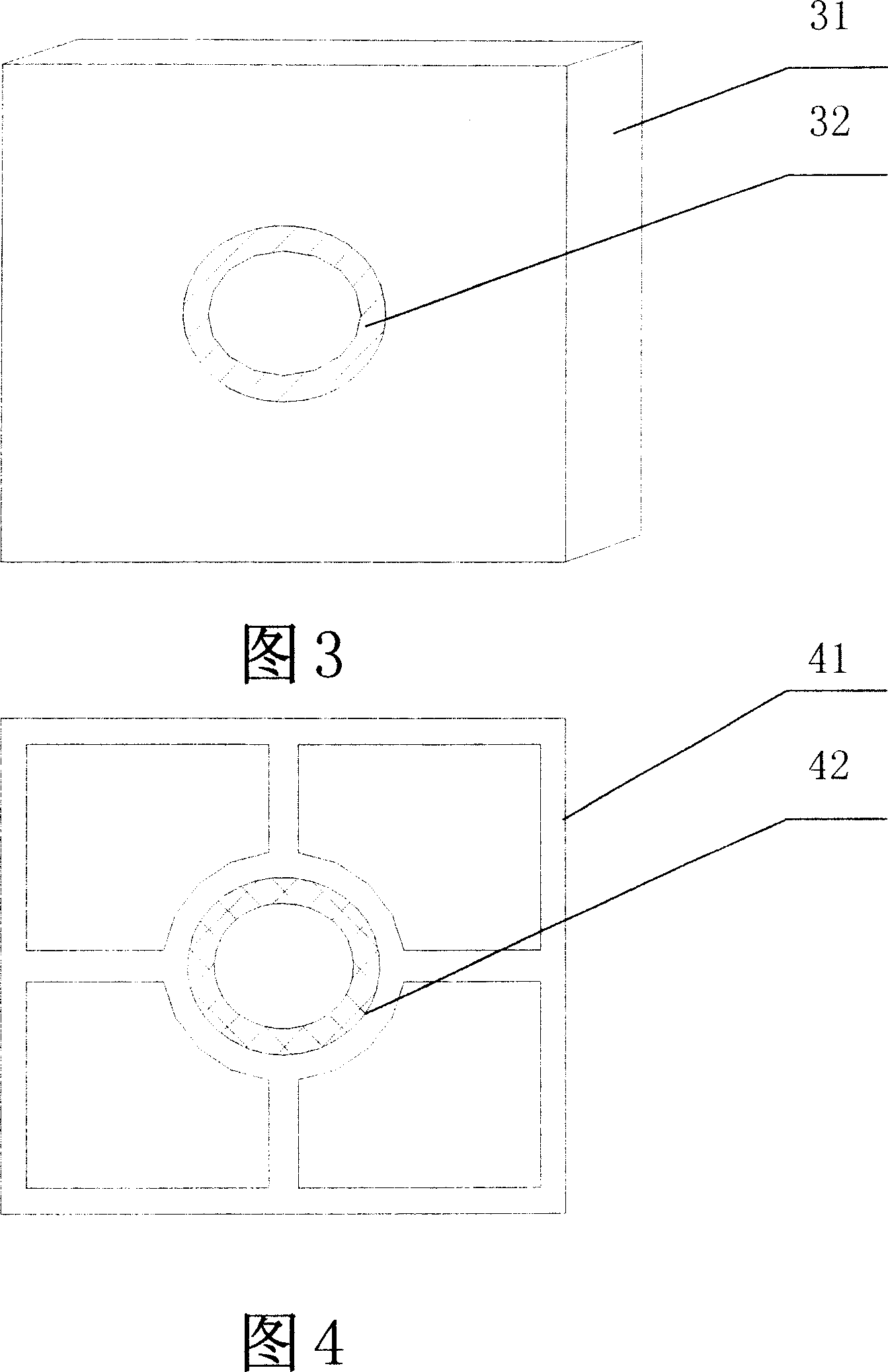

[0036]Please refer to Figure 3 and Figure 4. In Fig. 3, the specification is a groove (φ 外 =64mm, φ 内 =50mm, depth H=1.3mm) is equipped with a φ 外 =62mm, φ 内 =52mm, thickness is 1.2mm iron sheet 32, described porcelain floor tile 31 and described iron sheet 32 adopt adhesive bonding, and the outer plane of described iron sheet 32 and the lower plane of described porcelain floor tile 31 are on the same horizontal plane. In Fig. 4, the outer frame specification is the groove (φ 外 =62mm, φ 内 =52mm, deep H=8mm) a permanent magnet 42 corresponding to a piece of iron sheet 32 on the lower plane of the porcelain floor tile 31 is housed. The permanent magnet is of specification φ 外 =60mm, φ 内 =54mm, height h=7.5mm NdFeB; the skeleton thickness of the floor base 41 is 20mm, and its material is PVC plastic. When laying the floor, first fix the floor base 41 on the ground smoothly with cement mortar, and then install a piece of the iron sheet 32 on the lower plane of the ...

Embodiment 3

[0038] Please refer to Figure 5 and Figure 6. In Fig. 5, the two opposite sides of the solid wood floor 51 with a specification of 200mm x 200mm x 20mm each have a notch equipped with an iron sheet 52 with a specification of 60mm x 15mm x 1mm, and the outer plane of the iron sheet 52 is in contact with the floor 51. The side planes are on the same horizontal plane, and the lower end surface of the iron sheet 52 is on the same human level as the lower plane of the floor 51 . There is a notch on the other two opposite sides of the floor 51 to house a permanent magnet 53, the permanent magnet is a ferrite with a specification of 50mm×13mm×8mm, and the outer plane of the permanent magnet 53 is in line with the The side plane of the floor 51 is on the same horizontal plane, and the lower end surface of the permanent magnet 53 is on the same human level as the lower plane of the floor 51 . In Fig. 6, the outer frame specification is 200mm * 200mm * 35mm. The floor base 61 is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com