Full optical fiber digital inclinometer

An all-fiber and inclinometer technology, which is applied in measurement, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of limiting the uploading capability of downhole measurement signals, limited bandwidth of transmission cables, and inability to transmit formation information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings.

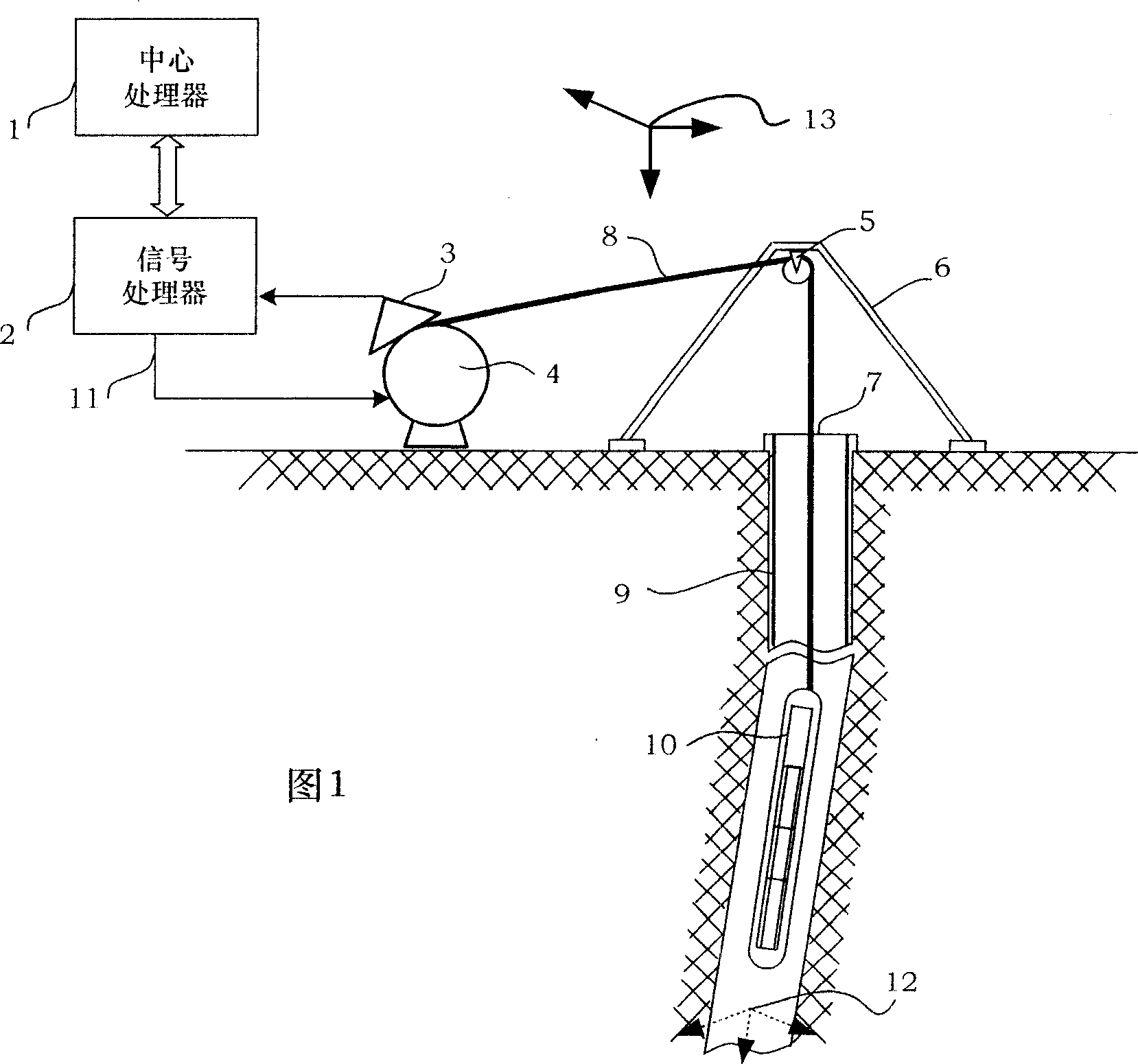

[0055] The present invention is an all-fiber digital inclinometer, which is composed of a central processor 1, a signal processor 2, a counter 3, an optical cable winch 4, a tension sensor 5, a derrick 6, an optical cable 8 and a downhole probe 10. The central processor 1 It is connected with the signal processor 2 through the RS232 interface, the optical cable winch 4 is connected with the signal processor 2 through the cable 11, the counter 3 is installed on the optical cable winch 4, the optical cable 8 is wound on the optical cable winch 4, and the derrick 6 is placed at the head of the measured well 7, a tension sensor 5 is installed on the derrick 6, and one end of the optical cable 8 is connected to one end of the downhole probe 10 through the tension sensor 5.

[0056] CPU 1

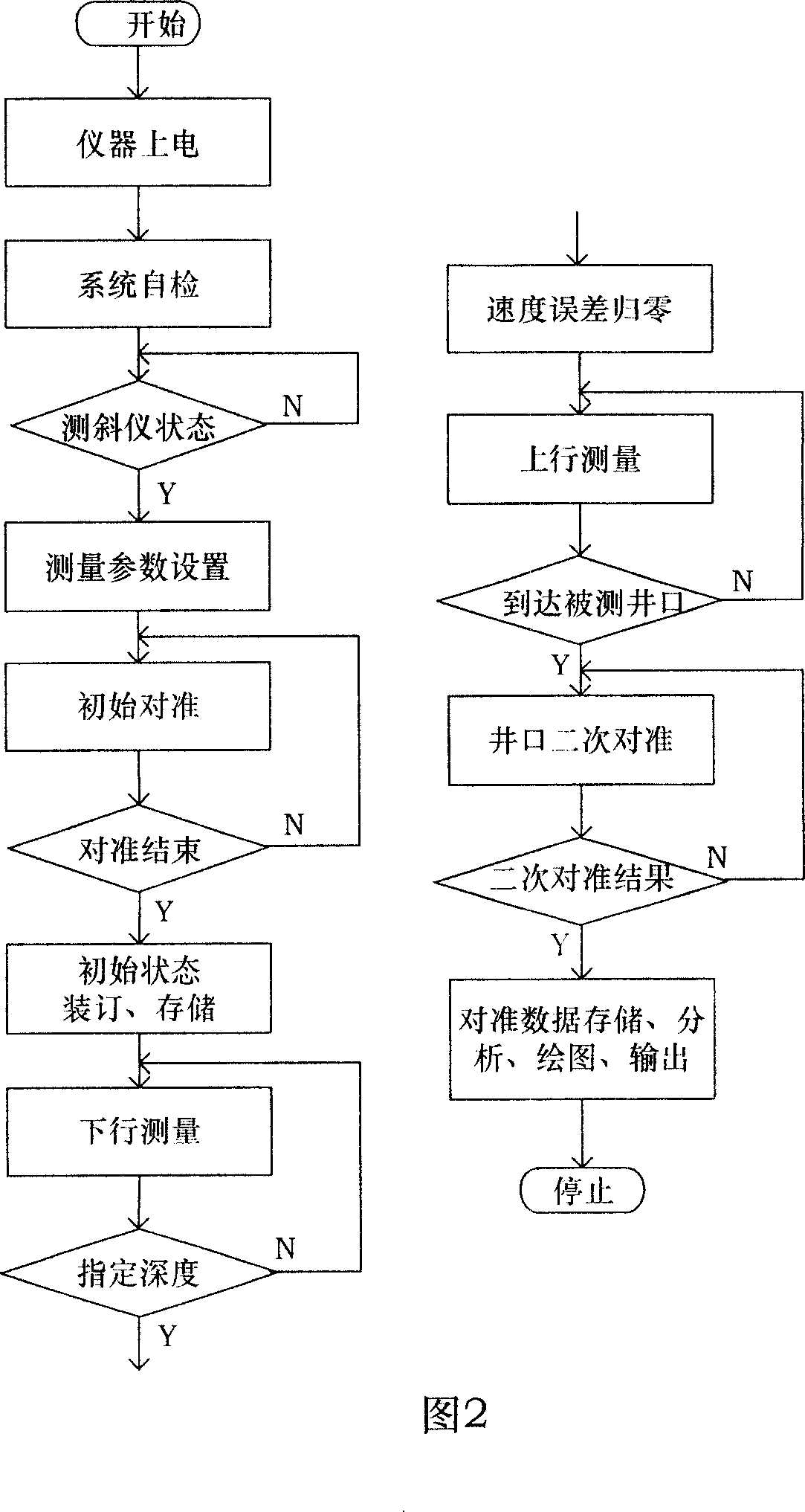

[0057] Referring to Fig. 2, the control flow of the central processor 1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com