Oil derrick stress data acquisition system based on fiber Bragg grating sensor network

A data acquisition system and sensor network technology, applied in the direction of electrical digital data processing, special data processing applications, measurement of the change force of optical properties of materials when they are stressed, etc., can solve the problem of inability to compare detection data in a timely and intuitive manner and other problems, to achieve the effect of perfect detection system, convenient search and comparison of historical data, and lighten the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

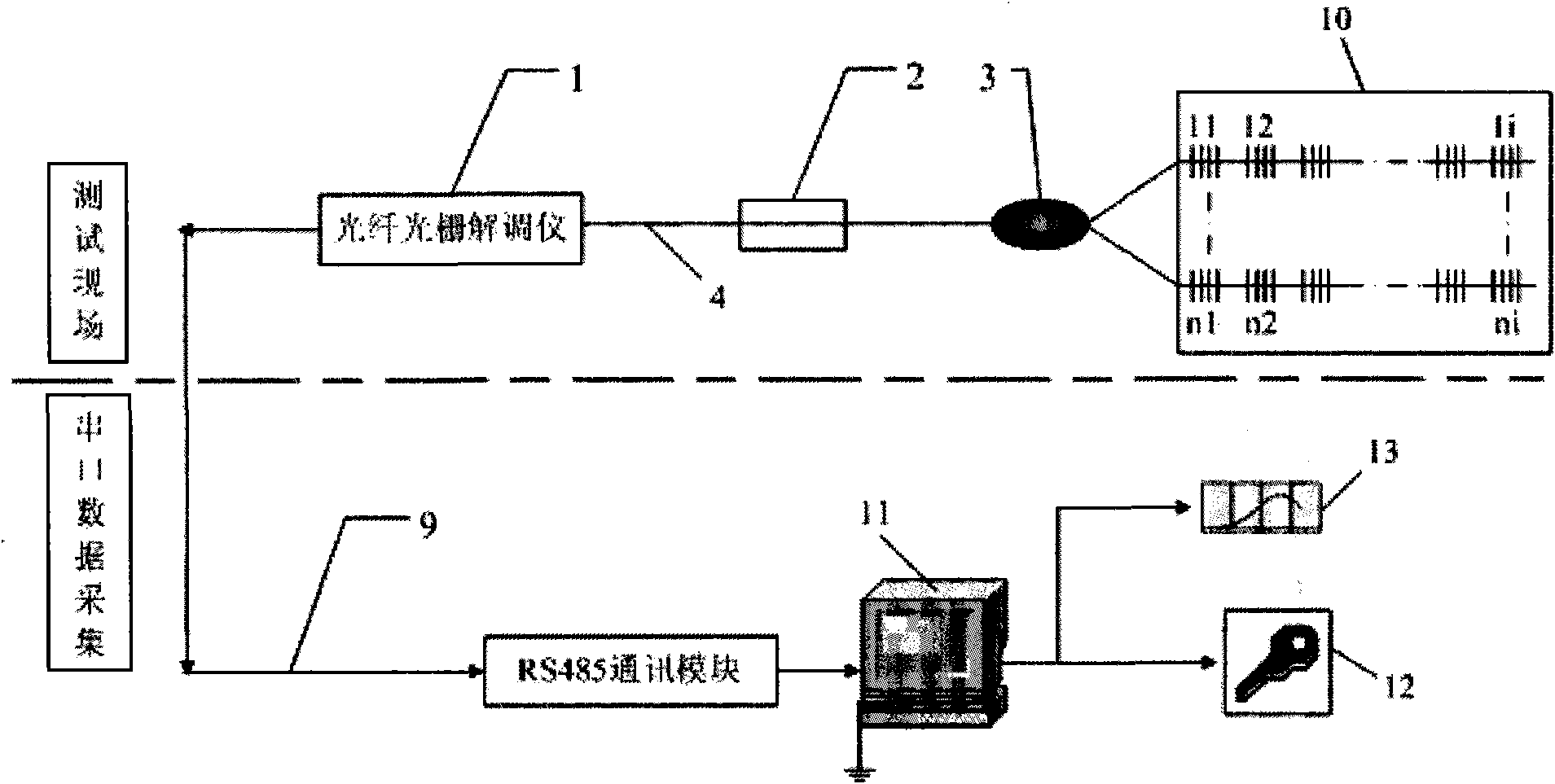

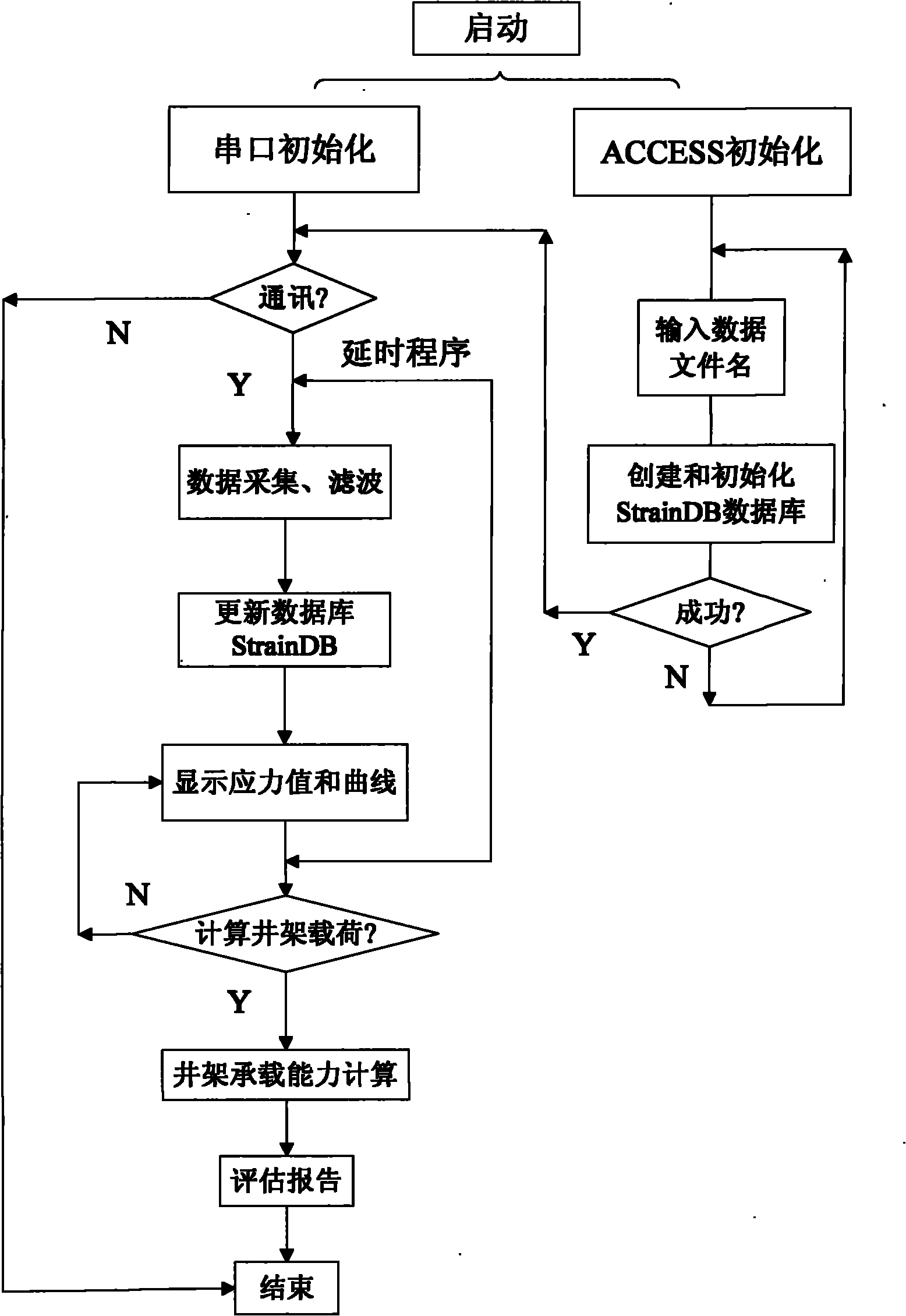

[0015] The oil derrick stress data acquisition system based on distributed fiber grating sensor network of the present invention includes: oil derrick stress and strain field data testing subsystem based on distributed fiber grating sensor network; oil derrick stress and strain field data transmission based on serial port communication technology And the storage subsystem, the oil well reliability evaluation subsystem based on OLE technology and Matlab calculation program, the three subsystems are connected by the industrial control computer through the ADAM communication module and the RS232 interface of the fiber grating demodulator.

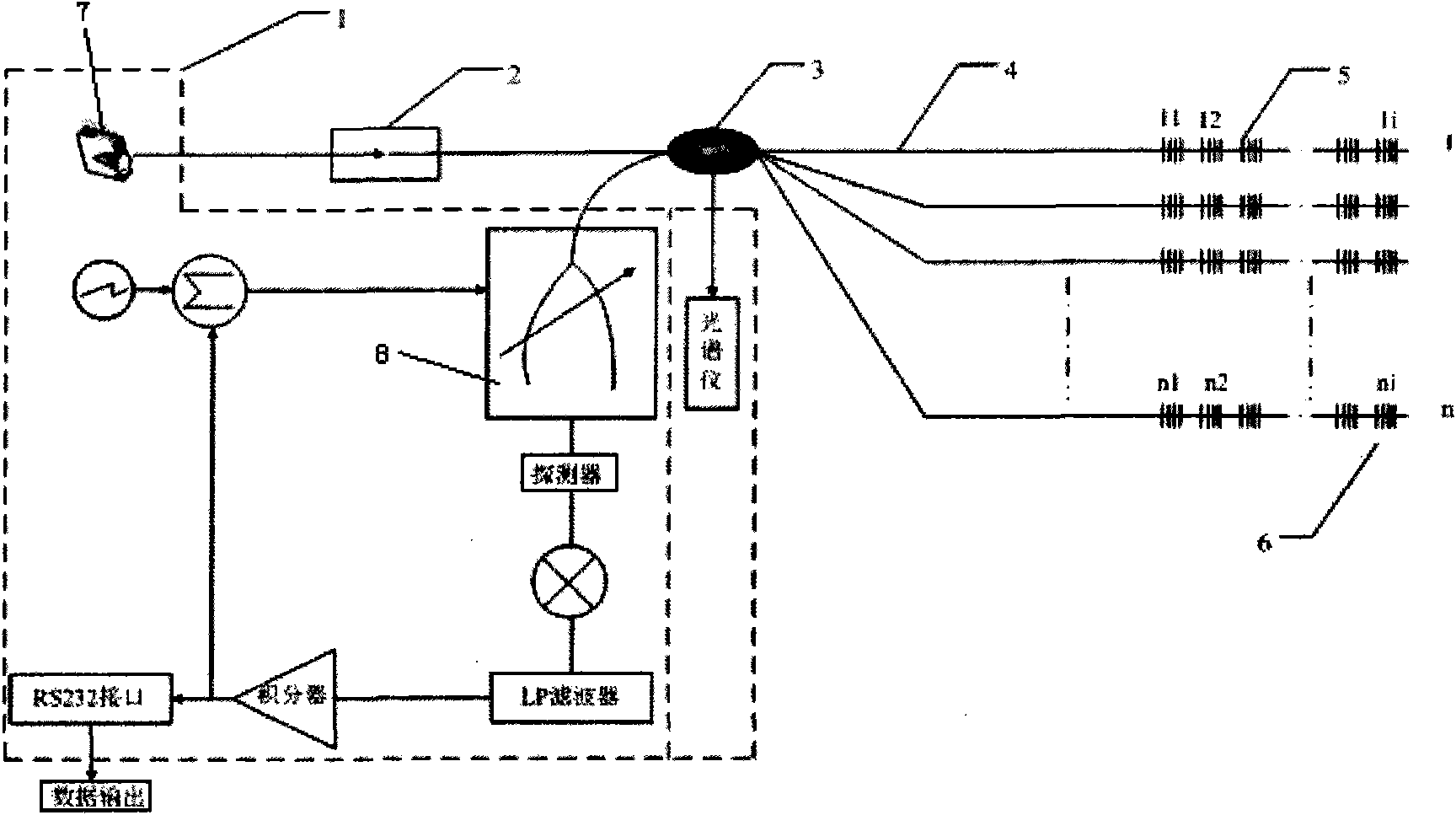

[0016] Such as figure 1As shown, the oil derrick stress and strain field data testing subsystem based on distributed fiber grating sensor network consists of isolator 2, coupler 3, fiber grating strain sensor 5, fiber g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com