Controllable gap for protecting transformer neutral point

A transformer neutral point and gap technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve the problems of electrode ablation, inaccurate distance adjustment, and harsh coordination requirements, so as to eliminate the influence of stray capacitance and determine the distance Accurate, satisfying effect of correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

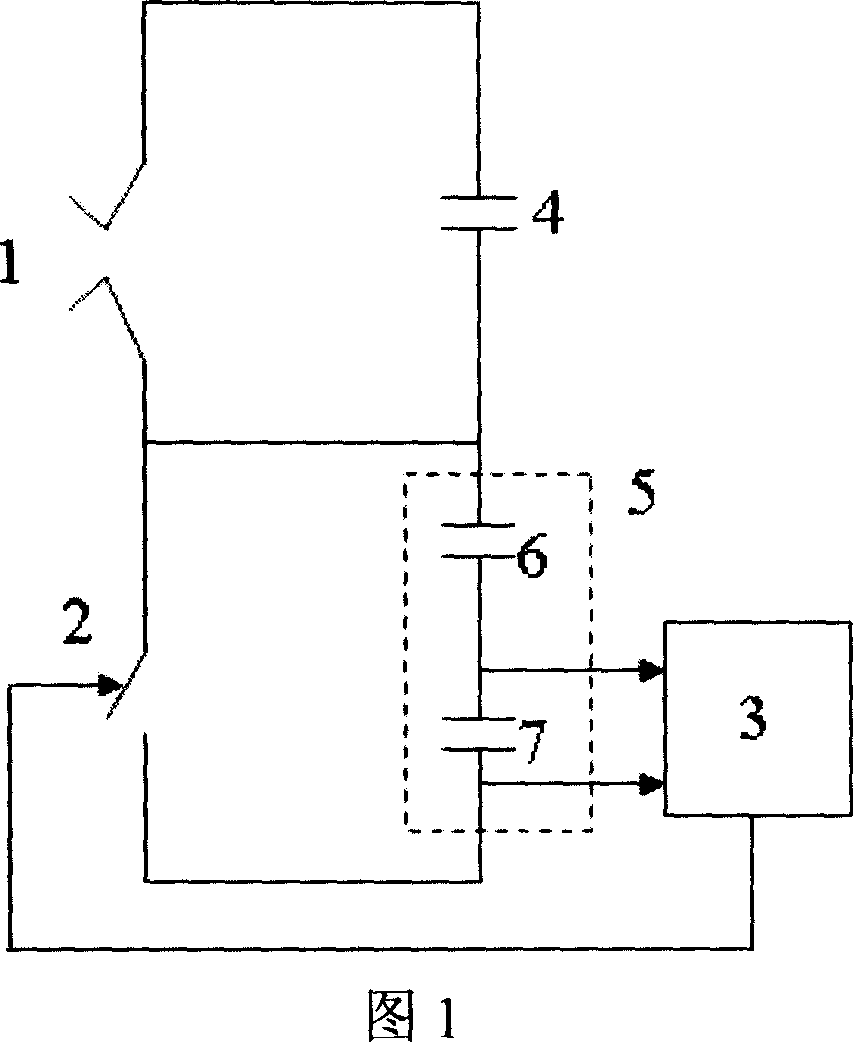

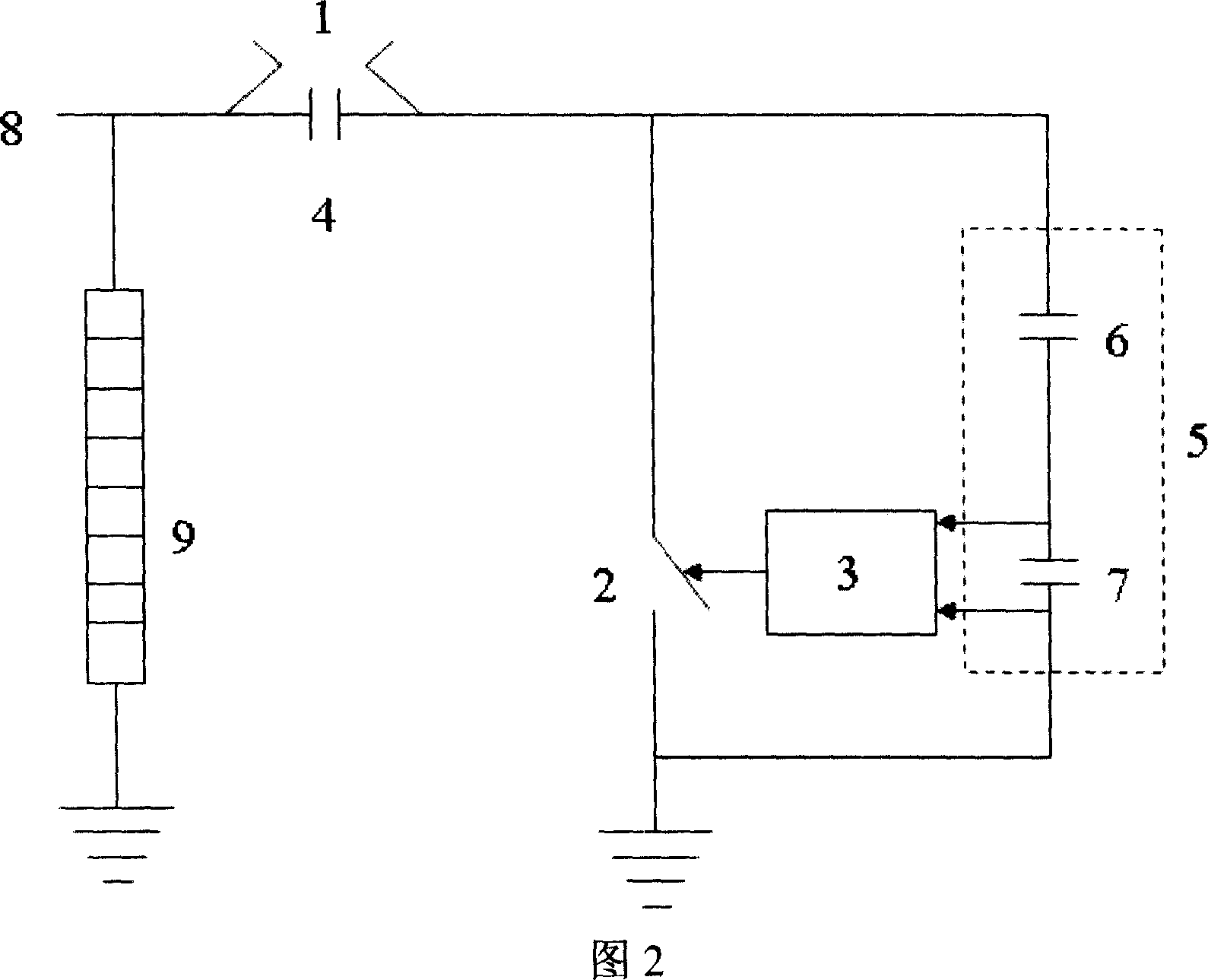

[0016] Referring to FIG. 1 , a controllable gap for protecting the neutral point of a transformer includes a fixed gap 1 , a control gap 2 and its control loop 3 , and a capacitive voltage equalizing circuit composed of voltage equalizing capacitors 4 and 5 . Figure 1 shows that the fixed gap 1 is connected in series with the control gap 2, and the control gap 2 is electrically connected with the control circuit 3 to be controlled by it. The voltage equalizing capacitor 5 is a voltage divider formed by connecting capacitors 6 and 7 in series. The upper arm capacitor 6 has a small capacitance and a high withstand voltage, and is also called a voltage equalizing capacitor; the capacitance of the lower arm capacitor 7 is hundreds of capacitors 6 , Thousand times, to provide an input signal to the control loop 3, also known as the measurement capacitance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com