Casting trough and method for casting copper anodes

A pouring trough and casting mold technology, applied to casting equipment, control of molten metal pouring from casting ladles, casting molten material containers, etc., can solve problems such as bottlenecks and slowness of casting steps, and achieve reduced fluctuations, reduced wear, and reduced fluctuating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

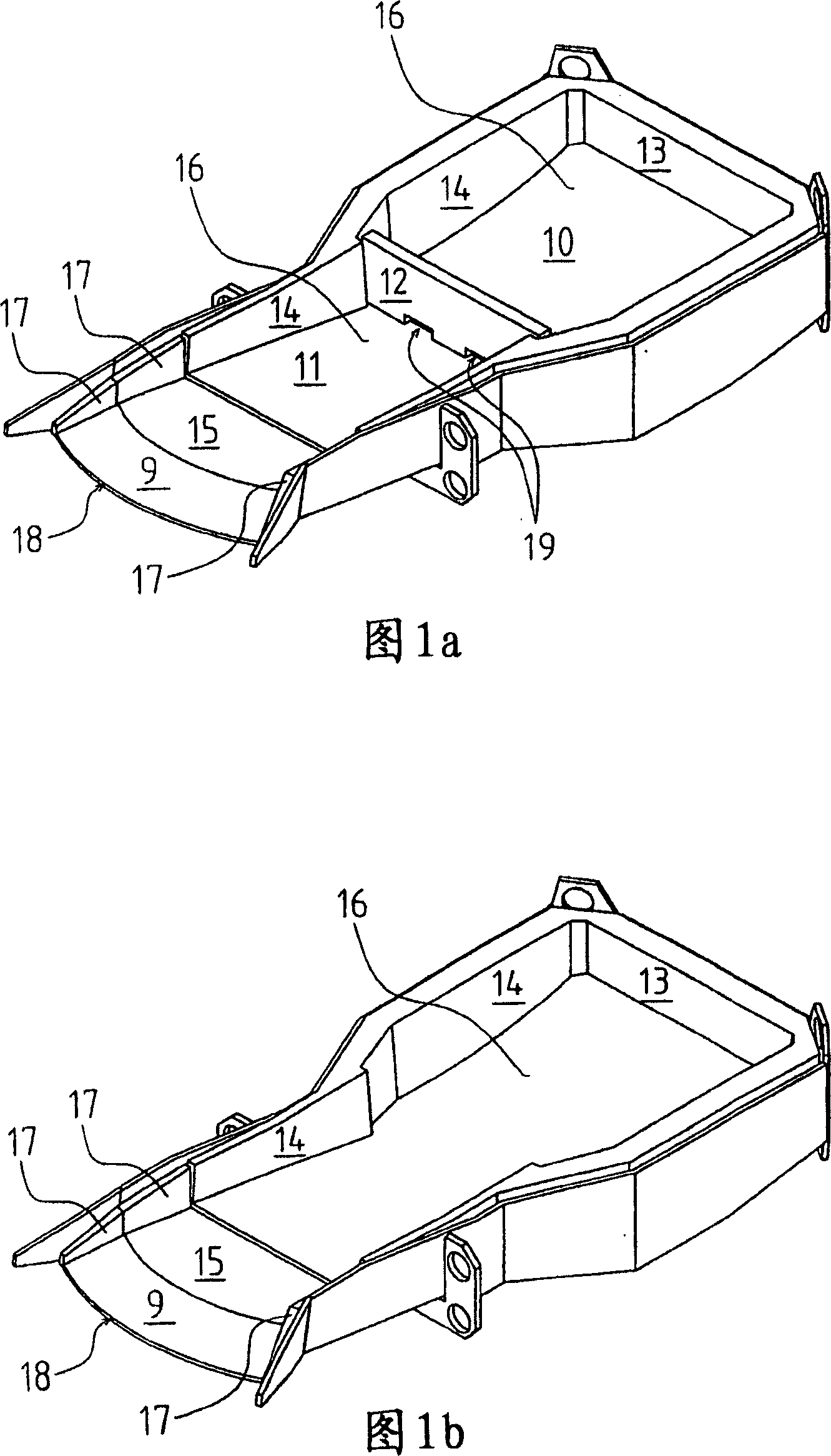

[0033] The pouring trough according to FIG. 1 a has a curved bottom 16 , side walls 14 and a rear wall 13 . A choke brick 12 is placed between the outlet, in this case the outlet brick 15 , and the rear wall 13 . The choke brick 12 divides the space defined by the bottom and the walls into the front part 11 of the pouring trough and the rear end 10 of the pouring trough. Notches made at the bottom edge of the choke block 12 and the bottom 16 of the pouring trough define a gap 19 through which molten metal flows from the rear end 10 of the pouring trough to the front part 11 . The height of the choke element is preferably chosen such that it extends from the bottom of the pouring trough at least to the level of the surface of the melt when the pouring trough is in the filling position. When feeding molten metal in the pouring trough, this metal is divided between the front part 11 and the rear end 10 of the pouring trough. It is preferable to supply molten metal into the spac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com