Floor processing machine

A floor and grinding machine technology, applied in the field of processing or grinding machines, can solve problems such as the power problem of mobile grinding machines, and achieve the effect of excellent maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

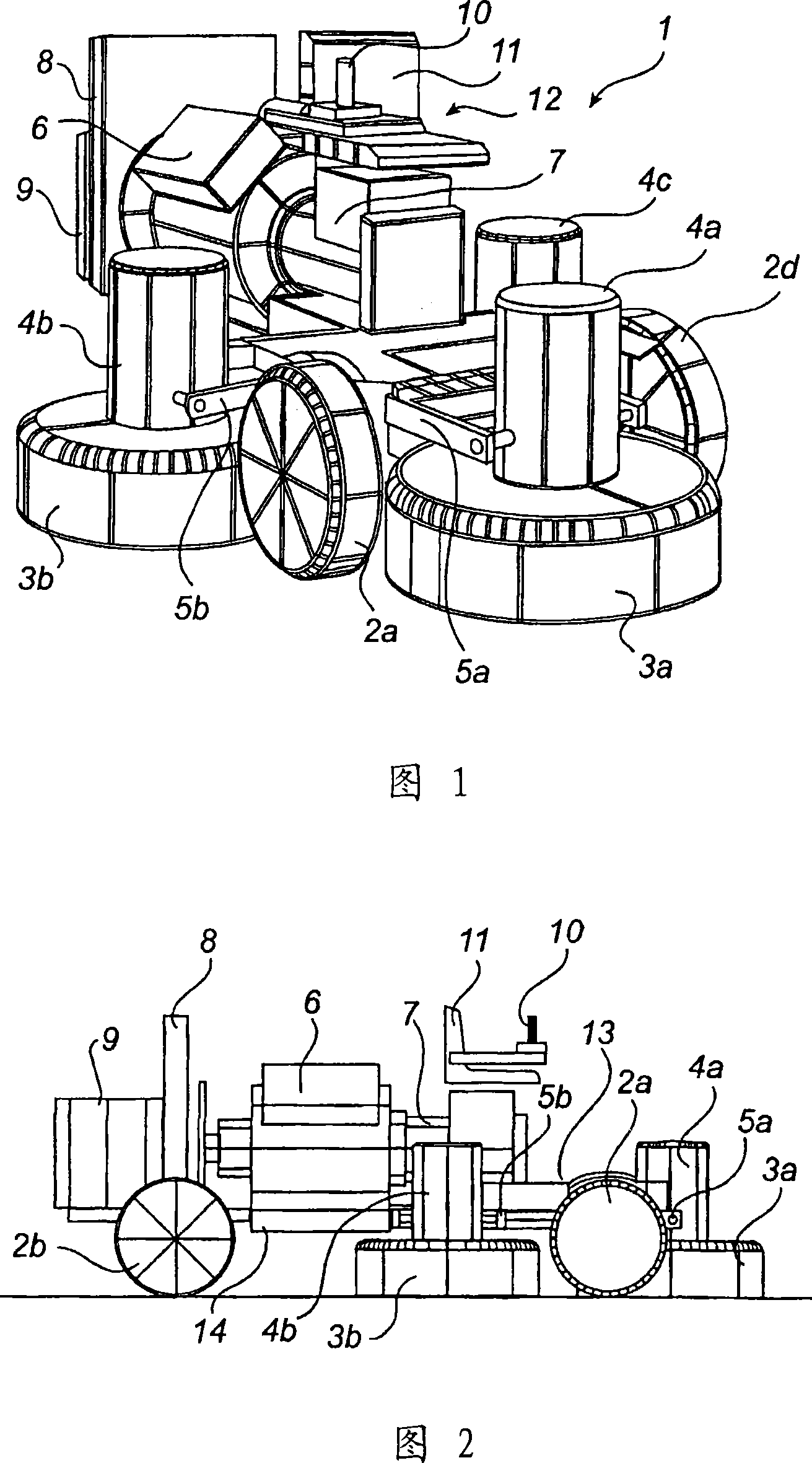

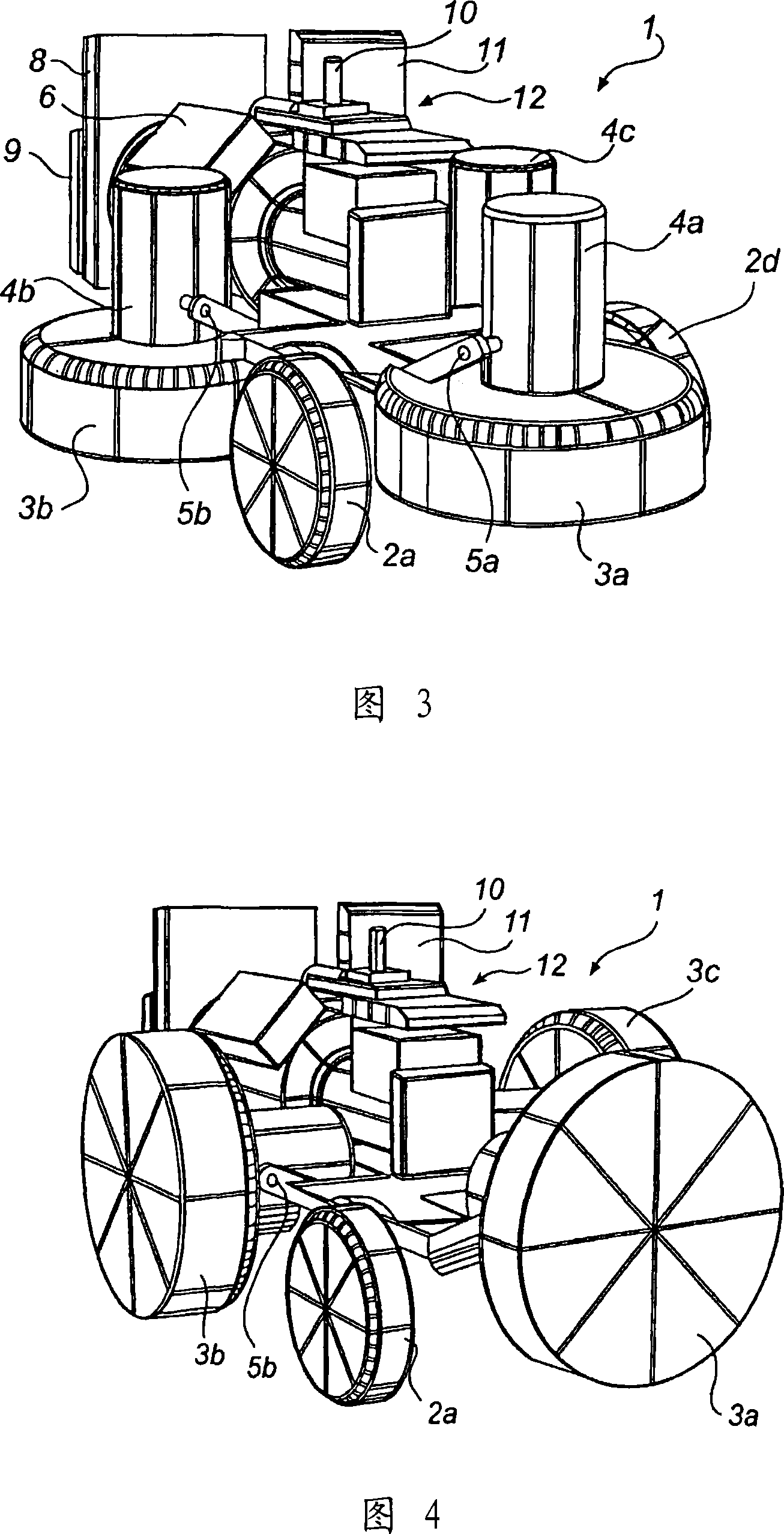

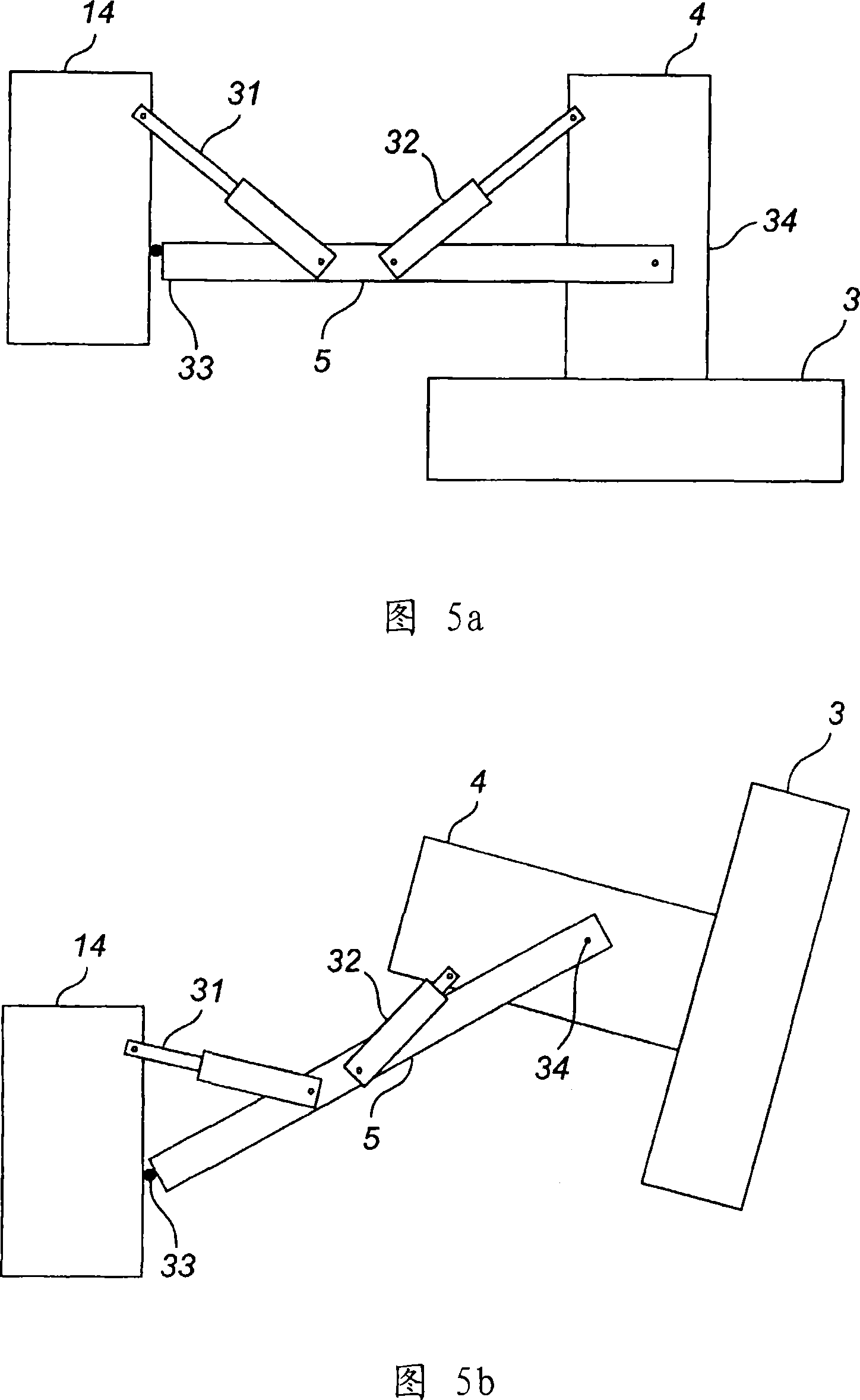

[0040] Figure 1 shows a ride-on grinder 1 comprising a frame 14 (Figure 2) on which a set of wheels 2a, 2b, 2c and 2d are arranged so that the grinder can be moved on a base 20 (Figure 2) .

[0041] The frame 14 of the grinder is arranged to support substantially all parts of the grinder. The frame may be a substantially rigid frame member or floor, or hinged, for example for handling purposes.

[0042] Said set of wheels 2a, 2b, 2c and 2d is used to provide a two-dimensional support surface for the grinder 1 on the base body 20 and can be designed in different forms, depending on the required drive characteristics of the grinder.

[0043] The frame also supports the engine 6 . The size and forcing / fuel of the engine are determined based on the power required by the grinder. In one embodiment of the grinder 1, the engine may be a gasoline or diesel internal combustion engine. The engine 6 is properly arranged to operate at a substantially constant speed and load, thus redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com