Oil-gas interconnection suspension with self-adaptive damping and adjustable roll stiffness

An adjustable and adaptive technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve problems such as insufficient installation space for vehicle chassis, high manufacturing cost of oil-gas interconnected suspension, and complex interconnected suspension structure. Achieve excellent handling stability, good design flexibility, and avoid the effect of vehicle rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

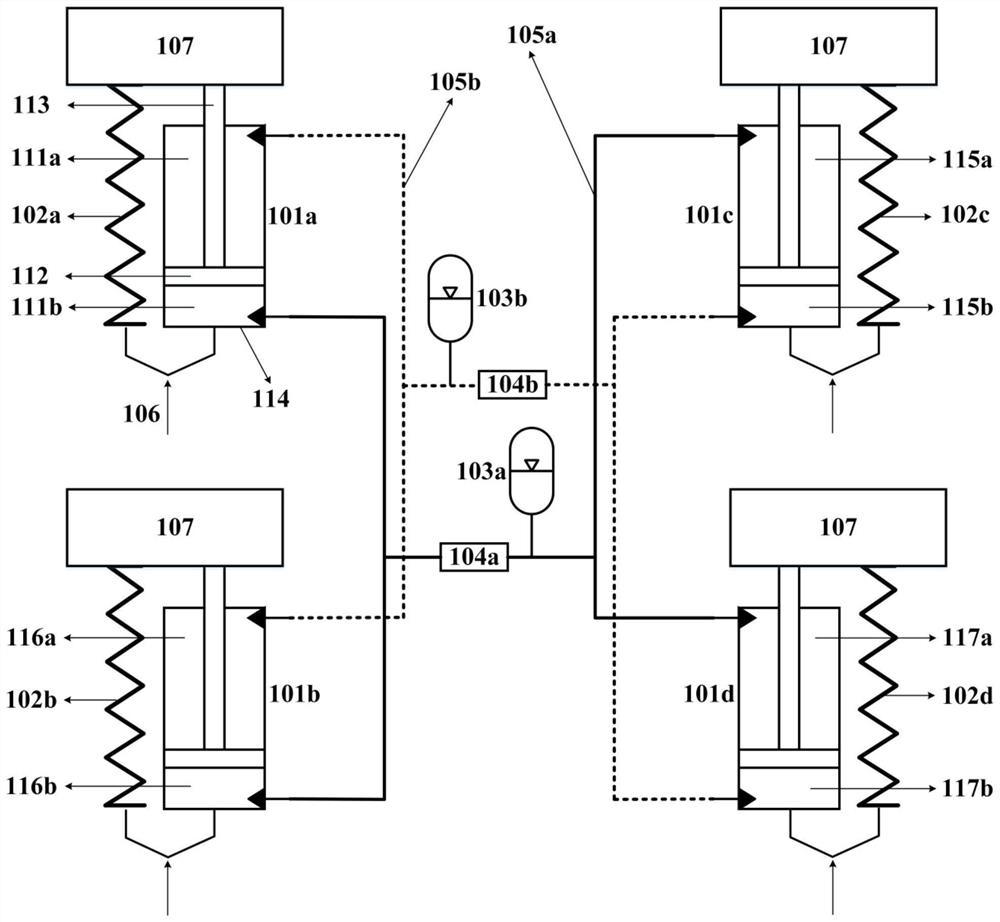

[0029] Attached below figure 1 The present invention will be further described. The oil-gas interconnection suspension system of the present invention is mainly composed of five hydraulic components: hydraulic cylinder, accumulator, control valve, hydraulic pipeline and required connecting pieces. These hydraulic components usually work in conjunction with air springs, which support vehicle loads and provide some vertical stiffness of the suspension. The basic structure of the biaxial oil and gas interconnected suspension system in the present invention is as follows: figure 1 shown.

[0030] The four hydraulic cylinders 101a, 101b, 101c, and 101d are located at the four corners of the biaxial suspension system, respectively. The four hydraulic cylinders are constituted by upper chambers 111a, 116a, 115a, 117a and lower chambers 111b, 116b, 115b, 117b, respectively. The upper chamber and the lower chamber are separated by pistons 112, respectively. The piston rods 113 of ...

Embodiment 2

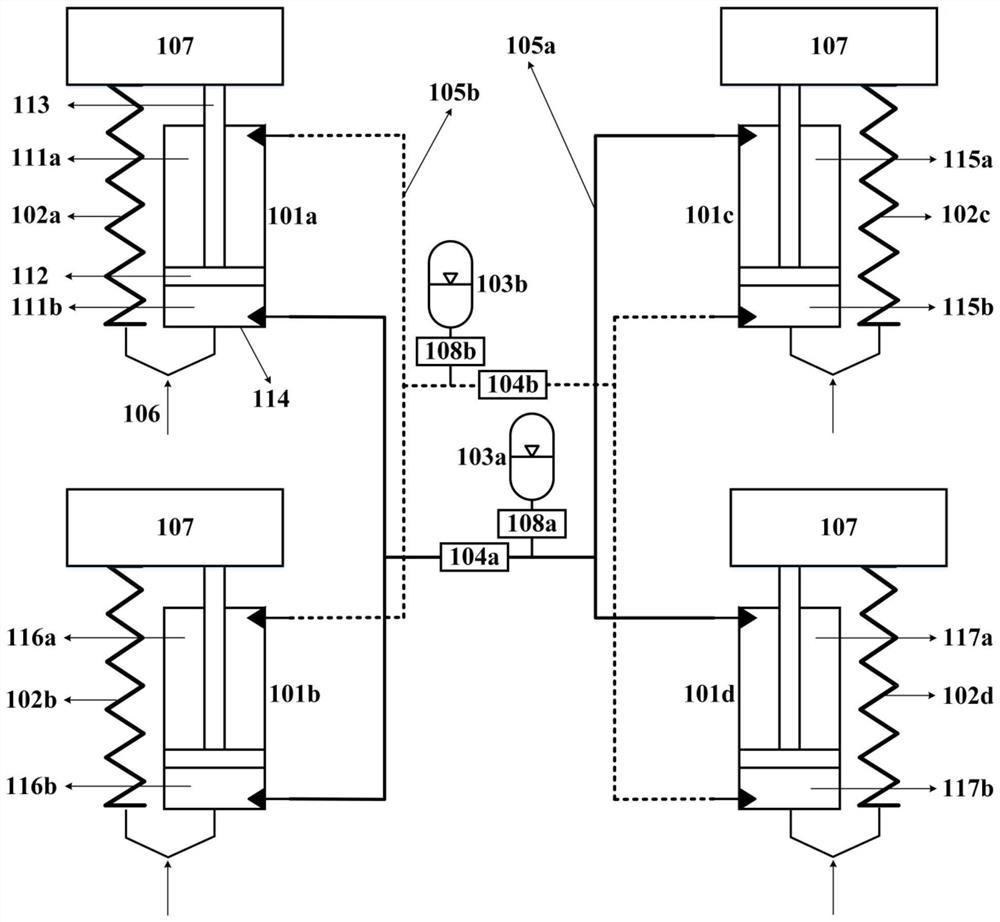

[0038] like figure 2 As shown, additional hydraulic valves 108a and 108b may be added at the inlets of accumulators 103a and 103b, respectively, to provide additional roll damping. The hydraulic valve controls the flow of oil into and out of the accumulator, and it produces a much greater damping effect in the roll direction than in the vertical direction. If there are no additional hydraulic valves 108a and 108b at the inlet of the accumulator, the suspension roll damping characteristics are determined by 104a and 104b, which is similar to a shock absorber in a conventional independent suspension. The main purpose of this embodiment is to enhance the roll damping of the suspension.

Embodiment 3

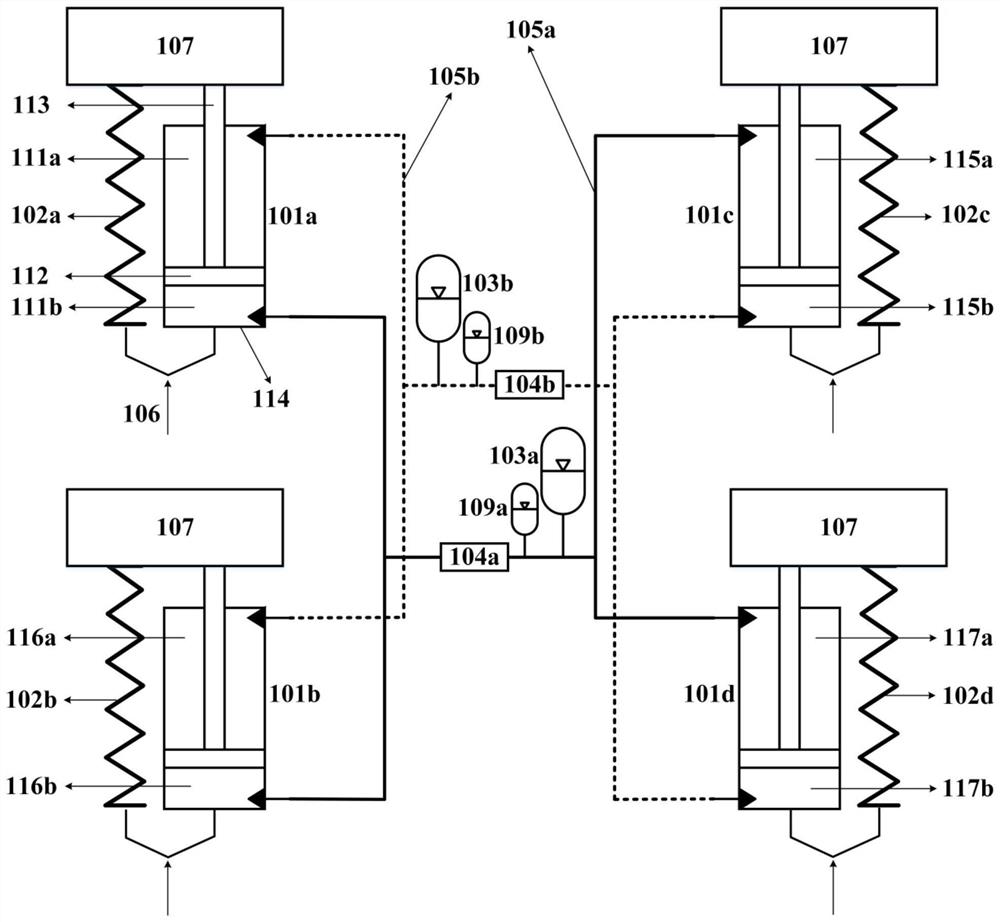

[0040] As the relative roll angle of the suspension increases, the air pressure in the primary accumulators 103a, 103b will increase accordingly. However, high air pressure is a potential risk for hydro-pneumatic suspension systems. This hidden danger can be solved by adding an auxiliary accumulator 109a and 109b next to the main accumulators 103a and 103b, respectively. like image 3 As shown, adding auxiliary accumulators to each hydraulic circuit results in a smaller volume and lower operating pressure for the main accumulator. The initial air pressure value of the auxiliary accumulator is set to the pre-warning air pressure. When the oil pressure reaches the pre-warning pressure, the auxiliary accumulator will be activated to prevent safety hazards in the suspension system due to excessive pressure. This design helps reduce the size of the main accumulator and the operating pressure in the interconnected suspension system. Therefore, adding auxiliary accumulators to on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com