Device and method for joining substrates

A substrate and sealing substrate technology, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., to achieve the effect of improving efficiency and preventing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

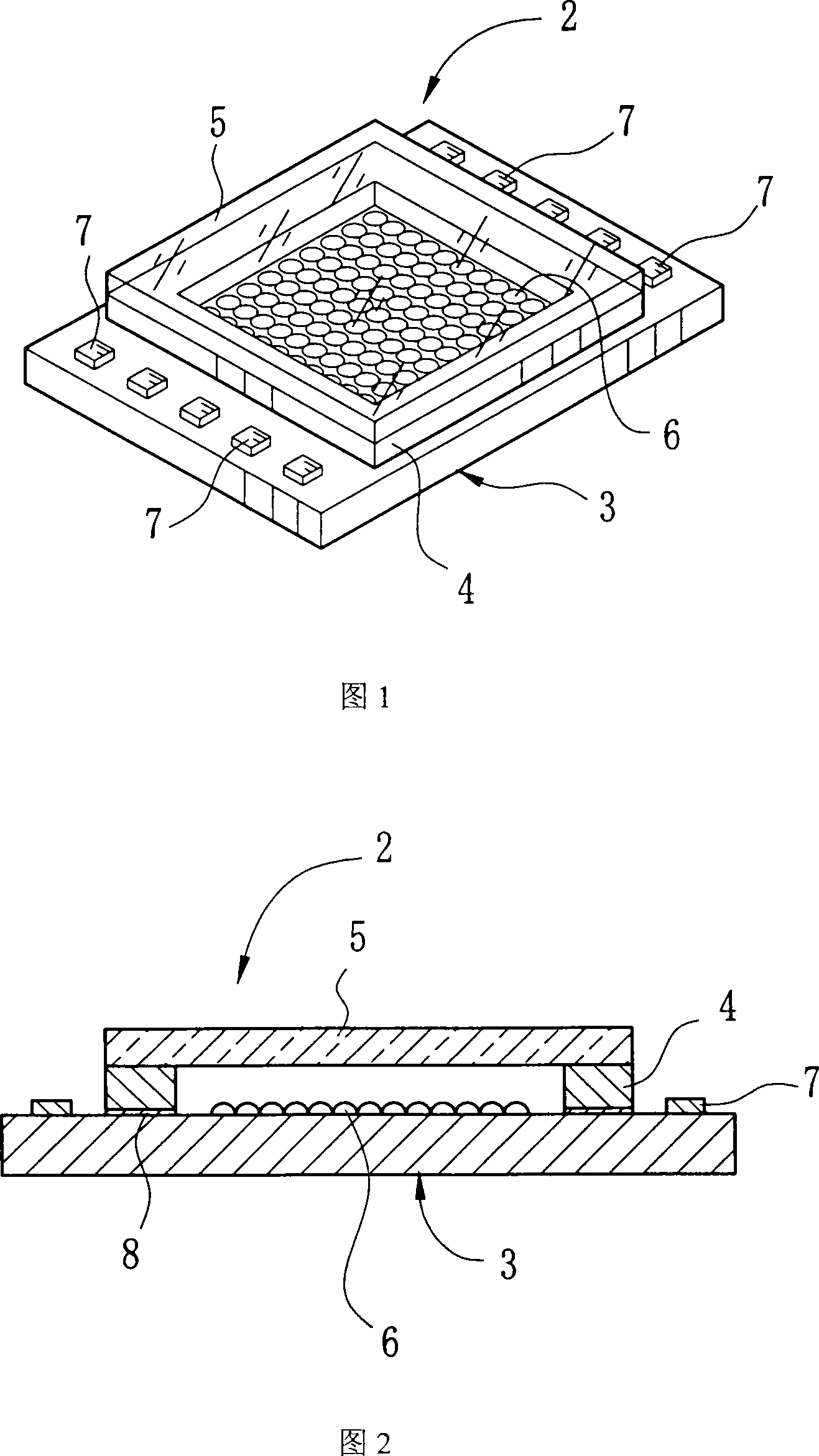

[0068] As shown in FIGS. 1 and 2, a WLCSP type solid-state imaging device 2 consists of an image sensor chip 3, a frame-shaped spacer 4 bonded to the image sensor chip 3 by an adhesive 8, and a frame-shaped spacer 4 bonded to the spacer 4 for The protective glass 5 that seals the interior of the spacer 4 constitutes.

[0069] On the image sensor chip 3 , there are an image sensor 6 including a plurality of pixels and a plurality of contact terminals 7 electrically connected to the image sensor 6 . The plurality of pixels generate electrical signals according to the amount of light received. For example, the image sensor 6 is a CCD (Charge Coupled Device) on which color filters and microlenses are superimposed. The contact terminals 7 are for printing conductive material on eg the image sensor chip 3 . In the same manner, each contact terminal 7 is connected with the image sensor 6 through printed wiring.

[0070] The spacer 4 is made of an inorganic material such as silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com