Electric spanner with variable torsional moment

An electric wrench, power shaft technology, applied in the direction of wrenches, power tools, wrenches, etc., can solve the problems of shortening the service life of the motor, burning the vehicle fuse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

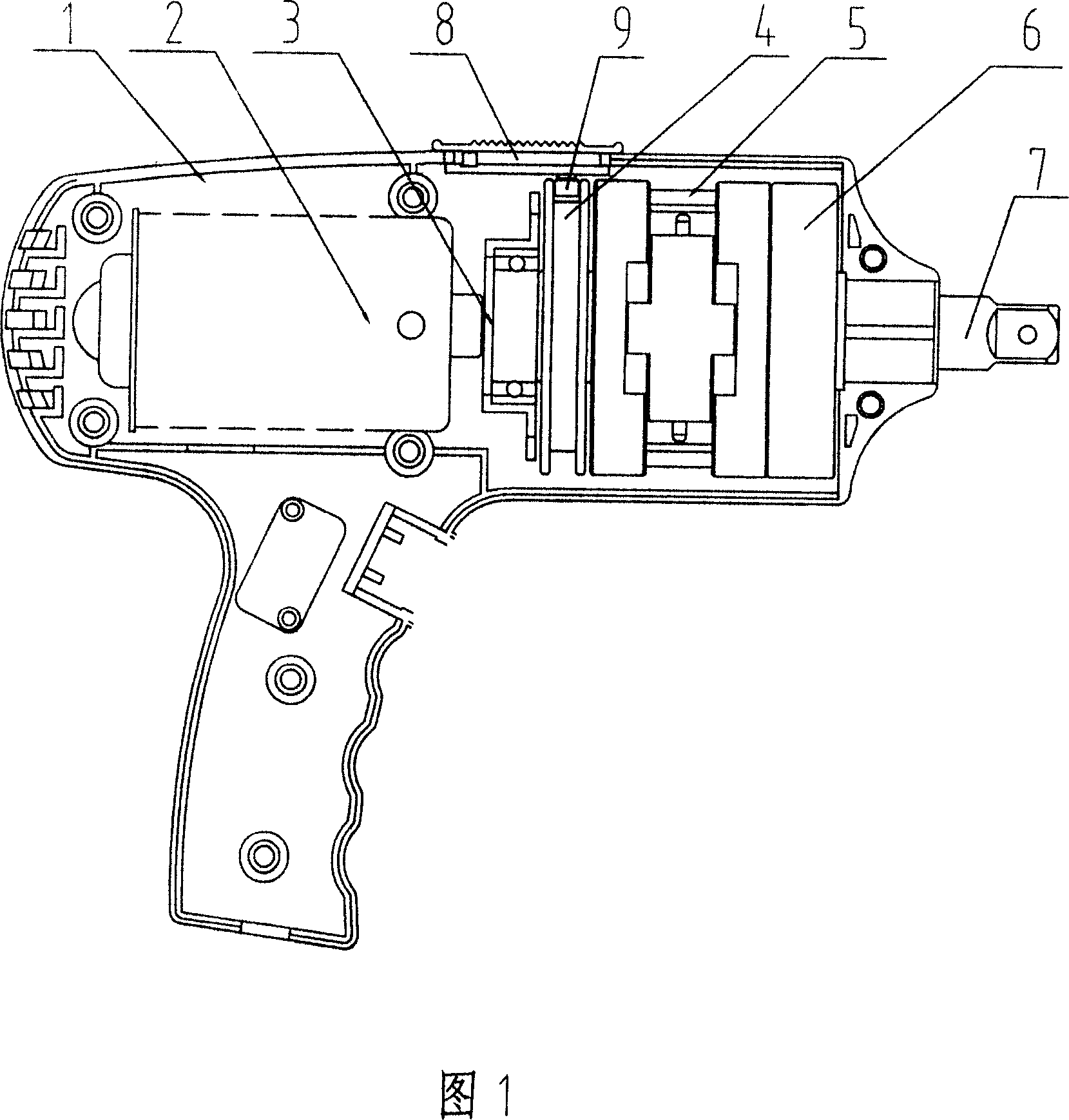

[0017] Below in conjunction with accompanying drawing 1 to accompanying drawing 5 illustrate embodiment of the present invention:

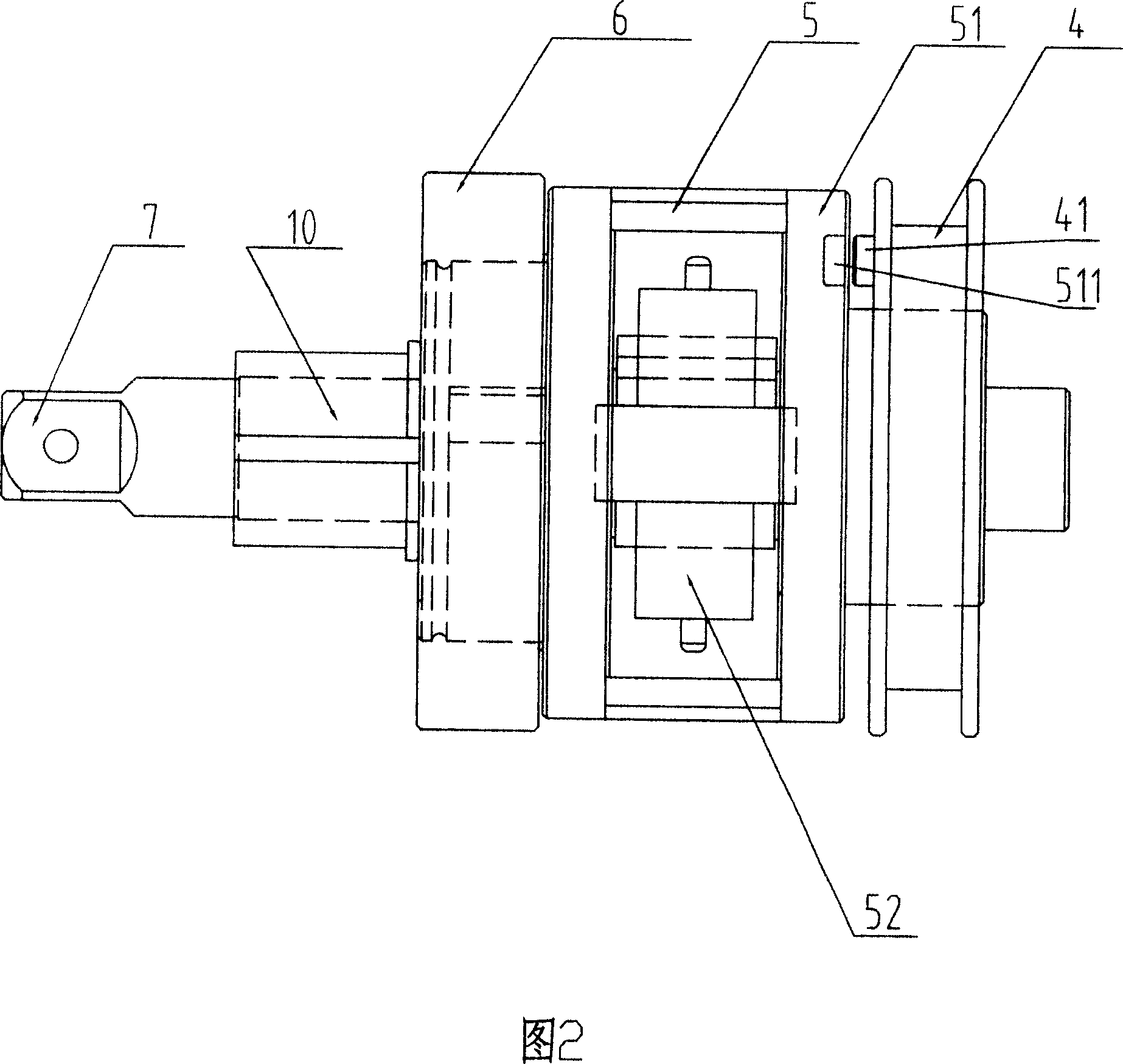

[0018] An electric wrench with convertible torque, which includes a housing 1, a motor 2 placed in the housing 1, a flywheel assembly connected to the power shaft of the motor 2, the flywheel assembly is connected to an output shaft 7, and the flywheel assembly is composed of a clutch assembly 3. The counterweight flywheel 4, the hollow flywheel assembly 5, and the reverse flywheel assembly 6 are sequentially matched and connected to form.

[0019] The clutch assembly 3 is composed of a frustum-shaped groove provided on the hollow flywheel 4 and a frustum-shaped friction clutch 15 arranged on the power shaft of the motor 2. The power shaft of the motor 2 is sleeved with a frustum-shaped friction clutch 15 and Compression spring 14 between motor 2 fuselages.

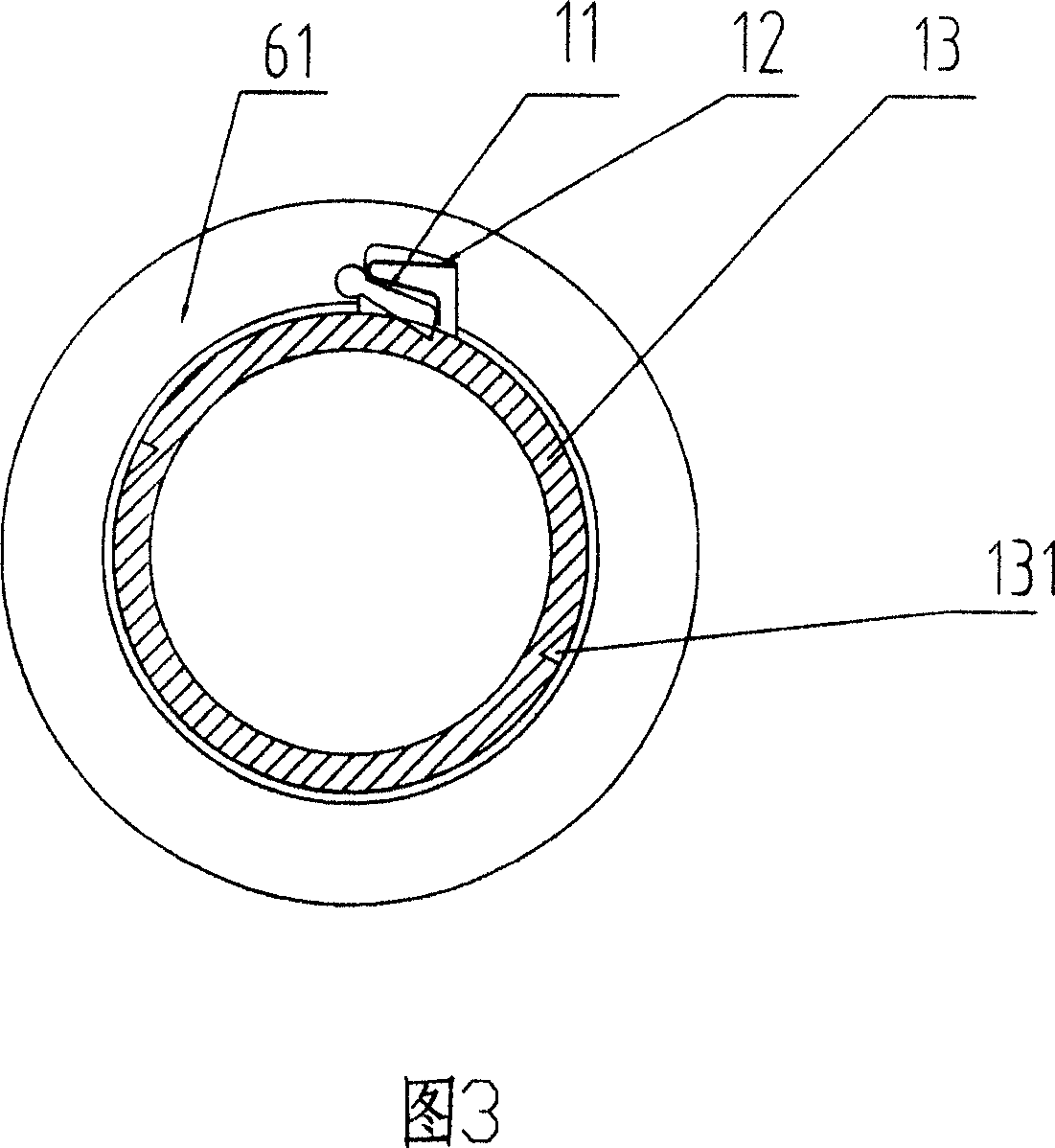

[0020] The hollow flywheel assembly 5 consists of a hollow flywheel 13 which is housed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com