Energy-saving tailed-gas exhaust pipe

An exhaust tail pipe and exhaust hole technology, which is applied to exhaust devices, mufflers, engine components, etc., can solve the problems of low efficiency, large exhaust resistance, insufficient gasoline combustion, etc., and achieves simple structure and exhaust gas. The effect of complete gas and full combustion of gasoline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

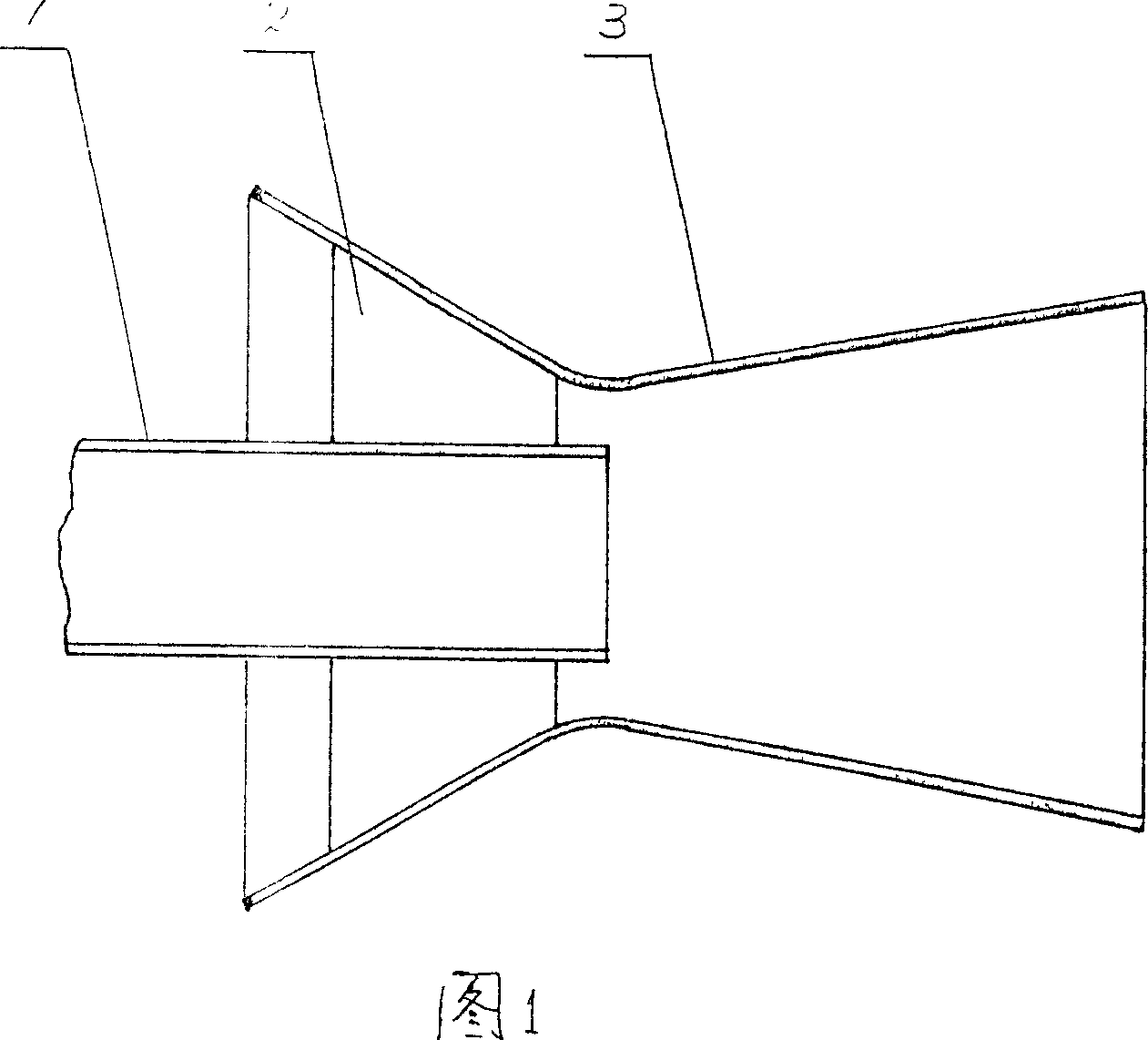

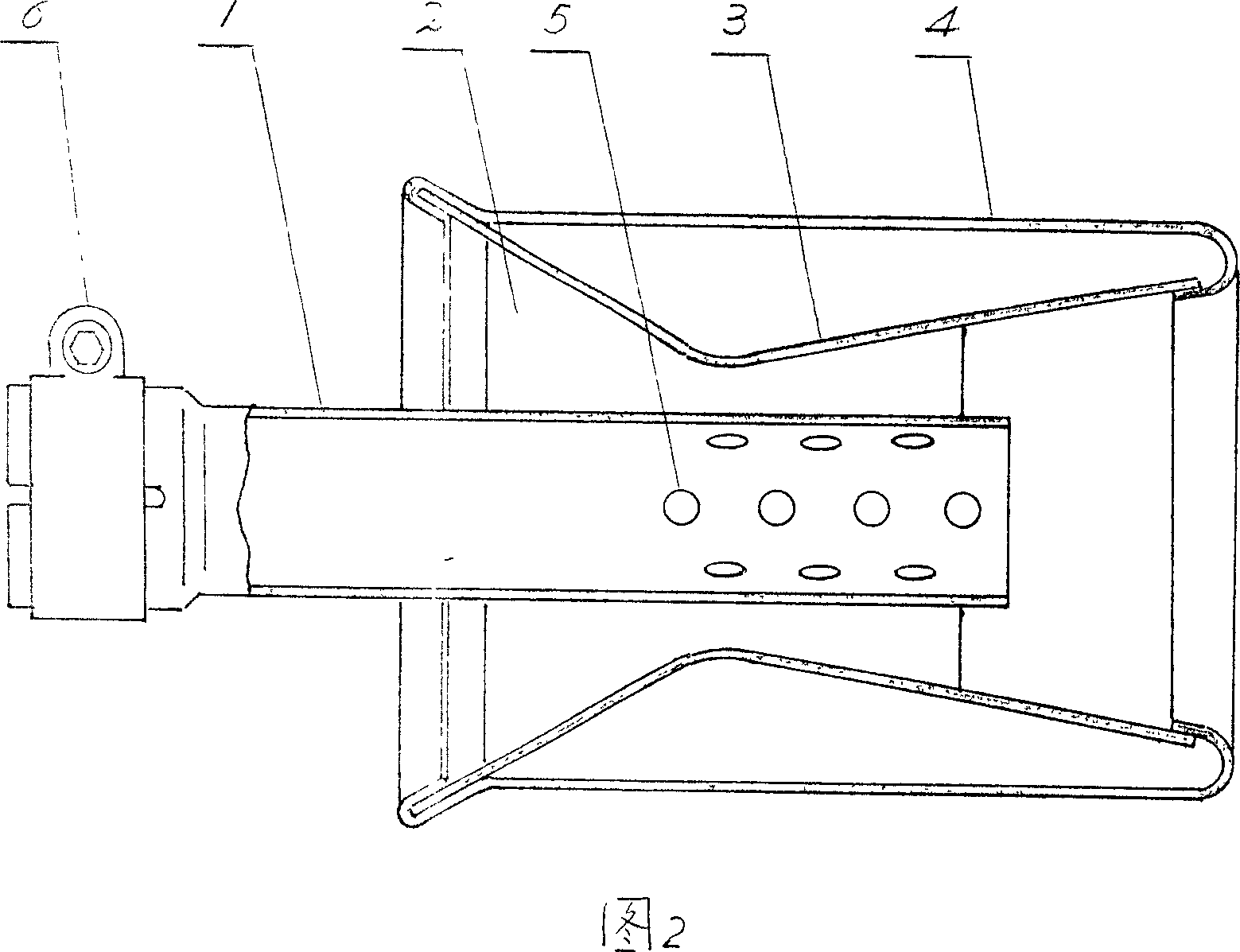

[0013] As can be seen from Fig. 1 and Fig. 2, a kind of energy-saving exhaust tail pipe is provided with a coaxial Lava nozzle 3 on the exhaust pipe 1 of the muffler. Exhaust gas pipeline 1 is cylindrical, and it can be a part of the exhaust tailpipe of muffler, also can be arranged separately, is connected and fixed with the exhaust tailpipe of muffler by throat hoop 6. The front part of Lava nozzle 3 is a conical convergent section, the rear is a conical diffuser section, and the narrow part in the middle is a throat, and the air inlet is larger than the air outlet. pressure. In the present invention, the Lava nozzle 3 is connected and fixed to the outer wall of the exhaust pipe 1 through several axially arranged webs 2 . The inside of the web 2 is a straight line, and the shape of the outside is consistent with the axial tangent of the inner cavity of the Lava nozzle 3 . There can be 2 panels 2, 3 or 4, or more. The exhaust port of the exhaust pipe 1 of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com