Pulsation type turbine shaft engine

A turboshaft engine and turbine group technology, which is applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., can solve the problems of heavy weight of the deceleration system, high material requirements, immature technology, etc., and achieve high power-to-weight ratio and mechanical structure Simple, lightens the effect of the deceleration system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

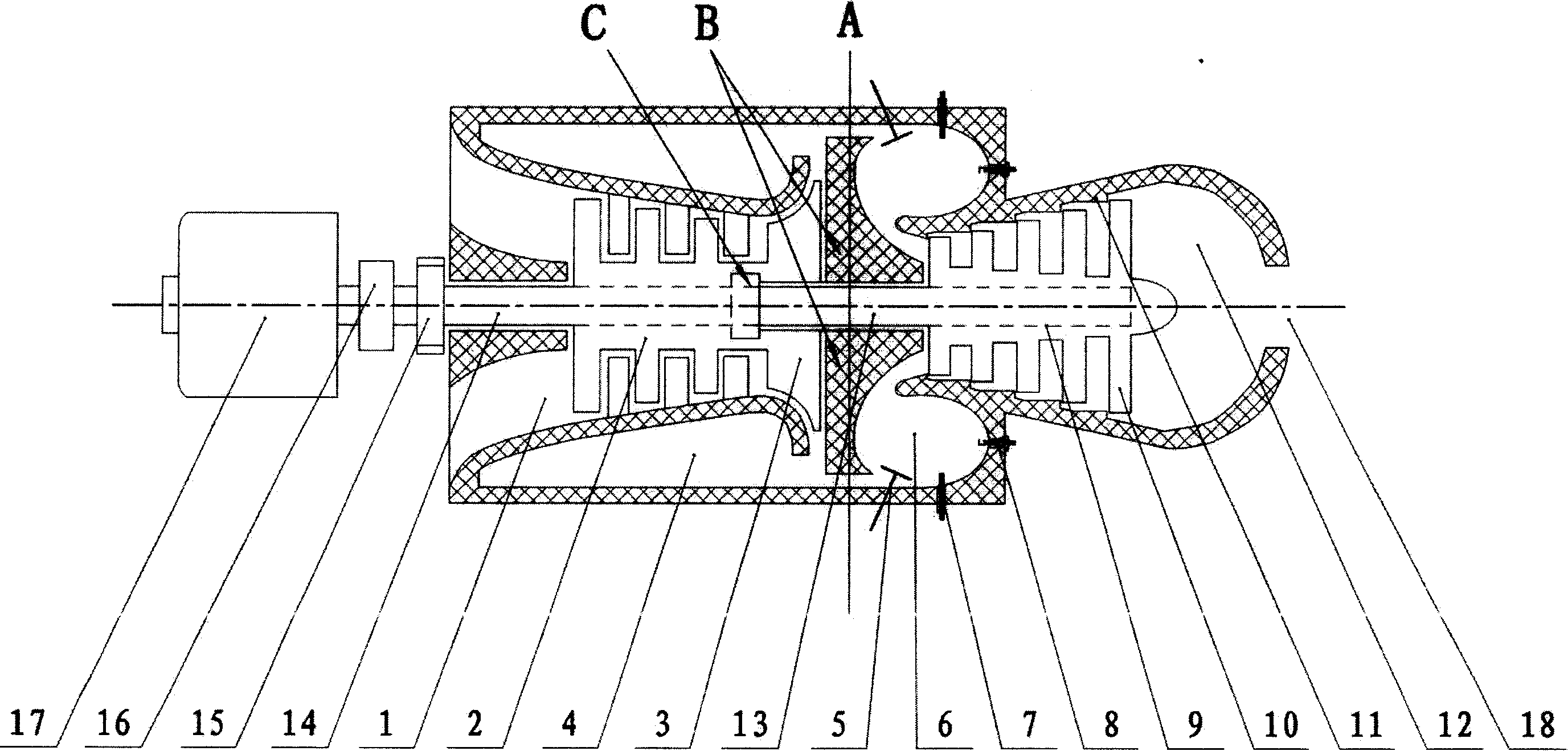

[0022] Accompanying drawing is the structure schematic diagram of the preferred embodiment of the present invention, namely engine is made up of three parts of air compression device, compressed air storage device and mixed gas combustion work device. The air compression device is composed of an axial flow compressor (2) and a centrifugal compressor (3) coaxially; the compressed air storage device is composed of a compressed air storage chamber (4); the mixed gas combustion work device is composed of a combustion chamber (6), The turbine group (9) and gas distribution device, fuel supply device, ignition device and other components. When the engine is started, the starter motor (17) drives the compressors (2) and (3) to rotate through the starter clutch (16), sucks in air from the intake passage (1) for compression, and the compressed air is pressed into the compressed air storage chamber (4) In the process, when the predetermined pressure is reached, the valve (5) opens, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com