Armchair structure

一种座椅、座部的技术,应用在座椅结构领域,能够解决没有考虑减轻疲劳等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

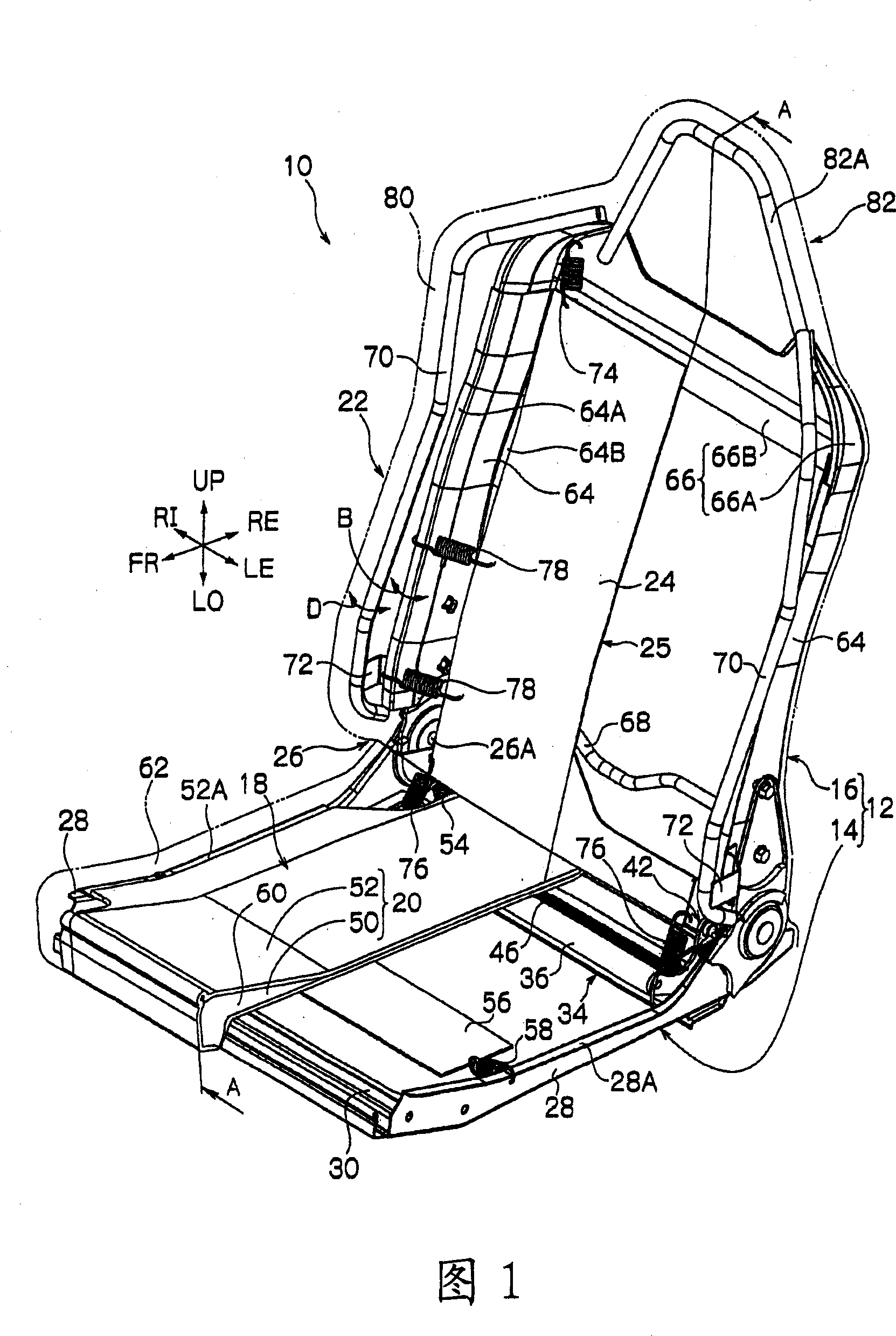

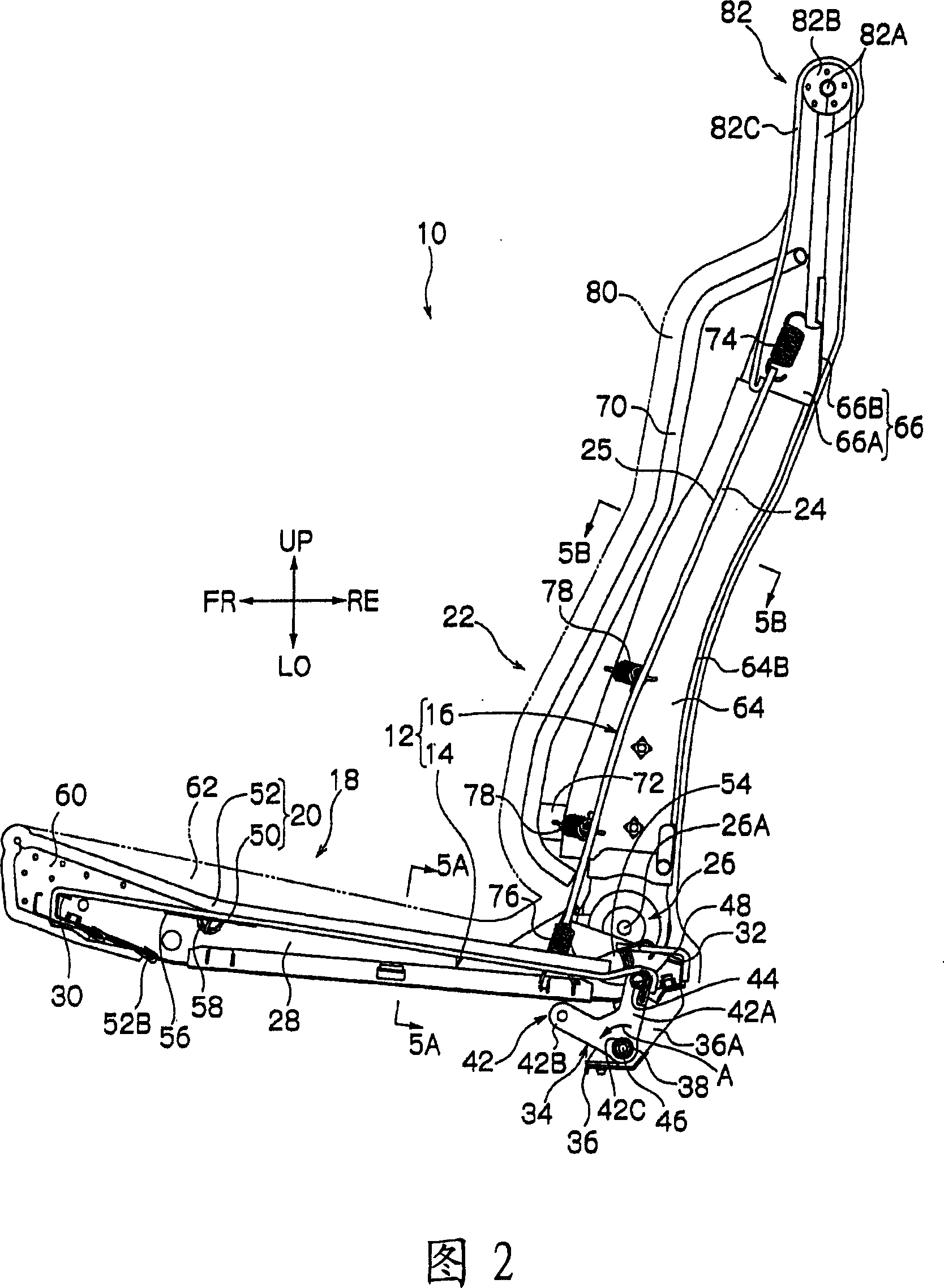

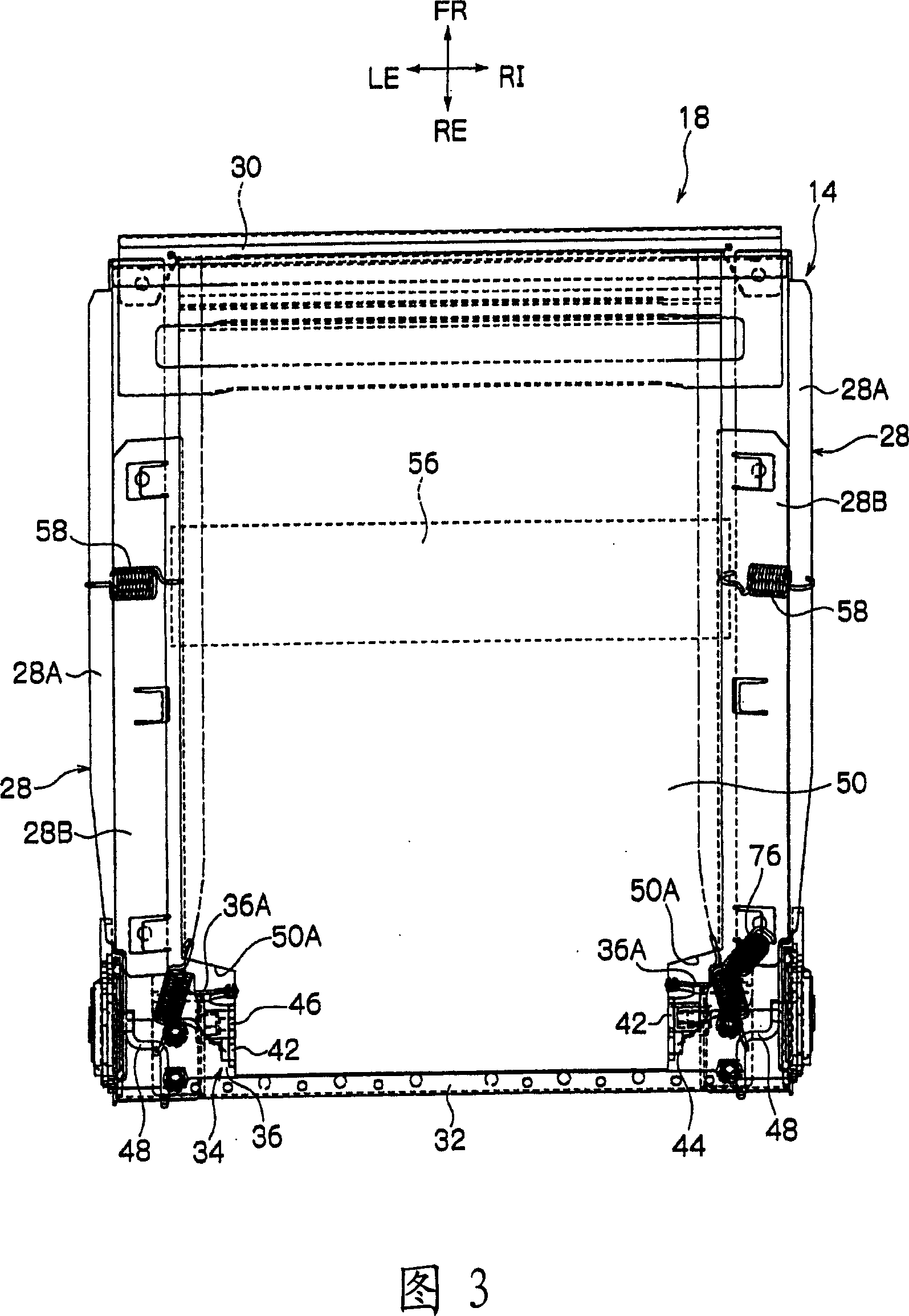

[0132] A vehicle seat 10 to which the seat structure according to the embodiment of the present invention is applied will be described based on FIGS. 1 to 34 . In addition, arrow UP, arrow LO, arrow FR, arrow RE, arrow RI, and arrow LE appropriately shown in each figure indicate the front (advance direction) with respect to the advance direction of the vehicle on which the vehicle seat 10 is mounted. , rear, upper, lower, right, and left, the following simply indicates that the situation of up, down, front, back, left, and right corresponds to the directions of the above-mentioned arrows.

[0133] FIG. 1 shows a schematic overall configuration of a vehicle seat 10 in a partially cutaway perspective view, and FIG. 2 shows a side view of the vehicle seat 10 . As shown in these figures, the vehicle seat 10 has a seat frame 12 including: a seat frame 14 serving as a cushion frame; and a back frame 16 serving as a seat back frame.

[0134]The seat cushion 18 as a seat is formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com