Bimetallic thermostat with printed circuit interposed between a sensitive thermostatic element and a relay

A technology for switching contacts and thermal elements, applied in thermal switch parts, circuits, electrical components, etc., can solve the problems of complex, expensive and difficult thermostat manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

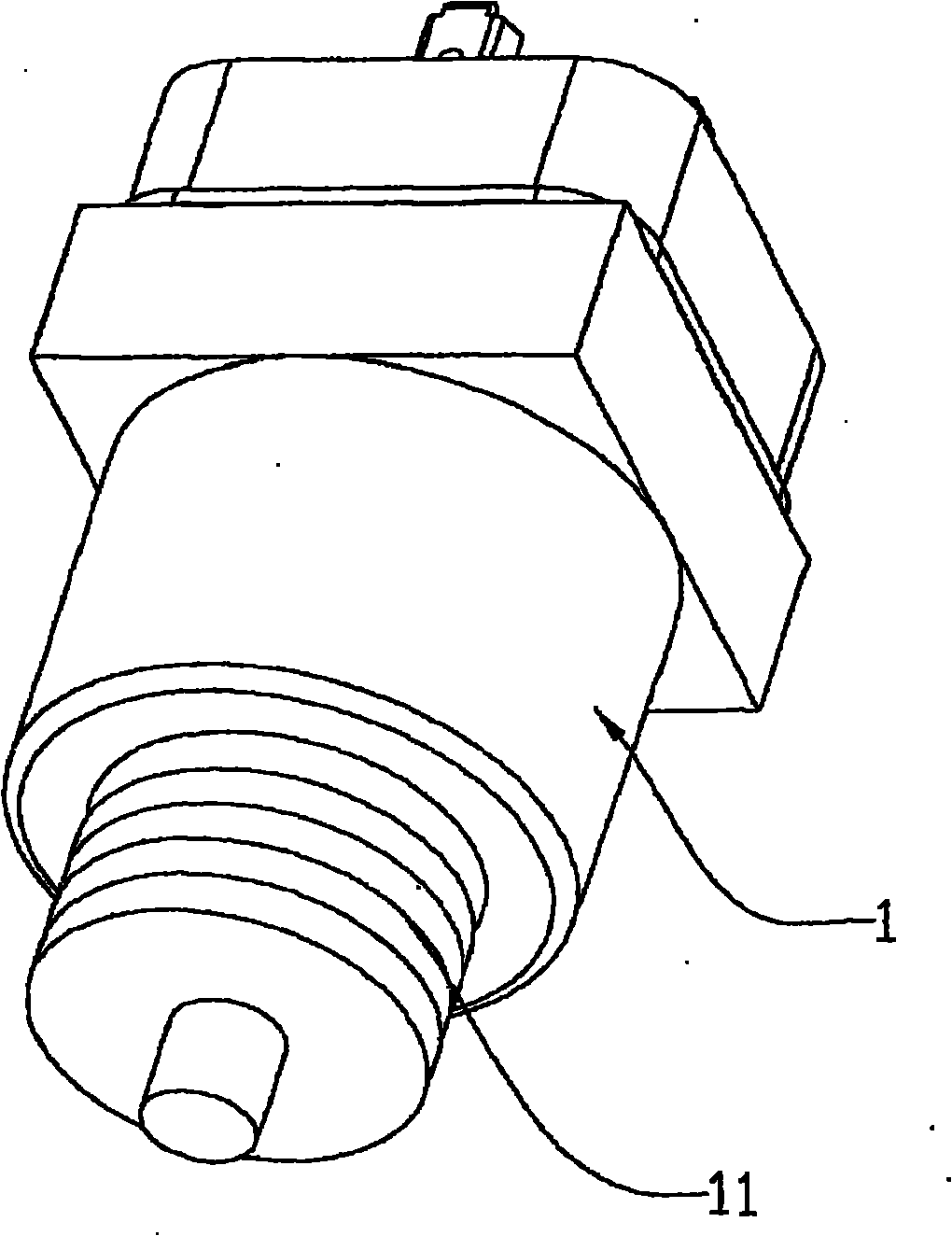

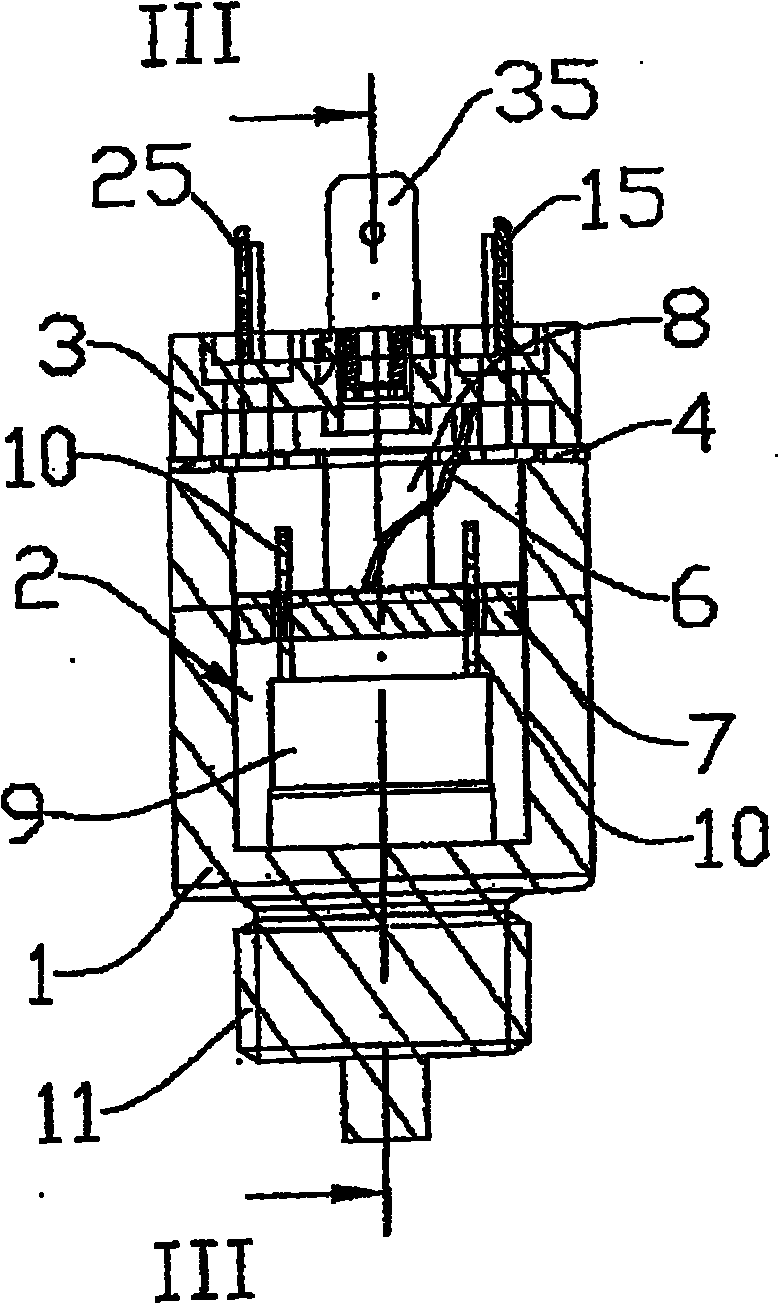

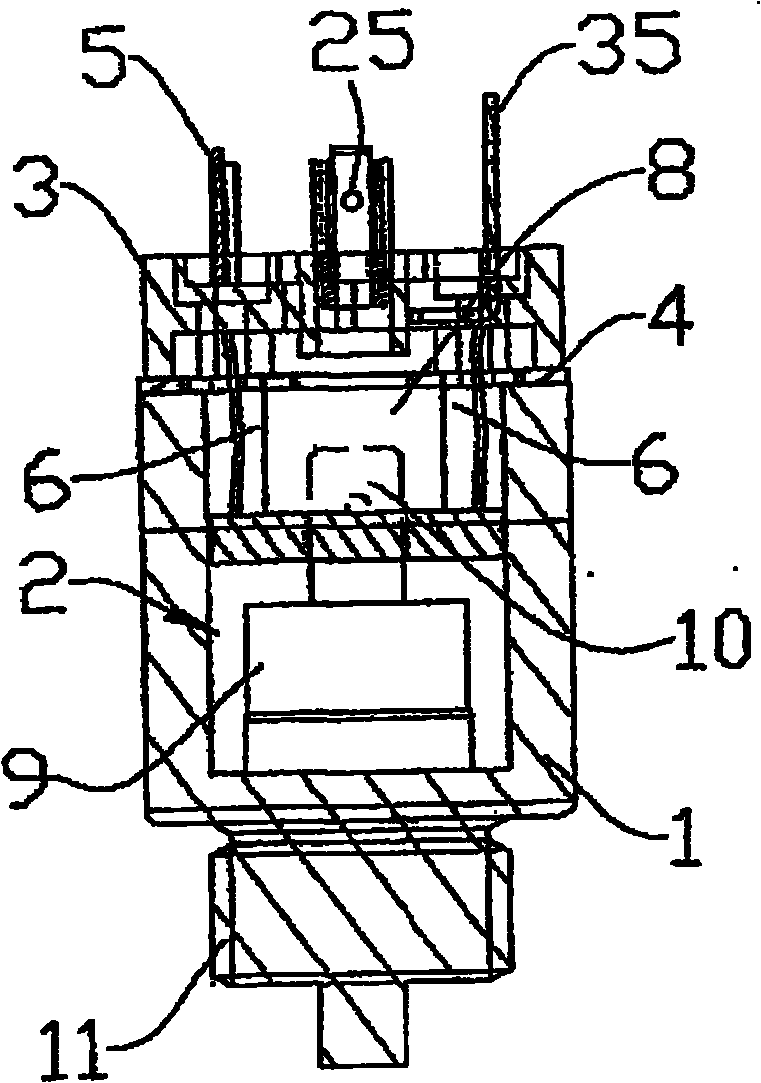

[0016] A bimetallic thermostat comprises an outer casing 1 with an external thread 11, the outer casing 1 supports an internal device 2, the internal device 2 includes a through-hole base 3 with a sealing ring 4, the base 3 supports electrical connection outer legs 5, 15 , 25, 35, these outer feet are connected to the printed circuit insulating board 7 by wires 6.

[0017] The relay 8 is fixed on the board 7 and connected with the thermal element 9 through the pin 10 .

[0018] Said plate 7 has on one of its faces two slots 12 for receiving the feet 10 and holes 13 for receiving the ends of the wires 6 . In addition, it includes holes 14 for securing the relay 8 and traces 16 of the printed circuit.

[0019] Said plate 7 prevents interference between the pin 10 of the thermosensitive element 9 and the wires adjacent to the relay 8, and prevents short-circuiting of the relay or any erroneous operation of the relay 8 to output a corresponding error signal through the external p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com